Everything posted by Elliott000

-

Where to go with unknown build ive acquired

Stroke is stock bore is hard to measure but the pistons have 1.000 stamped on top. I think im gunna just roll with it! No noise or anything. Pistons are flat top, if the clatters away at first start up in a couple yrs then I'll be damned and ill be forced into an early swap.... Now to focus on straightenin out the front end. Sent from my SM-N950W using Tapatalk

-

Where to go with unknown build ive acquired

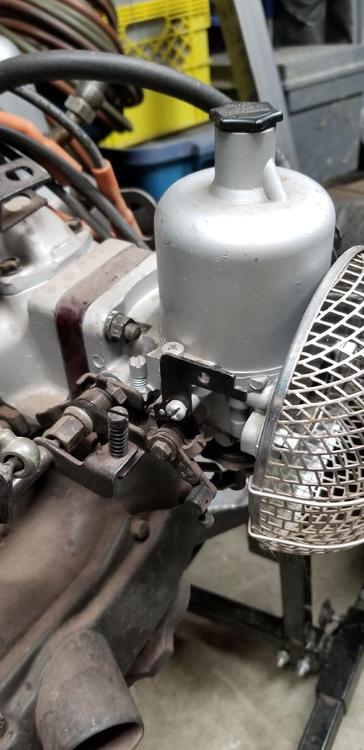

I got er on the stand and pulled the pan off. I can confirm it's an l24 I found that casting number. That in itself makes me want to pull the head and check for valve clearance as I've read an dbeen told from you guys there's possible co tact points. I lubed er up in n out top and bottom and turned it over, everything it smooth as butter. I did notice crank and rods are used but pistons are new and the motor is definitely un run. I have another head gasket, should I oull the head? Darcy is confident it's a 3.0 stroker but how can I confirm this? Thanks in advance. Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

Definitely nice knowing I have a dead to nuts center line. Tomorrow I'm going to triple check the car is level them plumb some points down and ensure everything up front is square at least within reason. Once I fi ish the driver side frame rail and tie a bit more in on the floors, the structure will be done and then the next step is replacement panels for the rockers and rear lips. I also need from fenders, always prowl g Craigslist so if you guys see a decent factory set of steel fender s let me know! What's everyones take on fiberglass fenders? Stay away or what Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

Sweet! My lower pinch welds match up at 51 1/4 front and rear. I'm going to go with that for my front and rear centre reference line Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

My buddys car has the same 900mm as does mine and his hood fits beautiful. I would not sweat it . Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

I appreciate all the help guys. I gotta work all weekend but on Monday I'm going to spend some time going over these numbers. Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

Awesome info. I appreciate that. Can i co firm, the "c" holes, they are about 1" in diameter just by the seat belt buckle buckets Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

I'm back in the trenches on the 240z... Looking to get some intel from u guys again. In relation to the drawing found in the FSM it would "appear" that the pinch welds where the inner rocker ties to the outer are parrallel. I plumbed these fixtures down and snapped some lines and in reality on my car at least they are not they are wider at the front. These are measurements taken from the top weld, ill compare with the bottom tomorrow. That's one thing, next is a true centerline, what do u think my best point is on the rear to drop a plumb bob and get a center mark. From center of rear suspension/spring bolts? Then up front from the firewall are there any sure fire center marks or spots. With the differences im finding in the nose from this cars possible accident at some time. The only real way I can sleep at night and trust its straight when I start welding stuff is to have a dead to bust center line to work off.... Any and all input is appreciated. I'll post a pic tommorow hilighting the areas in question Sent from my SM-N950W using Tapatalk

-

Home Built Z 'Full video build'

Jeff. I've just gotten a z and she is in need of rust repair etc. I've been watching almost all your videos and love it man well done. Inspiring to learn something new in terms of body work and really dig into the car. Yours is coming along nicely and look forward to the finished product Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

My rails were beat on but not like that, my issue is rust. On yours I agree that's either a poor jacking job or someone drove it over a boulder! I can take a picture of the dent when I'm home tonight. Me and my boy who's 9 but has a good eye , were looking at the front end some last night. We found a few ripples that had been hammered out and also a little separation on some folded steel wherr the hood pivot mounts. On that note, would one of u fine people be willing to measure the distance between the two panels where the hood pivot bolts on? I'll post up a pic tonight, it'll be easy to do when the hoods up. Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

It is bugging me aswell, looking at the upper structure that air horn part, everything seems pretty straight. I can see a bit of separation where the radiator mounts on some mating surfaces, the firewall is straight and there was some denting in the main frame member that had been hammered flat again. Im thinking I may have screwed myself by making the passenger side first. When I heck measurements in relation to the manual the driver side checks out pretty good. I may end up opening the frame i made and adjsuting the passenger side bolts holes to match the driver.... If i plumb bob down from the upper strut mount and compare those two points there is a variance aswell but it is only an 1/8" so theres less movement there up top.... AHHH dunno what to do haha, at least I have time on my side, i can just go down there and stare at it some.

-

Wheelbase predicament

Yea u have it right, if i run a framing square off the passneger frame rail aligned with a bolt hole. The drivers side holes are 1/4 ahead of it. I had looked at all the techno front suspension. I've also thought of fabbing my own adjustable lower stuff. Tc rod and lower arm. If i can build stuff to handle jumping my bronco the datsun should hold haha Sent from my SM-N950W using Tapatalk

-

Wheelbase predicament

Hey guys, the car im building seems to have suffered a bump or two. Iv'e rebuilt the passenger side frame rail (engine bay) and i'm working on the driver, after comparing numbers vs the manual and squaring things up i have a 1/4" difference when it comes to driver vs passenger location of cross member holes (from front to back). Ive got the car level, and multiple string lines for reference on straightness etc. The rails are parallel and square to the car as a whole. My thoughts are since iv'e already located everything on the passenger side should I just match to it? At the end of the day I will be doing a bit of cutting on the fenders and using flares so if there is a slight off center in relation to the shape of the fender to the centerline of the wheel.... I can hide it. My only real concern will be panel fitment. I might actually install the doors and fenders to see how things line up. Any opinions on this sort of situation.

-

Where to go with unknown build ive acquired

I tried to call the engine shop but they have been closed down for years Sent from my SM-N950W using Tapatalk

-

Where to go with unknown build ive acquired

Ok good intel, the stroker deal comes from the PO saying they used a 2.8 crank. Ive read a bit about it but not a lot of info. Sent from my SM-N950W using Tapatalk

-

Where to go with unknown build ive acquired

Thanks for the reply, I actually just bought that book and the modifications one too. Is there a way to spin up the oil pump with a drill, just to check flow and that it is oiling out of all the spots it's supposed to? Under distributor? Also which direction to turn Sent from my SM-N950W using Tapatalk

-

Where to go with unknown build ive acquired

- Where to go with unknown build ive acquired

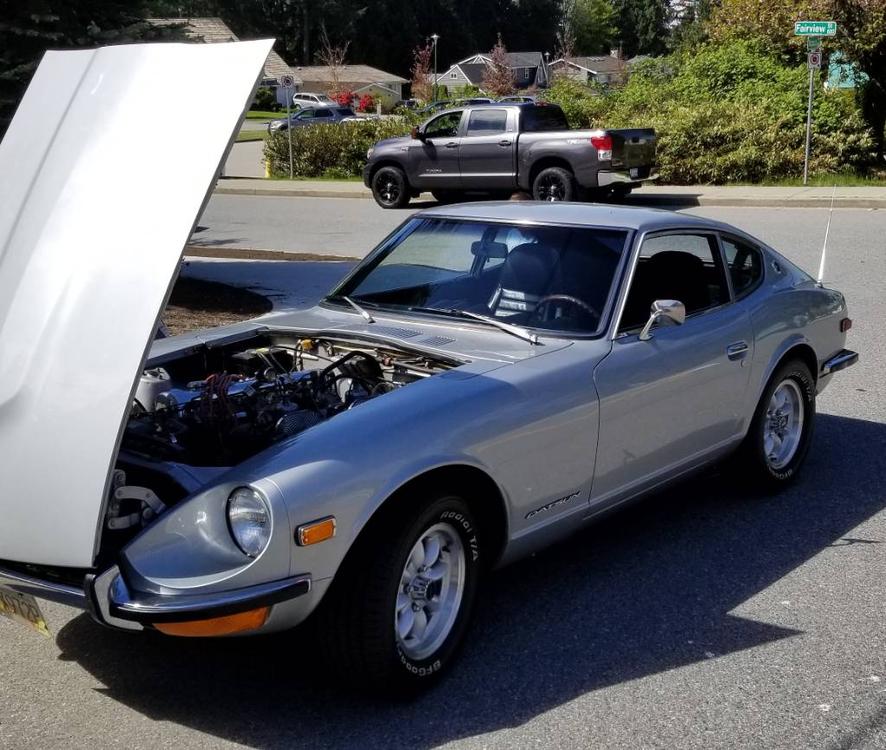

I grabbed a 240 of my buddy who had plans for it but it then sat for like 10 years. The engine has been rebuilt and from what I've been told and can see, never run. Ill post what specs I know P30 block, unkown as to 2.4 or 2.6, n42 head, unkown cam and valve train. Im going to mount it on my stand and take the pan off to measure bore and get an idea on con rods. Through the plug holes it appears the pistons are a dished type. Ive done work on a few v8's but never a l series or straight 6 in general. I'd like to know what avenue to go before committing to this motor. It's supposedly a 3 litre stroker. I have a brand new stage 4 cam that came with it aswell as triple Webbers and intake but according to the cam instructions I should have certain valve and rockers etc. Maybe let me know your thoughts aswell as if u know by appearance any part numbers for the rockers etc. First thing I noticed is a gap between the unloaded rocker and the cam? from my experience we set up for zero lash? Thanks Sent from my SM-N950W using Tapatalk- Installing tension rod mounts to frame

Hey guys, Im installing one of my rod mounts to the frame after doing a rebuild on the main tube. I have the mount all cleaned up and ready to go but im struggling to locate it perfectly and dont wanna screw er up! The other side is there for reference and I have done a rough install of the cross member and the lower arm/tension rod so I get a good idea of its location, BUT i never disassembled this car i got it in pieces. that being said, the lower arms are offset on the bushings, should the arms be mounted more towards the front of the car or the rear. like which arm is left and right, sleeve protruding forward or rear.... then I have the manual with all the measurements but its a bitch to hit the center of the mount hole as reference and get the angle etc. is there an easier way to locate these things? Looking at aftermarket lower arms and tension bars i might not have to be so exacting eh, adjustable plus heim joints. Perhaps ill nail em down as best I can then just start collecting parts! Technotoy might take some of my money haha thanks for any pointers- Discussion on idea for "air horn" fix

Made the new recesses for the cross member. Ill be triple measureung and comparing tomorrow before I center punch any holes. I'll probably cut in the sub frame connectors too and then weld it on the bench. I've got a center line and plumb bobs off the strut towers for reference measurement. BUT i do have a discrepancy of 7mm or about 5/16 of an inch on the dimension between towers. I think tomorrow I will fab a bar and bolt it in there to hold em at the 913mm spec while I build all this Sent from my SM-N950W using Tapatalk- Discussion on idea for "air horn" fix

Patcon thanks for all the input. I agree on that drawing showing that the sills can be my level plane. That being said, thier "zero" appears to be the sheet metal floor? That's a tough one because I've replaced the floors therefore it will likely be a couple mm difference than stock. I think with the engine frames I want to be bang on. Just trying to figure out what to call zero then add the measurements to my level plane on top of thier numbers Sent from my SM-N950W using Tapatalk- Discussion on idea for "air horn" fix

Is it one of the holes on the bttm Sent from my SM-N950W using Tapatalk- Discussion on idea for "air horn" fix

C point Sent from my SM-N950W using Tapatalk- Discussion on idea for "air horn" fix

I leveled the car with 6" blocks and a straight edge across the door/rocker sills which are straight. The tops of the rear strut towers aswell as the rear trunk deck are all level aswell at this position so that's positive. Moving forward, the existing frame rail accross to where the old one was is level but things are about 3/16 out of whack at the very front so she's got a bit of a twist to it. I'll have to check the manual later today and see where all the datum measurements line up. I think what I will do is hang a fixture ill make under the car and that will be my zero mark then ill install the frames as needed. I'll also try to figure out a true center line. It has suffered some damage at the front so I'd like to triple check everything. On the datum topic. Where is the "position c" physically on the car, in the picture with measurments. There's multiple holes and such under there haha. Back on topic with the air horns... Ill box those. Im not going to try and tackle the round edges but I will keep the form and dimensions the same Sent from my SM-N950W using Tapatalk- Discussion on idea for "air horn" fix

Wheres the best spot on the car to consider it "level and true" I want to have it flat for measurements. See attached pics for my thoughts. That bump in the firewall? Shes straight accross, i was thinking the panel under the cowl as its not dented of buggered or the upper windshield line. I just want the car level before I start shooting elevations with these lower frames rails Sent from my SM-N950W using Tapatalk - Where to go with unknown build ive acquired

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.