Everything posted by 26th-Z

-

Re-assembling my '71 Z questions

ZSaint, There is no "correct" order and of course you don't want to put things on that make it difficult to put other things on. Start with the fuel and brake lines / wiring harness. Once you get to the point of putting the suspension back in, the car should come off the rotisserie because of weight. I don't see why you can't put the gas tank in before you take the car off the rotisserie,

-

ALUMILITE casting resin

Funny you should bring up this subject. I just attended a seminar for mold making and casting. http://www.rubbermoldcompounds.com/

-

Factory restored 240z

Yes it is! Carl, new speedometers were not provided. Speedometers were not reset to 0.

-

keep working

Thanks for the pictures, Kats. That is a black distributor cap. The picture in my 1969 brochure shows a black cap.

-

gotta sell my 69 fairlady

Oh, you don't know the half of it Will. Go get that car! Nova, you mentioned having the original hub caps. I would love to see them.

-

another f.... car

Good luck to all you guys bidding.

-

gotta sell my 69 fairlady

Dover, Delaware? Too much! 27 came from Dover, Delaware. Interesting interior pose. The seat folds forward? Notice the seatbelt hook on the passenger seat.

-

gotta sell my 69 fairlady

OH YES ! ! ! Pictures Please. Lots of pictures! Serious interest. Lets have a look at your car!

-

keep working

That is a great photo, Kats. My original brochure for 26 shows a black distributer cap and I have a conversation going about what color cap is early. The blue air cleaner is fabulous! I wonder what decals are on it? Thanks for your photo, Alan. That clears up another question, incidently. Thanks. The first picture is of the throttle linkage end from 26 and 27. The second picture shows four of the same linkage parts. The two on the left are early. The one in the middle with the curved end is a later version. Notice the one on right is upside-down. What is that?

-

keep working

Tom, #16 and #19 have the same heat shield as mine. Z Therapy shows the same one as mine. Could this be a Fairlady part? We are stumped. I am also stumped about an air cleaner I have. Pictures soon. Kats, Would you please look up a part number for me from your 1969 parts book? Distributer cap. My book shows 22162-E3001 but the cap is green with aluminum contacts. I want to know what the black with brass contacts cap is - or if it is different. For that matter, what is the deal between the green caps and the black caps?

-

Who WENT to Z Fest?

-

Datsun brochure copyrights etc

I agree. For informational purposes, include in your post "copyright Nissan Motor Corporation".

-

Racing $$$

I think we are on the same page, SuperDave. I assure you the professional guys are having fun and doing it for the grins they get from racing. And I guess I should clarify that a bit by excluding NASCAR from my observations. I don't really pay much attention to NASCAR. Its just not my cup of tea. I don't know if those guys are doing it for the fun, but I'll bet they are. None-the-less, I wanted to emphasize the competitive spirit associated with racing when I made my comment. I raced many years ago. I won some and I lost some. I had a blast. Racing sports cars is one of the top three "most fun things you can do with your clothes on". Now, I am spending $$$$ on restoring cars. The game is pretty much the same - without the speed thing.

-

keep working

Kats, I have a bunch of pictures to post of strange parts I cannot identify. Can we do this here? As soon as I get photos of the alternators, I will post them. Just after you bought yours, I found one in Jim's garage. Then I took the one off #27 and sent them both to a shop that specializes in antique electrical motors and such. Both of my alternators were frozen solid! Both of them had to be rewound and those parts were sent to two different places! The fellow kept calling me on the phone to explain the delay saying; "you can't get parts for these things anymore"! They were finished yesterday and I must go pick them up. I can't wait! Here are two heat shields. The one with the throttle spring clips on the bottom is from 26 and 27. Look at this one with the throttle spring clips in the middle. What is that from?

-

FILMS "Road test in the U.S. & CANADA Oct-Dec 1969"

Hi Dan! Yes, Im talking about the grapefruit alternator. I just had two of them rebuilt. Lets take this over to Kats' new thread. Kats, My solid emblem has a very faint L marking. Bryan, More often than not, I find out all kinds of things here and when I see things pop up on eBay or in a classified add, I know what it is. I can't tell you how many false leads I have chased down!

-

Who WENT to Z Fest?

Sean, I see pictures of your lovely in all the picture collections. Nice ride. Looks like you had fun. Who was the guy they got up to dance in Hooter's? You all take care up there in the Panhandle. I was impressed with the club caravan and participation!

-

FILMS "Road test in the U.S. & CANADA Oct-Dec 1969"

Hi Kats! I have just one solid emblem. I know of some more, but they are owned by collectors like me and you. I must tell you that my alternators are finished and I will send you pictures. They cost me $100 each to restore. WOW! Bryan, you find this stuff by looking and knowing what you are looking for. Ebay is a great start.

-

Zfest Award Winners

Thanks for the links Gus. Next year we won't have ANY RAIN.

-

Who WENT to Z Fest?

Many thanks to everyone who helped with the car show. The pending doom of rainy weather is probably the reason so many stayed home. Only one stock 280Z was entered so there was no second place awarded! I lent a big hand to putting on the car show as a member of the Suncoast Z Car Club; assigned to the car show portion of the event. We had a nice number of judges and we kept close to ZCCA judging guidelines. I see from the morning e-mail that the conversation about next year's show has started. We learned a lot from this show and will be having lots of discussions about making it a better event. There has been talk about doing it indoors. Seriously, there was a real weak number of S30 models entered in the show. A lot of the Tampa S30 crowd showed up later but did not display. Mark your date books for next year! Enter the show! Help out with the judging! Think about it. We judged 98 cars and the total registration for the event was around 130. The show has all the potential of a major regional event.

-

Blue beauty

-

Anyone ID this decal?

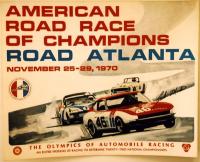

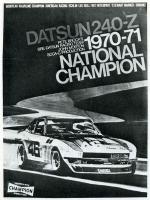

Your decal commemorates the American Road Race of Champions class win in C Production by John Morton in the BRE prepared 240Z. This was a Sports Car Club of America event held at Road Atlanta. John took the CP championship in 1970 and 1971. Here are the posters.

-

Who WENT to Z Fest?

Hey I don't want to hear a peep of whining from the S30 guys. It is shameful how few S30s showed up and entered the car show. Hi ZRush! I made it home in the rain! We had a spring storm in Sarasota Sunday. The flooding was so bad that I couldn't get to my shop until this morning!

-

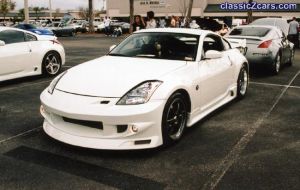

Best of Show

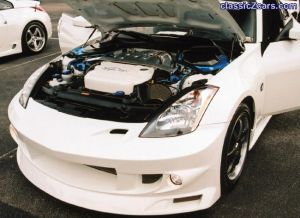

How many of you have your club logo painted on your valve cover? Very tastefully done engine bay - blue billet accents.

-

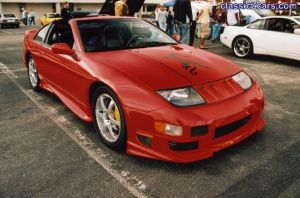

Best of Show

- Red Twin Turbo