Everything posted by 240ZMan

-

Pads recommendations for Toyota 4x4 calipers?

Thanks Mick, so if I get what your saying, the racing pads sacrifice pad life for the ability to generate more friction at higher temps?

-

Pads recommendations for Toyota 4x4 calipers?

Ed, your comment leads me to another question: before my last track day my pads were nearly gone (I'd used up about 1/2 their total thickness on the previous track day). Knowing I plan to switch calipers I put whatever Napa had available, which was as you suggest, some generic semi-metallics. Actually, once they were seated, they did much better than I had expected. Only cost about $15 or so. So my question is this: what do you get when you buy the expensive pads? I know they don't last as long, so do they tolerate the heat and still produce friction when really hot? Seems to me the limiting factor on 240z's are the limited heat capacity of the solid discs and the limited ability of them to dissapate the heat they create. I hope I'm not opening up a hornets nest...

-

Pads recommendations for Toyota 4x4 calipers?

I'm getting ready to put the Toyota 4x4 calipers on my 73 240z. I'll be keeping the stock solid rotors. Given that the Toyota truck isn't what I'd call a "high performance vehicle", I'm wondering what others have done for brake pads? Are there any sources for something better than stock? My driving is mostly agressive street, with a few track days each year for good measure!

-

Attaching hood emblem

Ed, I'm missing the clips. The nipples look fine, at least for a 31 year old piece of plastic... I'll try Carl's suggestion and see if a local body shop has a clip. Otherwise I guess it's double sided tape. Daniel

-

what psi do you guys run?

Echocluster, I'd suggest you experiment. My '73 with stock suspension and L28 seems to do better with more pressure in the fronts. This yields less understeer at the track. On the street I run 35/30 front/rear. At the track I've bumped it up another 3 psi all around mostly to try to reduce the wear on the outer edges. Again, remember my suspension is stock. Daniel

-

Attaching hood emblem

The hood emblem on my 73 came loose and I want to reattach it, but I can't find an source for the "clips" to hold it in. And while I'm sure double-sided tape will hold, I know I'll regret it later How have others done this?

-

Dyno results - what do you think?

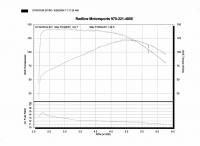

Abas, I'm not a tuning guru but at the dyno day there were two L28s with mods like mine, with the addition of a mild cam. One had triple webers, the other triple mikunis. Both put out about the same HP as mine, and both were much too rich at high revs. I suspect the richness hurt their power as they should do better, but the point is I think that both were over-carburated. There's a story I've seen mentioned many times about a guy up in the northwest who runs the quarter mile in the 12's using roundtops. I can't verify that, but suspect that it takes some very serious engine mods before the stock carbs can't keep up.

-

How do you install headers? Underneath or remove intake?

If you don't already have one, I highly recommend a 3/8" flexible adapter along with a deep socket. You have to be careful it doesn't get crooked and damage a nut, but it makes a few of the underside ones a lot easier to get at. If I were you, I'd be very worried about letting any of the muffler chain shops do this kind of work. They probably won't have the patience to get these bolts off and cleaned up. I used a wire wheel on my bench grinder to get rid of a lot of rust. I doubt the shop would do that.

-

Dyno results - what do you think?

Another question: I've experimented in the past with advancing the cam timing via the different positions on the sprocket to take up slack. I've noticed it extends the power peak to higher rpms at the expense of torque at lower revs. My question is if there is any INCREASE in power, or does it the same power peak just occur at a HIGHER rpm? Unfortunately I don't have access to the dyno again to measure this accurately. I figure someone might have experimented with this on a dyno with the stock cam.

-

Do I have to change the head gasket?

Finally had some time last night to work on this. I picked up a magnet on the end of a telescoping shaft (like an old FM radio antenna) at the local ACE hardware and after a few minutes of fishing, the washer was on the magnet. When I finally pulled the washer out the top, that was the greatest relief I can remember in a long time! Still can't believe I was dumb enough to drop it in the first place - only hope this is the last dumb thing I'll do with the Z - knowing it won't be:stupid:

-

Dyno results - what do you think?

As the operator explained it to me, the bottom chart is the air to fuel ratio. As the number gets smaller it means there is less air (richer). So we read this as I'm getting richer at the top end. Hence we tried turning the nozzles in a turn. He overlayed the two runs and they were virtually identical. And the engine didn't idle well at the leaner setting either.

-

Do I have to change the head gasket?

I dropped the smaller washer from the cam gear down the front timing cover (don't ask how :stupid: ) and I'm resigned to taking the front of the engine off to get it. A few questions: 1. Do I have to worry about it falling further into the oil pan? 2. Do I have to loosen/remove the head? 3. If the answer to 2. is yes, do I have to change the head gasket? Thanks,

-

Dyno results - what do you think?

Ed, I noticed the same thing. In fact, my first "butt-o-meter" impressions after swapping this motor in place of the old L24 was how much stronger it was at low revs. Looking at this chart I was surprised that there wasn't some increase in torque with revs. I suppose the cam/valve train would need to be changed to improve things, and the $$ would be significant.

-

Dyno results - what do you think?

I just got back from our local Z club event at the dyno. Results are attached. My engine is as follows: - N42 block with dished pistons (~80k miles) - E31 head (stock valves, ~10k on rebuild) - MSA 6:1 header w/2.5" exhaust - Pertronix electronic ignition - SU round tops with ZTherapy bodies, and .099 nozzles and SM needles I live at 6500 ft elevation although the shop was about 1000 feet lower. They say the results are corrected for altitude, temperature, etc. I tried 2 other runs. On one I turned the mixture nuts in (leaner) 1 full turn. On the other put the mixture back, and advanced the timing 4 degrees. In both cases peak HP dropped ~3 hp. So I figure I'm not too far off the optimum. Or am I? So my question is what you seasoned engine tuners think. Is there any "easy" power to be had through tuning? I'm not going to spend any more $$ on the engine for a while and instead begin to concentrate on brakes and suspension.

-

S12W and Wheel Spacer?

http://www.classiczcars.com/forums/showthread.php?s=&threadid=13509 I just read this post which sort of anwers my question. Still, if anyone knows for sure that the S12W WOULD work with the stock discs I'd be very interested to hear about your experience.

-

S12W and Wheel Spacer?

I'm a little confused here. I have a '73 240 and I'm going to keep my stock solid discs. I've read 2 opinions about the S12W calipers. One seems to say that they are fine to use with the stock discs and 14" wheels. The other is that they are for the vented discs from an S31. Since I might like to upgrade my discs to vented at some later time, can I go with the S12W calipers and use them now with my existing discs and 14" rims, and later upgrade to vented discs and 15" rims?

-

Header problem

No worries, Ed. If I were to do this again, I'd go the route you did. I just don't think it's likely that a bolt-on exhaust system is going to fit a 30+ year old car. Probably would have been easier to do a custom from the header back from the start.

-

Exhaust problem

I just finished going through the same thing as you. Here's the link: http://www.classicZcars.com/forums/showthread.php?threadid=12474&goto=newpost I would suggest you speak to Sal at MSA (x201). It's hard to get him live, but in the end he did the right things for me.

-

Header problem

Thought I'd give an update on how this all worked out. Turns out the supplier of the headers to MSA had a problem with the jig they use to bend and weld the pipes. They built up a second header, coated it, and got it to me. Also made some changes to the first pipe behind the header as well as the angle of the flange. It went together pretty well, and last weekend I had a local muffler guy make a few more bends as it was hanging down more than I liked. I also added an 18" glass pack as it was just a bit too loud for my neighborhood. Sounded great to me, but I knew my neighbors wouldn't have the necessary sense of humor:finger: It's a great combination now: quiet at light throttle, and still has a good deep sound when opened up. I had it on a local track on Saturday. 5 sessions and all is still solid. What a hoot! If you haven't taken your Z out to a race track you need to find a way. It's the most fun I've had in a long time! Brakes were a weak spot, but I expected that. Probably my next project...

-

All back together, but won't start

Thanks Beandip, turns out I'm using the MSA header and its gasket. But when I first installed it I wishfully hoped that I could "ignore" that the header flange wasn't as thick as the intake manifold. That didn't work. So I went back and ground the washers on one side to level them out. But i think I might have bent at least one stud the first time and so I still have a leak. I'm going to tear it all apart next week and see what I see. I hope I can see some discoloration where it's leaking and make the appropriate fix. Of course, nothing like doing something 3 times. I'm getting pretty good at taking the carbs off!:stupid: Have to say that it sure revs better and smoother. Can't wait to get rid of that nasty sound that comes from an exhaust leak. That sound just bugs me!

-

Header installation problem

So I put my new MSA header on yesterday and got the piping and all that sorted out. However, the flange on the header isn't as thick as the intake manifold. I had hoped that this wasn't going to be an issue so I just used the thick washers from my original exhaust manifold and let them settle at an angle on the studs that hold both the intake and exhaust. But I can hear at least one exhaust leak so I guessed wrong. What have others done? I fabricated a heat shield so I'm probably going to have to remove the carbs completely as well as the shield in order to get at the manifold bolts. Not a hard job, just not very satisfying when done for the 2nd, 3rd, time etc. So I'd like to just do it one more time and be done. Thanks,

-

All back together, but won't start

That was it. Rotated the oil pump shaft 180 degrees and it fired up on the first crank. Now to deal with the exhaust leak from the header...

-

All back together, but won't start

Just thinking this through a bit further, since I already have the head on the engine, the only way to do this is going to be to drop the oil pump and put the shaft back in 180 degrees rotated, right?

-

All back together, but won't start

Thanks guys, that's probably what it is. I didn't check to see the position of the dizzy shaft when I put the head on and set the cam timing. So the ignition would be firing 180 degrees off from what it should be, right? This is one time when it would be nice if the dizzy WASN"T keyed to go in only one way... :stupid:

-

All back together, but won't start

I finally got all the pieces for my new exhaust and assembled it all but can't get it to start. What I've done: - Removed my tired L24 and replaced it with an L28 block bought on ebay with my existing E31 head on it. - Installed a new MSA 6:1 header and 2 1/2" exhaust - I did not remove the oil pump so I figured I could just put my old dizzy w/Pertronix back as it had been on the old motor. - I didn't change any settings on my carbs as they ran pretty well before. What happens is that during cranking now and then a puff of gas comes out of the carbs. I also hear something from the exhaust, like a muffled backfire? The engine never sounds like it's about to start. I've moved the timing around within the limits of what the dizzy can move (+/- ~10 degrees) but it doesn't make any difference. I connected the timing light and it flashes when cranking. I checked and when the crank is at TDC the rotor in the dizzy is pointing to the #1 plug wire. I'm out of ideas without starting to tear things apart. Of course, I'm tired and may be missing something obvious. Thanks in advance for any suggestions.