Everything posted by 240ZBUILTBYME

-

Help with Front Bumper mount Area

My plan is to work the panels in the following directions to bring back to square. I will then reinstall the front end to make sure everything fits. If anyone has done this repair before or has any tips I’m all ears!

-

Help with Front Bumper mount Area

Just wondering if someone who has a untarnished original car can share the shape of the below area? I’m looking at building my rotisserie and feel I need to sort out the damage my car has before mounting the rotisserie to it. At some point it had a front end collision, most damage was on the RHS. Repairs to the area seem..... how do you put it....unprofessional, low rent, shithouse... in particular I need to know if the vertical panel that the front bumper mounts to should be perfectly straight up and down. As you will see mine kinks outwards where the bumper mount holes are. And I need a rough guide on the radius of the curve from the vertical panel to horizontal that leads to the lower grille mount. also need a photo from this angle, I believe the sharp edge shouldn’t be there and the shape is incorrect. ryan

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

Wow That is way too cool Mr X! no wonder you’re smarter than the average bear 🐻... that’s crazy the variation in length considering the tolerance of the build, is that due to differences in temperatures, metal expanding etc I would think the hangar where you build would be temperature controlled to mitigate that?

- 240ZBUILTBYME 1971 240z HS-001063 Project Georgia

- 240ZBUILTBYME 1971 240z HS-001063 Project Georgia

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

Hahaha thanks mm is much more accurate and you don’t have to work with fractions! I had no intention to patch the piece I cut out, (though I may just to practice!) it was to get a better look at the condition of the underlying skins, so yes I was a little nonchalant in my cut. if you have read my thread, that whole panel is getting replaced, I have the rear quarter tabco panel already and outer wheel arch. I’m not too worried. that dogleg panel I cut had been repaired previously so it may look like I cut layers underneath but it was the original skin that had not been cut out. Yes all the rust will be removed and patched do not worry. I have a very long road ahead of me and I will be an expert in rust repair by the end... next up for the car is build a rotisserie and send for blasting. Do appreciate all your advice! Ryan

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

finally finished building the chassis jig after much toil. It was a journey in learning the basics of metal fabrication and has laid the ground works and basic skills I will need for my rust repairs. Pretty happy with the results considering I hadn’t touched a welder previously. Still much to learn though... As I will outline in the video I wanted to replace the backbone of the car, floors, chassis and frame rails prior to mounting on rotisserie for blasting. As you will see this will be impossible without extensive repairs to the rockers/doglegs and rears arches. So I have decided to get the whole thing blasted prior to starting any rust repairs. I will be bracing the shell extensively before mounting to the rotisserie. please excuse the cheesy thumbnail photo... Ryan

-

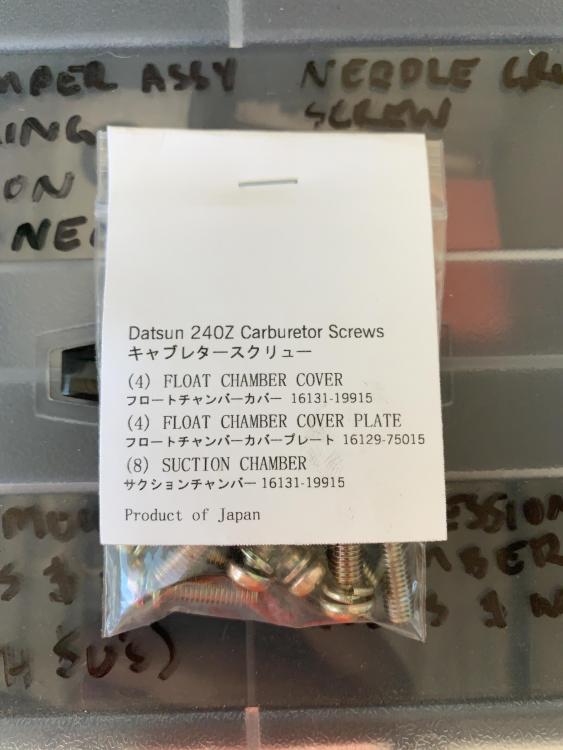

SU fasteners suppliers/throttle shaft?

Just for the record. ordered and received these eBay SU screw sets. Excellent quality and perfect match for the old screws. If anyone needs new depression chamber or float cover screws don’t hesitate to buy these. https://www.ebay.com.au/itm/Datsun-240Z-Float-Bowl-Suction-Chamber-Carburetor-Screws-Set-/164620649300?_trksid=p2349624.m46890.l49292 comparison with old screws, yellow zinc coating looks great thanks @Zup for finding them and sharing the link!

- 240ZBUILTBYME 1971 240z HS-001063 Project Georgia

- 240ZBUILTBYME 1971 240z HS-001063 Project Georgia

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

Minor update chassis jig is complete! Photos and video coming soon. I managed to free my carb insulator blocks from the intake manifold with a razor blade and cleaned them up. The gasket was pretty much glued to one of the blocks, attacked it with the razor blade and was careful not to inflict any damage. cleaned up further with paper towel and sugar soap. Came out pretty good! Question: are my blocks ok to reuse and do people normally recoat/varnish these blocks before reusing? If so what product would one use? ryan

-

Dash Differences : Under the skin

@zKars interesting, wonder what made them change the design. will you be writing a review on the overall experience and fitment of this dash pad? A review would be invaluable to anyone looking at restoring a dash... ryan

-

Rebuilding the harness

Namerow thanks for the detailed reply! I’m learning constantly on this forum. It is a god send. I will for sure be researching further into this topic. And with that I think I’ve clogged up your thread enough bill, looking forward to following along. ryan

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

More pieces of the jigsaw puzzle arrived today. Took MSA aka the z store 6 months to get these to me. Worst customer service I’ve ever experienced. I discourage anyone thinking of purchasing from them unless completely necessary. hopefully KF vintage jdm starts making these soon, the tabco pieces are very rough. But they will get the job done.

-

Rebuilding the harness

I havent had a look in much detail at my wiring condition, I'm so far away from sorting wiring! Lol my z specialist has restored a lot of z's so I don't think he has no idea what he's talking about. But interested to hear other perspectives. So you say it as though all harnesses & connections have corrosion and all must be changed out. Is this the case? Is it a matter of geography/weather or is it just the age of the wiring, hence all are affected. Ryan

-

SU fasteners suppliers/throttle shaft?

According to my limited knowledge but now confirmed by the captain , bushings were steel, shafts were brass, bushings are generally in good condition because the brass is softer and wears first. I would have posted up some pics of the shaft wear but my phone decided to $^!# itself completely. But some interesting comments have come up which I was not expecting! @Namerow I actually remember reading @240260280 thread on his solution. But cannot remember if it worked or not. I thought it was clever. Could one have a machine shop weld in new brass, lathe proud areas to spec then rechrome? Or would it be easier to be completely remanufactured? Seems there should be a bit of market demand for repro throttle shafts? Very interesting solution @Captain Obvious so the o rings are within the bushings? So what is the shaft rotating on? The o rings? Would they not wear quickly? Or would regular lubrication do the trick?

-

Rebuilding the harness

I was speaking to my z specialist here in west oz and he mentioned he usually reuses most of the connectors if they are in good condition, he said he just uses a Dremel and cleans the pins. Any opinions on this? Ryan

-

Rebuilding the harness

This will be interesting! I have to do this at some point and will be good to see how it's done. Lots of details please!

-

Z Front Frame Rail Replacement - T/C Rod Bracket

It's a creative endeavour starting and maintaining a build thread from start to finish. It is like a collection of evidence to your own passion, grit, determination, skill and hard work. The product of a good build thread is it's ability to inspire your fellow enthusiasts, which yours most certainly does! Ryan

- SU fasteners suppliers/throttle shaft?

- SU fasteners suppliers/throttle shaft?

- SU fasteners suppliers/throttle shaft?

-

SU fasteners suppliers/throttle shaft?

Hi all Wondering if any of you gurus can direct me to a fastener supplier that would have oem equivalent fasteners for my SU rebuild? For example the PO had stripped all the dome screws, I ruined the bowl drain plug and float lid screws on one float bowl. I ruined the throttle flap screws on one SU. Also struggling to find somewhere that supplies new throttle shafts, mine are worn into the brass. And before anyone says ask the guys at ztherapy, I did and they said they don't supply fasteners. Didn't ask them about the throttle shafts. Ryan

- Z Front Frame Rail Replacement - T/C Rod Bracket

-

Z Front Frame Rail Replacement - T/C Rod Bracket

I have mate they've just added some amazing new pieces that no other suppliers are making. If I could have I would get everything from them as their quality is amazing and price is great. Plus they are so much better to deal with than everyone else. I have their floors, outer rockers, seat mounts, rear slam panel. And I may be ordering a few of their new pieces depending ow bad mine are. I picked up some high quality frame rails from an aussie z specialist. Better than zed findings and comparable to kfs new frame rail pieces. Thanks mate I will check it out! Really appreciate the feedback! Thanks Ryan