Everything posted by kinser86

- 78 280z Severe Driving Problems

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

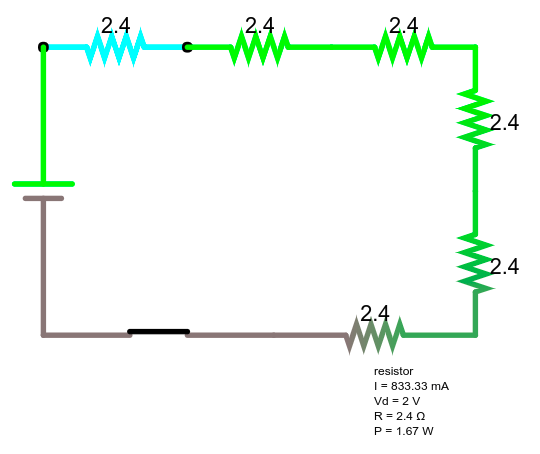

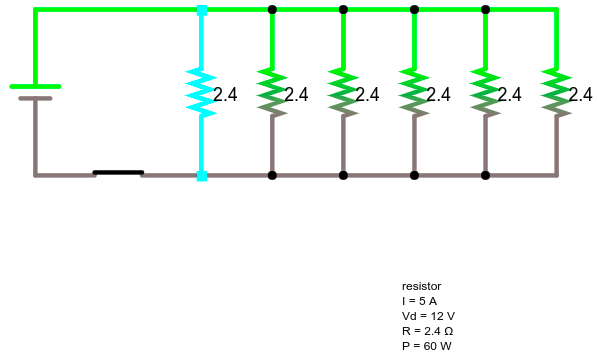

Did you run the supply voltage through the dropping resistor? I was thinking of 80% duty with the mosfet. This will help keep the injectors cool and I could run them for a fixed time. I could be over thinking the test stand but I have always been advised to not run full 12VDC through the injector. I think this will be a better test. I was unsure if the test I performed would work as intended but I can run the pump like you said and manually pull vacuum again and see if it reacts the same. I will pull the oil pressure wire and run the pump that way.

-

78 280z Severe Driving Problems

Thinking of a way to do this using an n channel mosfet and arduino. When the pump is running, I have seen above 40PSI without the engine running. I saw it today when I would prime the rail before injector testing. Once the fuel pump shut off, it would drop below 40. I don't remember if its 38 or 36, I would have to capture that. All injector seals were replaced within the past few weeks when I put the injectors back in the car. I have tested vacuum leaks with carb cleaner but was unable to find any leaks. I have not tried using propane. I think I will create a test setup using a n-channel mosfet and an arduino to run the injectors at a reduced duty cycle rather than getting the wiring in the car involved. I don't have a spark tester but that is a good idea. I can do those test but I think first I will pull the rail completely and do some bench flow test. When spraying the injectors, the fuel pressure gauge would sweep to 0 when spraying. That doesn't mean it can't get stuck though. Fuel Pressure gauge of vacuum gauge? I don't smell or see fuel in the line connected to the FPR but I wouldn't rule out a stiff/rigid diaphragm. The vacuum advance diaphragm was cracked and damaged a while back which warranted a replacement distributor. There has been a lot of good comments. As everyone mentioned, I need to measure volumes. I will develop a simple test circuit using an arduino and n-channel mosfet and run the injectors at a duty cycle that is yet to be determined. The test rig will require some work as to how I will have everything setup. Once I have those numbers, I will see where we go from there. I am hoping #2 and #3 are low.

-

78 280z Severe Driving Problems

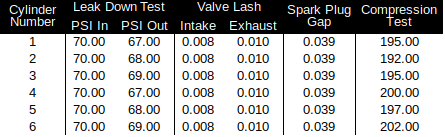

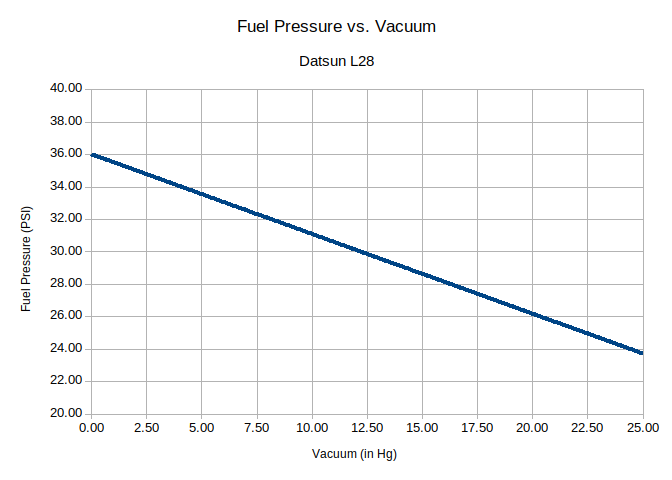

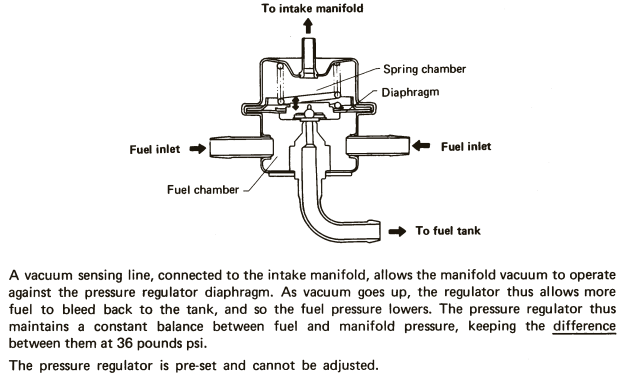

Time for an update. I ran a few test this morning. First thing I did was pop off the fuel rail to capture some video of the injectors. I made a quick ground interrupt switch to an old injector connector and tested the injectors. I sprayed all of them but focused the video on #1, #2, and #3. I disconnected the starter signal and would turn the key to prime the rail before each test. In my opinion, the spray pattern for #1 looks really good. #3 definitely looks suspect with defined spray trajectories columns rather than a large cloud seen in #1. #2 I think falls between the both in quality but I will let the video do the talking. The other injectors looked similar to #1. Next thing I did was pull all plugs and blow out all the fuel that got in the cylinders. I figured now would be a good time to do another compression check but the vehicle was not warm. Fuel was blown out of all cylinders before performing the test. Numbers again are high but they are still within 10% of each other. I then hooked up the FPR to a vacuum pump and put my vacuum gauge between the two to record FPR with respect to vacuum. Again, I charged the rail before doing this and slowly pulled vacuum until the pump couldn't pull anymore. It looks like 23inHG vacuum is only yielding 28PSI on the gauge. Is this an acceptable range? Now I made this chart for referencing fuel pressure with respect to vacuum. I read the FPR is to maintain a pressure differential of 36 PSI with respect to vacuum so if this chart is wrong, let me know. That is all I was able to do. I have a new set of plugs I will put in next time but the spray pattern on #3 is suspect to me right now. The rail is still loose on the car anticipating suggestions to replace the two. I did not check valve lash or fuel return due to some time constraints.

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

I did not try to drive it after #2 and #3 did not respond to injector connectors being pulled. I did check continuity to the ECU and dropping resistor for both connectors as a fail safe and they were both good. I can perform another leak down and compression test with a warm engine this time and also check the valve lash. If these numbers are good, then the only assumption would be the injector is truly not firing even though there is a clear audible clicking of the injector during idle. I marked the injectors prior to them being serviced so they went back to the cylinder they originally came from. One quick test would be to swap a known working to one of the #2 or #3 position and see if the issue follows the injector or stays with the cylinder. Right now a visual inspection on those two injectors is a good idea. I think switching positions will help determine if its an injector or the cylinder. Right now the priority list is: Determine why #2 and #3 injectors do not impact idle speed Warm Engine Compression test again Leak down test again Valve lash If out of spec, adjust and re-run compression and leak down Swap injectors with others on rail to see if idle speed follows injector or not If it follows injector, then bad injector If it stays at cylinder, something else is going on Vacuum pump test the FPR (still on the list but need to get #2 and #3 on board) I can't make any future decisions on next steps but if the numbers don't match up on #2 and #3 and injectors are good, then it sounds like the head needs to come off. As soon as I get those numbers I will post them up. I will take some videos and pictures again since they help so much. Thanks again for everyone's input, it is definitely helping! ?

-

78 280z Severe Driving Problems

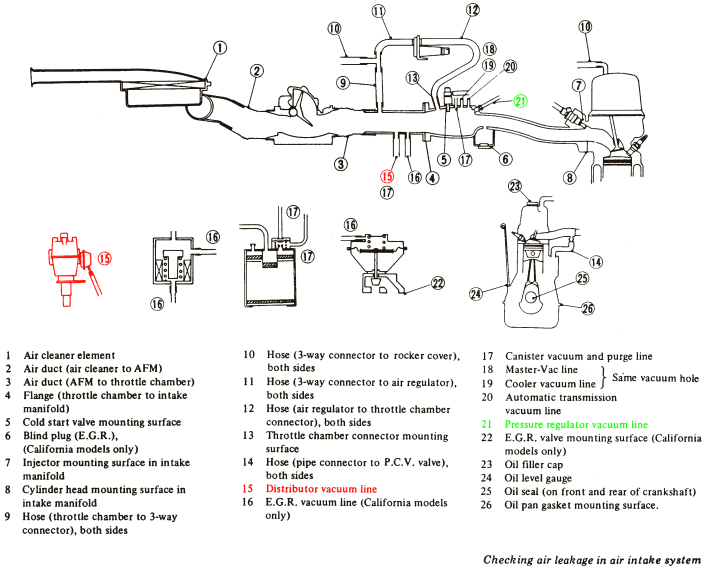

Alright here is an update.. We might be on to something but as promised let me check off the to-do list first. Verify vacuum line routing (Distributor) If incorrect, verify timing again (10°BTDC @ 800RPM) It was incorrect, vacuum source was after throttle body. I put it below the throttle body per the FSM. Timing/Idle speed adjusted back to 10°BTDC @ 800RPM. FPR exercise with hand vacuum pump I left this tool at home so I was unable to perform this exercise! ? It stays on the list... Verify firing order (caps and plugs with pictures) 1-5-3-6-2-4 CCW As promised, pictures. Also a video of each lead with a new plug in showing spark. Verify AFM pins not popping out when plugged in Pins are solid in the connector when installed. I still have the AFM cover off right now so those terminals are easy to access with a multimeter and measure to the ECU connector. Review injectors firing (I have video below) unplug one at a time #2 and #3 did not have an impact on idle speed when removed. I swapped connectors from Injector #1 and #2 after this, and when I perform the test again with the swapped connectors, #2 still has no impact on idle but injector #1 (with #2 connector) will drop about 90rpms like it did with the original connector. screw driver to ear All injectors are clicking. #2 and #3 are clicking the same as other. Granted I am using a tall screw driver to my ear, when the connector from #2 or #3 is removed, the amplitude of the clicking goes down a lot. When the connector is installed, it has the same amplitude as the other injectors. Record video of RPM/FP/Vacuum See video below. So after this, I am really perplexed with #2 and #3 injector having minimal impact on idle speed.In the video you can definitely see about a 100rpm drop on all other cylinders. I have not been able to reduce idle speed yet but I forgot my vacuum pump to test the FPR. The EGR system has been removed and blocked off on the intake plenum. The AFM does move freely, I have never been able to get it to bind or feel any resistance in its movement. Spark Test Pulling injector connector test. (Apologizes for the shaky video at times, it is not easy handling all of these items at the same time.) Reemphasizing the impact #6 injector connector has on idle speed. FP/RPM/Vacuum Video:

-

78 280z Severe Driving Problems

A lot of good information here, let me see if I can answer them. I went through an exercise believing the oil pump drive gear was off a tooth, so I spent a day going one tooth left and one tooth right to see if I wasn't seeing a true 11:25. This resulted in a waste of time because it was correct to begin with. This is before the injectors were rebuilt. I will take a picture of it tomorrow but 1-5-3-6-2-4 on cap to the plug is what I have. When validating the timing marks on the crank pulley, I checked TDC on the crank/timing marks on cam gear/ear lobes on cam/piston at top of bore. The rotor on the distributor points towards the radiator, and at the number 1 plug outlet on the cap which also has the reference mark. I just replaced all injector clips about 3in back from the originals. I used a screw driver to my ear in order to listen to each injector to make sure they were firing. They are definitely clicking, all at the same amplitude and frequency (to the best of my hearing capacity). I can try the unplugging method too and see if I notice an issue. I've gone through the valve lash a number of times, my initial post is the measurements after the third time of going through things (going in circles?). When I did the checks to the components, I did all the test through the ECU connector. I can check the conditions of the pins on the AFM connector to confirm they are not popping out when installed. I confirmed TVS works at all angles corresponding to the EFI-Bible. I removed the cap and made sure all contacts and moving parts were clean and free of any binding. They have some miles on them. The values in my first post were measured at the ECU connector. I agree with FP statement. I spent more time looking for a faulty AFM or other things that this might be more of the culprit. Understood on the AFM observation, thanks for clearing that up! I believe the distributor is connected directly to the intake right now. I will confirm this but it might be hooked up to one of the ports near the FPR port. In that case, the vacuum reading in the video was coming from the intake and not before the throttle plate. I will go over the vacuum lines and trace their origins as everyone has been pointing out. So right now the to-do list is: Verify vacuum line routing (Distributor) If incorrect, verify timing again (10°BTDC @ 800RPM) FPR exercise with hand vacuum pump Verify firing order (caps and plugs with pictures) 1-5-3-6-2-4 CCW Verify AFM pins not popping out when plugged in Review injectors firing unplug one at a time screw driver to ear Record video of RPM/FP/Vacuum If I am missing anything please let me know. I appreciate everyone's feedback. It is a lot to take in and I want to make sure the order of operations of the troubleshoot is correct, focusing on one thing at a time.

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

I am starting another to-do list, this will on the top. I did blow through all hard lines on the car and verified air was going through from the front to the back of the car. When I had the rail out, I also blew air through it. Record FP/Vacuum /RPM simultaneously Here is the video of it moving under its own power, it was a short drive.

-

78 280z Severe Driving Problems

FPR vacuum lead is connected. Removing the oil filter cap will make the engine almost die at idle. The reference to the 1K pot swings at idle was stating that it has an impact (it is installed correct). Driving the car is still next to impossible and I have a video I am working on uploading to show it driving. Trying to adjust the pot while driving is still not even an option yet but once it is, then I can start tuning it. Vacuum reading was taken between the vacuum advance and intake. The hose between the FPR and intake is new and still soft. It sounds like this is leaning towards the FPR being bad.

-

78 280z Severe Driving Problems

Alright reporting back some findings. Fuel Pressure: 34 PSI @ 800RPM Vacuum: 18 inHg @ 800RPM AFM rotated back 6 teeth (original setting) 1K linear potentiometer installed per atlanticz website at 480Ω. Increasing resistance causes the engine to idle lower Decreasing resistance causes the engine to idle higher There is definitely in audible difference in idle when changing the resistance Symptoms do not go away. Car is still unable to drive, popping and stumbling the second you try to drive off. Below is a video of the car after warming up with all the previous items performed. Notice the pop in the vacuum gauge.

-

78 280z Severe Driving Problems

A lot of responses. There are a lot of parallels between the driving characteristics described by FastWoman and the car I am working on. I am going to add a potentiometer and tinker accordingly to see if it makes an impact. Awesome. After reading about the Steinhart-Hart equation, I calculated the constants and now have a chart of my own to play with. Given the symptoms of the engine, lean. I have never been an expert spark plug whisperer but I will add 'Pictures of tips' to my to-do list. Resistances were checked through the harness at the ECU and at the sensor. I agree the compression numbers seem high, the engine was cold. I have not run one with a warm block but I can add it to the to-do list. I can't remember how well it ever ran but it definitely was never 100%. Definitely never broke the tires loose, bellow 3500 RPM was unpleasant (flat spots in throttle), above 3500 RPM, the car felt ok. For a while I thought the TPS was a culprit but I tested it both at the ECU and at the component without issue. Plug wires and firing order are correct. The connectors before the dexoit were actually not bad. I ended up cutting the connectors back about 3 inches when I put in the new connectors. I even checked the AFM carbon trace for wear grooves, also spraying the internals with deoxit. I have not changed the AFM connector. Fuse links were removed and replaced with a maxifuse system. In reference to the potentiometer, what power has everyone been running? 1/5W? 1/2W? 1W? adafruit has a 1/5W for $1 I can get. Otherwise I would have to go through digikey for some higher power ones. Revised to-do list: Record/report new fuel pressure numbers Record/report vacuum pressure numbers Take pictures of the spark plug tips Install 1K linear pot and adjust per atlanticZ Turn AFM 6 teeth counterclock wise back to previous spot. Thanks everyone for the help.

-

78 280z Severe Driving Problems

Correct. Since the cars history is unknown, I never knew who's hands were where. The glue blob on the AFM was already off and the cover had a different adhesive on it when removed. I had to assume someone had been in there tweaking something prior to me so given that, I adjusted per the atlanticz car site. Again, I can move it back to the previous setting no problem. Excellent! I will take the dive! I will get some fuel pressure numbers this week. The car is not at my house so I make plans of what I want to measure and test then go out there and go through those steps. If I pull the breather line off the valve cover, the car idle takes a heavy dive and almost dies but I will get better numbers once my vacuum gauge comes in. The healthy as a horse and falling flat comment represents this car very well with a lot of timing on the car. The tank wasn't bad at all. There was already filter between the tank and filter that was replaced. There was no filter inside the fuel pump inlet when removed from the car. At this point I was chasing potential bad fuel having the car sit for a while so I opted to change it out just in case. This is when I also blew all the fuel lines out from the back of the car up to the engine bay using compressed air thinking there was crud in the lines. There were no visible signs of debris in the lines when cleared out. I have a vacuum gauge on order and my next plan is to record the following data points: Fuel Pressure Vacuum Pressure I can always add more items to the list ?

-

New member, long time lurker

Thanks, its my mother's favorite car and she always wanted one. haha Thanks! ? Thanks for the welcome everyone. We were part of the Z club here in town, we have attended the NISMO festivals and other events locally. We have lots of toys so this is just one of the bunch.

-

78 280z Severe Driving Problems

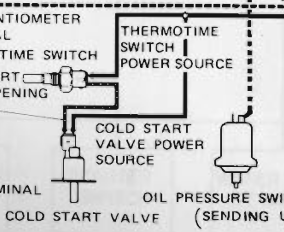

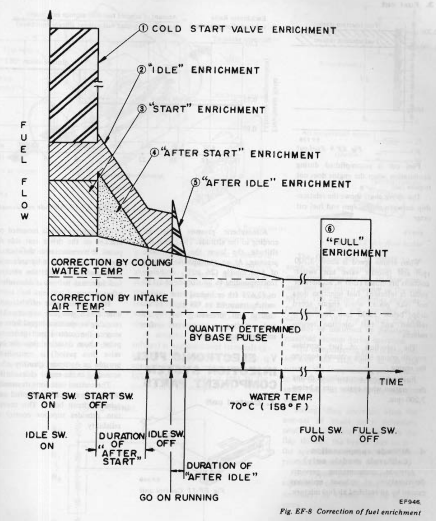

The charts might be overkill, but just trying to throw what I have learned up there to see if anyone else has seen the same thing. From what I read about the thermotime switch is that it is just an open/close type switch that closes the circuit to the cold start valve. After start, it should not impact the enrichment. Thanks, I have been trying to cover my bases and I have seen countless of FI threads with no data supporting any decisions and people ultimately getting pointed back to the EFI bible. I did mark the AFM, ended up adjusting 6 teeth clockwise to achieve 145mL water weights. I can always move it back but the car is acting exactly the same prior to adjustments. I need to get the numbers again now that the reconditioned injectors are in the car. They were within spec and even evaluated with the FPR off but I will get numbers next time I am next to the car for diagnostic record purposes. I have read about this tweak but have always felt it is a band aid to another problem. I ultimately tried taking the car back to zero without any modifications other than some components to see if anything would go away. Thanks, I hope to bring more to the forum than my pain and suffering... eventually. ? I really want to learn from others experience so I appreciate all the help. If I am wrong about something please correct me! I enjoy how easy it is to support replies with images in this forum, it has made things a lot easier for me. ?

-

78 280z Severe Driving Problems

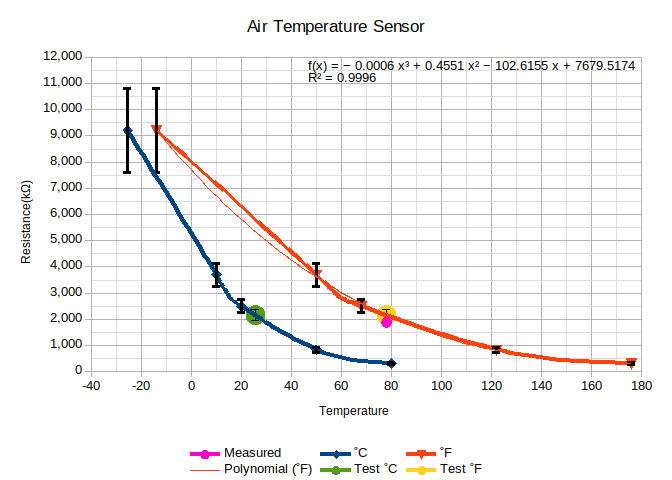

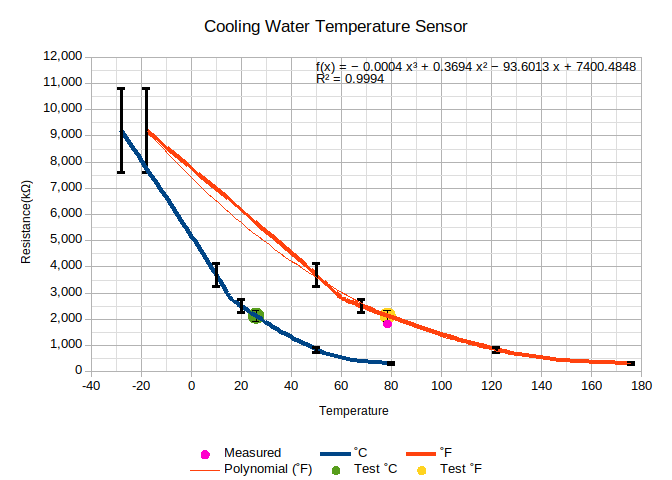

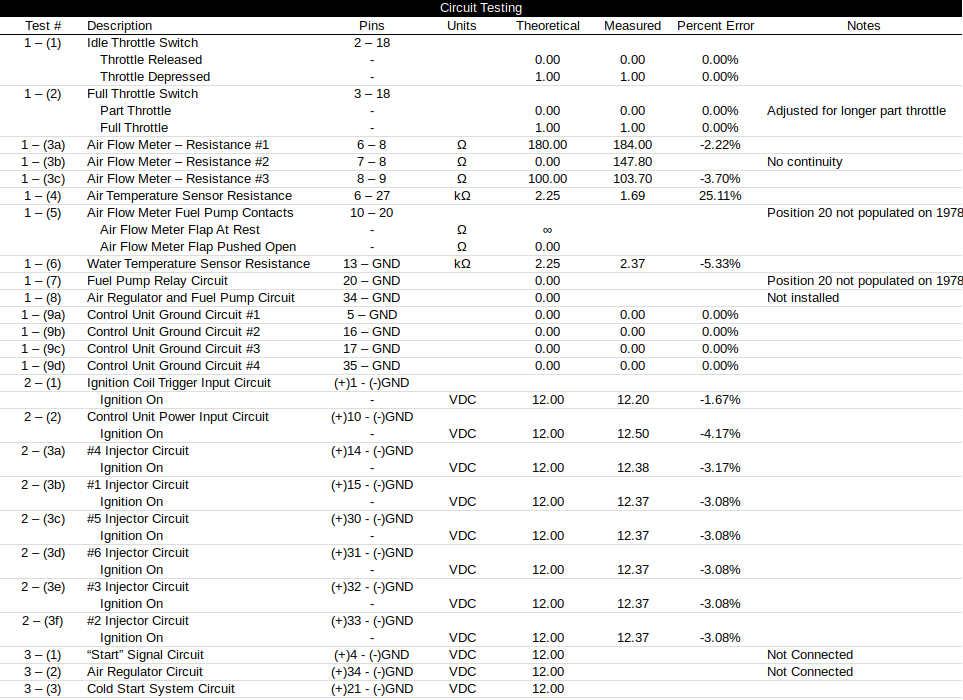

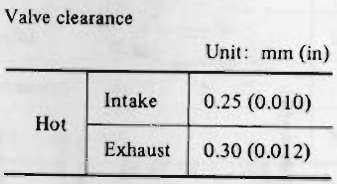

Hey everyone, I have been a long time lurker on many forums and I have decided to post some questions because I am at the point where I believe I need guidance on next steps and want to make the right decision. The car I am working on is a 78 280z California Car. It is not my car, it is my parents car that I bought them as a gift 10 years ago. It has been a long time since I have driven the car so I don’t recall its characteristics but it always had a presence of fuel smell in the exhaust. The car was parked because the fuel smell and rough driving started getting worse. The car then sat for a year and a half and now its time to get it back up and running. All the items addressed have been done within the past four months. Disclaimer: There is a lot of information here and if I am unclear on anything please let me know. I am trying to get some conversations going and wanted to put my best foot forward. Symptoms Bogging/hesitation/stuttering under any load to the point where the car can’t be driven, can’t emphasize this enough. Car idles immaculately Backfiring through the AFM Fuel smell through exhaust Current State Timing: 10° BTDC Idle: 800 RPM Aftermarket exhaust header and muffler EGR deleted Air regulator removed Coldstart injector still on rail but disconnected electronically Thermotime switch disconnected electronically Items that have been addressed Spark: New Plugs (NGK at .039in gap) New Wires (NGK) New Coil (MSD Blaster) Rebuilt ZX distributor (RockAuto) Vacuum advance confirmed working New Cap New Rotor Fuel: New fuel injector connectors Injectors reconditioned from Fuel Injection Services (confirmed working) New Walbro 255 fuel pump Tank removed and checked for rust Fuel hard lines cleared with compressed air New fuel filters (pre and post pump) Inline gauge added between filter and rail Air: AFM has been calibrated per atlanticZcar site rebuild guide Bench tested for smooth sweep (open to close) Calibrated spring force with water weights New PCV valve Engine: Valves adjusted to: Intake: .008in Exhaust: .010in TDC mark confirmed correct on main pulley Distributer shaft confirmed 11:25 position Leakdown test performed Compression test performed Electrical: New coolant sensor New coolant sensor connector New TPS wiring connector Contacts cleaned with deoxit ECU Harness tested in car to EFI Bible specifications Results Leak down and compression test performed cold because the vehicle was not running at the time. The AFM sweep was performed using a 9VDC battery and an arduino. I did two sweeps of the door by hand as smooth and slow as possible. The third sweep I intentionally pulsed the door through the sweep motion by hand to see if something else would happen. I did not see any signs of a bad circuit. The FSM provides a table relating resistance to temperature for the air temperature sensor and coolant temperature sensor. I generated a chart using this data in both °C(Blue) and °F(Orange). The trend is not linear so a polynomial trend(Thin Orange) was generated so I could plug in a measured value to determine a temperature. The table also provides acceptable ranges within specific temperatures so I added error bars to show this acceptable range. The test environment(Green and Yellow circle) was what the temperature should be and the measured (pink) value was within the error bar at that condition. I went through the circuit testing per the FSM and found nothing alarming. Observations Advancing the timing beyond the timing marks helps but doesn’t resolve the overall issue. Timing at 10° makes the car impossible to drive. Timing at 25°-30° makes it bearable but only above 30% throttle. Future State I have worked through what I believe to be the cheapest items to inspect and now believe it is time to find a new AFM and ECU set. Everything appears to be correct and by the book. Should I try to find a 78 280z ECU/AFM for a CA car, or should I find one for any 280z car (non CA). I have toyed with going standalone because at this point I am tired of poking around in the dark trying to troubleshoot this car. I need some assistance from people who have experience with the FI systems on these cars and I don't know anyone locally to reach out to. If I am unclear on something, please ask and I will provide.

-

New member, long time lurker

Hey everyone, I have finally joined the forums after being a long time lurker. I came in the z world after driving a 78 280z CA car around the bay area over 10 years ago. I later bought that same car, shipped it over the Texas and gave it to my parents as a birthday gift. The car was going to be junked and I got it for shipping only (not a bad deal). My mother always wanted one and it was the best way to bring one in the family. Below is what the car looks like currently although this picture is a few years old.

.thumb.jpg.7051a435795411d599223773a2c9c06b.jpg)