Everything posted by Dolfinz

-

1974 260z console

Anybody have any idea where I might find a radio bracket?

- Bracket

- Bracket

- Bracket

-

battery drain

The original RPM was 1000 at 2000 the voltage is 14.5v. Is that acceptable?

-

battery drain

I finally had a chance to check the voltage at the battery when running. It was between 13.5 and 13.7v. I assume this is sufficient even though the voltage is so low at the F terminal on the alternator?

- battery drain

-

battery drain

So I started it and checked the voltage at the F terminal. It was 5.5-6v. The voltage at the blk/wht wire going in to the VR was 12v. Motor off and IG switch ON at F terminal 11.9v. Suggestions?

-

battery drain

So I found the blk/wht wire from the engine harness going to C-7. I checked for voltage on the output side of C-7 and there wasn't any, with the ig switch on. I cut the wire and spliced it directly to the ignition switch blk/wht wire. Now in the ON position I have 12v at the blk/wht at the VR and just under 11v at the F terminal on the alternator. I will try starting it over the weekend and advise if this has resolved the issue.

-

battery drain

A few more thoughts. I was reviewing the manual transmission whole car harnesses wiring diagram and it appears that the black/wht wire beyond the C-7 connector at the fire wall, inside the engine compartment, only goes to the VR and condenser correct? There appear to be other places it goes from the ignition switch that aren't in the engine compartment that are apparently working; since it runs. From my recent experience troubleshooting and repairing my gauge issues I had to bypass the firewall connectors, thus I am very suspect of those connectors. I am curious to see if the condenser has voltage or continuity to the harness plug at the VR, but as previously stated I have no idea where it is. At this point I think I may need to bypass C-7 as I did for the other connectors related to the gauges and connect the blk/wht wire from the dash harness directly to the same in the engine harness. Open to other thoughts.

-

battery drain

The ballast resistor is located under the VR. Where is the condenser?

-

battery drain

Steve, I performed the suggested tests. On the wiring harness the white wire is hot regardless of key position. With key ON no other wires get hot including the black/white. As for the continuity on the VR connector, I have 3 ohms between those 2 terminals. Next steps to determine why black/white wire isn't getting hot with key ON?

-

battery drain

So I can just run a new wire from the ignition switch to the F terminal on the alternator? I was previously advised against it as it would bypass the voltage regulator.

-

battery drain

So, it's been a few months since we last discussed this due to my working on other things. Now that those are completed I still have to resolve the alternator issue. I replaced the voltage regulator and with the key on I still have no +12v at the F terminal. See my last question regarding if the motor has to be running for the F wire to get +12. Reading back through the posts to this point I'm not sure what to try next. Perhaps someone can advise me further on how to isolate the problem? I'm running out of ideas.

-

Gauge issues

But, does that confirm the gauge is working? It could be shorted and bypass the voltage without reacting to specified resistance.

-

Gauge issues

Since you're suggesting 100 Ohm pots would a resistor of say 47-50 ohms to ground give me a center dial reading, or at least confirm the gauge is working when a current path is properly provided?

-

Gauge issues

Here's where I'm at. I pulled the dash to try to solve the problems. Prior to pulling it the tach, temp, oil pressure and fuel gauges weren't working. I found the common green wire running to all the gauges feeding them B+ and verified continuity to each so to eliminate the possibility of a faulty connection at the firewall terminal block I separated it out to run directly to known good B+. I also continuity tested all the sender wires from the senders to the firewall terminal block and verified as good. Since all the gauges were working prior to the engine rebuild I figured the common B+ wire connection was a likely cause for them all to quit working. I cleaned all the connectors with the spray and reinstalled the dash. The tach is now working but the other 3 still aren't. At this point I'll pull the dash again and I need to test the gauges with the B+ applied to verify their functionality but don't want to burn them up by simply grounding the sender connections as I'm sure the senders have some sort of resistance range. Can anyone tell me a safe resistance to use to ground these connections to check the gauges? I will also check the continuity from each gauge to the firewall connectors as I didn't the first time. Any other suggestions would be appreciated.

-

Gauge issues

1974 is correct. Thanks for the suggestion on the contact cleaner.

-

Gauge issues

I was looking in the service manual and found wiring diagrams for the gauges on BE-33-36. That has solved my problem with troubleshooting the gauges. Still looking for suggestions on the terminal block. Also need to verify that the in line resistor for the tach is 2.2k ohms.

-

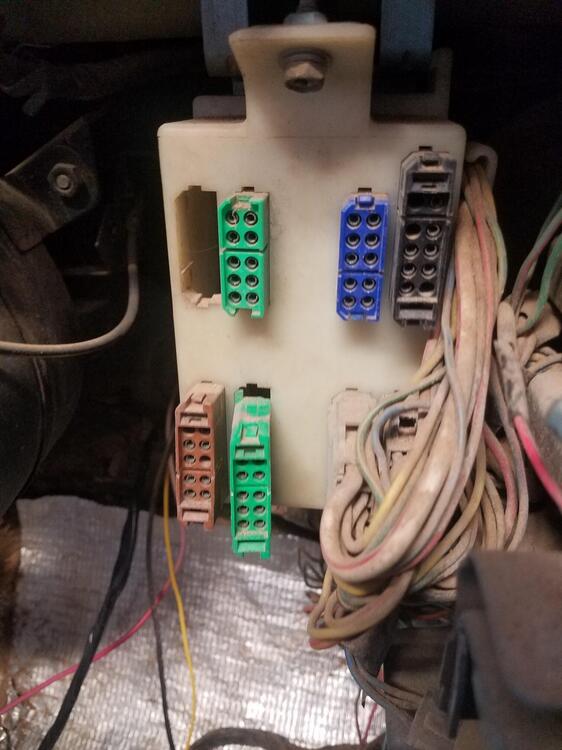

Gauge issues

Now that I have the engine running it's time to address the dashboard electrical issues. The only gauges that work are the speedo and ammeter. I figured it might be a wiring issue related to them all so I pulled the dash. I couldn't find any damaged wiring but notice the terminal block pic attached. Possible connection issues at this point? Is there any kind of cleaner or solvent that can be used to clean up the connectors? Beyond that utilizing the wiring diagram I tried to figure out the concept behind the workings of the gauges. Can't figure it out. Black wires to all gauges are clearly ground. Red/blu wires to all gauges appear to be +12 but they are just for the lighting and it appears the resistor/dimmer is in parallel and shunts the voltage but this also doesn't seem right. Basically I need to verify connectivity from the temperature sensor and oil pressure sensor and the fuel tank sensor to the appropriate gauges but can't verify the wires between the gauges and the sensors. I have no idea how or where the tach connects so I need some assistance with that as well. All these gauges worked prior to the engine rebuild so something has changed. Looking forward to your assistance.

- battery drain

-

battery drain

I will try reaching out to Pogden but I have 2 questions. How do you check valve lash and how do you verify oil flow at rockers before startup?

-

battery drain

First off, regarding my Grandson he's 8. A little out of his attention span at this point. As for what may have caused it I have an idea I'd like to throw out. I don't remember the rockers being so noisy. When it was running it almost sounded like a diesel. Could it have been an oil pressure problem that made the rockers so noisy? And caused it? Without an oil pressure gauge I have no idea what the pressure was. When putting the engine back together I replaced most everything including the oil pump. Are the rockers noisier than I remember? The engine isn't leaking any oil and the dip stick says full so I don't know why the oil pressure might be low. Any ideas? I think before I pull the head I'll get the scope and see what I can see first. But then, depending on what I find I'm pulling the dash and getting the gauges working. I'm certain for some reason none of them are getting their positive feed as my understanding from the wiring diagram is the sensors all route their connection from the gauge to ground. They were all working prior to my rebuilding the motor. Just to clarify, If I get the scope and see no damage odds are the valve is still bent right? Wouldn't this still require pulling the head to repair? However, if the valve doesn't appear to be bent or damaged then simply replacing the damaged components for this cylinder above the springs might result in the easiest solution? I appreciate all the ideas and advice but trying to determine a course of action is difficult. I really hate to dismantle the engine again.

-

battery drain

The engine doesn't have 2 miles on it. I drove it about half a mile before it developed the starting/alternator issues. Then I got it running and drove it 2 blocks and the rocker arm came off. $1250 for the rebuilt head, $1500 to have the head and block put back together with timing chain and front end in place and a few hundred to a friends son who helped me put it the rest of the way back together.

-

battery drain

I was really trying to have to avoid it but considering this happened it's probably in my best interest to pull it and and have it inspected and repaired. 4 years ago it was a freshly rebuilt head I bought from Z Car Source here in Phoenix. It sat in my garage for 3 years until I was finally able to start putting the engine back together about a year ago. I had taken the lower end to a machine shop and had it rebuilt; since it was apart, shortly prior. All I can figure is that all the time the head sat is why this happened. I really can't see that it needs to be rebuilt again unless there was some type of damage to the head due to what's happened. Question will be where to take it to ensure this doesn't happen again when I put it back together. I'm open to suggestions on the best way to accomplish this.