Everything posted by duffymahoney

-

Duffy's 1/71 Series 1 240z build

Well I drove the z! She runs a little rough. I think electronic ignition, check timing and fiddle with the carbs are next. Also install exhaust. Boy is it loud with nothing:) I had to take the brake switch block apart. It was gummed up and causing some issues. I also screwed up on the 1" Mc push rod adjustment. So it was stopping me from bleeding correctly and also gave me terrible brakes. Re adjusted and it's working well now. I could use a little more brake, but I think that would mean a bigger booster.

- Duffy's 1/71 Series 1 240z build

-

New Fujitsubo Exhaust System to be Released

I can tig weld stainless. But I would rather not weld on a brand new 900$ exhaust.

-

New Fujitsubo Exhaust System to be Released

Only thing I don't like about the new fujitsubo is the exhaust hanger not being welded onto the muffler. I wonder why they did that?

-

New Fujitsubo Exhaust System to be Released

I just bought the new version. Should be here in a week or so. I will be able to give details on its fit.

-

New Fujitsubo Exhaust System to be Released

You should have posted the pictures! It tucks up so nice.

-

123 Ignition distributor?

Lots of threads on here about it. Use the search feature, I think most people love it.

-

New Fujitsubo Exhaust System to be Released

I asked whitehead about spirit garage, I would love to see pictures when yours gets in. It's my favorite exhaust routing design, but I don't like the clamp system much.

-

New Fujitsubo Exhaust System to be Released

I am trying to get my series 1 ready for a local car show. The only thing left really is exhaust. Sadly my stock is shot, so I can't use that.

-

New Fujitsubo Exhaust System to be Released

Sadly they are back ordered for at least a month.

-

Velocity channel-new show

Wish I could stream it somehow.

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

I added this 120v solenoid for the air. So when i use my foot pedal it turns the air and the slurry pump on. Works so much better this way. I had great luck keep the slurry mixed by every 30 seconds or so pointing the jet to the bottom and mixing up the slurry mix. I could tell the slurry would be different for a bit.

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

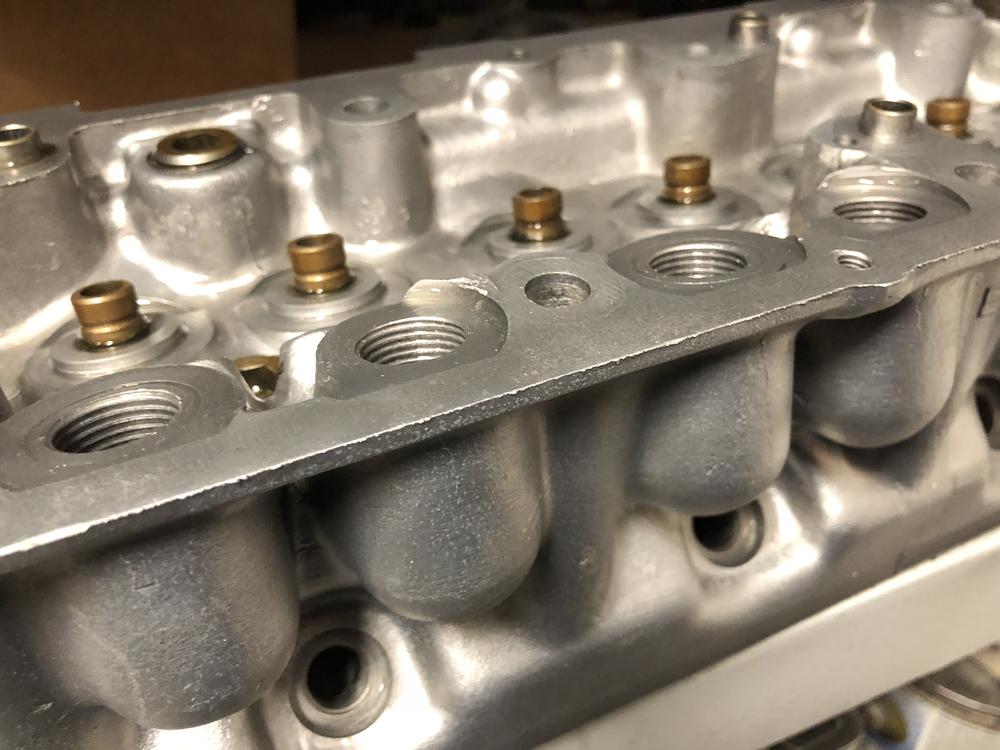

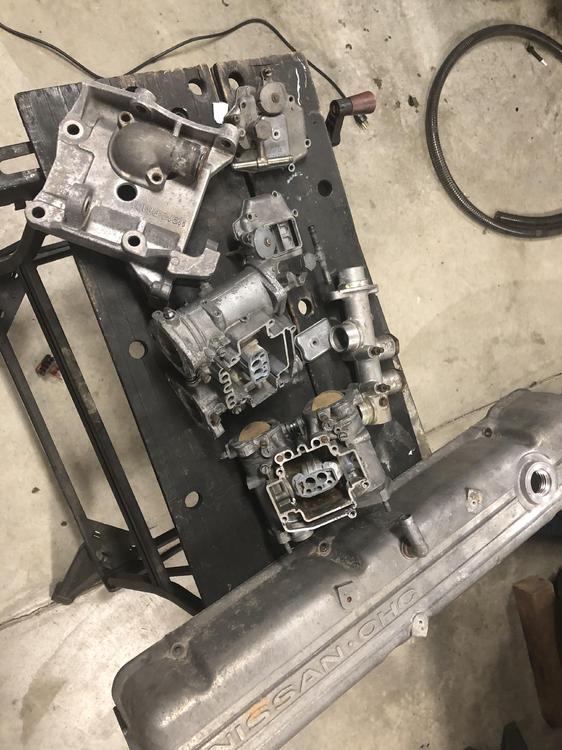

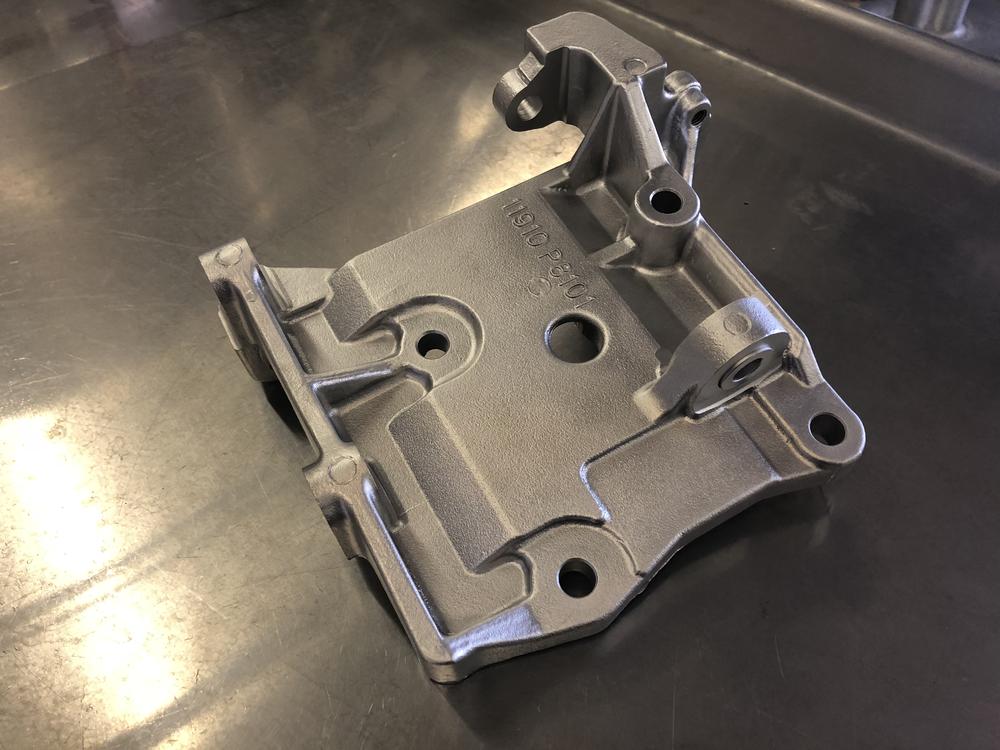

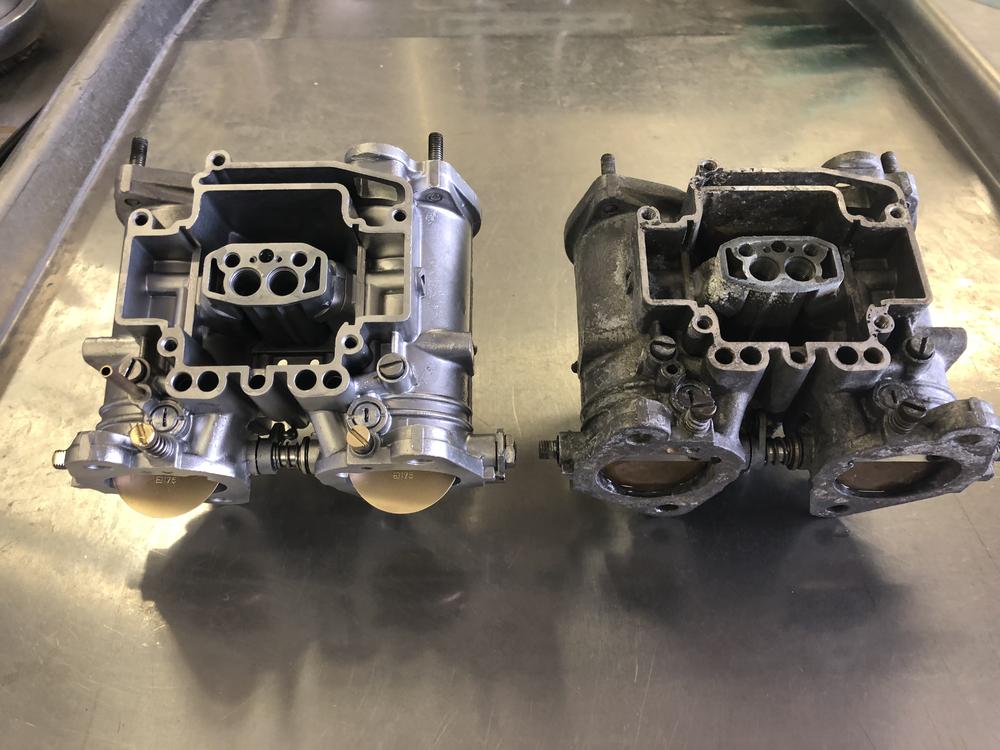

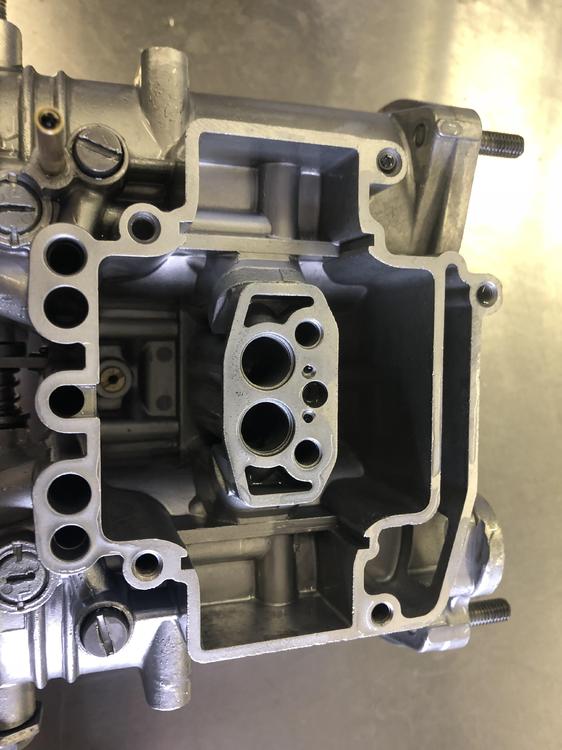

I don’t think vapor affects the aluminum at all. I think it just picks the dirt out of crevices. It won’t pull off silicone or gaskets very easily. Doesn’t affect zinc. Doesn’t damage anything Today I tried way less glass and had the same results. This valve cover was rough. Looks pretty awesome now. Trying to get the appearce to be uniform is time consuming. I just gave up. I plan on doing 3 covers. One wrinkle red, wrinkle black and this one and decide which I like the best. It it just barely big enough for this cover. The head will be tough to fit and get the ends done. Shouldn’t be that bad though.

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

-

240Z D hubcaps ... reproduction?

Glad that reproductions are now a thing!

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

Thanks guys. Walnuts would be more abrasive then this by a lot. This is so soft that it doesn't even take sealant off or silicone. It's sort of looks fake its so nice. No idea on cfm. I have a small compressor at home that wasn't good enough. I could go about 1 minute before I need to take a break and let it recharge. Beads clumped a bit, honestly the amount of beads needed is so small. Tomorrow I will try much less glass and see how it works.

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

I ended up using more of the water tight cord connectors, I also used a shower drain to make the vent pipe. Stock vent was just a aluminum cap with holes. This vent is just like vapor honing uses. Trying to dial in how much air to use. Might get to try tomorrow. I think I’m done for now.

-

Triple M´s?

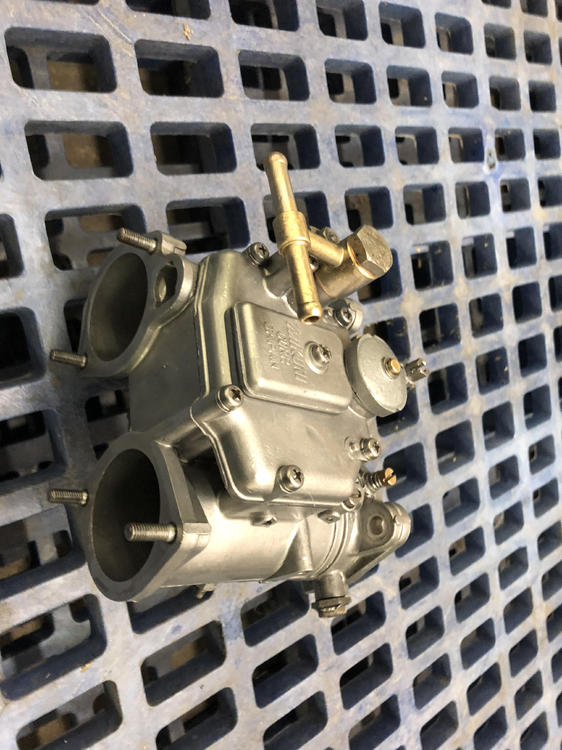

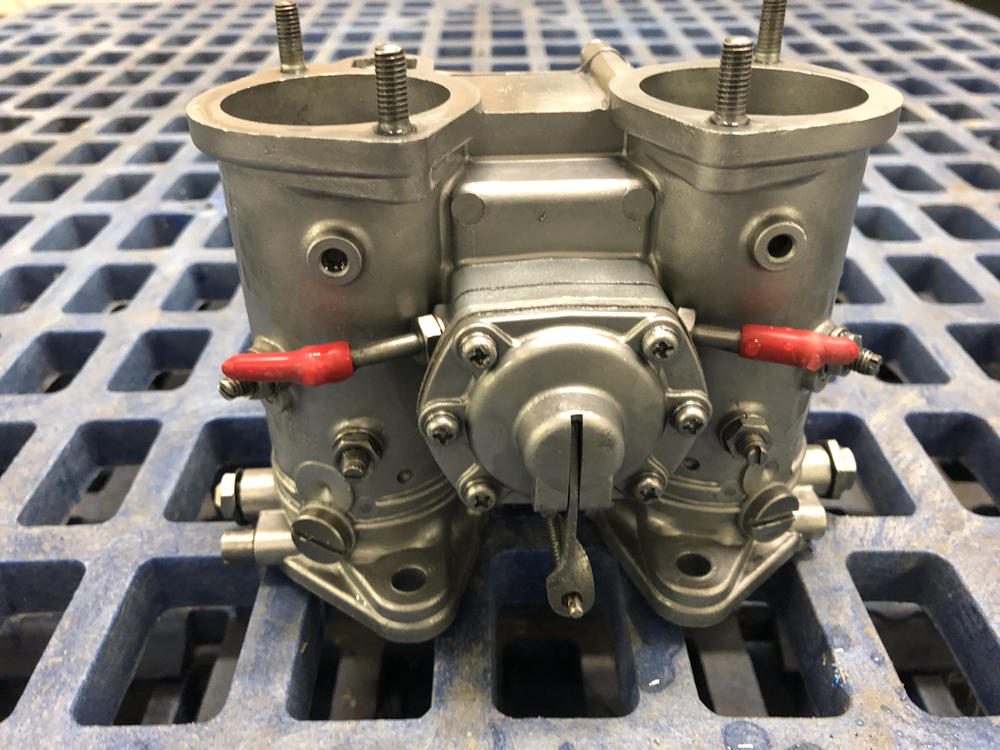

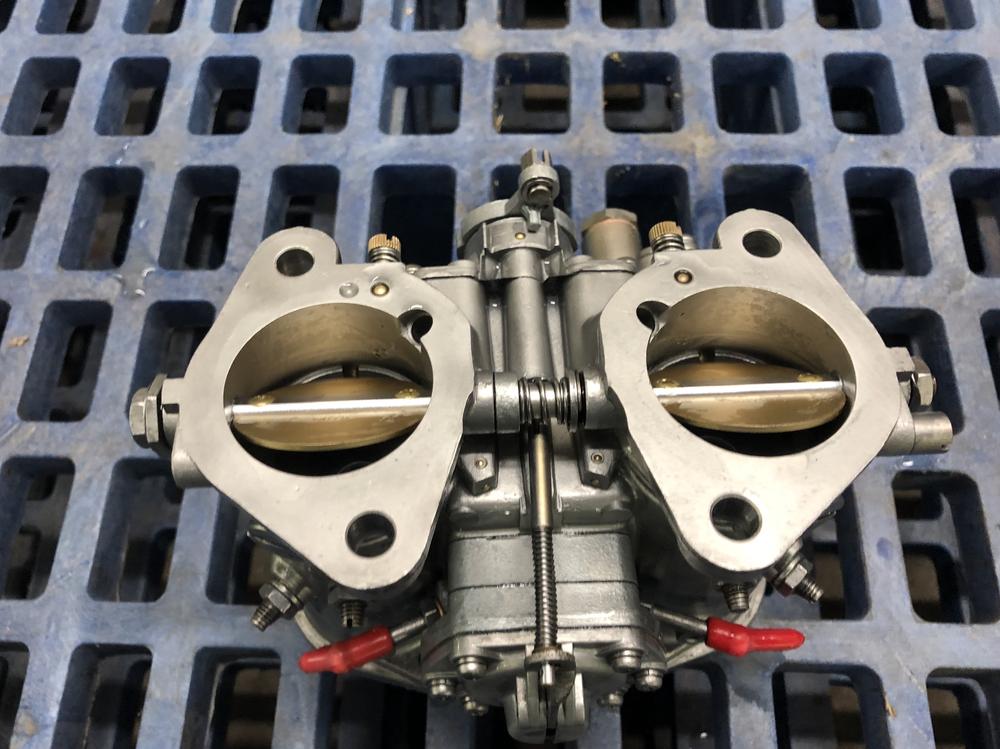

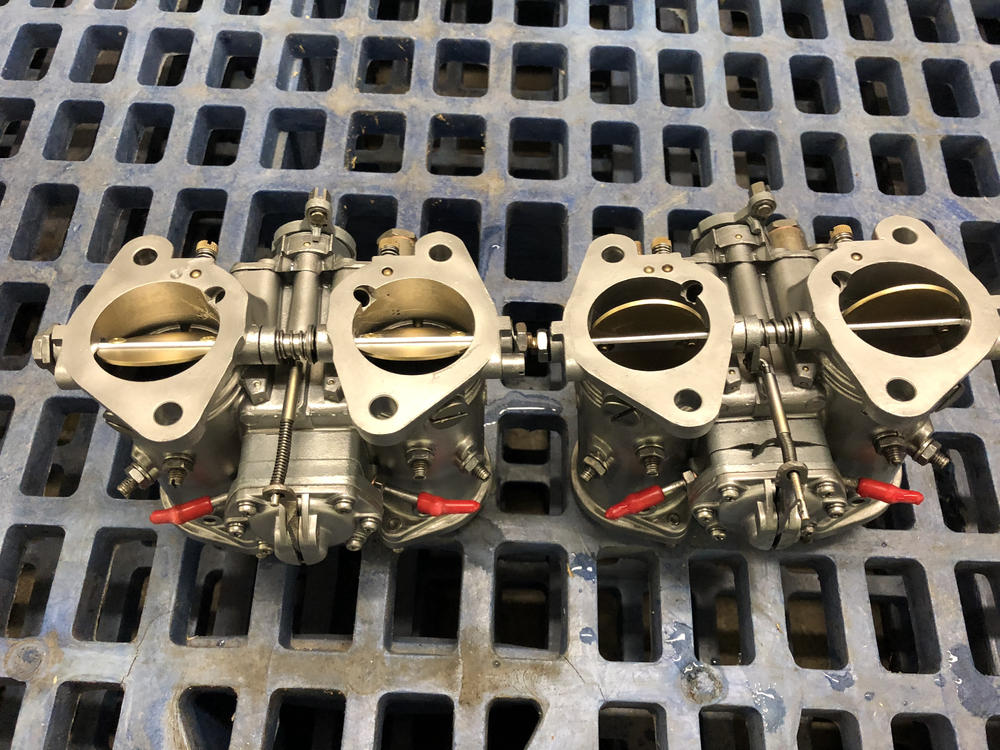

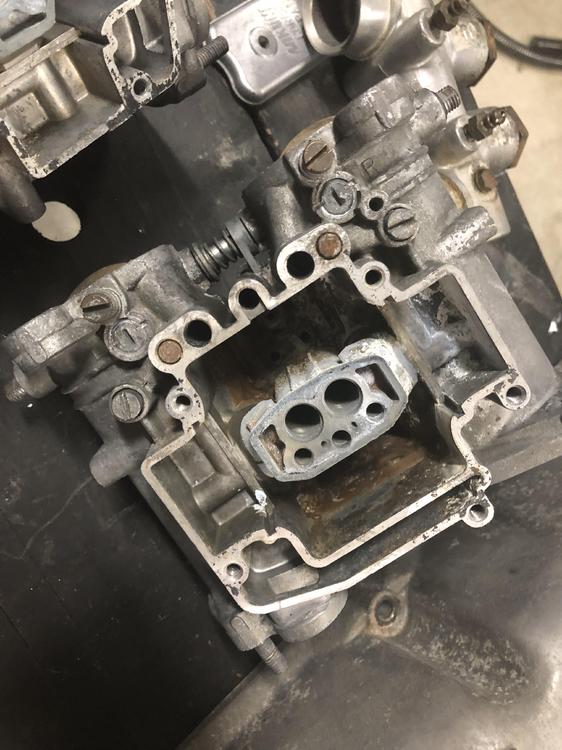

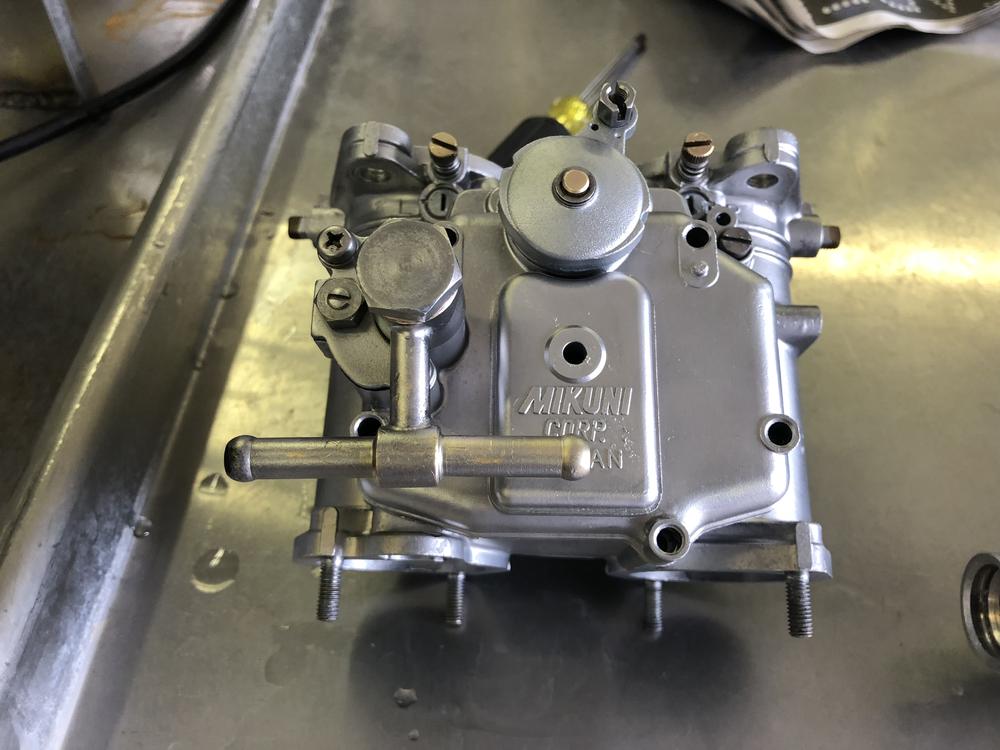

Someone paid some dollars! If you need tuning advice contact David Premo. http://tuning4performance.com/

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

-

Triple M´s?

They don't do much mikuni stuff these days.