Everything posted by Richie G

-

Tail Light Panel Paint Question

Cool! Curious what color did you use underneath just in case I get really ambitious 🙂 Those look great BTW.

-

Tail Light Panel Paint Question

Any suggestions on a replacement?

-

Tail Light Panel Paint Question

I've been working on a few things lately and recently pulled and repainted the tail light panel. Got the paint from California Datsun which supposedly is the closest to original but I'm wondering about the glossiness. The color seems right to me, but its awfully glossy. Was it this glossy when new? I could have done a better job honestly but many of the small ripples you may see didn't seem to show up until the gloss shined in the light. If this paint was matt or flat may not even notice them but with all this shine you can see even hairline imperfections. Debating if I pull it and try again once I get through more important things.

-

71 240Z High Beams Work Low Beams Don't

Thanks Steve, so switch meaning on the turn signal one that changes grounding from high to low right? I can't imagine why the combo switch would be an issue if its sending power to the lights overall. I actually think I have an old one of each laying around from a parts bin i can try swapping easily enough to eliminate.

-

71 240Z High Beams Work Low Beams Don't

Fiddling today before I put her away for a few weeks and noticed the high work but not the low beams on both sides. The stalk was in great shape when I last put it together about a year ago but maybe the low grounding in there has an issue? I really don't have time before my out of town trip to tinker, just curious if there's a list of things I should check when I get back? All other lights work great just the lows off for some reason. Could filaments in each bulb go at the same time for some reason?

-

Air Cleaner Manifold Hose

OK thanks guys. So cooler air = better performance, just like cold water makes better coffee 😉 I was just curious that the manifold pipe being left wide open wasn't a "good thing", no issues just leaving it like that? We don't cap it or anything? And for looks if I do decide to place it on and off at times, is that dryer vent looking hose from Z Car really accurate? I can't imagine they used that way back when, looks so out of place with everything else. I was going to get this from Dorman to at least have it match some of the hoses aesthetically. Only $10 or so currently on Amazon https://www.amazon.com/Dorman-HELP-96034-Preheater-Hose/dp/B000C5I7VC/ref=asc_df_B000C5I7VC/?tag=hyprod-20&linkCode=df0&hvadid=241973068692&hvpos=&hvnetw=g&hvrand=17963068419572466911&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9032516&hvtargid=pla-570818045410&psc=1

-

Air Cleaner Manifold Hose

My car doesn't have a hose for the wintertime connection from cleaner to manifold. I don't really need it in Sacramento, but do I want to put it on there anyway? I don't think I ever see one on most if not all of the cars that get a proper restoration on BAT, but it just feels weird to have that exhaust manifold going nowhere? A quick search here really didn't provide much other than a small thread from 05. If I do need it, is it really this from Z Car Depot as the original looking hose?

-

Early 71 vs Late 71 Dash Harness

Could this green / black be the seat belt lights in the later consoles? Makes sense since it's located with the rear defrost switch wiring. That could mean these two are the power for the ac switch and the power for the door lights maybe?

-

Replacing All Large Opening Seals & Hatch Small Seals

Could have saved me $40 bucks if I had seen those. Surprisingly they didn't show in my ebay searches.

-

Early 71 vs Late 71 Dash Harness

I have a 6/71 which should have the earlier harness with the longer pig tail fuse box connections. Seems the PO mixed and matched some stuff from a 72 or later and I think I have a late 71 / 72 dash harness and short pig tail fuse box. As I start on the dash area restoral couple of questions if you don't mind. First, are there any major differences with the harness I need to worry about or as long as the fuse box matches the harness I should be good? Everything seemed to be working off dash / console except the radio and rear defrost but I know why. The rear defrost had the inline fuse holder broken (needs replacing) and the radio was something he just threw in there. I have an original seek AM I'm going to try and get to work (supposedly it does) and it seems to match up with all the connectors. As I trace everything though it seems there are a few things unconnected if someone can identify these please What's this blue/red connector on the heater panel section? And this blue bullet connector maybe is power to the optional air conditioner? And this green / black connector coming off the rear defrost line? Maybe the optional door lights? Any help appreciated.

-

Replacing All Large Opening Seals & Hatch Small Seals

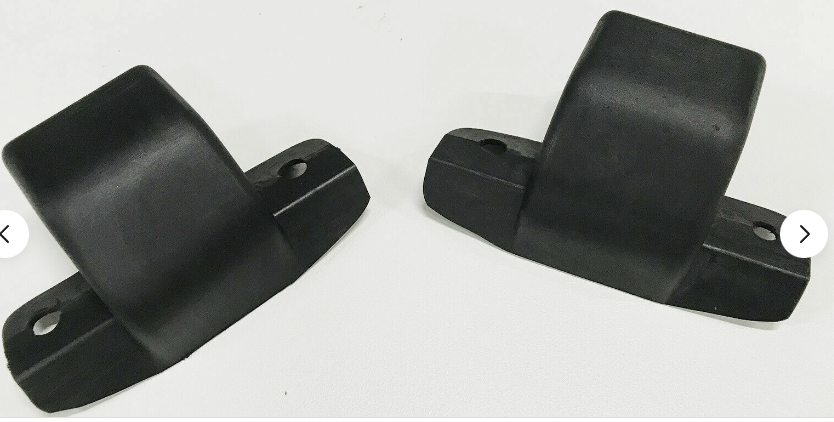

I'm lucky enough that it will close on its own. i can just drop it from mid height and it latches really well. It just isn't perfectly flush. I'm hoping it compresses will keep an eye on it. I was even luckier in that I didn't have to pull the hatch itself. My old hinge rubbers were intact and painted over but seemed still ok, plus it was only me and no way I was chancing it alone. Nothing in the roof that would indicate previous compromise so felt ok leaving them for now. I do have a replacement pair in case I ever need them. These were reasonable and very well made. With exchange rate tax ands shipping was like $112 US in case anyone needs a new pair. You'll have to keep your old compression plate and shims rubber only. https://www.ebay.com/itm/384879465523

-

Fuel Line Leak

Ah OK thought the PO had really gone nuts there for a moment lol. So brakes need the flare wrench for the various connections. Thanks as always

-

Fuel Line Leak

Thanks X yes I see the last one before the turn about a few inches. I just wasn't sure if there was a vertical one on the upside. May I ask a dumb question? You're comment about flange wrench I was under the impression at each end of a new hard line I would just install the correct rubber hose and clamp? I'm not exactly sure what else I would be doing or what would be flanged, my current lines just have a hose and clamp from filter to line and from line to tank on both supply and return.

-

Fuel Line Leak

Agree with all that was said, and jealous of Racer's tool collection and shop! I will certainly be doing this in the near future and keep an eye on this section very closely. I was already looking at the ZCD items and they also have the rubber mounts and clamp downs I'll need. The few sections I loosened had dry rot rubber and a few even had some give to the clamp but it's tightly down again. Couple of questions. I see ZCD has the stock finish or stainless. I guess I can ask them but if anyone knows is the difference really just the plating and the stock is also stainless? I was going to get both fuel lines and the vapor line in stock finish but not upsized (slowly starting to add some originality back to the car). Should I stick with this or get anything upsized? Also, I see when I did the tank there was a rubber mount for the end of the hard lines. Is there supposed to be one in the engine bay where the fuel line attaches to the filter? I don't recall seeing one there and wasn't sure if the end of hard line just came up 90 to meet hose for the filter or PO lost it..

-

Fuel Line Leak

That's probably the way to go. What specifically needs to come out and in what order if any? It seems engine side isn't much if anything at all. What about in the tunnel? It seems you have enough room to do it undisturbed about as far back as resonator but I couldn't see much beyond that with my limited clearance. Maybe if I had another set of rhino ramps I could get all four tires up and do it?

-

Fuel Line Leak

OK, hopefully this does it even if it's temporary. I was able to get the old fitting off and maybe understand what had happened. It was the type of fitting that required a flange not the traditional compression with sleeves. PO made some nice flanges, seemed clean without burs but i noticed on the tank side the tube at the flange was just starting to make a turn ever so slightly. You'd never really notice unless it was cutoff to inspect up close. So i think the flange wasn't sitting perfectly flat inside the fitting. Got myself a micro sized pipe cutter and with enough wrangling was able to cut it out. Removing the mounting screws all the way to the filter and a few in the tunnel got me enough play to get it done. Thanks for that tip. For some reason I look at these hard lines and am always so worried they're going to be stressed to the point I make it worse. Lessen learned. Ok now to the fix. Cutting the section out resulted in a gap too wide to bridge with another sleeve compression fitting no matter what i did. I had to resort to hose and clamps but since I couldn't get the bump ring on the end of the pipe i used 7mm instead of 8mm hose to make it more snug. At some point I think i can get a new section of line and make the bends to get a true compression on there (unless I just ignore this until i get a real opportunity to replace it all). I will leave it overnight again as it's too hot in the garage to know if its evaporating like yesterday. It started and ran excellent so that's a positive. If it does work, here's my trophy and I'm hanging on to this one! Thanks all!

-

Fuel Line Leak

I knew I shouldn't have said anything lol. This AM got a bit of a drip. Better than when i started but needs to be replaced for sure. I guess the heat in my garage was the difference. At least I have what I need now to attempt a replacement. Or I guess I can just keep my garage at 105, that seemed to work well lol.

-

Replacing All Large Opening Seals & Hatch Small Seals

One question I should have asked. HH do you notice the hatch riding a little high with bulb all around the outer hatch? I do notice mine is slightly off (maybe 1/8 measured at the bottom side) and I am not sure if the hatch was just misaligned by the PO or adding bulb down the sides is keeping it up. If I press down on the hatch there is a little room to make it sit flatter but I just don't recall noticing before i took the seals off. I did not remove the hatch to replace my seals. Maybe it being new just needs to flatten a bit under the weight of the hatch. Maybe that's why the factory didn't use bulb all the way. Either way I'm happy and can live with a little bit off if it makes a better air tight seal.

-

Replacing All Large Opening Seals & Hatch Small Seals

Late to the party but Z Store does sell a single bulb type outer hatch seal i just installed on my 71 if you're still needing it. Came outr great with just the 3m adhesive. https://www.thezstore.com/product/5487/rear-deck-outer-weatherstrip-one-piece-top-sides-70-78-240z-260z-280z-coupe

-

Proper Oil Pressure

I just changed my oil and filter for the first time (71 240z) and was wondering if my pressure readings seem accurate to folks. 10w30 at idle (9000 - 9500) with the engine temp at midpoint gets me about 1/4 reading on the dial. If I give it some throttle to keep it steady at 2K it climbs to 1/2 gauge and hold steady. Does this sound right? It seems the PO put on a new sending unit but it's the gold one which after some digging here it seems some people don't speak highly of. Also I did some reading on dipstick type and accuracy and it seems my e3001 has just slightly shorter dimensions from shoulder to tip than most folks report. My reading is about 3/16th over the fill line to the H symbol. If I account for the shorter stick length it still puts me about 1/8 over what should be the fil line. this was measured at cold engine after running it to idle temp and letting it cool down. New filter and 10w30. I know its best to have less oil than more but so far not a drip and it's been 9 hrs.

-

Fuel Line Leak

I don't want to jinx myself, but I think I fixed it! I was determined to do this myself and what really held me back was not having the right tool so I upgraded my wrenches and tried one more time. Got it lifted grabbed a few open wrenches and attempted to tighten the existing compression fitting. It was a bit easier this time and so far about 5 hrs ago not a drip. Now it is 105 in Sacramento so maybe a pinhole still exists and it's immediately evaporating but the finger test so far is holding true. I will check again over the next few days. I have a new compression fitting if I feel it needs replacement but so far so good. Again want to thank everyone. For someone like me still learning and trying to do this all myself I feel real good about what I've accomplished so far. 🙂

-

Fuel Line Leak

Good news bad news. BlueZ a 2x6 was the trick for the jack/ramp situation so I got it up safely. i can't believe I didn't think of that, shameful. That was the initial; good news. Bad news tightening didn't do much if anything. There's barely any thread left and it actually feels like it wants to strip or has possibly been cross threaded all this time so I didn't want to push it. That was the bad news. I put it back down, it started sweet and easy and then i let it run for about 5 mins. As predicted the drip slowed due to a probably air-suck but not fully stopped. It's at the point I feel safe driving it (if I can find the seats lol) so in the AM I'm going to call someone whos worked on this for me before with a full lift and everything we would need. While I was under there it really doesnt have as much play as it seems in the photo and i can't really get many tools up there even to cut it out. Gary Cook out of Sacramento had helped me sort a bunch of things when I first got this back in 21. Some of you local guys may know him, he's been racing and building Z's for a while and even had some time on the Shelby team prior. He'll probably have another fuel line he can swap in a jiff. Might take a week or so especially with holiday but the panic has left and I feel ok even if I had to leave it a bit. Thanks to all.

-

Fuel Line Leak

Just saw this towel trick, will try it later tonight (when wife is asleep and she wont miss the towels) 🙂 I used to lay a towel partially under each ramp so that it stuck out at least a foot in front of the ramp so that the tires would roll onto the towel and then ramp. That would keep the ramps from sliding.

-

Fuel Line Leak

Zed i actually tried that by using my floor jack under the cross member and its like 2 inches too short to get the ramps under fully 😞 Are you saying one tire at a time? If so can you show me where exactly? In the meantime I had an idea how to brace them with something but I'm open to anything.

-

Fuel Line Leak

ok so i just went out and set my ramps, started it up. the beauty is it starts and runs so nice!. The crappy part was my ramps are sliding all over the place as I gently inch forward. I have a typical smooth concrete floor that had some old garage floor pain applied to it. By no means slick, but certainly not rough. the tires get a bit up and they squirt out leaving skid marks where the rubber bad is on the low end. Any tips on getting up there? I've seen videos and all of them show them placing the ramps under the tires without any "run up" room between tire and ramp edge.