Everything posted by SpeedRoo

-

To replace or not replace ball joint.

Good to see someone else rebuilding them. He did miss out one part on reassembly, there's a disc with 4 holes in it that goes over the shaft to restrict the flow of grease into the rubber boot that he deleted. Also the Nissan boot has a bleed nipple on it, they are still available.

-

Daily driver for us guys who have to have cars that hold our interest.

I'm fortunate that I have multiple daily drivers, rather than just one. In summer time the 240Z is my daily, along with a R53 Mini Cooper S, a 1999 Mazda Miata Sport, an Aston Martin V8 Vantage and a Toyota GR86. For load hauling and snow runs the Subaru legacy wagon gets the nod. Between my wife, my son and myself we need at least 3 dailies!

-

Z Restoration Progam

I think you may find @26th-Z and @Carl Beck already have most if not all of the documents. I've hoovered them up for my archive. Will be interesting to see what if goes for this time, I think it sold at least once or maybe twice since the last BAT appearance 6 years ago.

-

Z's on BAT and other places collection

Missing dovetail on the passenger door, photo 150. Also the rubber weather strip under the door. They weren’t there in 2019 when it was last on BAT. I just remanufactured the early pre 1973 dovetails for my 1970/71 240Z as they were no longer available. Also did the plastic grease reservoir for the steering rack and the plastic cover for the battery. The Vintage Z cars were restored with parts that were available at the time, 1997/98; not always period correct parts but they did the best they could.

-

Odd Bolts in Balance Tube

You'll probably find they are JIS tapered pipe threads. Nissan used them on the 240Z in a number of locations in differing sizes, including for grease fittings.

-

Fact checking of this article needed?

All the information is here, Carl Beck's car that he has just sold I believe. https://www.zhome.com/Racing/BahaBREZ.htm

-

Door dovetails

I'm happy with how the dove tails turned out so I'll go ahead and have a batch made up if anyone needs them for a restoration. Just sourcing the right JIS screws.

-

Door dovetails

The early 240Z had handed dove tails for the doors, a left and right sided fitting were required. Part numbers R 80530-E4101 and L 80531-E4101. https://www.carpartsmanual.com/datsun/Z-1969-1978/body-240z/body-side-trim-side-window/62 On later cars there were replaced with a symmetrical part that fit on either side. 80530-N3400 Biggest problems with the early ones were the tabs where the screws went through breaking off. Replacement factory parts haven't been available for years. Fortunately I have a set of unbroken originals which we modelled up and reproduced in aluminum. We added an extra 1mm around the screw holes to prevent the cracking and breaking. Just picked up the first samples to fit check and they work just like the originals. The original one is on the right, you can see the slight increase in thickness around the screw holes on the left one. Also modelled up and replicated the original plastic grease reservoir for the steering rack. I'll post details in a separate thread.

-

240Z assembly line

And therein lies the problem and why history ends up getting lost. In the larger scheme of things it probably doesn't matter how our cars are built and the details will be lost to time. Time to close this thread.

-

240Z assembly line

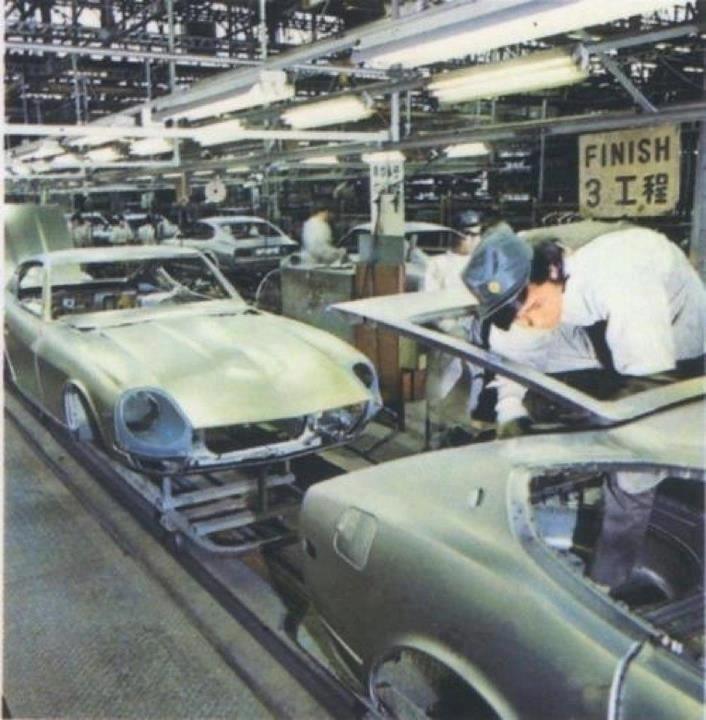

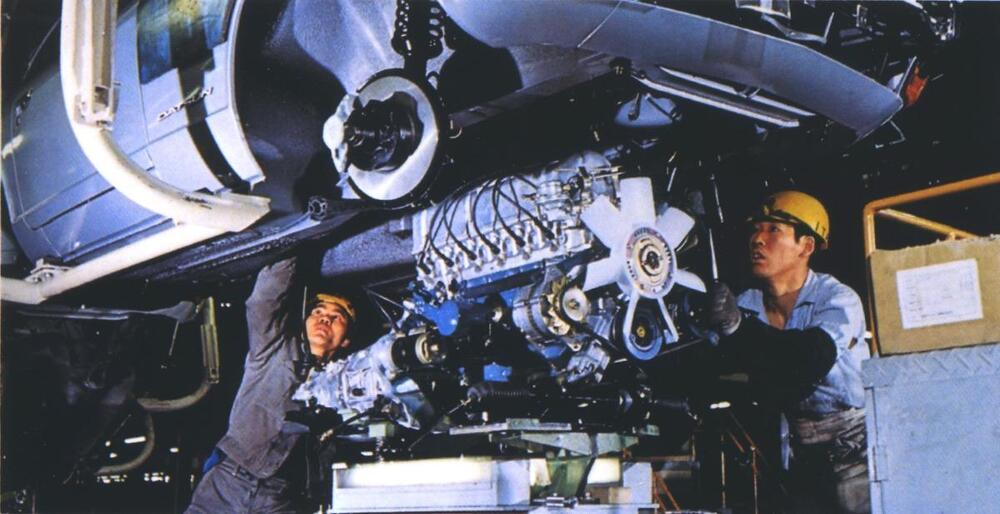

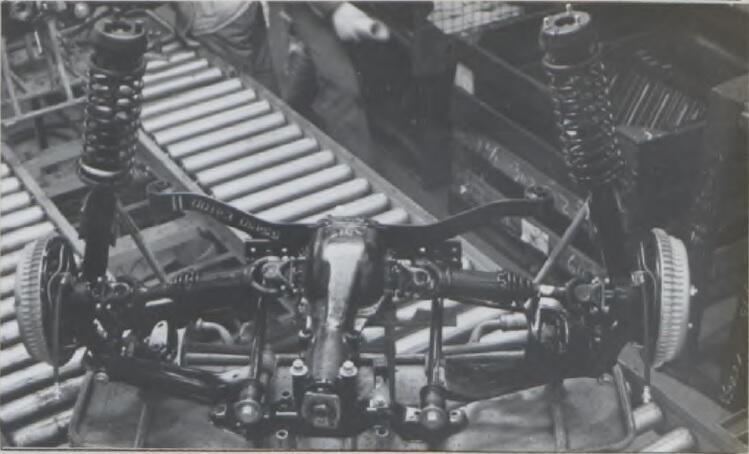

Like most car companies parts are made in different locations and shipped in for final assembly, in the case of the S30 model this was Nissan Shatai. From what you have said the engines were built in Yokohama, were the gearbox and other mechanicals done there as well. What parts were made at Shatai, the main body pressings? What were the other major sub assemblies and where did they come from? Do you have any photos of the Shatai assembly line and factory? What I have posted so far in this thread are from what was previously posted on these forums. Is there a document that details the procedure for the build. We know from looking at our cars that the bodies were welded together, then the sound deadening applied, gray primered, chip seal of the underside and then front wings, doors and cowling along with bonnet and hatch fitted before final paint. Interior and glass along with electrics fitted before the mechanical parts were then added on the assembly line. Is this the correct sequence?

-

240Z assembly line

I've reached out to @kats to see if he has more details but he seems to be MIA at the moment. Also trying to contact Mr. Miyazaki to see if he has any photos or videos of the assembly line; he used to visit it on a regular basis according to some notes @kats made in another thread.

-

240Z assembly line

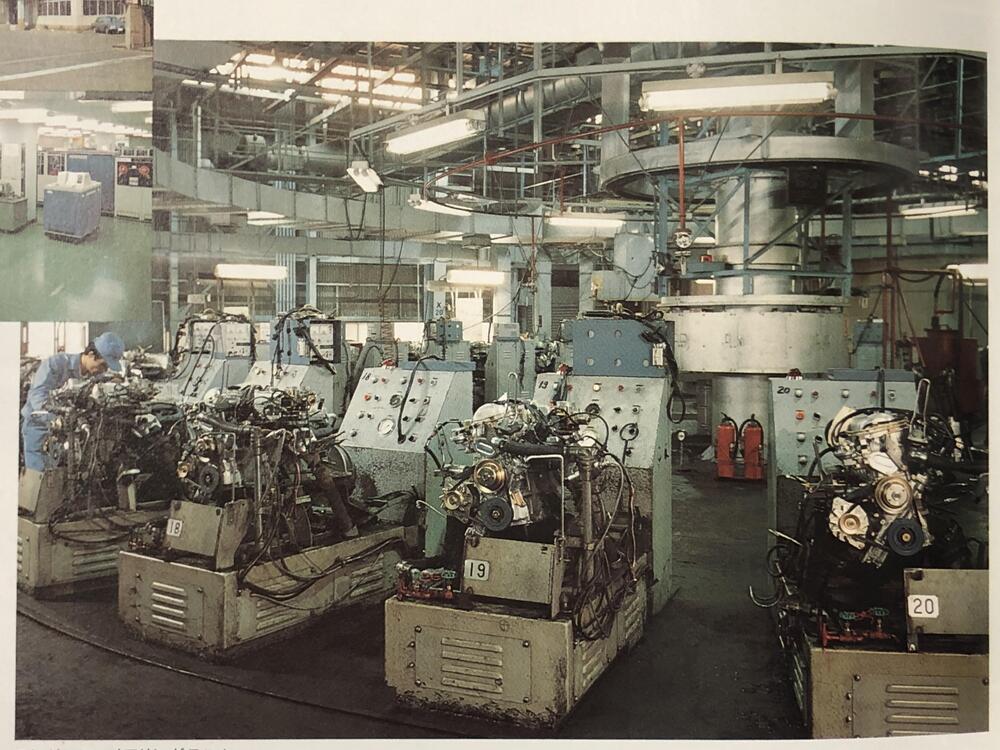

Where were the S30 L24 engines built up and fired-up tested then?

-

240Z assembly line

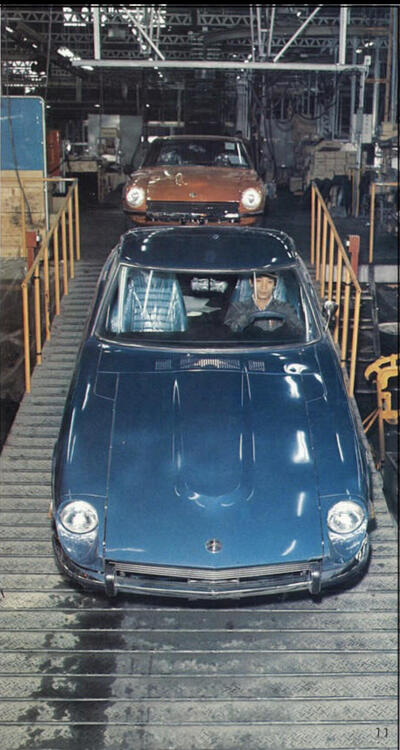

@Kats had posted this picture of cars driving off the assembly line. He also posted the engine test cell for the L series.

-

240Z assembly line

Did Nissan do any promotional or internal videos showing the Shatai assembly line?

-

240Z assembly line

With all the talk of restorations and factory correct details does anyone have photos or videos of the assembly line at Nissan Shatai. I've searched high and low and found very little here or online. Interested in the process of how they are assembled, primed, chipsealed, final paint and mechanical assembly. Here's the few photos I've found.

-

Z's on BAT and other places collection

Here's your comments about 00023 and S30's work on it. Alan puts this into even more elegant words: "A great privilege to experience this precious early production car, restored to immaculate original specification.

-

Z's on BAT and other places collection

Here's a good one for you, tell me why this is incorrect. The brake from HLS30 00057 It will give you an idea of the attention to detail S30 go to to get a factory correct restoration!

-

Z's on BAT and other places collection

Wow you make this too easy RAE! Which factory are they making it correct to, certainly not Nissan. Look at the underside of the white December 1970 240Z https://s30.world/collection/datsun-240z-hls30-15652-us nothing like that ever came out of the factory. Look under the front cowling over the windscreen wiper motors and ventilation, never seen that finish from the factory, it's usually gray undercoat beneath that panel. What happened to all the chipseal the factory applied under the car that was then covered with overspray when the final paint was applied. That's a factory correct restoration when you see that, not all this shiny stuff. So many other things that are wrong but I'll let you stew on the obvious that you seem to have missed. It may be a nice fully restored car but certainly not factory correct like you and your mate claims.

-

Z's on BAT and other places collection

Buyer beware, anytime a seller claims it is a factory correct restoration it makes you wonder which factory! Looking at a lot of the details on the S30 cars they have in their museum they are far from factory correct, nice and shiny but Nissan never built them to this level. Also quite a few important details on the early cars are different to how they were built. I'm no expert but if I can spot the difference how can the so called experts involved advising S30 have missed them?

-

The OG 240Z - Reanimation Project

Sometimes the journey is more rewarding that the show, congrats on all your efforts to make it to the event! Let's see what it can do on the track.

-

The OG 240Z - Reanimation Project

@Captain Obvious I wouldn't worry about the OG making it as you know how to fix it whatever goes wrong. You're not some rank amateur setting out blindly on a journey naively hoping all will be well. You know your car inside and out and and have so much experience with Z cars I reckon you could rebuild a seized engine on a remote Tibetan pass. My beach bomb 240Z is called Louey and definitely a "him". I've never thought of cars as females.

-

F4W71A Rebuild

@jfa.series1 I've had good luck getting all the parts through amayama, partsouq or nissan parts deal. You'll have to assemble the kit yourself, that's what I did.

-

The OG 240Z - Reanimation Project

@Captain Obvious Just had a look on my October 1970 240Z that hasn't been touched since built. It has the flat side up.

-

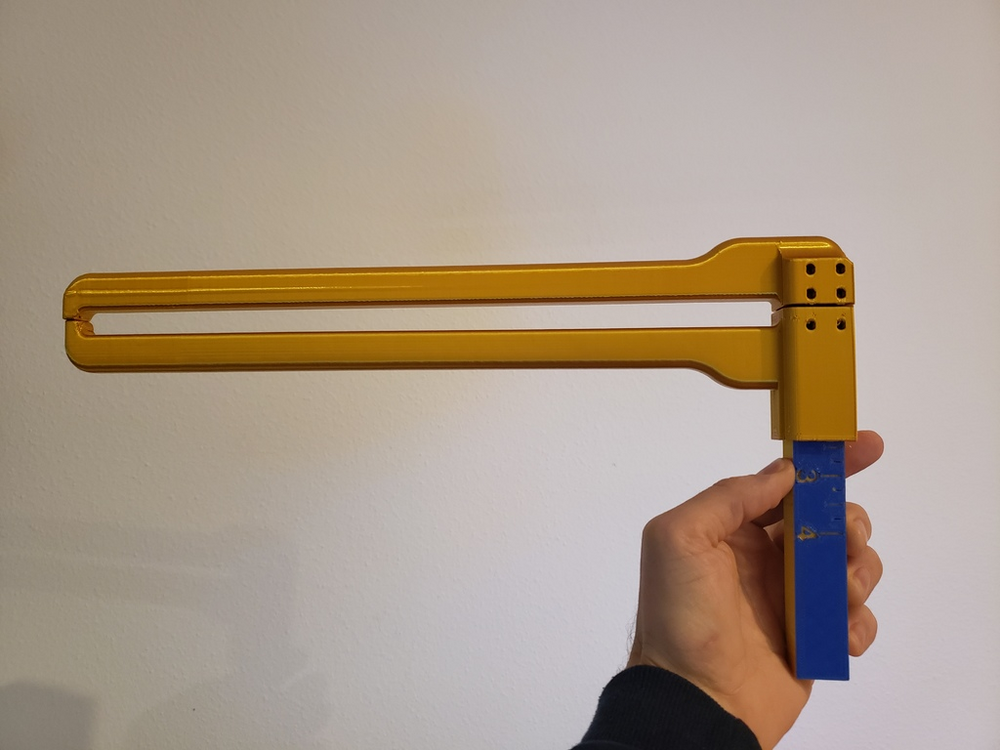

Helpful Gauge for setting SU jet depth

Pretty easy to do, simple scaling down of a surfboard caliper would do the trick. If I get time I'll design one up this week. here's a couple of basic designs.

-

3D printed Gearknob

@Patcon the exterior will print smooth, it's a graphics display issue and how SolidWorks saves the .stl file. When you slice it for printing the surface is rendered smoothly. Will post a picture of the first sample print when it's done, I'll do a trial piece in laser sintered nylon first. This is a sample off the Prusa 3D printer in SLA, much smoother than the graphic rendering. With laser sintering it uses powder to print the object so the layer lines and polygons are smoothed out. These are for my own use, I have no plans to sell them.