-

Triple OER/SK carb issues, not balancing (SOLVED)

The short list of things done 1. Repair bent shafts and rotating internals of carbs 2. Rejet to allow the progression holes to work better 3. Adjusting the idle mixture and idle speed screws in a very delicate fashion, seeing a cause and effect. All the tuning books provide general and vague information which is not helpful. 4. Lots of spark plug reading and road tuning.

-

Triple OER/SK carb issues, not balancing (SOLVED)

A big THANK YOU to all who has helped me. The car is now running and driving and on the road again.

-

Triple OER/SK carb issues, not balancing (SOLVED)

Okay, I finally managed to get the carbs balanced at idle by fixing various gaskets and bending back a few old bits of metal. But now there is another issue. The carbs rev just fine and they sound amazing but at part throttle the #2 carb starts to pop again. 1. Balanced at idle 2. Popping out exhaust and carb #2 at part throttle, around 2.5k rpm and holding it. 3. Engine revs up super quickly so no complaints about the accelerator pumps

- Triple OER/SK carb issues, not balancing (SOLVED)

-

Triple OER/SK carb issues, not balancing (SOLVED)

Yes, that is exaclty what one of my freinds just suggested!!! How do I go about checking that for leaks. I believe it has to do with plunger near the choke? Yes, the vacuum ports all have a rubber cap and I sprayed carb cleaner on them to double check. Thanks again for giving my issue so much thought.

-

Triple OER/SK carb issues, not balancing (SOLVED)

Yup, That was one of the things I looked into. The progression holes are #2 carb exactly the same as #1 and #3. However, that is with #1 and #3 turned about 1 turn, and they are synced perfectly. The #2 carb with the screw just making contact the progression holes match the #1 and #3 So the butterfly valves are all in the same place in relation to the progression holes; just barely exposing the edge of the first hole. CARB 1 :1 turn progression holes exposed the same amount but different turns CARB 2 :0 turns CARB 3 : 1 turn

-

Triple OER/SK carb issues, not balancing (SOLVED)

Fuel pressure is at a stock 3.5-4psi since I am running the stock mechanical pump and an electrical primer pump. And yes, the car is all warmed before I tried to tune it, it's common knowledge. As for afr, there is no way to get an O2 sensor on all exhaust runners, I can only tell via spark plug (rich or lean). And yes I couldn't agree more, moving it will help me tell if its the carb alone.

-

Triple OER/SK carb issues, not balancing (SOLVED)

Thanks, I have already tried the mikuni and weber baseline settings as I am no stranger to triple webers but this problem is something that confuses me and my fellow triple carb friends.

-

Triple OER/SK carb issues, not balancing (SOLVED)

I'd like to add that my lean condition on cylinders 3 and 4 are mainly caused by the #2 carb sucking in too much air through the throat. Since the vacuum can be read on the Unisync for a split second. It reads off the scale. Meanwhile the same unisync on carbs #1 and #3 read perfectly in the middle. I also checked how far open my butterfly valves are open on all the carbs through the progression holes and they are all in the same place.

-

Triple OER/SK carb issues, not balancing (SOLVED)

I will do that next time. Going to take apart carb #2 as well when it's off and report my findings.

-

Triple OER/SK carb issues, not balancing (SOLVED)

#2 seems to be a touch lower than #1 and #3.I will raise the float level. The needle valve looks clean and it moves up and down smoothly, but how do I check for clogs in a needle valve? Woud a lean condition also pull more vacuum as opposed to a simply rich mixture? I did do the valve adjustment a week ago before putting on the carbs, and the valve clearances are in check.

-

Triple OER/SK carb issues, not balancing (SOLVED)

I suspected the plates or the shafts as well. I did not know that the plates might not seal well. That is something to look into for sure. The thing that puzzles me is that this air flow imbalance is across both barrels of #2. But if they are bad I hope weber dcoe plates will fit these OERs.

-

Triple OER/SK carb issues, not balancing (SOLVED)

I'm using the stock fuel rail, as it also acts as a built in fuel regulator. As for fuel pumps, I am running two pumps in series. It goes in this order Tank>>>electric clicker pump>>>stock pump>>>carbs Its a crude system but it worked great for my old SUs and DGVs, never fuel starved even at extended periods of WOT.

-

Triple OER/SK carb issues, not balancing (SOLVED)

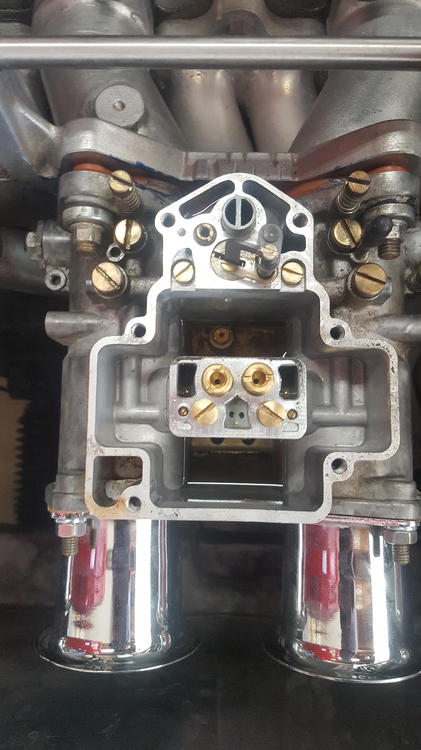

I checked the fuel levels for #2, they seem to be okay but I will compare them to #1 and #3 when I get the chance. As for a gasket leak, the obvious places like; manifold to head, and carb to manifold are all in good order. Though I suspect a leaking shaft seal. Jetting weber drilled: 140 main, F11 emulsion, idle 50F9, pump 45 Here is a pic of the fuel in carb #2 right after idling for 5 mins. Looks kinda dtiry because of the lighting. I did clean out a few grains of dust after taking the photo.

-

Jazz86 started following Triple OER/SK carb issues, not balancing (SOLVED)

-

Triple OER/SK carb issues, not balancing (SOLVED)

I have been having issues with my OER SK 40mm carbs. The problem is very elusive and I have not been able to find the source. I will do my best to describe the problem and I am willing to clarify if needed. I am going to refer to carb(#1) as cylinders 1 and 2. Carbs #1 and #3 are perfectly fine, it is carb #2 that is acting up. I started to sync the carbs, first by disconnecting all the linkages. I managed to balance #1 and #3 using an unisyn tool. However, #2 (cylinders 3 and 4) would be run leaner than the others. I unscrewed the idle mixture screws for #2 a few turns, and it leaned out even more resulting in popping out the carb and a nearly white spark plug. Also the #2 would draw a lot more vacuum than #1 and #3, and I unscrewed the idle speed screw for #2 and #2 still ended up drawing a lot more vacuum. #2 has enough vacuum that when I touch the unisync tool on #2 the engine will nearly die and then fuel spills out and then rpm picks up a lot. However, I got the car to idle smooth enough by tuning by ear and I would hold rpm at 2.5k and 3k and the #2 carb would cough and the exhaust would back fire, checking the plugs (cylinder 3,4) they were even whiter than at idle. Meanwhile the other plugs were a nice brown. This issue has bee driving me mad. Issues list: 1. carb #2 runs lean 2. (all linkages disconnected)(speed screw backed off 100% for #2) carb #2 still draws more vacuum that #1 and #3 3. Carb #2, touched unisycn tool the engine nearly dies, fuel drips out of throat, engine speed rises rapidly 4. #2 meaning cyl3,4 mixture screw(1 turn), nearly white plug, all others are a nice tan 5. #2 mixture screw(2 turns), completely white plug, all others are a nice tan 6. rpms held at 2.5k and 3k carb #2 cough and exhaust back fire 7. rpms held at 2.5k and 3k carb #2 (plugs 3,4) are bone white, all others are a nice brown 8. no binding in the linkages, linkages move very smoothly 9. Sprayed carb cleaner on all joints and seals, no increase in rpm 10. float levels all set to the same factory settings

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.