Everything posted by rcv

-

Clutch fork throw

I gave up work for the day right after I sent the last clutch picture - had to get on with my other weekend chores unfortunately ?. I really don't like adding on the extra washers without understanding why I'm having this problem in the first place. I'm worried I'm screwing up something more fundamental that's going to bite me if I just hack around it. Yup, same flywheel. I think I'll try actuating the fork with a crowbar just to see if it actually has enough throw. I'll make sure to keep my knees well clear! After that, I think I'm going to try installing the original clutch setup (collar and all) just to validate that the original setup didn't have this exact same problem somehow.

-

Clutch fork throw

-

Clutch fork throw

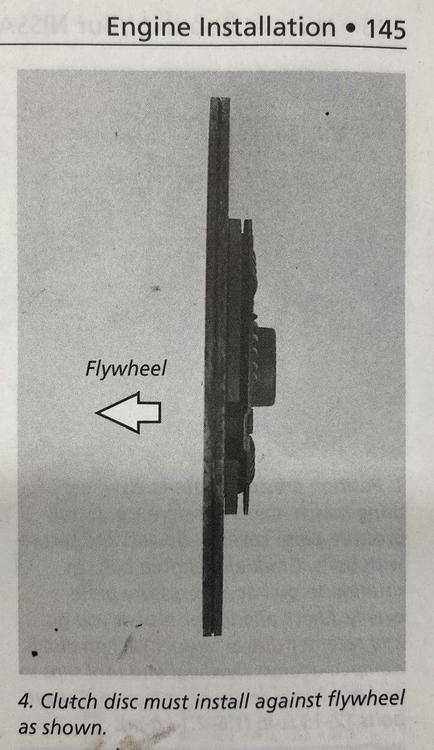

I put the driveshaft on, and with the transmission in gear I was able to spin the front pulley. I then had a helper turn a ratchet on the crank bolt while I held on to the driveshaft and I can confidently report that the two are very tightly coupled. Good idea - it looks like I only have around 12mm of clearance between the back of the fork and the case when the TO is touching the springs. Half of the slave stroke can’t be good ? I was pretty careful with this, so I’m fairly confident it’s on right. I installed it in the only way that makes sense to me, which is consistent with Tom Monroe’s instructions: I would absolutely consider just buying another clutch kit if I thought it would help, but given my 91mm stack up I don’t think it will. I don’t love having to resort to the washers under the pivot, but I think that’s my best shot at this point. EDIT I just reread your comment about the clutch disk being too thick, which could be pulling the springs inwards. That geometry makes sense, But given that the pressure plate and disk are sold as a kit, it would be pretty weird for this to be the case right? My 91mm stack up number doesn’t have anything to do with the clutch disk, so maybe there is something wrong there.

-

Clutch fork throw

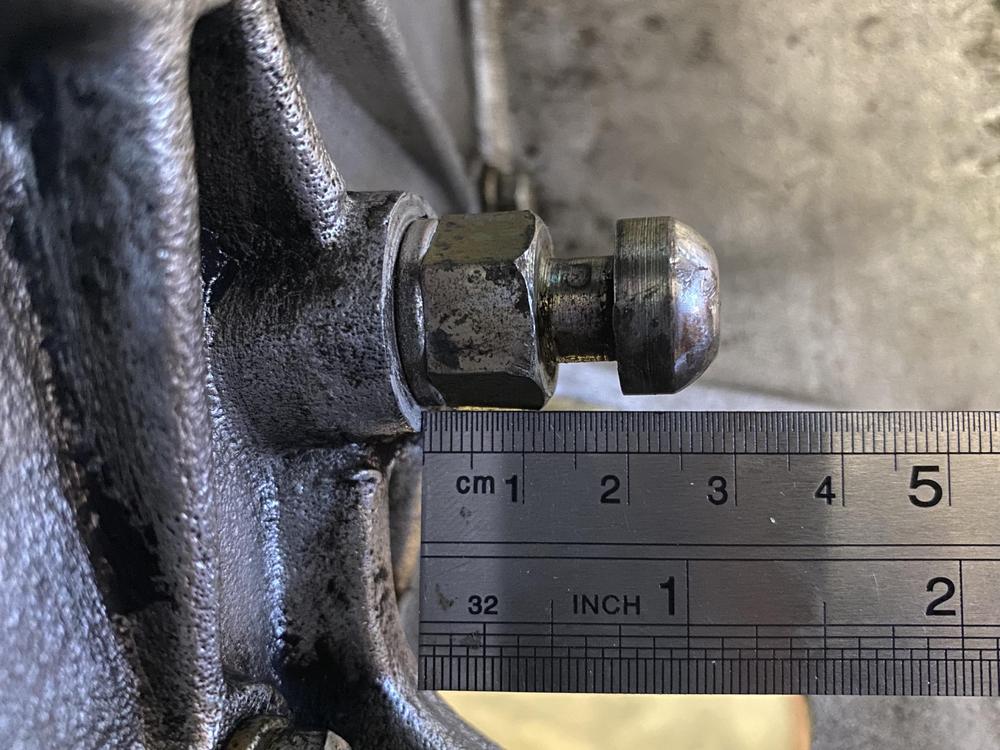

The retaining spring on the back of the fork is there, and I made extra sure it clipped around the groove in the pivot: Nope, I put a little piece of tape on the output shaft and watched it spin as I turned the crank with a ratchet. The belt I bought seems to be a little short so I can’t get it on, but the pulleys seem to be well aligned according to my ruler.

-

Clutch fork throw

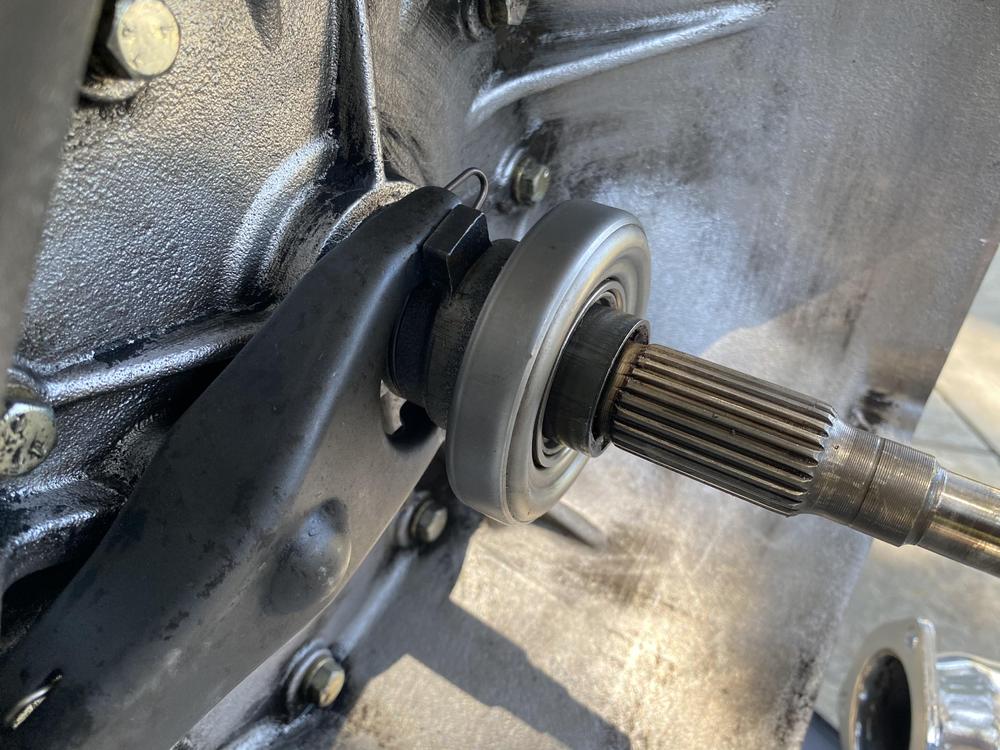

Ok transmission is back on with the new style fork. It looks like I’m down to a little over 125mm now: Here’s a video of me fiddling with it: I’ll take your advice and try this out. I haven’t installed my belts yet, I was going to wait until the engine was in the car, but I’ll do a test fit now to see if anything weird shows up.

-

Clutch fork throw

Hard to tell from the photo, but no there’s no gap. The bolts were torqued down to spec when I took the measurement. Heh you’re telling me. The worst part is cleaning off all the loctite from the PP bolts/holes. It’s a lot less work than getting this wrong though. I’m putting it back together now with the new style fork. The upside is that I’m getting pretty fast at this. I’ll update when I’m done.

-

Clutch fork throw

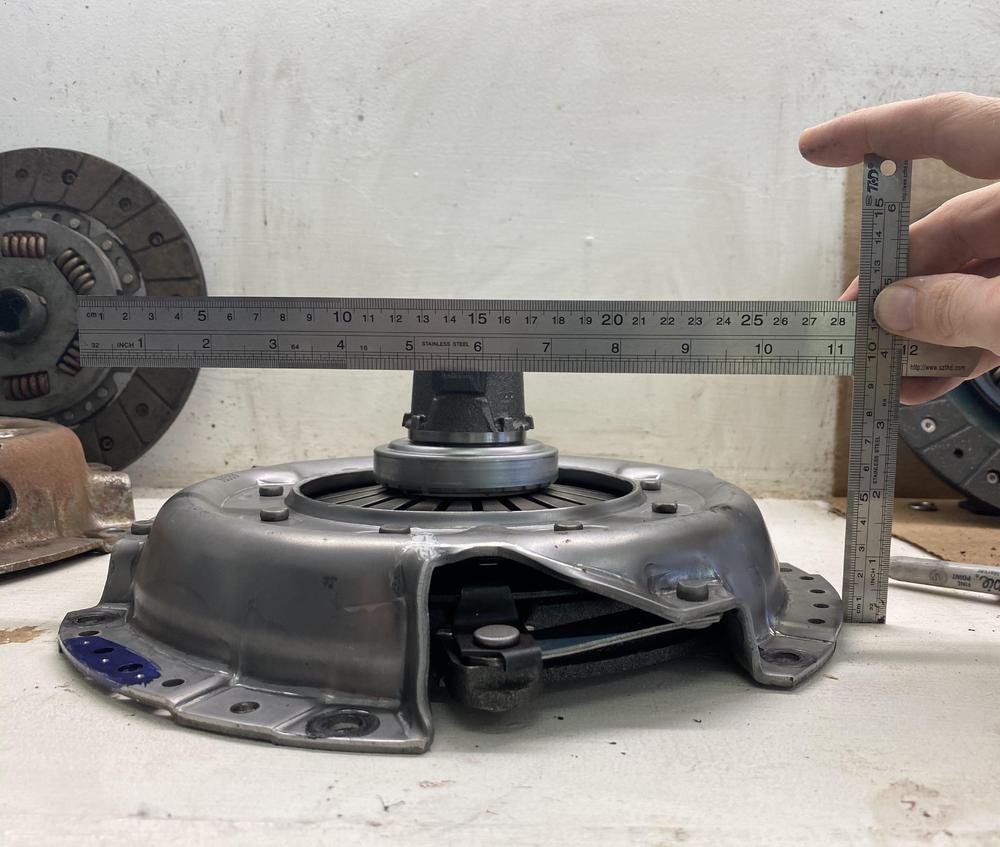

Took the pressure plate off again this morning and took a final measurement of the stack up. It looks like I’m right on 91mm from my bench to the ears. That’s 47mm from the TO bearing/collar and 44mm from the pressure plate: My pivot ball is right on 26mm without the washer, and ~28mm on the washer. I suppose it’s possible my flywheel has been dramatically thinned out, but I think it’s unlikely. So to summarize the story so far, here are the suspects in the lineup: Unlikely Culprits: PP/TO stack up: I measure 91mm which seems to be the consensus for the right height. Pivot ball height: Mine seems like the standard 26mm + 2mm washer. Fork geometry: Both my new style and old style forks have identical geometry, which matches those from @EuroDat: 120/65 Possible Culprits: Flywheel: Possible that it’s too thin. Mine measures 27mm from edge to edge. Anyone know what the spec is? Given the history of the car, I doubt the flywheel has ever been heavily modified. Localized Non-Euclidean Space/Time Warping: That’s it, I’m out of ideas after this. I really hope this isn’t my answer.

-

Clutch fork throw

Hmm looking online I found this longer looking pivot: https://www.datsun-garage.com/products/oem-clutch-fork-pivot-ball-1972-83-240z-260z-280z-280zx I’ve never seen one like this, but it appears to be much longer than the one in my 4-speed (which is the same one in my 80-something 5-speed I have sitting around in the garage). Maybe that’s worth getting and trying. I’m getting really antsy to move this project along, but I’m sure gonna regret it if I can’t throw the clutch once everything’s in the car

-

Clutch fork throw

Yeah the washer is there. The flywheel measures 27.5mm thick. As far as I know it’s never been shaved, but I can’t find any specs on what it’s supposed to be.

-

Clutch fork throw

I don’t think it has anything to do with the fork either. I used my old style fork with the hole in it because I’ve heard people prefer the adjustable slave cylinder. As far as I can tell, the old and new style forks have the same geometry. I think I’m going to just forge ahead with installing the engine and pray I have enough travel to actually disengage the clutch when I stomp on that pedal. Anyone want to talk me out of that?

-

Clutch fork throw

-

Clutch fork throw

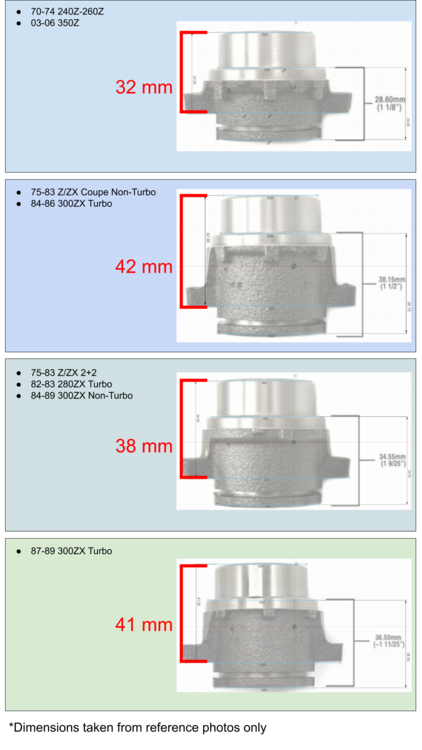

The fork is definitely on the right side of sleeve ears, between the ears and that circular retaining spring. It feels like I’ll have some throw left once the TO bearing contacts the PP springs - the fork isn’t quite bottomed out. Any way to tell if I’m going to have enough travel other than plumbing up the slave cylinder to the master and pressing on the pedal? This is a picture of the old collar, but I installed the new one the same way.

-

Clutch fork throw

I got the longer collar installed, and bolted up the transmission this morning. It’s definitely an improvement as I can actually feel the springs against the bearing now when I pull the fork all the way back. Should I be able to actually disengage the clutch with my hands in the fork, or would that take superhuman strength? I don’t quite get 115mm - more like 135mm which is at least an improvement over the old measurement of 150mm. Do you all think this is good enough, or should I pull it apart again and investigate further?

-

Clutch fork throw

Great, I'm going to order myself the "75-83 Z/ZX Coup Non-Turbo" collar and see how it fits. I'll post an update next weekend when the part arrives. As a tangent: I've been thinking about this. It seems like you and a few others donate a ton of your time to answering the same questions over and over again from newbies like me. It's a shame there's no good place to easily collect and refine this knowledge. Throwing up a wiki is a piece of cake these days, and I'd be more than happy to spearhead that. The harder part is getting a critical mass of people to actually contribute to and maintain it. I know there's the "Knowledge Base" section of this site, but it seems pretty dead. Maybe I'll make a post in the Chatterbox forum and see if I can get any traction.

-

Clutch fork throw

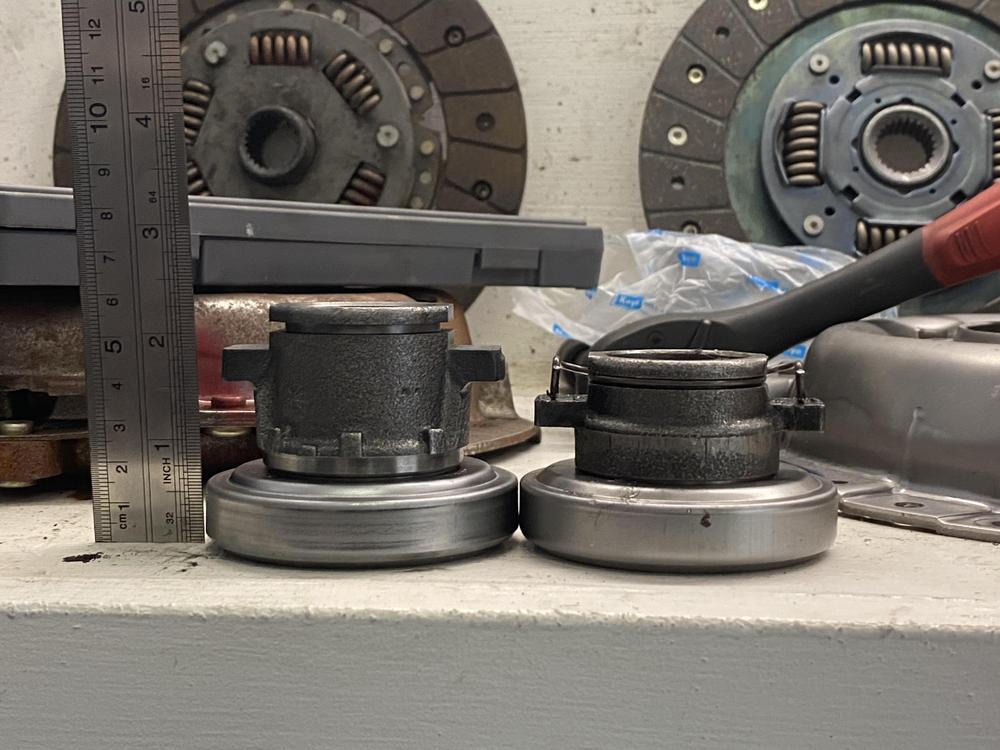

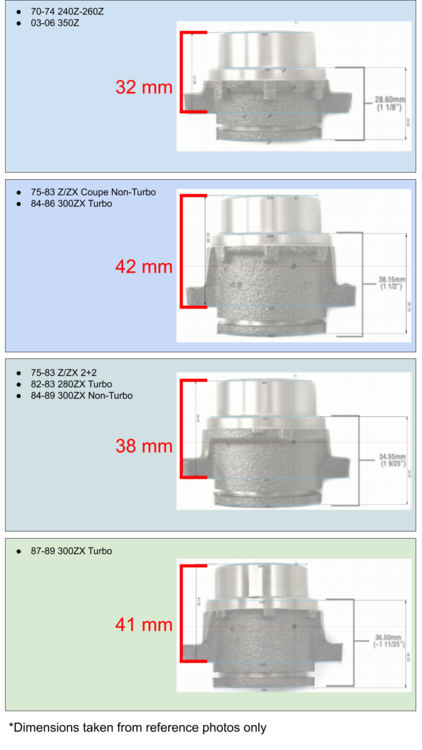

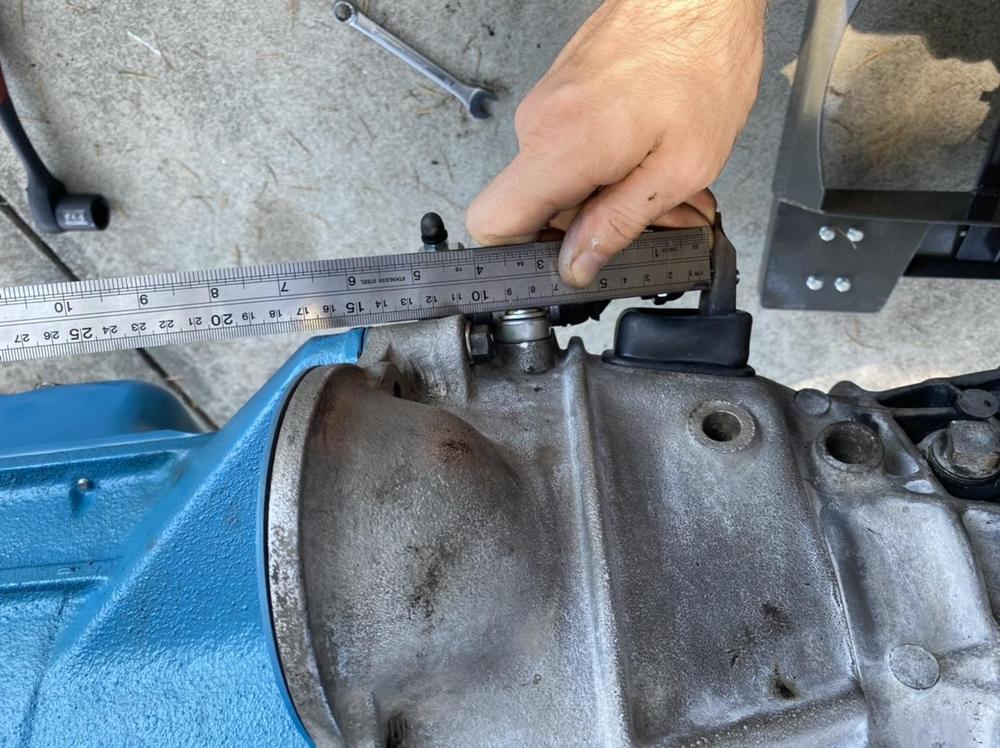

Ah, I think my picture just wasn't clear. I updated the drawing to make it more apparent that the measurements are from the fork surface of the ears to the edge of the throwout bearing surface (see red markup). Unless I'm still having trouble getting this concept through my thick skull, I think these are the relevant numbers. Yeah that makes sense, I'm betting zcarsource just sent me a 75-83 Z/ZX plate, as it measures ~44mm from the bench to the springs. According to my chart below, my best bet is the corresponding 75-83 Z/ZX collar which should get me up to 44 (plate) + 42 (collar) = 86mm. It's not quite 92, but add a few mm for the extra bit of bearing that sticks over and a few mm for my sloppy image measurements, and I think it may just work.

-

Clutch fork throw

Good idea, I downloaded Fusion360 tonight and figured out how to use their image calibration feature to get quick dimensions on all of MSA's collars. The big dimension listed is the bearing/spring edge to the ear/fork edge. The "70-74" looks exactly like the collar I already have, so I'm still totally confused as to why my pressure plate won't work - maybe zcarsource accidentally shipped me a clutch kit for a 75-83 Z/ZX instead of the 70-74 240Z? My receipt has the SKU as 14400101 which corresponds to "Clutch Kit, 240Z 260Z, 70-74 Coupe" but maybe it got mixed up at the warehouse. I wish there was a similar chart to mine below that listed the various flywheel-to-spring distances for the various pressure plates. It seems like my best move is to buy the 42mm "75-83 Z/ZX Coupe Non-Turbo" collar and hope it works. https://docs.google.com/drawings/d/1HuluAj7FVtCVHmtBPNeBAm5UFJZXZPKCaLfyJISMyLM/edit?usp=sharing

-

Clutch fork throw

With my new pressure plate back on the bench, the distance from the bench top to the tips of the springs is ~44mm. I’m assuming that 92mm is from the flywheel to the ears of the collar, right? That would mean that I need a collar where the spring-side of the bearing to the fork-side of the ears measures 92 - 44 = 48mm right? Does anyone out there have one they’d be willing to part with? Just as a check, I zero’d my calipers at the ears and took a measurement on the old plate, and I got 91mm:

-

Clutch fork throw

So after looking online at part shops, I'm even more confused. The total height of my collar is ~46mm with the height from the rear to the bearing of ~27mm so it definitely seems like the "Type A" collar in the picture above. Looking online, it seems like everyone is listing this same part as the only "70-74" throwout collar: Z Car Depot: 1.86" (47mm) total height MSA: 1 3/4" (44mm) total height, 28.6mm from base to bearing Datsun Garage: 1 3/4" (44mm) total height, 28.6mm from base to bearing Z Car Source: No dimensions listed These all seem to be the same as the part I already have. @EuroDat - in this thread from 7 years ago (wow!) you mention that the collar from the F4W71As has a bearing to fork mating surface distance of 16mm, and the B's have one that measure 29mm. My transmission is an A, and I measure 16mm on my collar from the bearing to the ears so seems consistent. What I don't get is that there were way more F4W71B transmissions made than the A's, but every store online seems to be selling the A collars. What am I missing here? Does anyone have the flywheel-to-finger measurement of a pressure plate + clutch disk that works with any of the collars listed above? It bugs me that I can't make sense of this, but is there any reason this 55mm long 75-83 collar wouldn't just work for me?

-

Clutch fork throw

Actually it looks like I mismeasured the setup on the engine. I was measuring to the bolt pocket on the flywheel which is ~10mm deeper than the friction surface. That means that I almost certainly need the longer collar. Damn I was really hoping to drop the engine in over the long weekend. Ah well. Thanks for the help!

-

Clutch fork throw

Hmm the height of the spring fingers looks really similar between my old clutch setup and the new. It’s hard to get a great reading, and the new one is bolted/compressed against the flywheel but still, they seem really close. Is it possible I screwed up the install of the fork/TO somehow? (sorry about the image rotation - I’m posting from my phone and it’s not obeying the EXIF data I guess)

-

Clutch fork throw

Got it, I’m betting I have the “Type A 4 Speed” collar but the plate is meant for “Type B”. If that’s the case, any reason I can’t just buy a type B collar and drop it in? Are the forks any different between the A and B?

-

Clutch fork throw

Yeah looks like I read closer to 150mm. Possibly this pressure plate isn’t right for my setup? I could have sworn I checked the height and it was the same as the old one. I’ll pull the transmission off and check again. I’m really hoping I don’t need to get another pressure plate as I already had this one balanced with my flywheel.

-

Clutch fork throw

I’m nearing the end of my veeery long rebuild project on my L24 and I finally bolted on my original F4W71A. I’m using the original throw out collar and fork, but installed this new clutch kit from zcarsource: link. When pressing on the slave cylinder side of the fork, I was just expecting to feel a nice gradual resistance as the TO bearing engaged the pressure plate. Unfortunately I feel absolutely nothing until almost the end of travel. I can’t imagine that small amount of travel is going to be able to get enough leverage to actually disengage the clutch. Any ideas what I could have done wrong? Here’s a video of me fiddling with the fork to show what I mean:

-

Help identifying 5-speed

I've just finished my engine rebuild, and am about to finally mate up the transmission. I excitedly bought this transmission a year ago assuming I'd be done with the rebuild in no time (stupid me), and I blindly trusted the guy who sold it to me when he said it was a close-ratio without doing any homework (extra stupid me). Now that I'm ready to mate it up, I'm thinking it's not an 82-83 which as I understand it was the only year with the desirable close ratio. This transmission does have the speedo cog bolt at 6-o'clock, but I'd be hard pressed to describe the shifter ears as "tall". Can anyone help me ID this transmission? I still have the original F4W71A, but I'd really like to have a 5-speed so I'm hoping I've got the good one. While we're at it, can someone help me identify what these three ports are on the side? I'm guessing A and B are reverse and neutral switches, but I have no idea which is which. C is just a threaded hole and it's pretty hard to tell if there's something to interface with on the inside of it.

-

240Z Distributor Questions

Can/will Nissan dealerships actually track down vintage parts? I never really considered I could walk into my local "Nissan of Van Nuys" and expect them to find me a part for a 50 year old car.