Everything posted by ckurtz2

-

1977 280z EFI Nightmare

Ok, those are all super helpful things to know. Here is a video from yesterday when it was at 18 deg btdc. When colder it would idle and rev almost perfectly, and then this weird issue developed once warm. You can hear when I rev it that it almost surges. It will rev up, stop, then rev up again. Essentially its super jerky. It didn't do this as much on the test drive, but I definitely noticed it bucking in first.

-

1977 280z EFI Nightmare

Thank you for all the advice, I just got outside and gave everything a try. To confirm, when I pinch the return line it definetly likes more fuel. I accentuated this when I lowered the idle rpm and could really notice the stumble and chop from the motor and exhaust. I then pinched the line about 4/5 of the way and it smoothed out significantly. However, it did still have a small stumble. Regarding timing, my light says that it is firing 18deg advanced. Interesting thing is at idle the timing read the same with or without vac advance. In addition without the vac advance plugged in when i revved the car the timing advanced further anyways and then came back. What could that mean? Essentially, the vac advance connected or disconnected made no difference. Even more interestingly when I put my finger over the hose that should be holding the vacuum against the dizzy vac advance I feel almost no suction. I tried other vacuum ports around the engine and I do feel suction there. Also removing and connecting the hose made no difference in how the engine ran. I tuned the advance to about 10btdc to prevent pinging for now. At this setting it seems to idle just a tad smoother but surges when initially revving. Another thing I noticed is that the rotor has slop. Not the rotor itself but the shaft it is connected to. It is radial slop, so I can twist it about 1/4 in each way. I also can pull it further one way which I assume is the vac advance function. Here are some photos of inside the dizzy I am lost here on what is going on with the vac advance and dizzy.

-

1977 280z EFI Nightmare

@Zed Head You are right, it won't take too long for me to verify and readjust a few things. When I said a rebuilt head I meant that I took it off and removed the cam and cam towers. Sent it to a machine shop where the cleaned it, shaved a little of the bottom to flatten it, and then did a valve job with new valve seals. I then re installed the cam and so on. I can get you officially timing readings later this week, but I am likely to change where it is at knowing that the car has a stock shortblock so the compression ratio isn't causing the issue. A simple question I have is which way turning the distributor advances or retards the timing. I had mine turned as far as it could go clockwise on both adjustment points. it does have the stock dished pistons and they looked good as new once I wiped all the carbon off. How do I check the advance mechanisms to see if they work properly? Also to see if the potentiometer trick would work without doing it, should I adjust the AFM idle mixture to test and see how much better it would run at idle with a slightly richer or leaner mixture?

-

1977 280z EFI Nightmare

Before you commented this I made it up in my mind to try and go give her a rip. No hydraulic brakes, just the good ole handbrake and an empty neighborhood. So i gently drove onto the street and man things went fantastic. My clutch noise went away and I could feel that she wanted to go. So I lightly pressed on the gas and I could hear a faint clanking. Hmmm what could that be. So I listened close and couldn't tell if it was coming from the front or the rear of the car. So I decided either the driveshaft had a weird u-joint problem or the engine had a small ping. Only one way to test it, so I pushed the car to about 3/4 throttle ready to shoot for the moon and all I heard was hell from the engine. Had great torque though. Anyways, the motor is pinging like a mad man, so I think I had a little too much advance:( Fingers crossed no serious damage was done, but man I never want to hear that sound again in 1000 years. I will have to go in with a small camera and check the pistons, valves, and other doo dads out. So @Zed Headshould I try that potentiometer trick mentioned earlier? I think that it is not a timing problem anymore, and instead I have been compensating another problem with timing. Vacuum and fuel is solid. New AFM and water temp sensor. Not much else I would be able to try. Also the TVS sensor works as it should.

-

1977 280z EFI Nightmare

Ok, interesting. Any reasons why when idling it sounds like it's stumbling? When really warm, but still within a good temp range when I press the gas it almost surges. It will go up in rpm, fall, then go up again slowly getting higher, or it will just plain backfire out the intake after idling for a few minutes and pressing the accelerator. Cold though, the engine seems to run really well with way less stumbling. Also when pulling the injectors while the car is running I have noticed some cylinders make more of a difference then others, same with spark. However all cylinders seem to at least make a minute difference. Needs to run longer before I can inspect the plugs and see what secrets they share.

-

1977 280z EFI Nightmare

Hey guys thanks for the tips. I found that other adjustment screw and it helped give me lots more range. The firing order, distributor allignment, etc are all correct. I decided to swap the spark plugs, because the old ones were fouled from my AFM "diagnosing". Anyhow, she runs much better, especially when cold. A few things to note, it takes a long time to start (I am thinking that the fuel pressure bleeds off) and it runs much better when cold. However when warm there is a very clear missfire happening and very, very occasional pops out the intake, but the new spark plugs mostly fixed that. It just sounds like its stumbling. I have done tons of little tricks and tests to rule out spark, which is completely fine. I also believe the timing is almost good, as I have the distributor set where it runs best. Now the missfire and stumbling baffles me, but I have some questions. First, I reppined the fuel injector connectors for new ones and I am worried that I have every single connector exactly backwards. What I mean by that is that the two wires were swapped potentially. Would this affect how the injector fires. Online has many different opinions as they are just "solenoids" and will work no matter what. Other people say that if they are backwards they may fire out of phase. Second, does it matter which injector connector goes where. I remember reading somewhere that it didn't matter on these old z cars. Last of all, I was wondering if someone could test their own car with the ignition on, and see which port in your injector connector is the switched positive and which is ground. That way I can determine if mine are backwards. We are so close to correcting all the millions of mistakes I made on this car originally, I see the endzone.

-

1977 280z EFI Nightmare

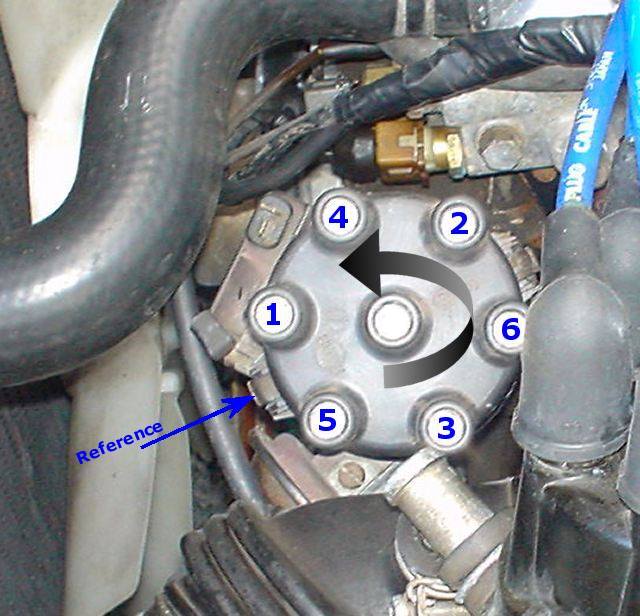

I stand corrected. I am praying that this might rest the demons once and for all. I had the firing order different, adjusted after the following photo I attached. Is this wrong? If it is I wonder how the hell this car ran enough to even try and idle. Now that I look at it though, the order seems the same, the distributor just seems rotated on one of the photos. Correct me if I am wrong

-

1977 280z EFI Nightmare

I did not know that the vacuum advance was supposed to be capped. Great tip, thank you. Which bolt are you referring to? I checked all around and all I could find were the two mounting bolts and the adjustment bolt. In addition I checked my firing order, all looked good there!

-

1977 280z EFI Nightmare

No worries, you are still a huge help. I am just a college kid with a dream and set of tools so🙃. I am pretty much wondering why I need to push the distributor past the stock adjustment plate to get it to run right. I know the timing is off, but I don't know why it is off so much. Even at that point it still stumbles a little bit, the engine is just 1000% happier running like that then it was before at 10deg btdc like the sticker on the hood recommended.

-

1977 280z EFI Nightmare

@siteunseen thank you for the help! I have some good news for today So I decided to just swap the AFM as a future investment for the car. It had been tampered with previously before I got the car, so I had no idea where the OEM specs were for the cog. Picked it up from zcarsource about 20 minutes from my house. Slapped it in and WHAM nothin, though it may have ran just a tad better. I also bench tested it, and the specs were a little closer to the online manual's. @siteunseen You were right though, the 150ohm didn't matter. I pinched the return line briefly and it started leaks all over the fuel rail showering a highly pressured mist, so that with the pressure test confirmed the fuel pressure is solid. Also good to note I have a new pressure regulator. I hadn't timed the car since the first start, and after fixing all the vacuum leaks it had me wondering. So while the car was running I moved the distributor and wellah! Idled much better (was still popping out the intake) and I could actually free rev it. It seemed like it wanted more, so i pulled the bolt out and twisted it past the little mount it had. Here, it ran even better, although when the car is warm it still stumbles at idle. However, it now free revs as I imagine the car should, and sounds healthier. So, what could this mean? Should I do some tests on the dizzy like if the vacuum advance works and such. Educate me, cause I am an idiot. So far my best theory is that somehow I messed up the mechanical timing and the ignition timing is compensating. Now that fuel and vacuum and the EFI system is set, its a matter of timing this puppy. When running the timing light I could see that it was off of the pulley indicator and was reading somewhere in the negatives. Here is a photo of what the dizzy is set to temporarily. We are close to settling this engines demons once and for all.

-

1977 280z EFI Nightmare

@siteunseen now that you mentioned it that had me thinking. Took a peep though and all looked good @Zed Head that tweak is very intriguing, and I won't hesitate to use it as a last resort. However, for now I am trying to get the system to function as it should without any extras, but if she is too stubborn I'll just have to do it haha. Now, I pulled the AFM to give it a nice "bench test" instead of going through the car's wiring harness. Thought it would give a more accurate result. Everything was pretty much the same! However, between pins 7 and 8 I was reading 182.2. It is supposed to read "approximently 150ohm". In addition, pins 6 to 8 read exactly 182.2 (supposed to be 180 so that one checks out good). I found it interesting how both of these tests are the exact same resistance. What could that mean? What is the function of pins 7 to 8? Simply put, pins 7 to 8 have about 21.3% more resistance than it should, which isn't "approximately 150ohm". I am not afraid to put a new AFM from zcarsource on her, I just want to hear honest opinions of you think I should get it done.

-

1977 280z EFI Nightmare

Hey guys I am back. New injector seals seated nicely. I was on a camping trip so just got back to working on the car. Anyways, fired it up, and it ran about the same, I can still hear a hissing in the same spot. The only other spot that I could imagine be leaking vacuum is the vent PCV hose from the block to the intake near the headers. I pulled it and it definitely had cracks, but looking from the inside shining a light and bending the hose it looks like none of the cracks go through. I still think it needs replacement, I just can't find one in stock. I also for the hell of it loosed the cog tension on the AFM about 4 teeth. It helped, but it still wanted more fuel, so I stopped knowing that something else is amiss. I had a new water temp sensor laying around so I decided to toss it in. There was a positive impact, but only marginal. So right now I am thinking a new AFM may be justified, but I am curious what you guys may think. I also redid all the engine bay wiring harness connectors, so those are now a solid connection. When revving the car I also noticed it would occasionally pop through the intake, so maybe my ignition timing is off? It is just hard to set it, because I can't keep the car to hold a steady idle when it is warm. Looking forward to hearing advice!

-

1977 280z EFI Nightmare

@Captain Obvious Yeah sorry about that, I kind of just updated things as I went...I just went very quickly haha. Essentially, it has been narrowed down that the main cause of my motor running like crap is not electronic, however the AFM may be slightly at fault. However, with a vacuum test it showed I had 0 vac at idle. Which is confusing to say the least, but I have never used this vac gauge before. However, I also pulled several vacuum ports and tried to plug with my finger and I felt no suction, and the motor did not run worse. So it must have poor vacuum. However, I think it must have some vacuum, because when I give it throttle the AFM meter moves too. In addition, since I did those previous vacuum fixes you mentioned a long time ago I am now able to rev it. I could not do that in January. So progress is being made, no matter how small. I heard hissing coming from where injector 1 was. I pulled off the rail and saw that the seal was ripped and not seated. Another vacuum leak right there. I also saw that many other injectors were not seated properly. Likely due to my stupidity of not greasing them before the first install. Learned my lesson:) So tomorrow that will get replaced. In addition, I removed the intake and exhaust and put them back on making sure they are torqued properly. Essentially, I am taking no **** from this car and finding every vacuum leak possible:). If the car still runs like marbles, well I will cry myself to sleep, burn the car to the ground, curse the heavens, or take it as a taunting from the car for a hammer. Lets hope it doesn't come to that🤠

-

1977 280z EFI Nightmare

Also, thank you for that guide! I am going to start using that one:)

-

1977 280z EFI Nightmare

I had the yokes the proper way, I had to use two washers for one of the mounts though, because I was missing one on the car to begin with. Can I just reuse this same gasket and plug everything up properly torqued this time? It was new in January. Then my big leak must have been that injector seal, praying that is was at least haha. There's not much more for me to look at for vacuum problems once everything is back together.

-

1977 280z EFI Nightmare

Ok that's good to know. I got my specs from 280z EFI Bible . Who knows it may be wrong. The test I am talking about was the AFM #2 or 3b. I guess it says small resistance, but I am not sure what it considers small. Also thank you @Zed Head for listening to me. I know I am posting a ton, but it is a good way for me to log what is happening as I go along, and any advice given has been super helpful. In addition, I can confirm that one of the injector seals was leaking (nearest the front of the engine where I heard hissing). It had a big tear across the small o-ring. In addition, I spilt water all over the intake and let it dry before I loosened any bolts. I hoped that the water would find its way around the manifold and seep into areas where the gasket was leaking. It turns out that a large part of the intake gasket was moist where I could hear the engine hissing. Do you think it's possible the gasket is bad here? the nuts were torqued on pretty tight, so I don't think it was too loose, but I could have been wrong. I actually think it was way over torqued. Here are some photos of what I mean. On the intake itself, you can also see where fuel seepage was happening. If I over torqued things is the gasket reusable? I put it on in January as new.

-

1977 280z EFI Nightmare

@Zed Head I cleaned the afm where it hits the carbon trace to see if that is why it had a high ohm reading. No change, if anything it read a few ohms higher. I can hear the hiss of a leak from the fuel injector area/ intake manifold. Looked closer and realized that the injector seal wasn't in all the way. Seems to be like that on a lot of them, so I am just going to redo the seals. In addition, what are the torque specs on the intake manifold gasket. It seems that I possibly over torqued it really bad, and that could be another cause for leaks. So I think I knocked down my vacuum problem to the injector seals or intake gasket itself. Every other connection I know is solid. Also I did a fuel pressure test and it tested perfectly fine. After I replaced the gaskets I will listen for the hiss again. If that fixes the vacuum and the car still runs poorly I will know it is down to the AFM that is ruining how the car performs. What is the "temp sensor tweak" you mentioned? I was just going to get a rebuilt unit from zcarsource. Regarding battery voltage I am just using a standard multimeter I got from ACE, I am positive there are no decimals. The voltage from the car's gauge reads about 13, interesting.

-

1977 280z EFI Nightmare

Here is my next update. Did some of the circuit tests for voltage. Everything pretty much seemed like it was receiving voltage, the only one in question was the AAR. It was supposed to slowly warm up to voltage, but it first read a lower voltage and immediately spiked to the battery voltage. My battery voltage said 27v. ?What the heck? What would that voltage indicate? I attached the sheet of tests I did today off the EFI bible. Let me know your thoughts. In addition, I decided I would record a video of how it runs so everyone can see. Here it is. I noticed for the first time a hissing noise coming from where the thermostat is. Could that be a vacuum leak. I ran a vacuum test and it literally read zero. To confirm this I pulled a few different ports while running and put my finger over them. I felt no suction and the way the motor ran made no change. However, I must be getting some vacuum, because the AFM meter moves. Before I fixed all the vacuum leaks that @Captain Obvious mentioned I could not rev the car at all, but this time I can. So i must be getting closer. Could a bad injector seal at the manifold cause this big of a vacuum issue? Or perhaps the intake gasket itself? Fyi the exhaust leak you here is a big one between the mid pipe and the header. Problem for another day.

-

1977 280z EFI Nightmare

So I did as recommended and toyed around probing and poking. I realized that nothing was grounding, because I did not have the battery ground connected before. Gee I am so smart. It seems like all the grounds in the engine bay are good. Everything read 0.1 to 0 ohms. I tested from across the engine bay on a harness ground to the battery, from the manifold to the battery, and every which way around and it all seemed solid. So I went and redid the harness pin test for the ones that failed and here were the results AFM #2: Fail 183 ohms. Should be 0 Air Regulator and Fuel Pump: Fail 60 ohms. Should be 0 Fuel Pump Relay Circuit: Fail 60ohms. Should be 0 Water Temperature Sensor: Pass It was within spec Control Unit 1: Pass 0ohms Control Unit 2: Pass 0ohms Control Unit 3: Pass 0ohms Control Unit 4: Pass 0ohms So I think I can confidently say that the harness grounds are not the issue, at least in the engine bay. So What exactly would this mean? I think a rebuilt AFM is justifiable due to failing that test. However, what the heck could be the problem with the circuit surrounding the fuel pump, air regulator, and fuel pump relay. I checked the ground between the air regulator connector and the battery. It checked out good. I also have an aftermarket fuel pump, would this account for the resistance? The resistance at lest dropped thousands of Ohms when I hooked up the negative terminal on the battery. I wonder if I should run a ground between the chassis and the ground on the starter motor.

-

1977 280z EFI Nightmare

@Zed Head interesting, my connection on the intake looks good. However, the little tower that the two grounds were connected to was painted where it touches the intake manifold. Would that ruin the ground?

-

1977 280z EFI Nightmare

With all of those tests failing when grounded it makes me believe I have the harness royally messed up in the engine bay. I am fairly confident I have everything right besides these two wires. When I got the car they were messed up, and I am not confident I put it together right. Do you have any idea how these are supposed to be hooked up? I had one running to ground on the battery, and the other leading to the positive terminal on the battery. This definitely could have been wrong In addition, I tested the resistance of the water temp sensor at the housing. It read about 1300ohms which sounds about right, because the water still is a tad warm inside. So does this confirm I have a harness problem?

-

1977 280z EFI Nightmare

Yip, was very disappointing when I felt it do that. Problem for another day though, just won't use the clutch while I try to get the engine running properly:)

-

1977 280z EFI Nightmare

UPDATE 2: Resistance Checks at 35pin connector Well it looks like we have some work ahead of us. The things that I know failed were one of the AFM tests and the water temp sensor. However, any test where I grounded one of the points to the car it failed. I just grounded it to the bolt on one of the kickplates. Is this how I am supposed to ground it? Idle throttle switch PASSED? Proper spec should be continuous and not continuous throttle released it read 0.6. I think that is ok. Throttle depressed it read 1. Not continuous Full Throttle Switch PASSED Proper spec should be continuous and not continuous full throttle: 0.1 which is close to continuous enough part throttle: 1 Not continuous AFM#1 PASSED should be about 180 it read 182 AFM #2 FAILED should be continuous it read 184 AFM #3 PASSED should be about 100 it read 101 AFM#4 PASSED there was a wide range depending on temperature. Did just fine within specs read 1411 AFM#5 PASSED AFM flap at rest should be not continuous. Fully opened should be continuous. Read 1 so not continuous. Then read 0.1 so continuous Water Temp Sensor FAILED should read within temp specs I got 1, so it had no continuity Control unit ground #1 FAILED should be continuous 62.9k control Unit ground #2 FAILED should be continuous 62k control Unit Ground #3 FAILED should be continuous 62k Control unit ground #4 FAILED should be continuous 62k Air Regulator and Fuel Pump Relay FAILED should be continuous 64k Fuel Pump Relay FAILED should be continuous read 1 so not continuous Let me know your thoughts!

-

1977 280z EFI Nightmare

It continues knocking only when the clutch is depressed and the car is on. I can feel it in the pedal as well:( I can feel it start knocking when I begin to start applying pressure on the pedal.

-

1977 280z EFI Nightmare

So the fun begins. Fired it up yesterday. Still a very unhappy motor even with all the vacuum fixes I did. Also the car knocks when I push in the clutch so somehow I messed up the throwout bearing, and I have literally zero I idea how. Actuates super smooth when the car isn't running. Anyhow, ran a compression check. I forgot to open the throttle valve to full throttle, but I didn't open the throttle for any so I know the numbers are consistent. Cylinder # and psi 1: 148 2: took a few more turns, but 150 3: 153 4: 150 5: 144 (didn't turn the starter motor as much for this one so I am sure it's fine) 6: 150 So the numbers aren't perfect, but I would consider them consistent enough? When I pulled the plugs I noticed they were extremely fouled. So my little bird is running super rich. Odd thing is that if I move the counterweight on the AFM to lean it out, it runs much worse:( So idk what that could mean. So I am going to do the 35pin continuity check on the harness connector at the control module. Am I supposed to leave the battery connected for this? I am a super noob with electronics, and this will be the first time using a multimeter

.thumb.png.8dcb2f9a37a5aa90004224e15c2d7065.png)

.thumb.png.ab4fd5536935894e9b758e3646ec969f.png)

.thumb.jpg.bab81041537a01f9c30250dcef6f992b.jpg)