Everything posted by adivin

-

Painting Undercoat

My 72 240Z must have dealer installed undercoating in the wheel wells. I'm not sure if they did this at the factory. I am (my Dad) the original owner. Can this undercoating in the wheel wells be effectively painted? I don't want to remove it and it makes no sense to put more undercoating or bed liner on top of it. I'm wondering if paint will adhere and not flake off easily, or would this be a waste of time? Any suggestions for what to use, or just leave it?

-

Rear Wheel Bearing Related

Everything is back together and feels good. As far as the grease catch, I straightened the lip and made sure the everything is pressed in enough to where the lip of the grease catch is in the groove on the housing. At first it was binding and I noticed it need to go in just a bit more. Also, I noticed that as soon you put the companion flange on it makes contact with the inside of the grease seal and will cause some friction. The axle went from spinning really easily, but when I inserted the companion flange I did notice some friction even before the putting the lock nut on. I have the copper washer so I torqued it to 100 ft lbs. The pre-load using a fish scale is still under 2 lbs. Now for the other side...god I hope that spindle pin comes out easy!

-

Rear Wheel Bearing Related

Now I suspect the seal could have contributed to part of my problem. How do you know when the seal is in all the way?

-

Rear Wheel Bearing Related

Ak260, what was your grease seal issue?

-

Rear Wheel Bearing Related

It is my understanding that the torque spec is the same with the 280zx nut. Someone, perhaps the Captain, can confirm. The difference is not that it's an earlier car, but that it is an earlier car with the copper washer installed that goes between the bearing and companion flange that makes the difference in torque spec. I suspect the thickness of the washer changes things.

-

Rear Wheel Bearing Related

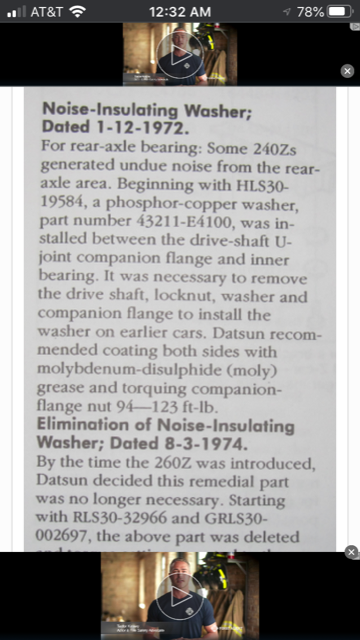

Just to add another wrinkle, I have the "noise-insulating" copper washer which calls for a reduced torque spec. 94 - 123 ft-lb.

-

Rear Wheel Bearing Related

I was theorizing about using the original type nut but not peening it and using Loctite instead. 😬

-

Rear Axle Grease Catcher - Needed for Disc Conversion?

I swore I saw the little man in the parts diagram.

-

Rear Wheel Bearing Related

Thanks for showing me your nuts Captain...I think. 🙄

-

Rear Wheel Bearing Related

A generous amount of red LockTite?...

-

Rear Wheel Bearing Related

Right, you see I have a problem with commitment. My luck, the minute I peened the nut, I would find a reason to have to remove it. This is why I was wondering if the 280ZX nut is reusable.

-

Rear Wheel Bearing Related

I suppose if you're careful peening and un-peening the original nut, you could reuse it. Just a theory. I've never attempted this.

-

Rear Wheel Bearing Related

This is good info. Can I use the original 240z washer with this nut?

-

Rear Wheel Bearing Related

Thanks Captain! So is this some sort of self-locking nut magic? Is it a one-time use nut also?

-

Rear Wheel Bearing Related

It must be the year of the grease catcher. 😄

-

Rear Wheel Bearing Related

Interesting, what is different about the 280zx axle nut that it doesn't need to be peened?

-

Rear Wheel Bearing Related

I was wondering if the rear wheel grease catch (the bracket that the wheel studs go through - part 56) can be eliminated without issue? I am also converting the rear brakes to disk if that makes any difference. Second, do you guys feel it's necessary to peen or stake the axle lock nut?

-

To buy or not to buy...that is the question

What year Kia Sportage weatherstripping did you use? I have the same issue.

-

Rear Control arm bushings!

Ha! What do you mean "so close" to ever try? He never actually tried or did he try and fail? Apparently if you can get the urethane bushing in with the outer sleeve, you can achieve legend status?

-

Poly Bushings for Transverse Link and Spindle Pin

-

Poly Bushings for Transverse Link and Spindle Pin

Install instructions from Prothane. Prothane.pdf

-

Poly Bushings for Transverse Link and Spindle Pin

Urethane Spindle Pin Bushing Kit, 70-78 240Z-260Z-280Z Quantity in Basket:none Code: 23-4180 Price:$39.95 Quantity: Description: Replacing your spindle pin bushings is a must when removing your spindle pins, especially if the pins have never been removed before. This urethane kit replaces the factory rubber washers and spindle pin bushings without replacing the inner control arm bushings. Sold as a complete set for both spindle pins only, see Related Items below for the complete rear control arm kit that includes these. Note: The outer metal sleeve of the factory rubber spindle pin bushing is retained for use with this kit. Urethane Spindle Pin Bushings are oversized and will require a press or vice to install. Please call with any questions prior to removing your stock spindle pin bushings. Model Guide: Datsun 240Z, 260Z, 280Z Code Guide: Datsun S30 Year Guide: 1970, 1971, 1972, 1973, 1974, 1975, 1976, 1977, 1978

-

Poly Bushings for Transverse Link and Spindle Pin

MSA and Prothane both say that the outer sleeve is retained but the bushing looks like it's never gonna go in with the outer sleeve in. Can someone verify?