Everything posted by Parman

-

Saving car #34464

Restoring the hubcaps. I decided to freshen up the hubcaps a little. 3 were a faded gray, and 1 was a darker color, almost blackish gray. My first step was cleaning the area between the chrome and the paint. The tape line. I used 0000 steel wool. Then I degreased it and applied 1/4" fine line tape all the way around. It really helps to see so I used these magnifying goggles and a headlamp, and a good light. Once I had that tape on, I used a wider tape and continued around until it was masked off. Same for the center cap. Then I used a scotch Brite pad and scuffed and cleaned the old paint. Blew it off with air and degreased the old paint until the rag was clean. It took several cleanings, but this is a very important step. Then when the wind quit blowing, I gave them several coats of the Datsun Gray paint purchased from California Datsun, great stuff! An hour later, I removed the tape. It came off easy, pulling at a right angle to the paint.

-

Distributor rotor identification

Nice! Thanks

-

Distributor rotor identification

Can anyone identify the logo or symbol on this rotor? It's of high quality and I would like to find another one. Could it be Mitsubishi?

-

Saving car #34464

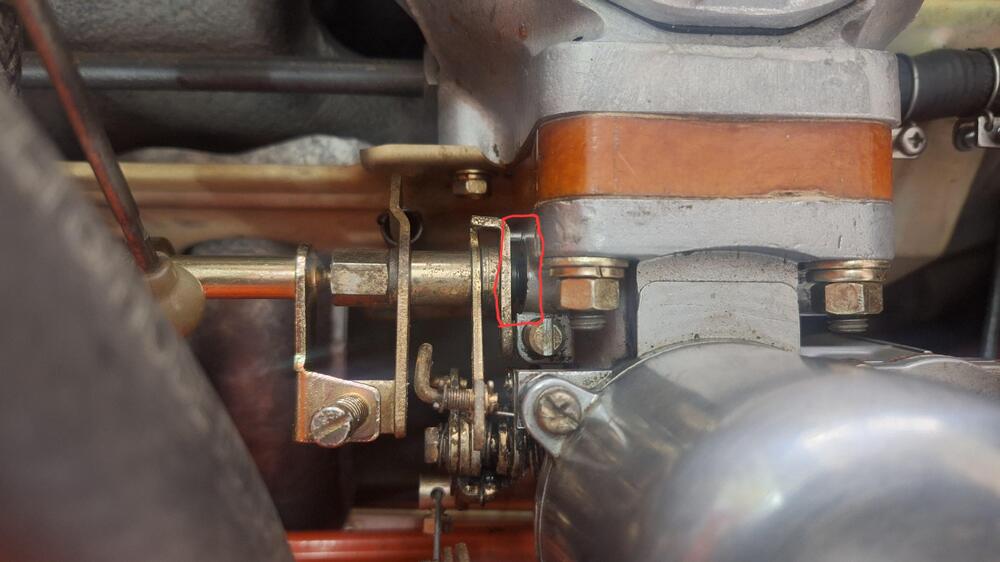

After adjusting the valve lash a couple times, I timed the distributor which was really close. I tried my hand at tuning the carbs. This video VHS and flowmeter came with the car. I backed everything off, but still was getting a 1,000 rpm idle. Seemed a bit high. I would put the flow gauge on the front carb and adjust it so the ball was in the middle. Then go to the rear carb, the ball was way high, no way to back down the idle screws anymore. I figured there must be a vacuum leak somewhere. I squirted brake clean around but didn't make any noticeable difference. I couldn't get them the same. The next day, while fiddling around with it, I grabbed my broken stethoscope, and started poking 1 of the hoses around when whaaam! There it is. The rear carb is leaking around the throttle shaft. These carbs were just done by ZTherapy 2 or 3 years before the car was parked some 22 years ago. I had a chat with them, boxed them up, and they are now in their hands. I hope it's an easy fix.....

-

Saving car #34464

Time to put gas in it and build fuel and oil pressure. As I was siphoning gas into the tank, I decided to check the fuel gauge, turned the key, and watched my oil pressure gauge slowly rise. The fuel gauge did nothing. After freaking out a little bit thinking did I mix up the wires somewhere? Got my spare gauges out and the connectors on the back are the same, but the oil pressure/temp gauge has 4 wires instead of the 3 wires going to the amp/fuel gauge. So I stuck my head up behind the dash with a light and saw they were connected correctly. I unhooked my oil pressure wire at the engine and now I had no oil pressure showing. This car came with a NOS oil gauge press sending unit that I had installed. I put my original sending unit back on and now the gauge zeroed when I turned the key. I moved the connectors a bit at the tank, now my fuel gauge worked. The NOS gauge I had is part #25078-32200. Found out that's not for this car, maybe for a 280z. If anyone needs it, I don't. I removed the spark plugs, the valve cover and cranked the engine over. No oil getting to the cam oiler, which is a Michael Yoes upgrade. I did a little research here and someone mentioned galley plugs. That's the first I've ever heard of them. Were they removed and if so were they replaced? I don't know. I called my machinist who did the block and asked him if he removed the galley plugs. He said, "of course I did! it's standard procedure!" I asked him if he replaced them, "Of course not, that's the assemblers job!" Oh no! I don't remember anything about galley plugs, did they come in my kit? So, After a little more research I found out there are 2 galley plugs, 1 in front, 1 in back. I found a picture I took of assembly, the timing chain, and aha! there's a galley plug in it. Found a picture of the back and the plug is there. They were never removed, thank God! I did not want to pull the engine again. So, I found a great tip here, which was to remove the oil filter. Get a piece of clear hose and stick it in the hole to the galley and shove it as far forward as it will go. Get a small funnel, and fill it with oil until no more oil will go in. I did that, re-installed the filter, and the valve cover and cranked it over. I immediately felt a change, I had oil pressure, my pressure gauge went up. I guess I had to prime the pump. Next I took a vacuum pump and sucked fuel from the tank to the filter. I removed the fuel pump and connected a hose to it into a jug of gas. Back filled it with gas and let it soak in a bit, then pumped with my hand. I had gas squirting out in force! Reinstalled the fuel pump. Cranked it over a bit until I had gas in the carbs. Got some distilled water and started filling my radiator. Used just water because I didn't want antifreeze everywhere when I found the hose clamps I forgot to tighten. Turns out, the water pump seal had dried up and water came pouring out that little hole. Several day later, which was only 2 weeks ago as of this writing, I get my new Aisin water pump from Rockauto and install it. Fill up the radiator, no leaks. It's time! I turned the key and It didn't even make 1 revolution and fired right up! Wow! It started revving up so I shut it right down. My linkages needed adjusted. Got the idle down and after adjusting the clutch a bit, drove this thing out of my shop on it's own power. Yahooo!

-

Saving car #34464

The mice chewed the warped spare tire cover, so my daughter and I went to home depot and bought a 4' x 8' sheet of 3/16" pressed hardboard. It looks identical, might be a hair thinner. Traced my old one and made a new one

-

Saving car #34464

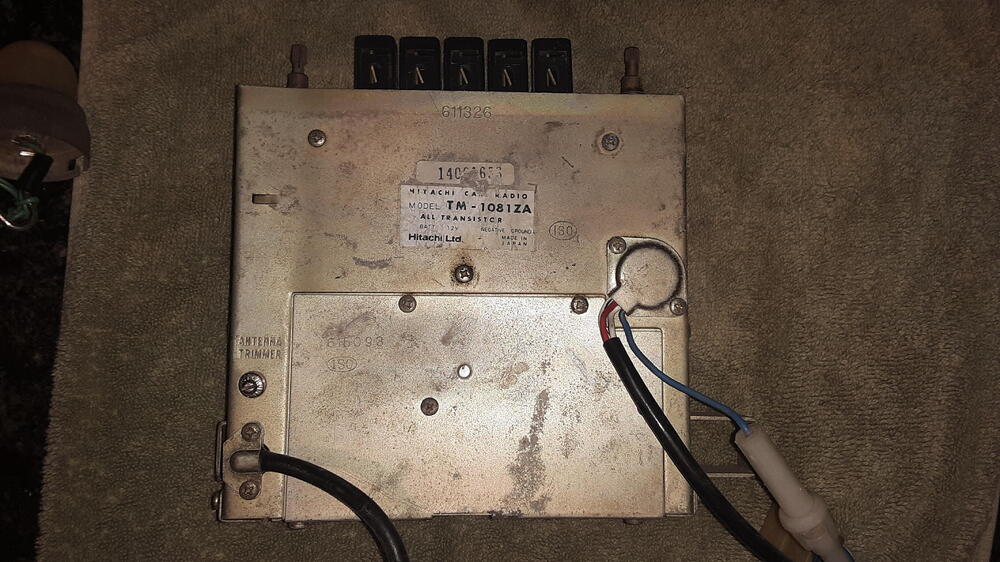

Honestly, I really tried hard to get everything correct for my build date. I came pretty close, but at a certain point I got what I could because financially, this car was eating my lunch. Just because it was a 240z part, the price was 10x the normal. Brake wheel cylinders for example. One of the parts not original to the car, is this bullet tip antenna. My 6/71 came with this tip, I think, unless it was switched. One of the first articles I read on this site was how to fix these antennas using weed trimmer line. I couldn't figure out how to get the tip off, I ended up cutting it off...nooooooo.😣 oh, it unscrews.... The second part is the radio, the one I found is too early for this car, like the antenna and brake master cylinder. It's the red light radio, mine should have came with a green. I would possibly consider trading somebody for the correct pieces........😏

-

Saving car #34464

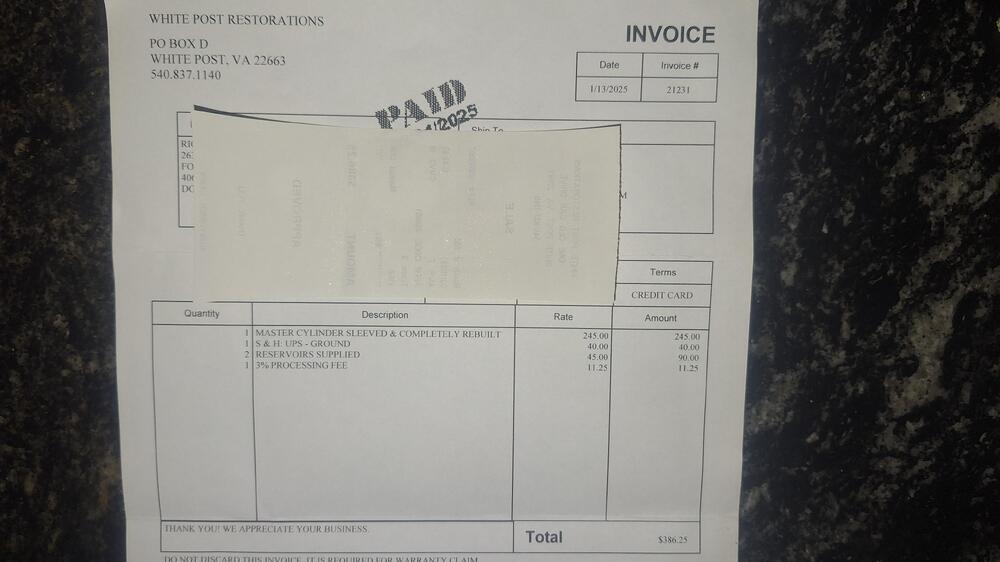

Captain! Yes, they did completely rebuild it. It cost a little more than I was quoted because they said the plastic reservoirs were brittle, and cracked. Thank you for the information, I knew it was probably from car #1042, but I didn't know there was another version. I appreciate all the help you and others have been on this project. PM me your address and I'll send you a couple choke handle screws. 1 for using and 1 for losin.

-

Saving car #34464

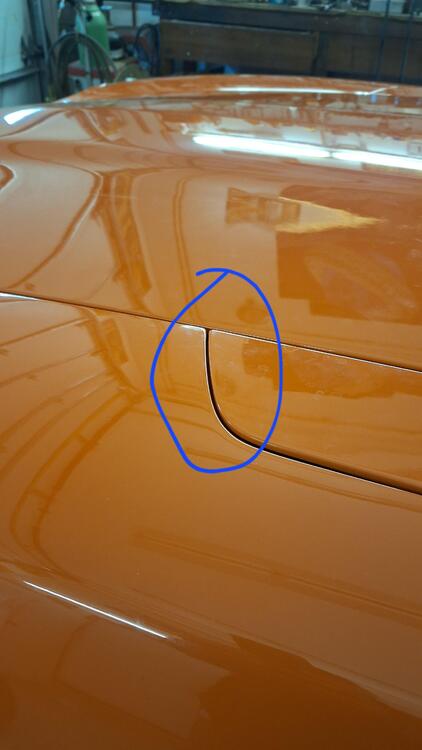

Why don't I have ground to my horn? If I ground it separately, it works. It's the paint! I painted everything. The solution was to remove the bolts, 1 at a time that bolt the steering column to the firewall. Then grind the paint off underneath the bolts/washers. It solved the issue, but now I have 1 loud horn and one not so loud, which led me on entirely new horn obsession. Why doesn't my dome light come on, it's the paint! Where the switches go into the door jambs, I removed the switches, ground some paint off, and they also work! This is fun! Time to install the hood. I noticed I had some areas that were not aligned that great. But one day I realized they were all related. I loosened the left fender and slid it forward. All these bolts are painted so I used a piece of plastic bag and inserted it into my socket, so to cause minimal damage to the paint. After sliding it forward a bit. I salvaged some rubber pieces for the tool boxes from my parts car and glued them on. here's the tools that came with this car. I cleaned up the old carpet I had and installed. It didn't have cutouts for the luggage straps, it was chewed on and it had shrunk. I like the floor mats. Anybody know where I can get a nice carpet kit for this car?

-

Saving car #34464

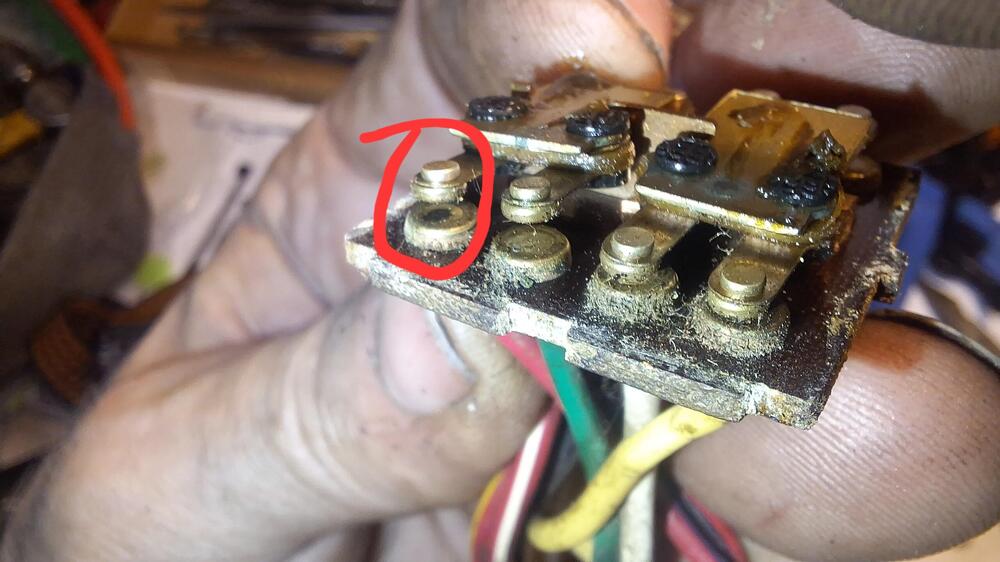

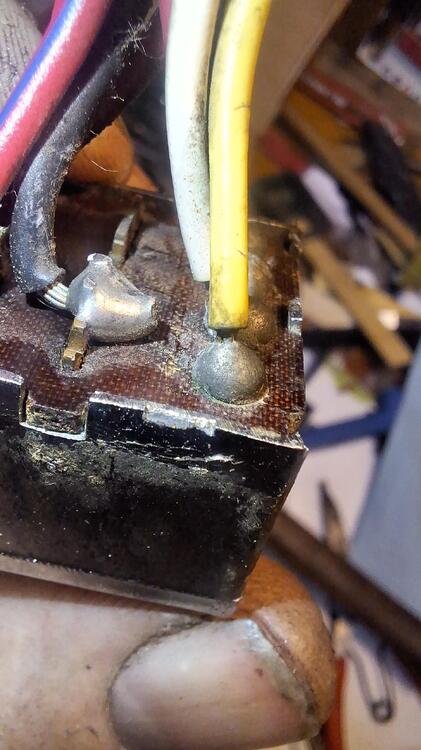

After connecting the heater control cables, and disconnecting them because I forgot to hook up the map light wires, and reconnecting a couple more times..for one reason or another, I finally got it. I think it's time to hook up a battery 😬 I did, and didn't smell anything, the engine bay inspection light came on. The side marker lights worked. I had no horn, 1 bright headlight, 1 dim one. No turn lights, no hazards, no dome light. I have taillights, but no brake lights. I read through some of Steve J. posts and decided to remove the hazard switch. Found it! the contacts were not contacting. I took some fine sandpaper and shined them up, then cleaned with alcohol. then reassembled. I now have hazard lights, turn signals, brake lights. Still no horn, no dome light. I fixed the headlight problem, it was just connected wrong.

-

Saving car #34464

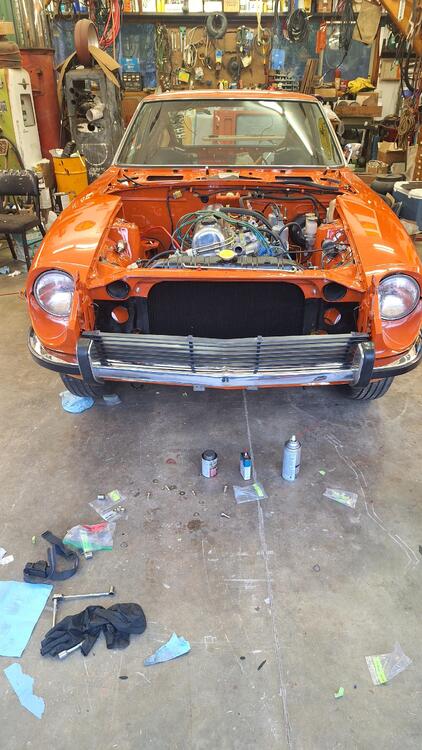

I started installing the console but first I had to route the choke and throttle cables. This is when I noticed how long the throttle cable was. I routed it this way but it was still a bit long at the pedal. If anyone needs some choke lever knob screws, I have 98 of them left 😆 I wasn't about to cut it, it looked original. Then I researched here a bit more and found the length of one for a left hand drive car. Huh, I had one for a right hand drive car. How in the world did it get on a car here in Montana? My solution was a piece of motorcycle fuel line, slit lengthways, and used as a spacer. It worked. I later cut the firewall pad around the throttle shaft so the wing nut rests against the grommet. Look how nice the dash finisher matches the dash. Installed the under fender brackets with foam, the fenders, headlights and the radiator, grille, horns, and bumper and the decals

-

Saving car #34464

My brake troubles were not over yet. I noticed some fluid on the line going to the right front brake near the firewall, in 2 spots. The plating was gone and it was seeping out these pin holes. I have everything to make a new line, so I did. It isn't going to be plated but at this point I just want brakes. Also one of the rear wheel cylinders was leaking. At this time, I never thought to look on my parts car. I'm not paying $500 for an original wheel cylinder, that's just absurd. I bought some from Rockauto for $45 each and made new brake lines for those, keeping my original lines for later. I got all the leaks stopped and had a heck of a time bleeding the rear brakes. I finally realized the highest point of the line had to be at the firewall. That's where my bubble was. I had the front of the car jacked up, I let it down and the air bubble travelled to the rear and finally out.

-

fuel tank sending unit question

Oh thank you! I ended up having 2 spare gas tanks around from that parts car 🙂 so I just swapped the sending unit, softened the rubber boots so I could get the connectors on easily, which worked great. No more leak. So if you were going to repair a leaky connector on one of these sending units, would you repair the inside of it with sealant, jb weld, or the outside of it, or both?

-

Saving car #34464

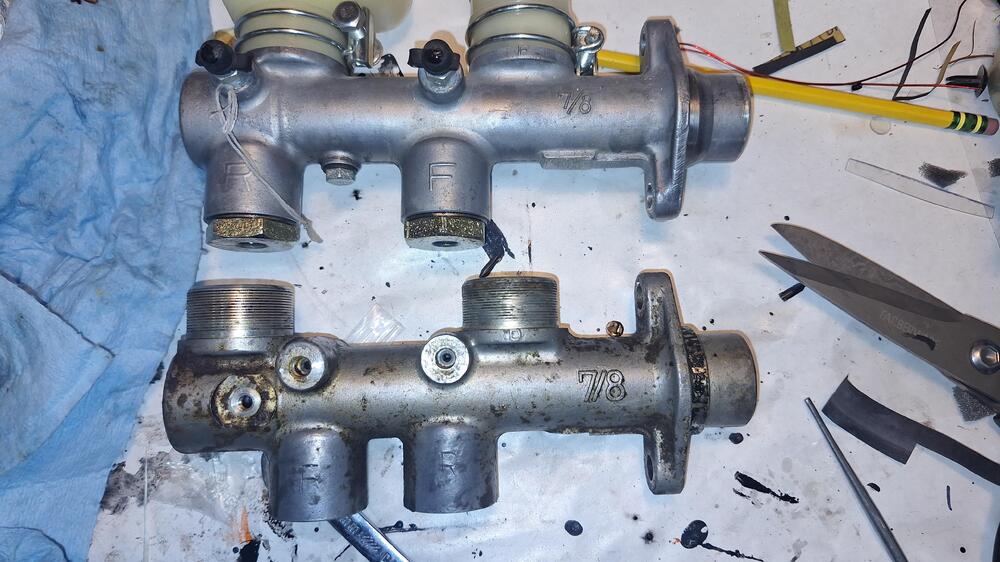

Installed the fan, 1st of many times, and the horns. I had the radiator re-cored back in 2021, it's been in a box in the loft for 4 years. I had the brake booster re-done as well in 2021. I tried to rebuild the brake master cylinder but...........I'm about to learn something. I have a few fenders off that parts car and measured and located the holes for the emblems, as well as the hatch. My hatch emblem holes were covered up, but I could find them from inside the hatch, underneath. So I removed the hatch. The fenders had no holes as the bottoms of them were replaced. The master cylinder on my car leaked, not only the copper sealing washers leaked, but was leaking back into the brake booster. Not a good situation with all this fresh nice paint. It was about this time I realized I don't even have the correct master cylinder on this car. The rear reservoir is going to the front and visa versa. That's the way I found it. Makes me wonder of it really makes any difference, this swap was done decades ago. It just so happened I got a master cylinder with my parts car, and it was the correct one. It had one good cap. Here's what an early cap looks like. Too late to stop now, haha, dang it, so I sent it to White Post Restorations. I installed it and guess what, it leaked...out the copper sealing washers where those big fittings are on the bottom. Because these new copper sealing rings are too hard, harder than they used to be, I heated them up to a glowing red, to anneal them, align the properties. I don't think it matters how you cool copper, quickly or slowly, the end result is the same. Sure enough it made them soft and they sealed.

-

Saving car #34464

I got all the rear bumpers together, I had 2 off that parts car, That car is really paying off now. I got the best pieces and decided to treat the backs with POR. here's the difference in the 71 and 72 rear bumpers. I straightened out the dents on my press.

-

Saving car #34464

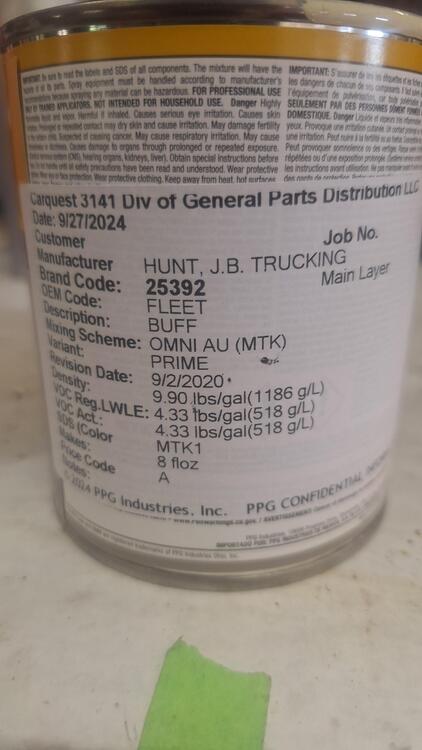

I decided to move on to refinishing other pieces, starting with the fan. I took my fan into Carquest and went through their paint color books. I found a match! They mixed it up. I bead blasted my fan blades, primered and painted them. Well, my seat belts now looked out of place as well as the seat brackets. I took the buckles apart and just lightly wet sanded the rusty areas and scuffed the rest. Same with the seat brackets. I painted them. I got some clear vinyl .03" thick and made new pieces for between the brackets and the seat. I got some black dye and dyed the luggage straps.

-

Saving car #34464

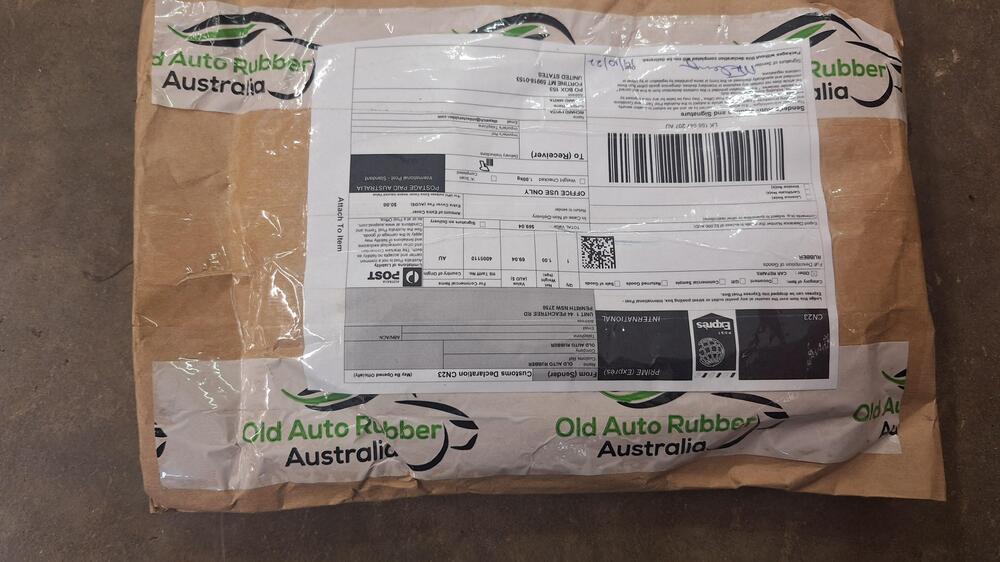

This was my first attempt on the hatch weatherstrip. I used the one that came in my precision complete weatherstrip kit. I had read on here earlier it would be better to buy an original as well as an original windshield weatherstrip. In Feb of 2021 I called the local Nissan dealership and ordered what was available, the windshield weatherstrip 90305-E4100. I ordered 2 of the hatch side weatherstrips 76911-N3000 and there was 1 76912-N4500 inner hatch seal available. I waited months but the 76912-N4500 had disappeared and never came in. The others did. After installing the precision seal, and letting it dry for a week.....I bumped it and it came off. I re glued it with the 3M super weatherstrip adhesive, it fell off. The hatch wouldn't close all the way anyway. So I cut it up into pieces and tried different glues. I asked a local glass place what they use, they said go to the hardware store and get a tube of GOOP. Out of all my tests, GOOP was the clear winner, and it was clear. So I ordered another hatch seal, this time from vintage rubber. Their door seals fit so good, I thought this would too. Not the case, pretty much the same seal with spliced in molded corners that are too thick and they don't compress like the rest of the seal. My hatch will not close all the way and I don't feel like taking a hammer to the car.....yet. I just ordered an inner hatch seal from Scott's old auto rubber in Australia. It doesn't have molded corners and is sold by the metre. But it's the same throughout. I will update on that when I get it and install it. this is attempt #2

-

Saving car #34464

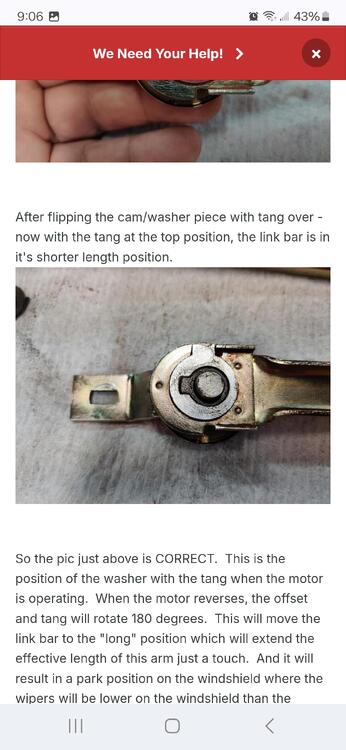

The wiper mechanism couldn't be saved. It was seized at one of the pivots. However, the motor was in great shape. I just needed to dress up the contact points with some fine sandpaper. The contacts are under that rectangular cover. I assembled the linkage to the motor/bracket and tried to install it. Many cuss words later, I got it to fit, only to realize I had to remove it because it wasn't parking correctly. Found my answer here. Got it oriented correctly, only this time I installed the motor and bracket first, then installed the wiper arm assembly, WAY easier! Then tighten the nut to the motor. I really struggled assembling the hood hinges. They came apart pretty easy many moons ago, But I couldn't figure it out. Fortunately I had a spare assembled set and I took it apart. The rod laying on the little purple stool is in the correct orientation. Hooked up the steering and installed the transmission. Installed a new Exedey clutch after having the flywheel resurfaced. Installed the engine. went underneath to torque some bolts and noticed the clutch fork was loose, what! I had to adjust it all the way out just to get the throwout bearing against the clutch forks. That isn't right. I'm used to doing everything twice or more by now, so after reading the same issue on this site, I removed the engine. I added washers behind the pivot ball, I don't know why I had to, but it fixed my problem. I noticed my new oem clutch boot replacement was not like my original. Why? The new one left a big gap at the fork, so I used my old one. Also at this time I bumped a piece of weatherstrip I had installed using 3M super weatherstrip adhesive. Absolutely did not stick to the rubber, but stuck to the car good. Real good. Fortunately I have a can of 3m adhesive remover. haha, I can't figure out which one I dislike more. The adhesive remover turns the adhesive into the state it was when you squirted it out of the tube, a sticky mess. It also removes paint. This is just the beginning of my aftermarket weatherstrip nightmare. Something so simple and easy turns into the worst part of restoring this car.....

-

fuel tank sending unit question

The rubber boot over the connector gets hard, causing you to apply too much force to the positive fitting trying to remove or replace it. At least that's what happened to me. I'm soaking the rubber in wintergreen oil to soften them up.

-

Fuel tank sending unit leak

My fuel tank sending unit is leaking, but not from the O-ring, but from the black electrical fitting. I think it's loose. Guess I'll remove the sending unit and see why.

-

Saving car #34464

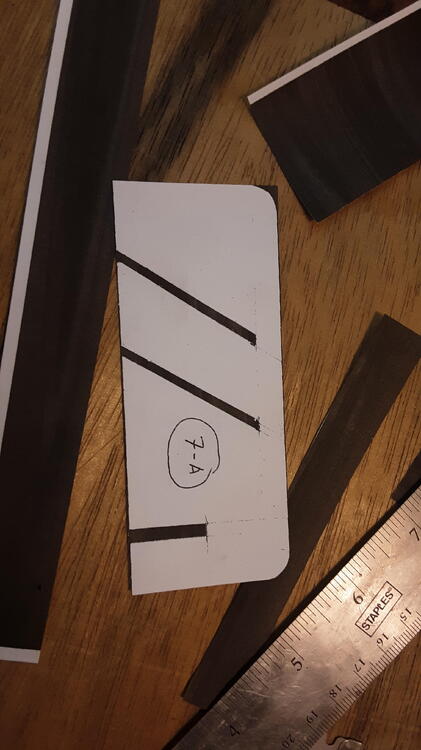

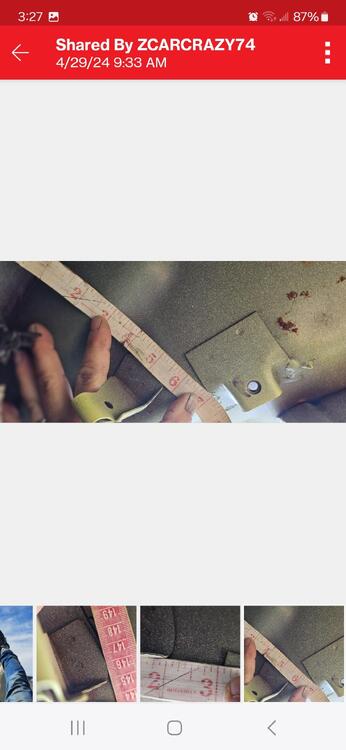

For some reason, I can't locate my pictures of this, but the hardest part was finding the rubber. It's in Australia somewhere. Lol, sorry but I also misplaced my receipt. Edit: It's called "Old Auto Rubber" Update: Found it! Here's the part number, the old rubber, haha and the new one. I took a razor blade and sliced off this protrusion all the way along. Now it matches real close. Okay, get a dremel tool and grind or sand the staple folds or if the heads of the staples holding the rubber are showing, I took a small cutoff wheel and ground the heads of the staples off so the rest of the staple can be pushed through. Remove the old rubber strip. Then I had some T-50 staples, I took the same cutoff wheel and made them the correct length, even pointed the ends. I cut my rubber strip to length, held it in place and I believe I took a small drill bit and going through the staple hole in the stainless moulding, drilled through ther rubber. After installing that staple, and crimping it over with small pliers, I continued that process until all the staples were replaced. I remember in the YouTube Video I saw, he used rivets. I thought they would stick out too far, so I went like the original, with staples.

-

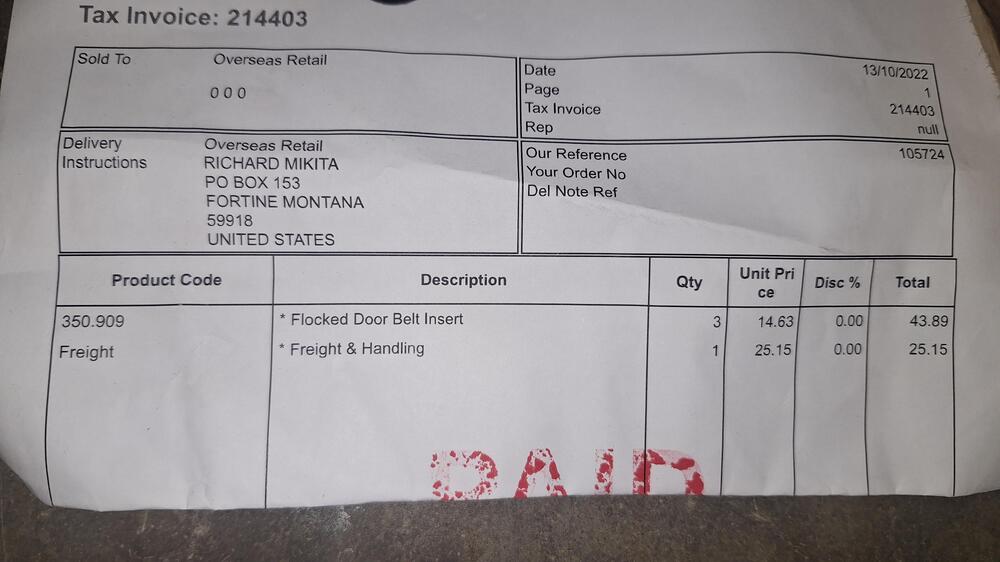

Saving car #34464

One of the first parts I looked for were the belt moulding rubber strips. That's how all the water got inside the doors, they were disintegrated, hard, brittle. I couldn't find them anywhere and I wasn't satisfied with the non-fleeced variety. I happened upon a YouTube video of a guy, restoring his doors on a 260z I think. He was in Australia. He went down the road from his place, to an outfit that specializes in old rubber for automobiles. He bought some material by the foot and it was exactly the correct shape with a fleeced back. And it was cheap. For the life of me I can't find my paperwork receipt from this. But I called the place and they shipped me the rubber. I carefully ground off the staples on my belt moulding, removed the old rubber, and modified some T-50 staples, dilled out the new rubber where the original staples were, and restored my belt mouldings. If I ever find the missing receipt, I'll post it here. I even lost my pictures.

-

Saving car #34464

I ordered all my hoses from bell metric. The green car was coming in very handy for grommets and rubber bits I was missing. If not just to know what I was missing. It took 2 people to install the gas tank after hooking up all the hoses to it, and getting them started up through the floor. I added some insulation to the back of the vapor tank, like I found it. All my original vinyl was okay. I showed this picture to Jenny and she says, "why do you have a grab handle on the drivers door! lol?" I said because the holes were there! and the handle was there! I didn't know it's usually not on there. So I tried to take it off.....and I couldn't without breaking it. What kind of a Japanese torture contraption is this thing? The only way I could install it was to loosen to 2 phillips screws. Now I can't get it off. I finally got it removed and I made some plastic threaded plugs for the holes. I realized that back in 1999 when the previous owner got this door panel from the Nissan Dealer, maybe all they could get was one for a right hand drive car.

-

Saving car #34464

I disassembled and blasted the grille pieces in my blast cabinet. I think I had to cut a hole in the door for them fit. primed and painted along with the tail light finishers. They hung here for 2 years, and the rear suspension completed was in my way for 2 years. I kept knocking my head on the refinished gas tank that had been hanging in my shop for just as long. 😆 Here's the rear suspension and gas tank kanji before I blasted it. I got the firewall pad installed and things escalated from there very quickly. I used door seals from VintageRubber. They fit great! I also added some of the Wurth floor pan tar sound deadening insulation inside the doors. I bought the tar from Auto Atlanta. Using the templates downloaded from this site, thanks Namerow, I rebuilt a heater box, definitely not the box I removed from this car.. I installed the door glass and mechanism, and the door panels, the drivers side panel was NOS and came with the car along with 2 grab handles etc. I removed most of the plugs off the engine bay wiring harness just to install the grommet. I hope I got it back together right. I took lots of pictures of the plugs.

-

Saving car #34464

I asked if he would sell some parts off the car, what do you need? I said, "the choke cables and levers" okay. I want that alternator too and ash tray, hehe. I paid him and held my breath. Now there's 3 different gas pedals that I know of, there's at least 2 types of throttle control cable brackets. I think the earliest type of bracket and pedal are what I found on car #1042, the wrecked green, red and white car. The bead blasted (top) one, came from 1/70 car. The bottom one came from 6/71 (my car) The middle one came from in between. It goes with this bracket that Jenny removed from one of her cars. This bracket is a beefed up version of the first version which clearly failed. What I learned was the original alignment of the cable bracket welded on the bulkhead to the pedal tab (the cable hooks to) is offset. I installed the pedal on 1042 and noticed this. I measured her measurements and mocked up her bracket on my car. I get the same offset. I consulted with Patcon ... again, he's been such a big help. We agreed that I should line it up! Now I was adamant about restoring this car to exactly original state, but......this is one thing I'm going to add. Because of cooler temperatures here in Montana, I thought it would be nice for warming up the car. Plus, it's cool.

Subscriber

Subscriber