Everything posted by Richie G

-

Alternate OEM door mirrors?

Me neither, but did anyone ever replace the mirror for the correct convex piece of glass?

-

Driver's window glass falling off track

Heres a direct link https://www.amazon.com/dp/B011A8ZPL4?psc=1&ref=ppx_yo2ov_dt_b_product_details

-

Driver's window glass falling off track

If your only problem with the original glass was scratches you should try this first: I had awful roller scratches all the way up and down the window and used that amazon product and it came out like new glass. Pictures don't do it justice.

-

SEM Method Alternative?

Sorry for the bad pic Yarb, yes 15013. I actually bought them all on amazon june of 21 so the product lasts quite a while in the can. The soap got a little separated but since it was just soap it was fine. the black sprayed a little thick for about 10 secs until the nozzle cleared but other than that it was amazing.

-

SEM Method Alternative?

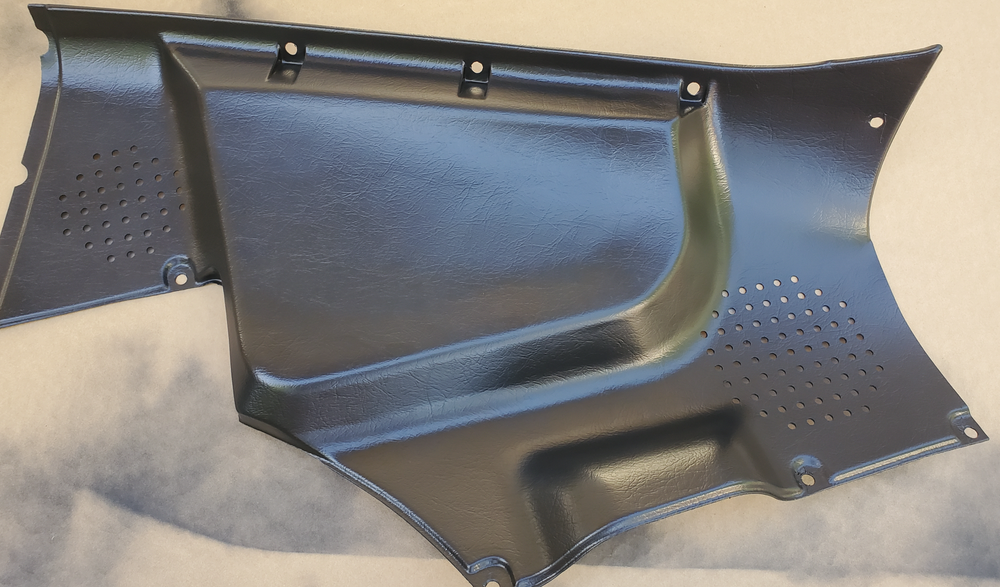

I finally got around to doing the plastic trim and tried this rad paint alongside the traditional SEM way. The SEM way was much simpler than I had imagined and the results were fantastic, practically factory fresh. I followed this demo from the product https://semproducts.com/product/color-coattm-mixing-system/system#product-videos I just did one of the rear panels and it literally took me 20 mins from start to finish and that includes total drying time and ready to install. Sounds crazy, but really it was that easy. If anyone still needs to do this here are the products I used I started from left to right, hosed it and washed it with the soap and pad. Dried it then wiped it down with the plastic prep and it quickly evaporated on its own. Then a quick thin coat of the promoter and quickly followed with several light coats of the landau black. Below is a picture of it fully dry, this is not still wet it literally dried in like 60 secs basically bonding to the plastic.

-

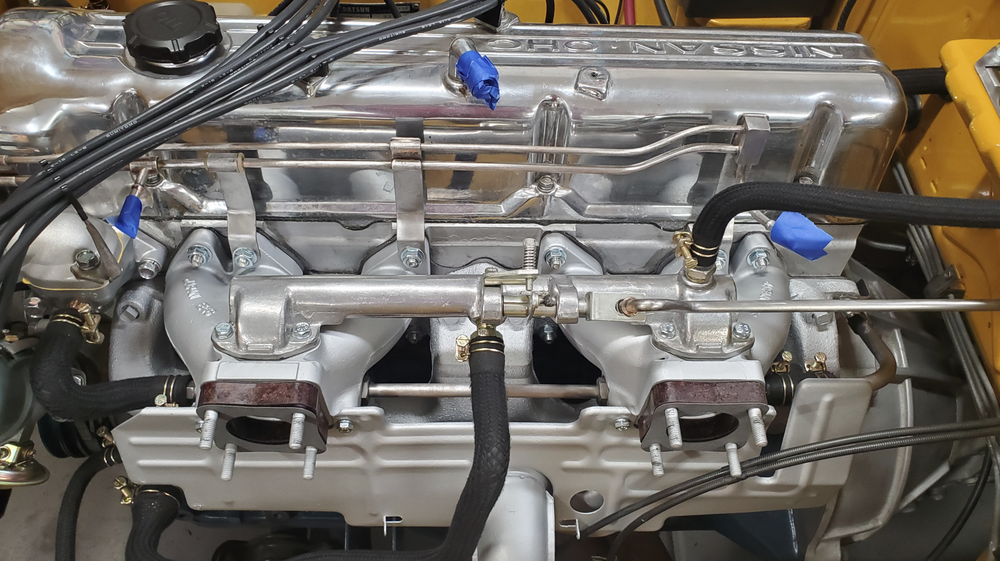

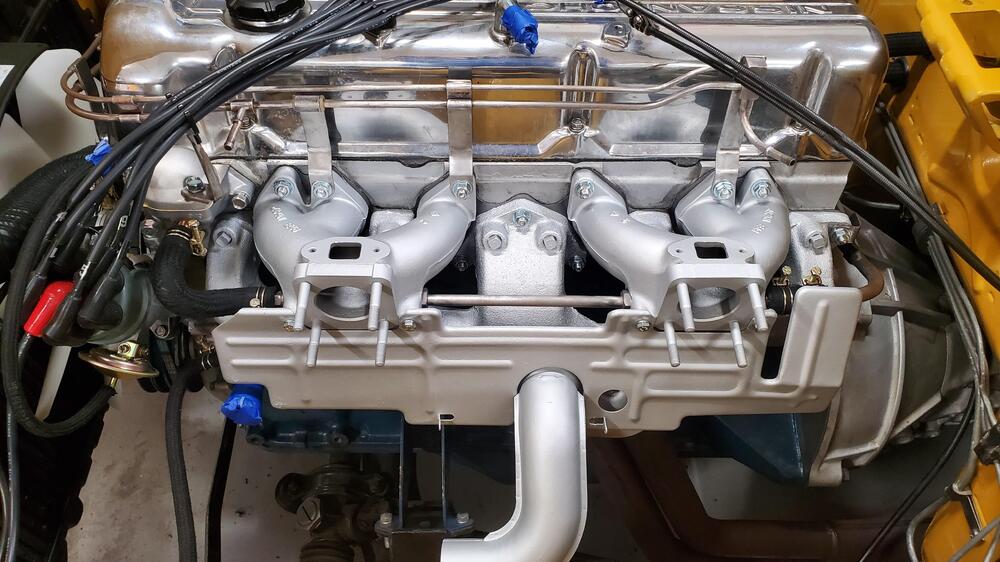

Bad Air Pump Valve?

Well, everything is back and Ive attempted to balance the carbs. I think i did it right from all the reading Ive done. i madse sure to balance the airflow in each carb, then tested the mixture by slightly lifting the piston in each. Idle was pretty much un changed after I got them where It felty ok. i didnt have an impedence trype rpm reader was relying on the gauge and the sound of the engine. It feels around 850 from what i can tell. I'll have a friend come by and double check my work lol. One thing i did was go back and find the "before" pic and compare it to my new after. I'm pretty proud of theprogress Ive made as a newbie and 1st time owner. My work is probably not perfect but I continue to advance it little by little. Before, first pic from buying it after with all the changes / eliminations I really want to thank everyone for all the help these past two years. I couldn't have gotten this far without the community. Next up is getting the seats redone and back in so i can test drive it.

-

Bad Air Pump Valve?

So I just went out and rechecked and sure enough it is stamped Japan E46 but what's weird is it's not where it normally would be it's closer to the firewall manifold then the radiator manifold and I would think if this was a normal 46 even though they ground down the spots where the smog accessories were screwed in there's only the single plug on the horizontal location for the booster not a second plug on top next to where I have my booster connected. You would think even if that was ground down he would at least have to put a plug in there there's no such plug so I have no idea what this thing is

-

Bad Air Pump Valve?

if you flip it over you do see an E46 stamped on the tube so it's weird somebody polished this thing it's certainly not that stock look at least what I had before this has that semi glossy polished appearance to it.

-

Bad Air Pump Valve?

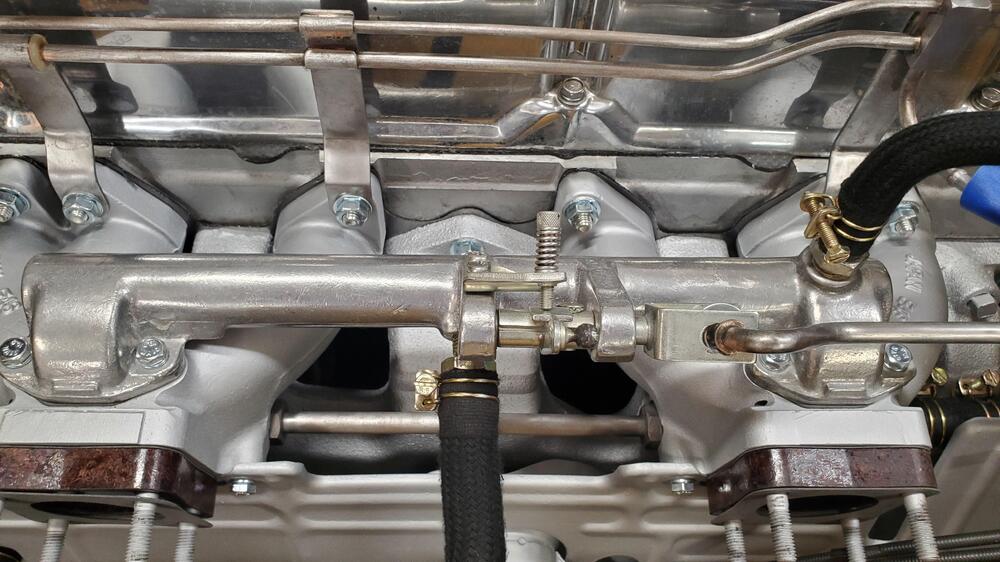

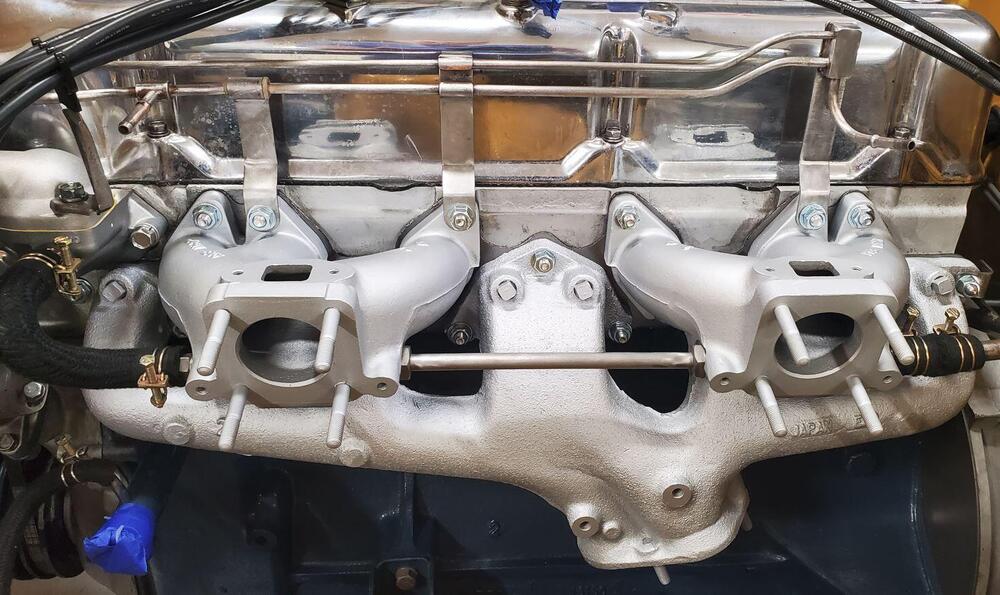

@w3wilkes @KenFirch heres that euro tube installed. Came out super sweet. And Wilkes you asked if it was a ztherapy and I think it might be now that I have an up close look. It has their polished look to it in my opinion. I'm cleaning and readying the carbs for the last step, hopefully attempt to start it this weekend. I'm going to atytempt to time it, balance, and adjust the mixture so fingers crossed its my first time lol.

-

Bad Air Pump Valve?

Chickened out on painting the pipes, when I went underneath i can see the PO has a jury rigged j bolt welded on and connected to the rear cross member. The support bracket where the pipe meets the muffler has a broken weld from the frame. It all seems stable but I'm not going to mess with it. I'll repair and replace all the pipes when i go headers down the road. added the shield

-

Bad Air Pump Valve?

Oh duh, maybe i drop the pipe and slide it forwards with the car on rhino ramps! that should be much less twisting and work.

-

Bad Air Pump Valve?

Making progress. A little ways to go waiting on some gaskets for the carbs and balance tube along with the brake booster hose switched to the top load rather than side valve. I decided to get all new studs and HW for the block because the previous set was a mess of sizes. MSA had a decent set all sized and ready to go but it did require me changing out the intake bolts to studs. I kind of like it only because it made the mounting easier rather than having to hold it in place while i bolted it. the exhaust manifold arrived already media blasted nicely but not such a great color so i painted it with vht. I ended up using aluminum to try and match the intake I had already. then i restored and painted the intake, polished the coolant tube and fuel rail Coolant back in and as i wait for the gaskets I'm polishing the linkages as best i can. i'm contemplating painting the front section of the exhaust pipe its currently a rusty looking brown. Without a true lift might be a bit of a challenge getting it out the back but i'll see what i can do. if its not reasonable ill leave it and deal with new pipes anyway down the road with the headers.

-

Bad Air Pump Valve?

You're absolutely right no mention of one anywhere. But in doing more research looking at pictures of my E46 manifold that is out there on the web they all seem to have the same valve connected on that side but I can't see what's inside the tube. I'll just try and clean it up as best I can.

-

Bad Air Pump Valve?

Thanks. Another question as I plan the replacement steps. I notice the coolant tube through the intake manifold has nasty looking valves on each end. Wehn i did some research on replacement it seems the rear one is a thermostatic valve which is different than the front typical standard adapter. When i look at mine, i can see clear through the entire tube one end to the other. Am I right in guessing the PO replaced the back side thermo one with some standard pipe fitting? Any implications to this? Should I try to source and replace it?

-

Bad Air Pump Valve?

Thanks. Ok so at least my setup was right but i think i still need new bolts because the set on there are annoying with various head sizes from home depot lol. So are the studs removable, I'm assuming so but I think i'll leave them for now and tackle that with the new header down the road. I dont want to push my luck again lol. although i just found this old pic from the PO restoral book and it looks like the studs are intact and maybe he even painted over them when he painted the block. Either pure lazy or he couldnt get them out and left them

-

Bad Air Pump Valve?

Okay couple of more questions. As I was falling asleep last night I was thinking about the bolts and washers and stuff I took off the block and I started looking around because the previous owner had a bit of a mismatch of various bolt head sizes to deal with taking off the intake. So I started browsing the typical sites to see if I can find some relevant replacement Hardware and some sites seem to sell a set of studs nuts and washers others a mix and match of studs and bolts. I don't have access to the car right now but I'm trying to recall if those studs were the type that can come out or could they have been part of the block? They looked really old and I can't imagine the previous owner leaving them there when he had the engine worked and rebuilt unless they were part of the actual block. the question is should a 71 have studs for the exhaust but bolts for the fuel rail and intake like I had set up? Or should it all be studs?

-

Bad Air Pump Valve?

Yes had those and just got done with everything. Wasn't as bad as i expected. Drained the coolant and luckily enough no spills from the back tube or the thermostat to deal with. Then i disconnected the choke, gas lines and pulled the entire intake and set of carbs off all at once. The old gasket surprisingly for only 2500 miles came apart in quite a few pieces making a mess and what i noticed is some of the paint the PO had used on the block started flaking. I saw some particles sitting on the intake ports so hopefully nothing went in there. I did my best to gently clean those out. One thing that I'm not sure if its "normal" or an oh boy is looking inside these ports they sure are dirty. the exhaust ports look like the inside of a chimney and the intake look like they have a bit of sludge on them. As a reminder, this all started when i replaced the plugs and found them dry sooted to heck. That led me to believe things were not right and now I'm seeing the inside of these ports kind of confirms at a minimum i need to start over on balancing and tuning these carbs. I've never done that before so may need some help if things dont go well 🙂 before i did all this the engine ran really well from what it felt like ion the garage. idle was real clean at 800rpm, car came to temp nicely, pulling the throttle seemed like it was very responsive, but seeing those plugs like that just really spooked me. someone said maybe its just the additive you put in to keep the gas fresh, they tend to do that but this is way more than a light coat. Here's where I'm at and it will probably sit like this for a week or so until things arrive and i have a chance to get them ready. the manifold will certainly need some work to get it to look decent plus i need the gasket, the booster hose, and the balance tube to show up. I'm trying to convince myself to not go nuts becasue its very tempting to grab that rail and maybe get it polished and coated while i wait. but again this isn't concourse this isn't concourse lol. we'll see.

-

Bad Air Pump Valve?

You're right Ken, even though i dropped the downpipe to disconnect from the manifold its impossible to get the manifold out without removing the intake. i can't cut the air pipe close enough to the nut to get free. Oh well, gonna do it right and take it all off. As of now I think i got it but will certainly PM you if I run into trouble. This whole thing is a good opportunity to learn. Taking things apart is pretty easy, its making sure it goes back correctly lol. I ordered a new gasket because it looks like the one in place will split as I take off the manifold. Newbie question, I'm assuming when i take off the intake and exhaust manifold no issues with any oil to deal with? There's nothing to do with oil where I am with the engine right? Oh and Captain, for now i'm thinking i may hold onto these hoses but I tend to change my mind quickly lately with this car. you're the first person i'll ping if i do.

-

Bad Air Pump Valve?

I stumbled on a real one. Nothing but the pcv valve and the booster port mounted vertically. I don't think there's even a plug in the old horizontal booster port out the back. Smooth all around.

-

Bad Air Pump Valve?

Thanks @KenFirch yes got em off after seeing someone on youtube 🙂 I made some good progress today getting ready. Air filter, balance tube gone. Smog pump hoses brackets gone. Cut out the air tube to make a little more room. Removed the nuts from the mani to exhaust. I have not yet removed the carbs / intake or the coolant hoses running through them. Eye balling it maybe they don't have to come off? i hate to have to drain this radiator, I literally filled it like 10 days ago after flush and refurb of heater unit and radiator lol. i took the nut off the bracket holding the rear coolant tube and the bolt out of the 3 way heater valve on the otherside. With a little wiggle and loosening of some of the hoses I can get the tube bracket off the bolt. maybe those pieces dont have to come off? I think I'll wait until i get the new stuff before i bother trying anything else.

-

Bad Air Pump Valve?

Nice. As i start taking this apart it seems like it will be easier than i thought. One extra question or two as I get through this. I see the emissions control screw / linkage will now basically be useless and flap in the breeze. Just leave it like that I guess? And another real newbie question, because I'm afraid of another slip up, How do you take the "ball joint" link off the balance tube to the throttle linkage? I definitely dont want to crack that ball joint.

-

Bad Air Pump Valve?

Thank you all for the well wishes and advice, especially you @KenFirch for the generous pair of hands offer. Here's what I think I'm going to do and I'm looking at it as a great learning opportunity and challenge rather than a disaster. After a few days of thinking and listening to the crew here, I think i'm going to take incremental steps so as not to make this too big of a project and waste more time with it just sitting in the garage. Ultimately I'll end up with headers and new exhaust, but for now I'm going to delete the smog equipment all together by replacing the mani with a plugged AIR delete one I am getting from Junkyard Jenny. Its the same type I have so should match right up to the existing exhaust. While I'm at it, I'm also going to swap out the balance tube with a euro style and go balls to the wall removing all the stuff other than the PCV valve and brake booster. This will require me to get the later brake booster hose for top load rather than the series 1 side one I have now but I can live with that. Quite a drastic change from my original approach of "near stock" configuration lol. I think i have all the steps down, and @KenFirch I may contact you if I run into trouble but a couple of quick questions before I start tearing it down while I wait for new parts. 1.) If I understand the smog delete correctly, and with my euro style balance tube, all that's left is to plug the port on the air filter going to the intake on the smog pump. I've seen some comments here and there around fuel rated rubber plugs for that but couldn't find anything. Any suggestions on how to safely plug the air filter port? 2.) Is removing the smog pump as easy as just literally removing the pump, belt, and associated (and frigging newly bought) corresponding hoses? Anything to "tune or adjust" now that its removed from the belt system? 3.) The euro style tube has no accommodations for the servo diaphragm and control valve. Do I need to rethink this? I'm not even sure what those things do and more than likely on this car they are not working right anyway, just like the check valve that got me into this in the first place. 4.) I had recently replaced the AB valve, again trying to get to stock, does this now introduce the opportunity for back fire? Or is that a dumb question now lol? 5.) Once all said and done, do i have to re-tune the carbs to accommodate anything I've done? They felt like they were pretty good as I trust the person that did them before I started this. 6.) Am i crazy and did I miss anything?

-

Bad Air Pump Valve?

OK, kept thinking and maybe I have a hail mary option #5. What about using JB Weld Extreme Heat to plug the crack? https://knowhow.napaonline.com/how-to-use-jb-weld-extremeheat/ Seems like I can easily get to where the cracked air pipe is by just popping the distributor cap off, might not even need to touch the thermostat housing. I know this is far from the right thing to do, but for someone like me who's not really excited about tearing everything down to the block, even for the replace it with another manifold option, maybe its good enough for now? My check valve is frozen dead shut. That smog pump isn't doing anything other than maybe feed fresh air to the backfire valve when needed but I'd probably leave it for now since I can't get the check valve off anyway to properly plug it. None of the other exhaust ports are getting any fresh air, would plugging this one really make anything worse? It certainly won't make anything better, but I was about to drive the car like this without even knowing the check valve was dead and was blissfully ignorant lol. I'll take what miles I can out of it and deal with it down the road (yeah that's what they all say lol). @KenFirch i think i saw your post from 22 in the exhaust section, looks like you were happy with how it turned out. maybe I go that route eventually. Is that shop still around?

-

SEM Method Alternative?

Heres the final product after adding the emblem i cleaned up and redid. Looks like new if you ask me. This paint was a fantastic stumble upon.

-

Bad Air Pump Valve?

Well, worst possible scenario. Cracked the tube off the fitting on cylinder 1 😞 SOOOOO effing mad at myself! Why Why Why! I'm sick to my stomach, a year of work, a seat install away from driving it and I do this!!!!! OK, rant over and I've got to start assessing my options. @KenFirch yes initially I was going for the stock look slowly doing this and that, but this may change my whole approach. I've come to realize this will never without a significant amount of money be a concourse car. I'm also not looking to race it anytime soon so I need something in between the extremes. I think i have four options: 1. Source a new galley and attempt to replace just that. From what I've seen, its very difficult to find and B its nearly impossible to remove those nuts. This would require pretty much everything taken off the engine except the exhaust manifold and associated pipes. Not a great option unless by miracle the nuts come off. Since the galley is already kaput, breaking another nut in the manifold wouldn't be the end of things. 2. Source an appropriate manifold and galley already in good working order. Still have to take everything off but in addition I have to take off the manifold and deal with that and the pipes reassembly. This is probably a little more work than option 1 because I have to disassemble and reassemble the pipes. Pro I get the stock look back, con I guess is it basically gets the car back to where it was without any benefit. I think the mani coming off would be easier than the galley out the manny cause I canb guarantee after seeing the previous owner work he didn't take the two apart when he had the engine rebuilt. So hopefully mani bolts will be relatively easy to deal with. 3. Same as 2, take it all off including the exhaust mani but replace it with a plugged mani. Allows me to eliminate the smog equipment, somewhat resembles stock for non us cars, ties back up to existing pipes. Benefit or dropping the smog, cleaning up the engine. 4, Go balls deep and tear it all off and get headers as @KenFirch did. The heck with stock, gets some new shiny stuff to play with, but lots of extra work in dealing with new pipes probably all the way to the tip. I havent really decided yet and I think the level of effort will determine what i choose, or maybe i start down 1 path and eventually go all the way to headers if I run into trouble. Some of my obstacles will be, I'm really not a mechanic but getting better, have no lift other than a couple of rhino ramps, can't weld if I have to fab something or deal with that type of thing for a better pipe fit, and have never done this before. I'm definitely not as intimated as I was but still something like this isn't like painting a glove box or even restoring a radiator. @KenFirch I have a 71 and that offer is super nice of you. Not sure it fits though? Question, what type of headers did you get? What about pipes and the rest of the exhaust? I did a quick search today and saw MSA has a few sets that are way reasonable and I like that they are flange type without the need for any welding all the way through the tip. Thats probably something i could piece together from end to end myself, but I saw some complaints about not hanging high enough / limited hanging and at least one person had to go to a shop to have some cutting and welding done to make it fit. I need something that can bolt to the enghine and just match up and hang / bolt all the way to the tip so its just me and my wrenches 🙂 If anyone reading this could weigh in on my thinking, the four options, offer some others I'm missing or encouraging words that would be super appreciated. I'll continue to read and think about it along the way. Is there some type of simple way to plug that hole in the temporary maybe? Its already cracked off and more than likely I'll never get the tube out of it anyway, whats the harm in drizzling something over the hole lol. Oh and back to the newbie side for a moment. I only ran the car twice for maybe two to 5 mins each time once I heard all that knocking. Did I do anything to the internals at all in that cylinder? Did I make more of a mess of this than I already have to deal with? And if I did decide to have to take this to someone because I just couldn't handle the repair myself, is it even drivable for short say 20-30 mile distance? Or am i really pressing luck and looking for trouble?