Everything posted by Trnelson

-

Hand throttle

Finally had some time to spend fiddling with the choke and throttle linkage and I feel like I’ve hit the sweet spot. After bending the arms to the nozzle, adjusting the linkage and cable slack I now have some throttle control with the choke lever. At full “pull” I get the enrichment needed on cold start then can ease off that to a leaner mix while still giving some throttle. No more babysitting while it’s warming up! From dead cold I can give it full choke, crank it up, let it run till it stumbles then ease off the choke to more of a high idle setting. Let it run like that for a few minutes then I can take off with no issues. I still have the vacuum leak from worn shafts but have temporarily mitigated them with a light greasing, I am looking forward to the Ztherapy carbs coming in October. @SteveJ I’d like to meet up sometime, looks like you have a great Z network not too far from me.

-

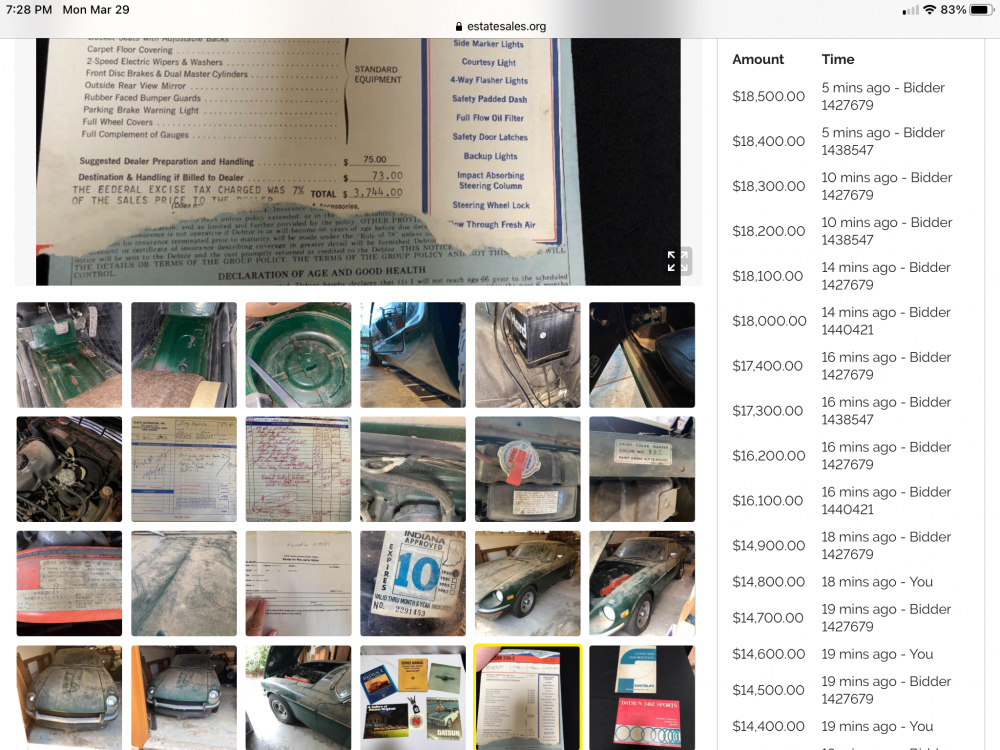

Well that escalated quickly

I saw the fiberglass edit. The receipts showed some body work and paint job in 1980 then some more minor work in 94. Hard to tell by the pics but I really don’t think too much fiberglass was involved. I shared the wrong pic, the auction closed at $18,500, I just stumbled across it Sunday and watched it for the last hour or so. I have a feeling we will see it on BAT for about $30,000 in a couple months.

-

Well that escalated quickly

- Hand throttle

@zKars I got a chance to fool around with the linkage yesterday and that has made all the difference in the world! I initially overshot the runway and full choke had me at about 4k RPM, probably not a great setting for a stone cold engine... I'm still dialing it in but I have made a huge improvement from where I started. One question: when adjusting the cable do you shoot to have zero slack in the arm that opens the throttle blade? My initial setting after bending the linkage was no slack but that's where I wound up with too much throttle. I put a little slack in it and it came down a bit but I'm not sure if it will be enough with the bend I put on the linkage. Right now I'm thinking about straightening the linkage a little bit and getting the slack back out of the cable since it seems that the first 1/2 or so of the cable travel is what opens the throttle blade.- Hand throttle

That sound great! I’d like to meet some Z people close to home. I’ve recently completed a refresh and overall it’s running very well, just got home from a 60 mile mountain cruise with almost no traffic so plenty of opportunity for spirited driving. I do know that my throttle shafts are worn, I’m in the LONG Ztherapy line, so I do have a bit of a vac leak there, maybe that’s a contributing factor. Let me know a good time and I’ll come on down. Thanks for the offer and I look forward to hearing back. Tom- Hand throttle

I do use the choke, as it begins to stumble I’ll incrementally start “closing” I know it’s not restricting air flow like a conventional choke but lowering the nozzle to allow more fuel i.e. creating a rich mixture, it. It’s just pig rich when I do that vs getting it cranked, letting it stumble, “close” the choke and then adding a bit of throttle till it’s warm. If the hand throttle isn’t for cold starts then what’s it for? Cruise control? I’d doubt that would work very well outside of a perfectly flat road. As @zKars said it would be great to separate the richness for a bit of idle control. It seems like the plugs get carboned up while warming the engine and it takes a moderate pull or two to get everything cleaned back up and smoothed out. Maybe I’ll just cut a stick to length 🤔🤔- Hand throttle

I’m searching for a hand throttle for a 71 240z, we all know these engines are cold natured and I’d love to be able to set a hand throttle vs sitting in the car for 10 minutes while it warms up. Just wondering if any of you guys may have one or have come up with some DIY solutions. Thanks, Tom- Things I'm growing tired of.

Jump in one of your Zs and make a few rips around Cheaha Mtn, be sure to slow down and enjoy the views, grab a Mata’s, a 6 pack and call it a day that many will never be blessed with! These are trying times for sure but this is a great group to commiserate with ✌🏻- .01 Ring with Standard Piston

I have not checked compression yet, I wanted to let the rings seat for a couple hundred miles prior to testing. Probably be a couple weeks, damn job interferes with my play time in the spring! here is a pic before I dropped it in- .01 Ring with Standard Piston

Update: Engine is in and I’m about 100 miles into break-in. So far so good, it fired right up, sounds and feels good. Plan to put another 100 miles on it then change oil, coolant, filters etc. Plan to recheck compression then too just to see if the numbers have come up from pre refresh.- Variable Clutch Cover Height or Thickness Availability

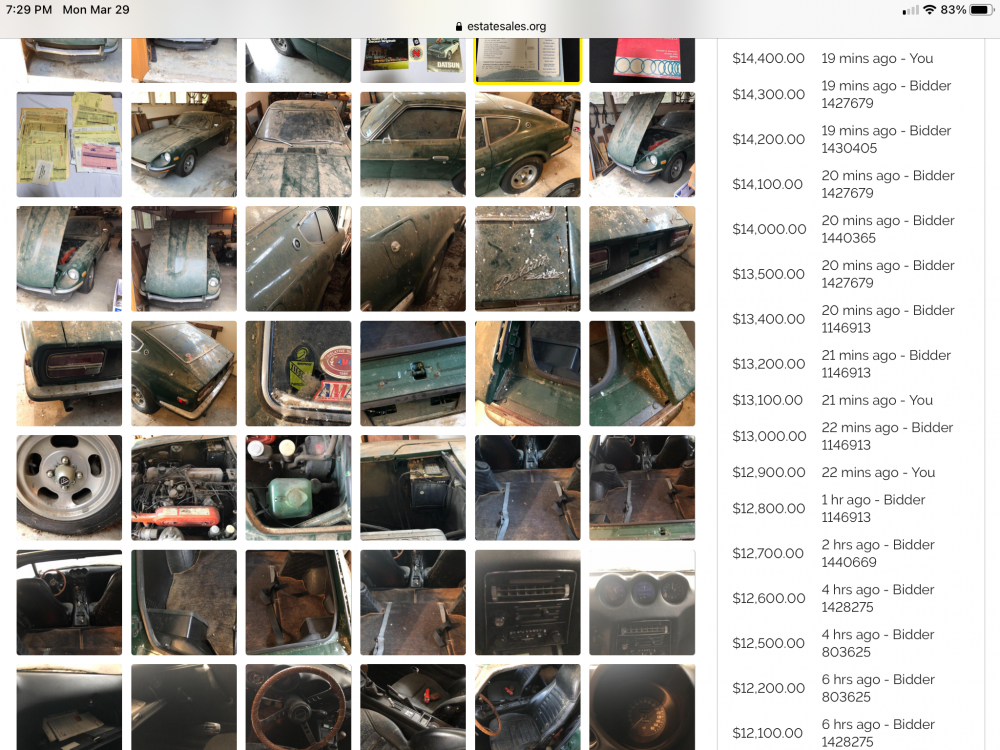

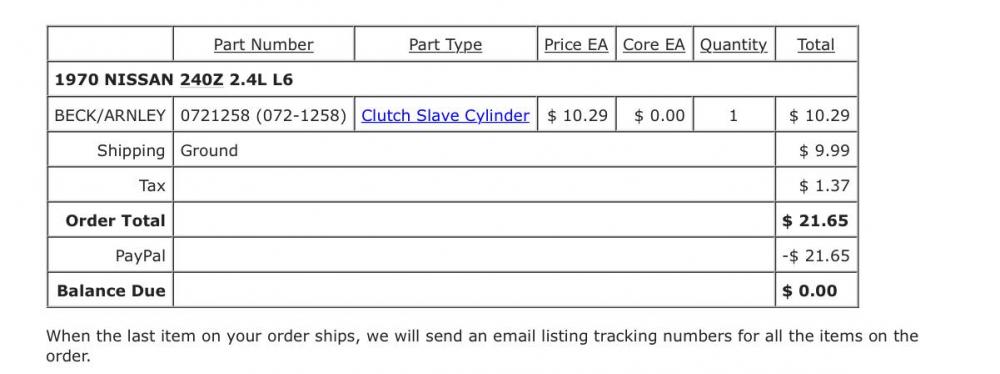

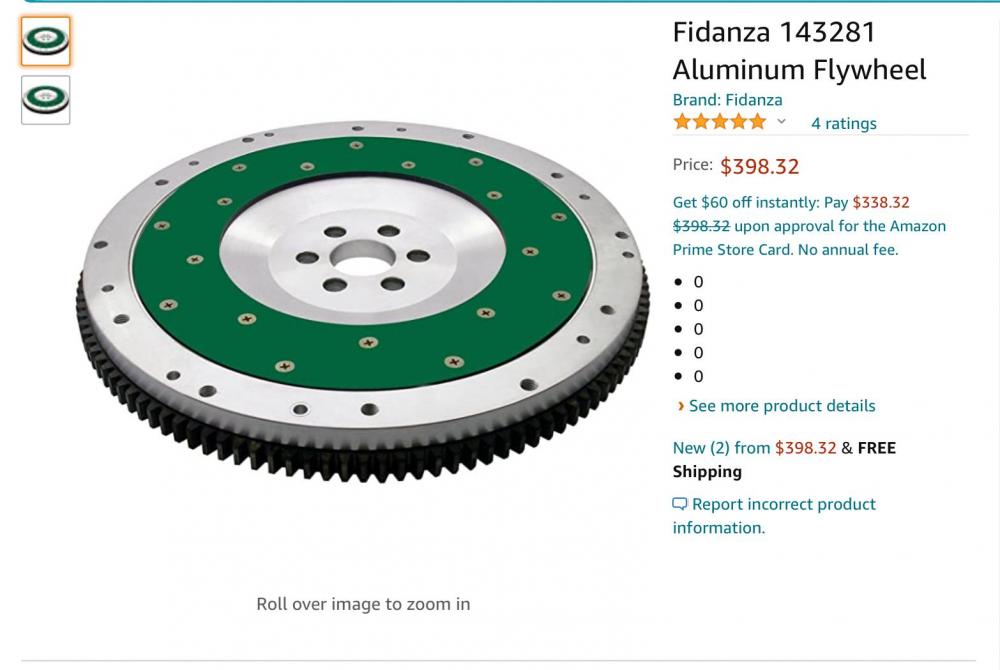

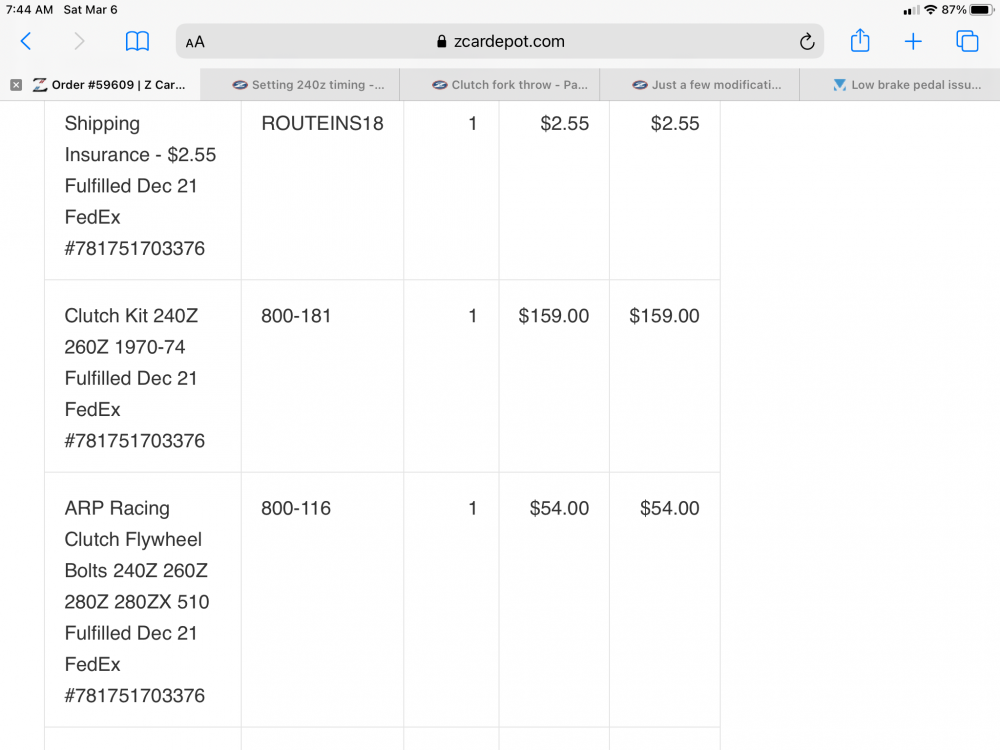

I have installed the following parts and 100 miles in everything is working well, I have the shortest collar that goes with the “Type A” 4 speed- Any Maintenance Recommendations

I tried washers initially but didn’t get the results I was looking for. I think it was due to the fork being stretched out more at the bottom than the top. I was also doing this work with it in the car so it was very fiddly and difficult to get all the pieces in place! I just applied steady pressure with some channel locks until it fit snugly. If I remember correctly I kinda overshot and had to stretch it back out a hair to get it to move smoothly. I suppose there is a chance you could break it but I doubt you will if you just go slow and steady. Thinking about it you might just use the bolt and Teflon nut to squeeze it back into the desired width, maybe over tighten it a little and back off till it moves freely? It would be worth a shot anyway- Any Maintenance Recommendations

Here are two pics of the bolt I used to replace the pin. It seems that the fork gets spread out from use causing the excessive slop in the shifter. I squeezed it back till the fork just slides over the rod (not too tight as it needs to be able to move freely) then installed the bolt, washers and Teflon nut. It took a little trial and error on finding the sweet spot where the slop is 99% gone but the shifter still moves easily. I did it in the car but it would be A LOT easier to do out. I hated the sloppy feel and this fix drastically improved the overall driving experience for me. When you order the bushings be sure to specify this transmission, I don’t know the production years off hand but I’m sure you can find it either here or a google search.- Any Maintenance Recommendations

Looks like you’ve got the monkey motion, no worries though. When you’re in any gear can you move the shifter all over the place nearly as if you’re in neutral? That’s how mine was, easy fix, I’ll post what I did when I get back home later this weekend if you want to see a pic. edit: Just had a flashback to disassembling my engine, found a long piece of plastic in the oil pan, turns out it was part of the tight side timing chain guide. I would definitely include at minimum checking the timing components and a good look around in the oil pan/bottom end/oil pick up screen. Tom- Any Maintenance Recommendations

I’d second all of the above in regard to seals, timing kit, crusty bolts, plugs etc. I can’t tell for sure but if that is a F4W71A transmission AKA “monkey motion shifter” I’d replace the bushings and swap the pin for a bolt, Teflon nut and washers. You can slightly squeeze the fork to get rid of some slack. It can be done in the car but it is MUCH easier to do while it’s out. Worked great for me, just be sure to trim the bolt to length so it doesn’t hit the housing in reverse. Engine looks great!- Help with dizzy ID

post#1, I had proclaimed my ignorance! and now I know that optical trigger = LED light... one has to crawl before they can walk I’m getting there albeit slowly, thank for your patience and continued support.- Help with dizzy ID

Thank you for the information, I had no idea that there was a light! I’m finished with the engine but not ready to drop it back in yet. I’ve got a couple weeks worth of items to take care of while the engine and trans are out. I may get it touch when it’s time to fire it up. In the mean time I’ll dig through some old receipts to see if there is anything on the coil. Tom- Help with dizzy ID

No issues, I’ve spent the last 2 months refreshing the engine and I’m just looking at everything as I put it back together to make sure it’s in good condition or replace parts as needed. It ran fine before I pulled it so I’ve just put a new cap and rotor on it as part of the refresh. Glad to hear that you’ve had good luck with this setup. What coil do you run on yours? Thanks- Help with dizzy ID

240 10/70 build date. It was upgraded at some point and I’m trying to understand exactly what is what- All dressed up and no where to go

@siteunseen, Seems like I remember you saying you had jet hot headers, if that’s right have you been satisfied with them? I had them coat mine and they look great, just hoping they stay that way for a while anyway. PS, did you make it to Mata’s pizza yet?- All dressed up and no where to go

Been putting the last bits of the engine together today, I think she looks pretty good for a neophyte’s first go round. Now if we could just get the damn salt off of the roads... Hopefully it will crank easily and run well when the time comes, till then it’s brake line bending school. P.S. I know #6 plug wire looks as tight as a guitar string, pretty sure PO adjusted the dizzy cap etc to accommodate a short wire, had me scratching my head for a while- Variable Clutch Cover Height or Thickness Availability

@Zed Head, our posts must have crossed paths! Well now I’ll have to do more measuring when I finish up the engine and bolt up the clutch. Stay tuned- Variable Clutch Cover Height or Thickness Availability

I had measured the finger height when I had the parts out this morning and there was only 1/16” difference if the new one being shorter. Sounds like that may or may not be indicative of its compatibility with the other components that I have. I’m not in position to install the clutch etc as I’m finishing up engine assembly and it’s on a stand, maybe in a few days. I did check my current slave cylinder and fork. It appears that I already have the adjustable version, albeit crusty, on the car. My plan as of now is to install the new clutch with the slave cylinder setup that i have, sounds like it will need some adjustment but should work. Thanks Tom- Variable Clutch Cover Height or Thickness Availability

Saw this and wanted to compare what I pulled out with what I purchased. New one is on the left. Does this mean I need to send this unit back and get the correct size? I would assume so. Still have a month or so before I’m ready to install- Help with dizzy ID

I know next to nothing about distributors so I can’t fully answer your question. I can tell that the points have been deleted but I honestly have no idea what they were replaced with. Do you think this is something I should try to work with or think about upgrading/replacing all of the components? Maybe cap and rotor for now and run her till she lays down? Thanks for the links, I’ll check them out. - Hand throttle

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.