Everything posted by 26th-Z

-

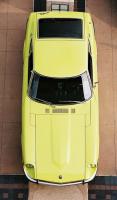

New discovery; the story of solid/chrome Z emblem

They made the chrome emblems because Her Majesty the 26th does not look good in white. They made the emblems solid in the very early days because Her Majesty the 26th likes heavy jewelry.

-

Scarab on eBay?

-

Help Fund the Datsun Museum and Get Something Really Cool for Your Donation!

Will, That link is several pages. There is a page about the Bob's glove box eBay auction. It looks like the BOD has expanded from what I have seen previously. Looks like a good group of people. CW-

-

Great new BRE 240Z Poster

Some of you may be horrified when you find out how much it is going to cost to frame your poster. As much as I admire the talents of a good framer, I have been buying frames and framing large posters for years from pictureframes.com. Check out their collection of metal frames - the "rainbow" line. These frames are thin, screw together, and hold a poster very well. I buy foam-core board at a local art supply shop and glass from a glass shop. Non-glare type glass is best for these larger formats. You order the frames by exact size and everything comes pre-cut. All you have to do is assemble everything. I might also suggest using acid free materials for backer boards or matting; anything that comes in contact with the poster. The acids in normal paper and cardboard will eventually brown the paper of the poster and affect the coloring. Make the same consideration if you decide to dry mount the poster to a board. Dry mounting will prevent the poster from wrinkling inside the frame and works best on thin papers. I'm pretty handy with a matt cutter and have layout tables and bars to do most of this work but it isn't very difficult. Matt board comes in a million colors and matting gives the piece depth and richness.

-

Help Fund the Datsun Museum and Get Something Really Cool for Your Donation!

Just got my Z-Car Club Inland Valley newsletter today. Thought I would post some new info. The Datsun Heritage Museum will host the grand opening September 12-14 (Mr. K's birthday). The address is: 41610 Date Street, Suite 103, Murrieta, California 92562. Phone numbers listed: 951.696.1087 and fax 951.696.9506

-

Brits vs. Z's

Carl, Your statement' "For Nissan's part..." refers to vehicle design, not mechanical design or reliability. And, yes, I believe anything used for "sport" requires maintenance exceeding what might be considered normal. Dauhh! I spent my college summers working on British cars in a shop in Gainesville, raced a British car in SCCA, and drove a British car daily. I have fond recollections of packing everything I owned in an MGB when I left home for school. The first real race car I ever owned was an Alexis. This year marks the 50th anniversary of one of the finest race car manufactuers in the world - a British Company. There is nothing wrong with a British sports car; all jokes about the Prince of Darkness aside. British cars were never marketed very well in America. They sold to a small niche in the automotive market and didn't build a service industry. The "Japanese invasion" was every bit marketing as it was reliability. And frankly, it was more economy than anything else. Toyotas, Subarus, Hondas, and Datsuns were far less expensive to purchase than the limited offerings from Britain. The Japanese provided far better service for their vehicles including ready availability of parts. Those are the sorts of things we can thank Mr. Katayama for. I'm convinced that the Japanese persuaded the American public to buy their cars more than anything else.

-

Production Photos, Sketches. Illustrations etc.

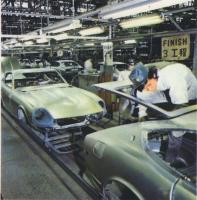

Sorry to jump in on this so late. For the record, the pictures I posted on the Kanji thread came from a Nissan Shatai Co; LTD. company brochure circa 1973. It is written in English and about 23 pages. This would be the kind of brochure you would get with the annual report if you owned stock in the company. "To our customers and friends abroad". There are many pictures of the company activities and I only scanned and cropped the images pertaining to the S30. There are many other sketches and the strange coloring of the graphics is part of the brochure graphic theme. Some time ago, I read the book; "William R. Gorham: An American Engineer in Japan" and became interested in the design engineering of the unibody. At the time, I was in the unibody restoration phase of my car, Her Majesty the 26th, when she was stripped to bare metal and I could examine the various welding techniques and panel fabrication. I started collecting pictures of individual body panels I saw on eBay as well as study the various sketches prepared for the parts manuals published by Nissan. I began to see some logic with how the panels were placed to build the structural integrity of the unibody. Then Ron and I got into this e-mail conversation about building the cars in a factory. To give you an idea of the enormity of Nissan Shatai, in 1973 their combined facilities totaled 424,307 square meters, produce 40,000 cars (Datsuns) per month, (600 buses, 500 forklifts) and employed 9,000 people. They were capitalized 4,800 million Yen. Katsuji Kawamata was Chairman of the Board. A little history...The company was formed in 1941 as Niho Kokusai Koku Kogyo Co., LTD with 36 million Yen to manufacture aircraft. Hope everyone enjoys this conversation as much as I do.

-

Rust removal chemicals

I have read that OSPHO is an encapsulator. It has a very low percentage of phosporic acid. I use it all the time for cleaning and metal prep. You are supposed to be able to paint right over it, but I wipe it off. The PPG metal ready is very good and I used it on my car before I primed it. I didn't sand blast my car and I don't agree with sand blasting but wiping it down with metal prep before you apply the primer is a good idea. You can use etching or non-etching primer at this point. It doesn't matter. I used etching primer inside the unibody because I couldn't wipe the metal and I used regular primer on the outside shell afterwiping it down a couple of times. Enrique should be in the conversation. He's the pro. I see no difference between blasted metal and mill finish metal. There is nothing on the metal - it is bare.

-

Hls300220

I missed a bunch of early parts in Virginia once. I think it has something to do with the water.

-

Kanji found when removing a dash

Sorry to deviate a little bit. Perhaps this photo helps get us back in the general direction. I suppose, Ron, that the yellow paint was applied at this point when the alignment was set? 26th had yellow paint as this photo shows except there was a dab of red on the left compression rod.

-

Kanji found when removing a dash

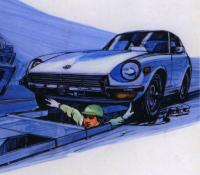

Ron, This sketch evidently didn't make it into my last posts. These came from that booklet Dan sent me when we were having the e-mail conversation some time ago. There just aren't many pictures out there that describe the production process of the S30. And when we talk about the HLS30 and S30 and the PS30 all running on the same line, it is quite difficult to imagine. Then there was the conversation of how sequential serial numbers were painted the same color. Or the conversation of build sheets (the elusive build sheet!) Once I started looking at these pictures and others, a lot of things fell into the logic notches of my brain. Thought the pictures would help everyone understand how when and where all those little scribbles and stamps found their way onto the car.

-

Kanji found when removing a dash

See how the assembly line snakes around? In the background you can see body shells going the other way? As this line snakes its way through the building, certain sub-assembly "feeder" lines come into this main line with sub-assemblies (like the dash). The guy driving the car off the line in the last picture is Mr. Ok.

-

Kanji found when removing a dash

Here are some pictures of how the bodies were fabricated out of sheet metal stampings. See the stitch welding over the tunnel? At some point, the floor sub-assembly was placed on a jig and welded to the firewall and front frame assembly.

-

Kanji found when removing a dash

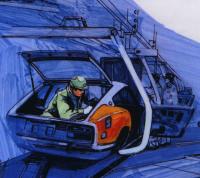

Sounds like a good time to post some pictures! These were collected from scans of Nissan "Shatai" brochures which I believe to be publications Nissan put out to stock holders and corporate people about Nissan production capabilities and their manufacturing facilities. Alan, you are certainly welcome to chime in on this. I have a couple of these brochures from the 70's time period. Arne mentioned that he couldn't visualize the manufacturing process and Ron is discussing things that make a lot of sense when you get the idea of how the cars were built. We all understand the concept of the production "line". What Ron describes are the various "lines" that feed into the main assembly line and all the people involved at various assembly points along the "line". The first picture is from 1959 showing what a manufacturing assembly would have looked like. Then a number of S30 assembly line pictures. The welding picture isn't S30. That's the machine that made all those spot welds though.

-

Gas Tank Leak??

Hey MidLife! Your vent hose is broken and you pretty much have to drop the gas tank to replace it. The Evap stuff is behind the quarter panel over the passenger shock tower. When you drop your gas tank, look for manufacturer markings on the top of the tank. You may find something interesting. I can't believe there isn't a fuel system diagram posted in the archives. This problem has been discussed a million times. Very common problem. So how's Wisconsin? I grew up in Mequon. Go Packers.

-

Brits vs. Z's

Oh my, yes it was! As you may recall, the American thing was to stuff a big V-8 into a small British car...

-

Brits vs. Z's

I was thinking of the late 50's early 60's when I answered, but what did America build as a sports / road car? Alan, have you ever driven a Corvette? Appalling.

-

A 1970 Z car approaches $30 grand!

Seth, No. He was NOT significantly responsible. Here are some photos of what was being produced in the Nissan design department in 1966. The bottom photo is concept AC-1 which went to full scale mock-up along with other concepts in 1967. One of those concepts had pop-up headlights and another was a targa top configuration. Nissan had experienced some success by marketing their roadster sports cars in America and the corporation was interested with increasing their exports to America and replacing their aging design. In addition, American law was demanding significant roll-over cash protection which devistated the open top roadster concept. Mr. Katayama had established a very solid market and dealer network program in America. He was certainly influencial by his marketing reports and suggestions, but Nissan was clearly headed for the export market with their new sports car design. If one would hail Mr. Katayama, one would appreciate his work marketing the Datsun brand in America. He is most noted for introducing the concept of the small pick-up truck to America. Mr. Katayama was indeed a sports car fan and credit goes to him for providing the cars to various racing enterprises. (Brock, Sharp) But put the guy on the proper pedestal for cryin out loud! He was a marketing man. He took something he thought he could sell and made a success out of it because he had the dealer network and reputation already established.

-

Kanji found when removing a dash

I always loved this conversation. Search back through the archives and there are plenty more threads on this subject. Thanks, as always, Alan for providing your insight.

-

Brits vs. Z's

Corvette and Thunderbird

-

A 1970 Z car approaches $30 grand!

Carl, I happen to subscribe to "Old Cars", have for years, and it has nothing to do with Kruse the auctioneers. It's KRAUSE, not Kruse. I'm lead to suspect you have nipped something off the internet without understanding it. I notice that your definitions are abridged; on you site as well as in these threads. How about if we use the unabridged definitions. Always. Wouldn't you imagine less confusion from that manner? Certainly your opinion is appreciated. However, modified cars are most certainly part of the collector market and the guidelines are written specifically if you understand the grammar and punctuation. #1 Excellent: A close to perfect original or a very well restored vehicle. Generally a body-off restoration, but a well done body-on restoration that has been fully detailed may qualify. The vehicle is stunning to look at and any flaws are trivial and not readily apparent. Everything works as new. All equipment is original, NOS, or excellent quality reproductions. Note: This is NOT a 100 point trailered show car. See show car description in How to Use section. #2 Very Good: An extremely presentable vehicle showing minimal wear, or a well restored vehicle. Runs and drives smooth and tight. Needs no mechanical or cosmetic work. All areas (chassis not required, but may be) have been fully detailed. Beautiful to look at but clearly below a #1 vehicle. #3 Good: Presentable inside and out with some signs of wear. Not detailed but very clean. Body should be straight and solid with no apparent rust and absolutely no rust-through anywhere. Shiny, attractive paint but may have evidence of minor fading or checking or other imperfections. Runs and drives well. May need some minor mechanical or cosmetic work but is fully usable and enjoyable as is. #4 Fair: runs and drives OK but needs work throughout the vehicle. Body shows signs of wear or previous restoration work. Any rust should be minimal and not in any structural areas. Cosmetics, body, and mechanics all need work to some degree. #5 Poor: In need of complete restoration, but is complete and not a rust bucket beyond repair. May or may not run and drive. Not roadworthy. Parts or Salvage: Incomplete vehicle most useful for parts. Generally, take 40-50% of the #5 value. ANd just for grins, whenever I see a discussion of the 240Z in a "collector" oriented publication, I always see this picture to describe the original 240Z. Talk about ironic!

-

Great new BRE 240Z Poster

Well...then I guess there are more than 46 of them out there. So much for the value of mine!

-

A 1970 Z car approaches $30 grand!

Here are but a few number one cars to show. I have plenty more examples. It would be pretty hard to dispute them. Certainly, Carl's example is a number one. The guy's whole collection is nothing short of number one examples. I don't understand the hesitation. Perhaps your "standard" is a little over the top, Carl. The whole 1, 2, 3, 4 thing is a basic standard for evaluation. It does not encompass "how it left the factory", "all original unrestored", yadda- yadda. Those standards are superimposed and have nothing to do the values published in the magazine. I don't necessarily agree with the values in the magazine, but there they were. Incidently, the red car is the most awarded Z in America. I am not aware of any other Z in the world that has won more top honors than that one. The orange car is the Franklin Mint car.

-

A 1970 Z car approaches $30 grand!

Here is some information that might help to answer the original question and perhaps throw some fuel on the fire: According to the August 2008 issue of "Collector Car Market Review" a 1970 - 1973 HLS30 is worth #4 condition - $2,050 #3 condition - $5,175 #2 condition - $8,525 #1 condition - $13,100 Add 5% for air conditioning and subtract 15% for automatic transmission A 1974 260Z is listed as $1,800, $4,500, $7500, and $11,125 respectively condition 4 to 1. The same percentages are given for A/C and auto trans. Incidently, the magazine reports that muscle car prices are off about 20% over the last two years and that gains for imports like ours have experienced 4% to 7% over the same period.

-

A 1970 Z car approaches $30 grand!

A #1 or #2 example car WOULD have perfect paint, wouldn't it? If it didn't, it wouldn't be a #1 or #2 quality example. Poindexter, just have your problem areas repaired. A good painter can match your repair areas so that no one will be able to notice. And don't worry about the judging thing.