Everything posted by duffymahoney

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

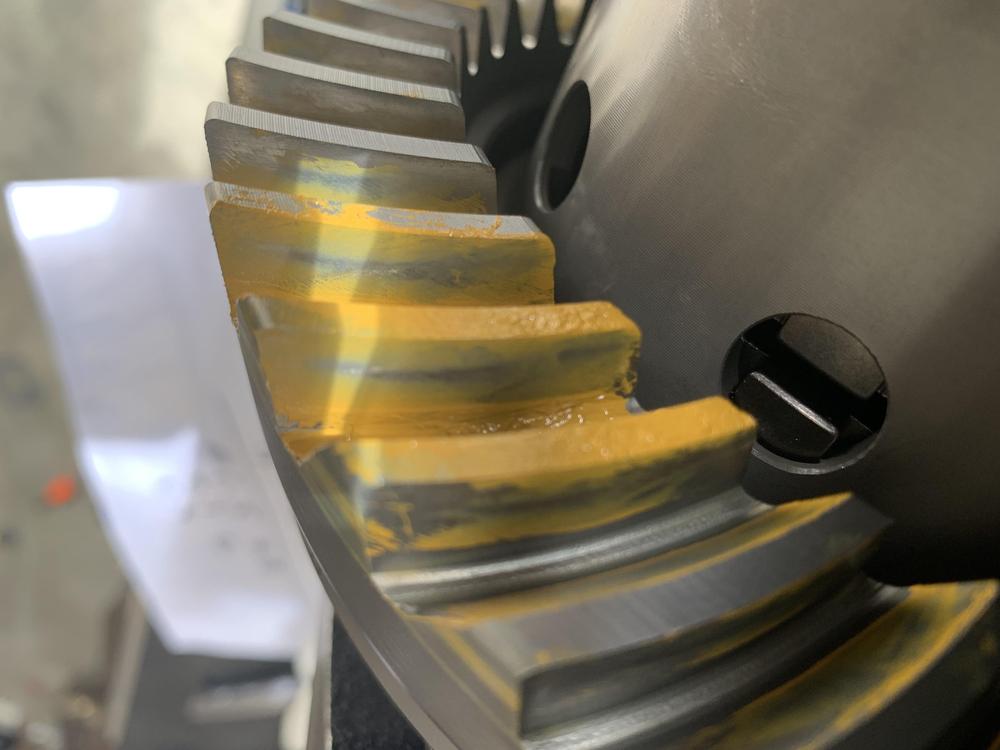

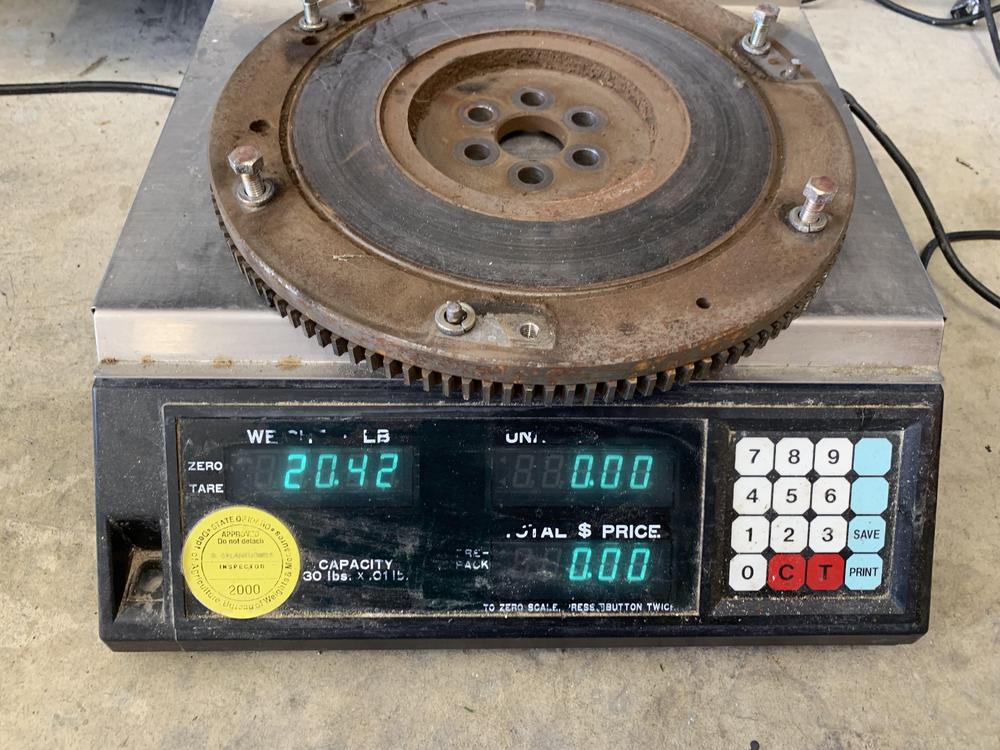

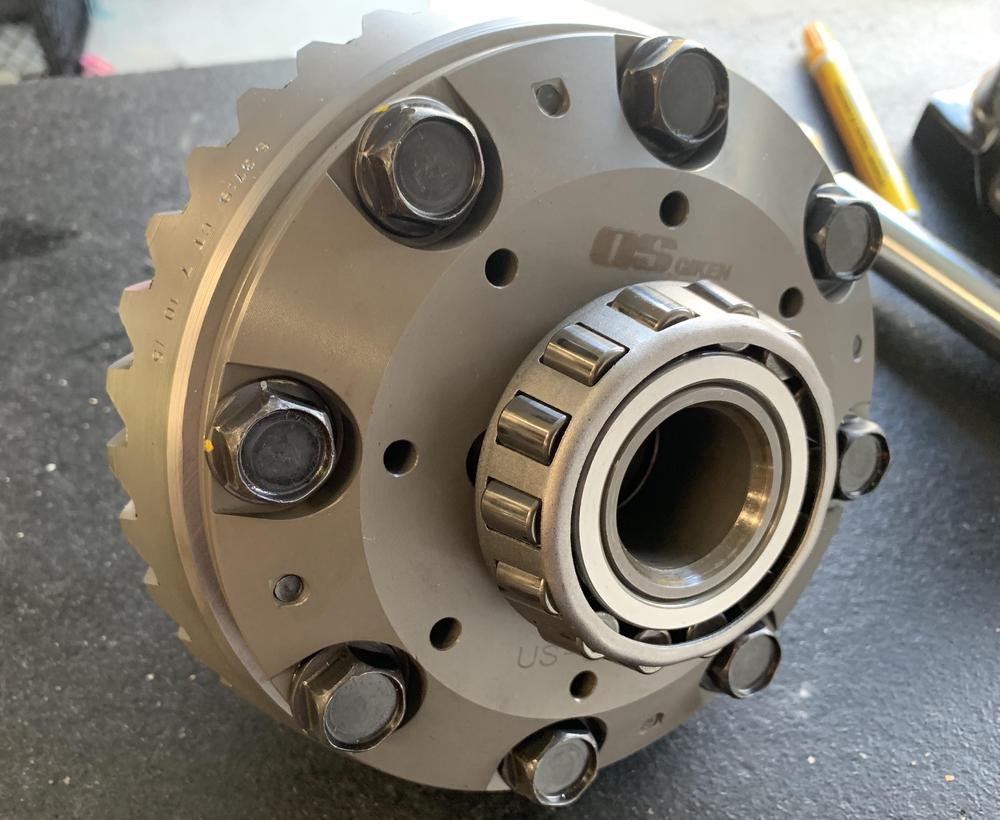

Well shimming the r-180, backlash, pre load and wipe pattern took most of a couple days after work and most of a Saturday morning. I think I took it apart 20+ times. Finally happy with the wipe pattern. Luckily I didn’t have to change the pinion shim. Edit: I think in a perfect world I would have had a special tool to set the pinion nut at the factory 125-150ftlb. Then used different shims to get the bearing pre load perfect. But I had no way, so a couple of hits with the impact is what I used to set pre load, I found that info on here and a few youtube videos. It's not precise at all, just hopeful the factory had it correct enough. A bunch of site posts and a few guru told me to just reuse the pinion shim and move on. Everyone basically told me backlash is the most important. Ended up with 5 thousandths for backlash give or take and then ring side backlash shim if .05 and other side of .07. Total inch pounds is around 8-10 on the pinion. No carrier I had around 3 inch pounds for the pinion. This is worth paying someone to do. Just FYI. I had fun. But super frustrating.

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

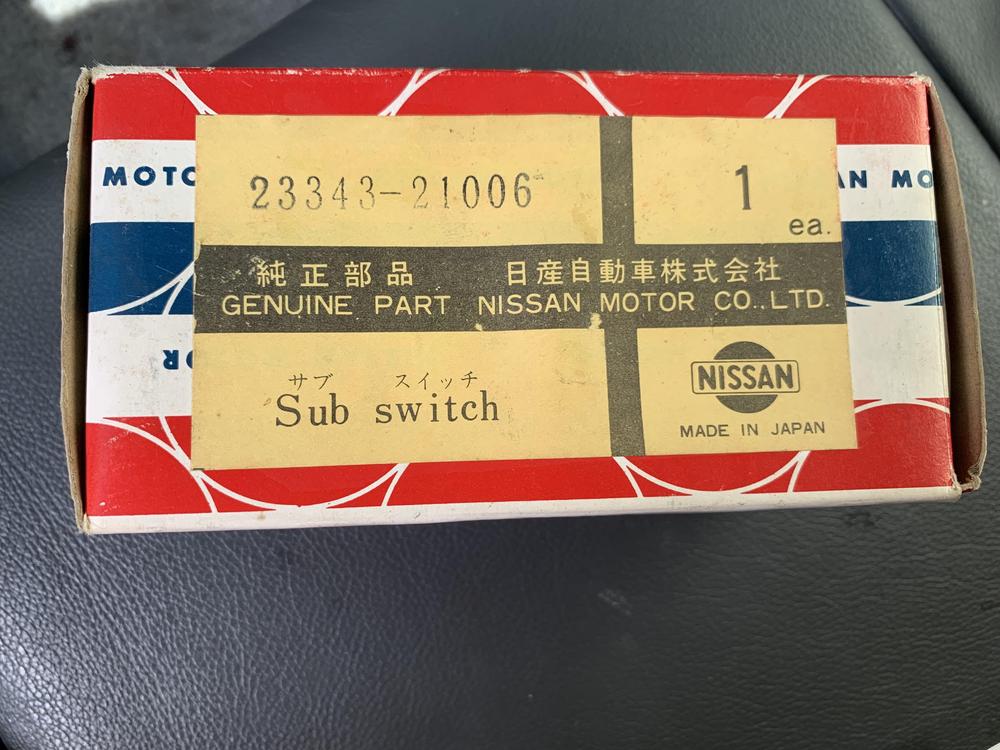

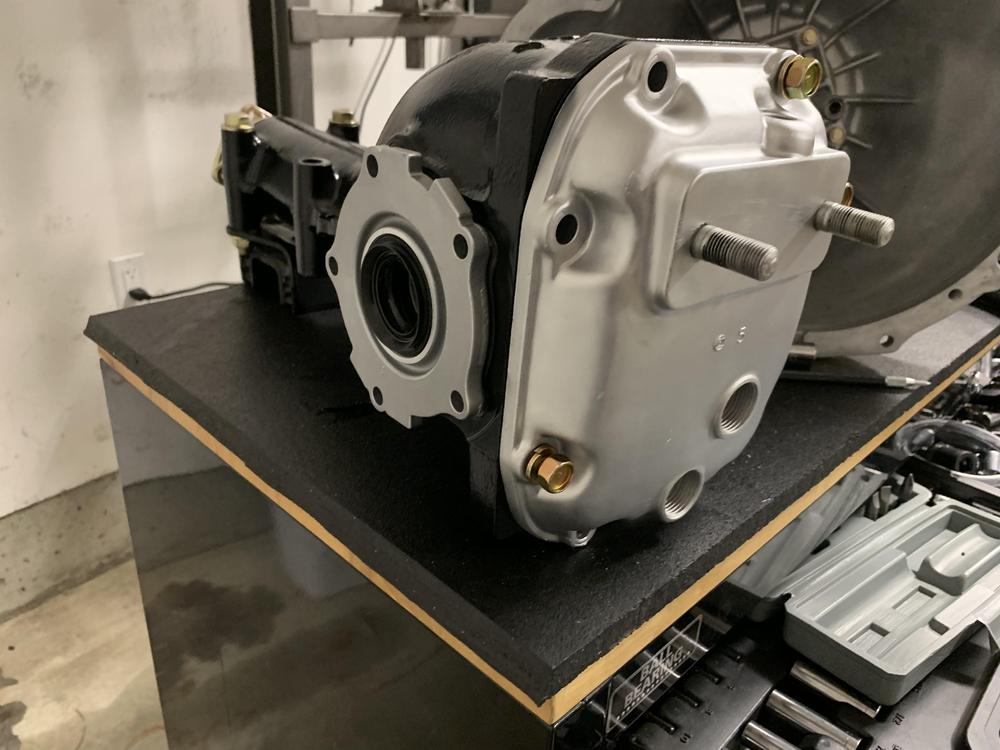

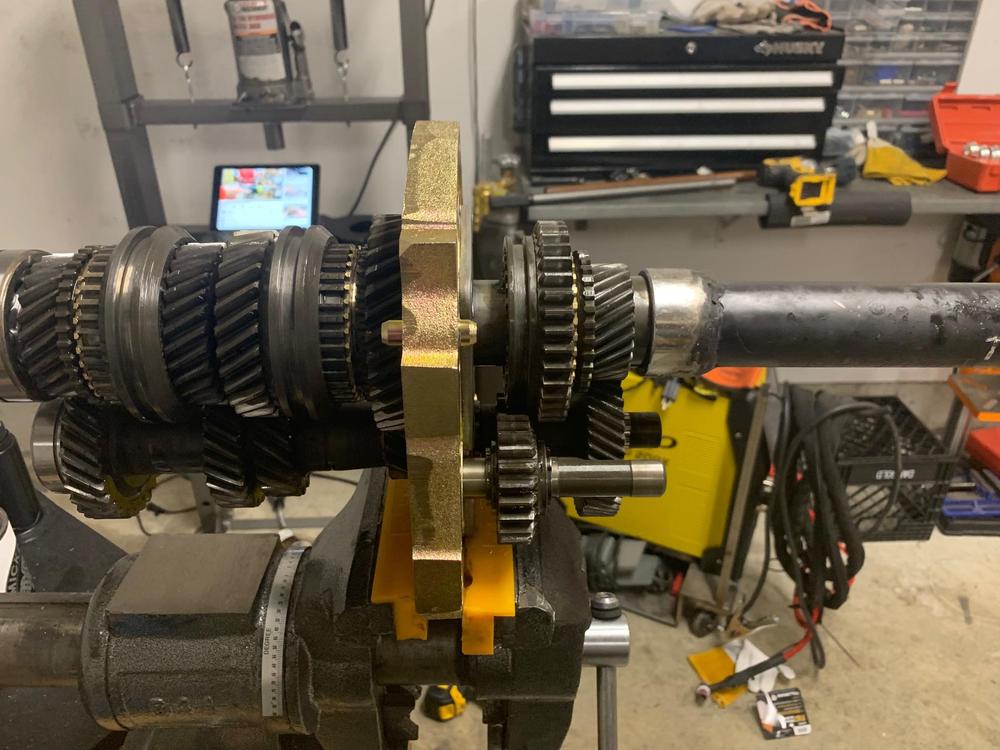

I screwed something up in the trans rebuild, it becomes tight with the front cover on, plus I guess I love spending money, so I decided on the KA swap for my 240z. This is a longer tail shaft on the trans, so it should fit in my series 1 better (no cutting), plus the 1st is better gear ratio and 2nd is slightly better. I found a 1989 240sx trans, with 576 miles on it. It's been in storage inside since 12/01/89! Zinc is still in tact. Paid too much for it, but hopefully it's good. The shop tested all the gears and syncros. Troy Emerish Racing will do the bell housing mod. He is just about as cheap as my local machine shop, plus has done a ton of them. Using this info for reference http://zhome.com/ZCMnL/tech/240SX5spd/Transmission2.htm http://zhome.com/ZCMnL/tech/240SX5spd/Transmission2.htm

-

1973 240z Brake / Fuel Lines - SS or CAD

Stainless lines and steel fittings is very nice. I wouldn't do stainless with stainless, I had to tear a brake line kit in my bronco for that reason. Plating is super super cheap, find a local shop, you will be surprised. I would guess all the brakes and fuel lines would be 50$-75 for me to have plated. Can you get all yours off? Proper brake line wrenchs, heat and time and I got all to break free but 1.

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

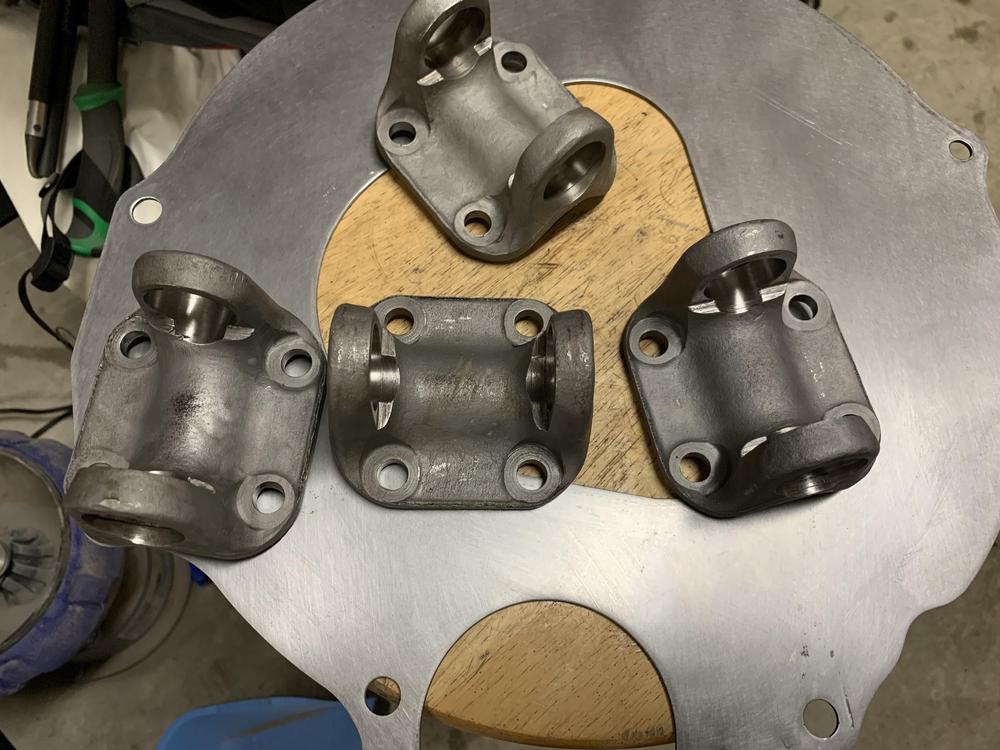

Got the trans parts back from zinc and got most of the trans rebuilt this weekend. This is my first time doing this. I used the FSM, friends and this youtube video. Super helpful. Also a shop press jumped for sale locally, I picked it up for 80$. Youtube video. Below. Here is mine spinning. I had to take mine apart a few times. So I am a little worried I put some wear on the bearings. I got a brass hammer which seams to help a lot.

- Duffy's 1/71 Series 1 240z build

-

Z31 N/A RB project

Wow, what a cool build.

- Duffy's 1/71 Series 1 240z build