Everything posted by HusseinHolland

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

Great idea. I thought about checking the pump control circuit, and didn't get to it. I'll figure out a way to monitor the voltage at the pump connections & see what I get.

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

The thing is, if that were the cause, I would expect the pump to start whining as the restriction takes effect - I manually crimped the feed hose with the engine running and the pump noise increases significantly. when the symptom manifests, there is no change in the pump sound, and the fact that blipping the throttle & holding an steady elevated idle can 'pop' the pressure back up. Makes no sense to me .

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

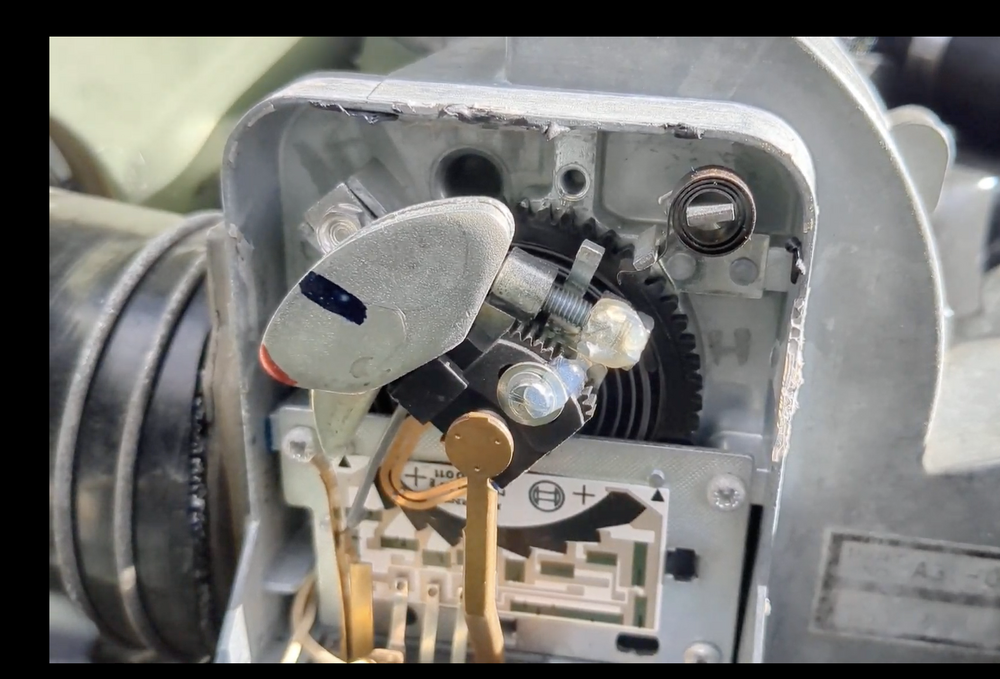

EDIT - Note that the cause was the EFI system relay failing Tried to take the Z out for dinner last night, and only got a block from the house, no throttle response, engine stalled. Restarted readily, but would only idle. WBO2 indicates that the system goes waaay lean when any demand is placed on the delivery system. Today I looked it over. Again, the car would idle fine - but - sometimes (ugh) the pressure (mechanical gauge after filter, before rail) drops off until the engine stalls. Blipping the throttle would sometimes make the regulated pressure pop back up. YT Vid What is bugging me is what the heck in the system could cause the pressure to drop off & then pop back up? I'm not familiar with the workings of the air flap meter to understand if there is an element of it that can shut off fuel delivery. I replaced the fuel filter to eliminate a possible flow restriction. After that, I swapped out the fuel pump, no change. Removed the pulse damper, no change. I pulled the cover off the AFM, couldn't see anything out of order, checked the connector & pins. When the pressure drops off, the pump doesn't get louder, so I don't think it's a flow restriction with the tank or feed side. By the end of all my futzing the car was running normally again. Very frustrating, since I haven't found anything concrete. Did remember to put the protector plate back in finally. Couldn't find the original screws though

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Removed and remade the targa, 1/4 and trunk striping - the coating on it had peeled since I last did them, 3M tape too.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

I am. I will 😁

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Replaced the ac clutch today. I bought one meant for a Mini, so I had to change the harness connection, and modify the outer magnet plate hub, the Mini version had a smaller OD compressor shaft. Also had to redrill the magnet mounting plate. Why might ask why go to all the bother, it was because the Volvo factory clutch is over $250, if you can find one, vs. $50 for any number of readily available sanden clutches . When I looked online, for ones that might fix the Volvo DCH compressor, I was focused on the bearing depth and dimensions. New belt length is (6PK)1650, 25mm shorter due to reduced OD of the pulley. Took some back & forth to get the plate clearance in the .010-.015" clearance range. Fortunately I had a stash of M4 stainless washers Engine bay needs some detailing, the body shop left my car out in the rain, uncovered when they had it last fall. I NEVER did that - if it ever got wet, I drove it until it was dry back there.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Working on the X1/9... I Installed the new frunk inner cable after school, fairly uneventful install. To access the lock screw on the latch, I had to remove the right cover mesh, undo the latch, & move it around some to get to the lock screw. Today on my lunch break I ran the thin 3M tape down the fender, around the nose and back up to the pass door edge. I think it looks OK without the wide stripe on the nose, at least I feel that way today.... After school I removed the spoiler, located the correct push pins & primed & painted them to match. I don't like them standing out more than necessary. More tomorrow

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Thank you Steve. Unfortunately it's going to be sometime before the next major update on the Z - I need to get the X1/9 prepped for BaT, and get some more tidying taken care of beforehand. So, keeping track of what happens in-between helps me😁 Z is back inside, I'm going to drive the X1/9 while the weather is clear for a couple days, also to make sure all is good with it

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

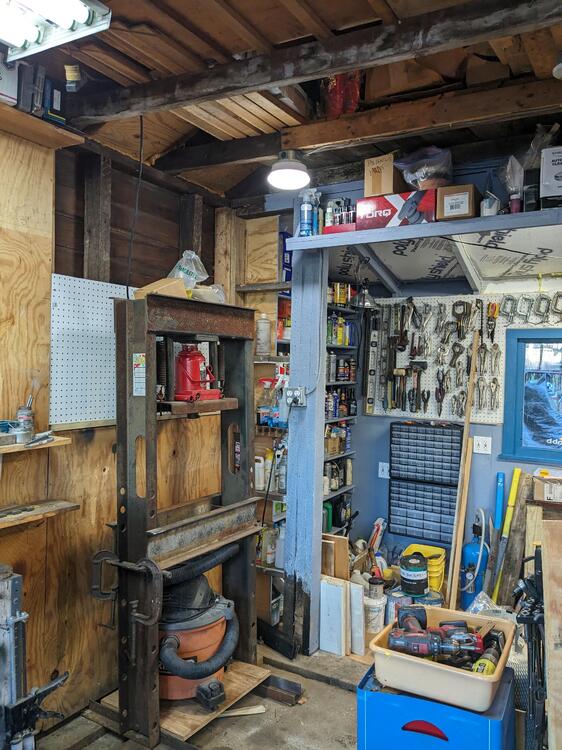

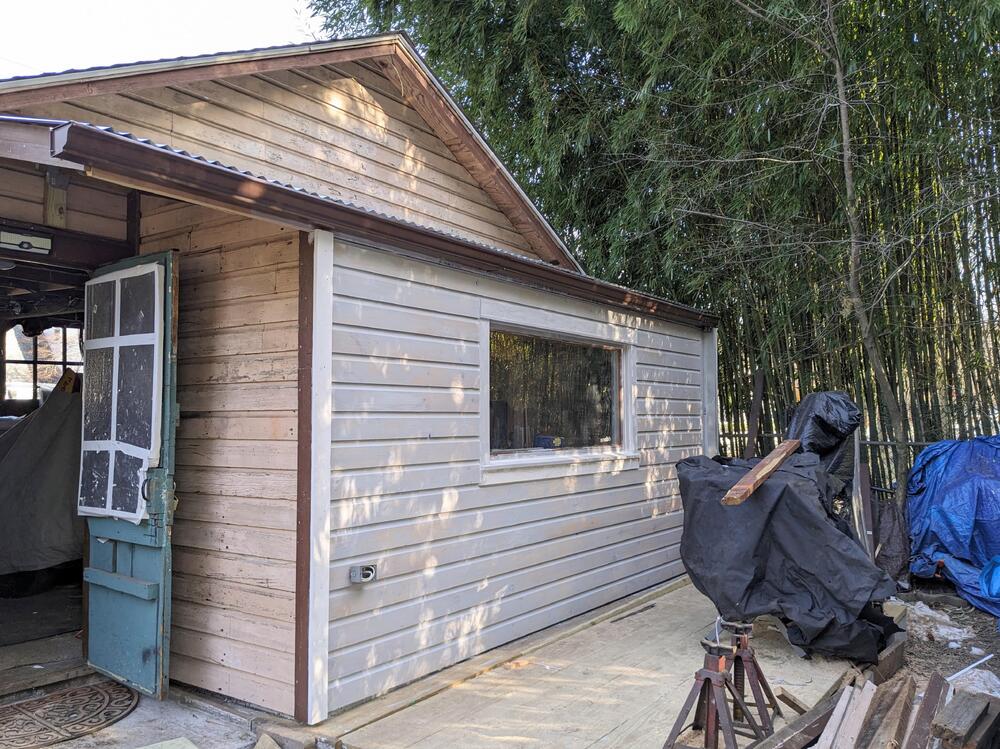

Slowly getting the south wall cleared. Need to move all the stuff at the base so I can remove the sheathing, add insulation & pegboard, then rethink the shelving for this section

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Larger items - Volvo C30 Turbo/manifold, cat/DP, Intercooler plumbing, driveshafts, spoilers, bumper panels/skirts, Instrument & dash panels, Headlamp assemblies, Boxes of relays, Bosch injection & ignition components, Boxes of parts for other projects: LS conversion parts for the pickup, VQ35DE subframe kit for the Z, new repro door panels & rear spoiler for the Z, and so on. That will need tiding up also. 🤪

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Continued with the clearing of the shelves on the south wall, which also meant I had to make some shallow shelves on the left of the back wall to store more chemicals Put stuff up on the right, so slowly making way also added a 7" deep x 12' strip of pegboard on the backside of the LVL beam, to store rolls of hose that were also taking up shelf space. Much more accessible this way - and harder for me to forget I already have

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Light rain (mostly) much of the day - even so I spent most of it outside, moving stuff around behind the garage. Just needed to make it a little more orderly than it has been the past couple months. Had to cut a bunch of 25'-30' bamboo in the far left corner, so I could relocate the truck bed liner & other bulky items out of sight. One of my neighbors likes to use the bamboo poles for his veggie garden, so I cut some down to about 10' After that I got some top coat on the shelving and upper sheathing Still had a little time, so I cleared the top shelf on the left & removed it, so I can move forwards

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Hey - the two lower siding runs I'm going to replace, and cut out the sill plate as needed, then I'm going to pour a concrete foot(ing?) and put a new sill on top. Outside, I'm going to keep the gravel level below the sill so rain etc can't creep up/in to the siding Got some primer on the upper sheathing and top shelf, I spent the day in the city at the Whitney Museum with fellow Art educators, so that was all the time I had to spend on the garage.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Still plugging away on the inside sheathing/insulation/shelving - I cut the 4x8's in half so I can put the top back together, and deal with the sill plate later. I've got too much stuff under my feet right now 😞. Added 3' of pegboard (H) and 10' wide Putting a 10' shelf up high There is a gap at the base of this 4' section (2nd in from the right/west end) where the clapboard rotted away from soil/moisture, I stuffed foam in it for now, just to try & deter critters. Raining steadily for the last couple of days, and in fact there is not a lot of water on the south side of the garage, I did add a drainage gutter just before the rains came.. I think I can get away with just putting a gravel bed to keep soil & water away from the foundation.

-

ECU Connector

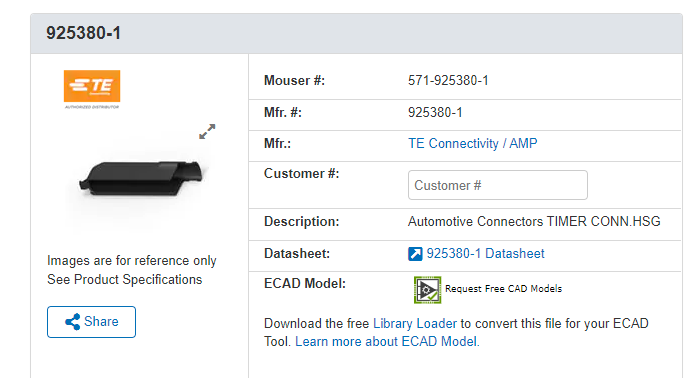

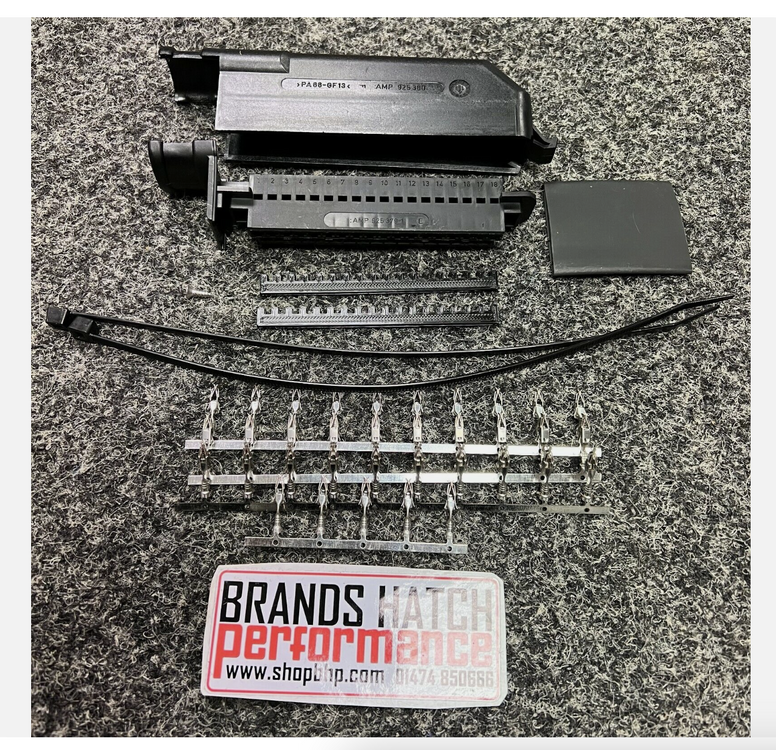

Good point - I hadn't considered he meant the ECU side connector/housing (825213-1). Those you can also buy new....

-

ECU Connector

The part number is actually right on it - 925 380. Mouser carries them (JPT terminals separate) for about $9

-

ECU Connector

Should be the same 35 pin AMP connector used on all L-Jet systems, Fiat & others used it through the '80's. Example on eBay

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

We have a high water table - I have a sump pump in the basement that operates much of the year, just less in the July/August time frame. That was the one that died just before we went to Baltimore & partially flooded the basement main area. I'm going to have to figure out what to do about the drainage behind the garage, however I don't want to get sidetracked on that right now, so I'm going to deal with the sill repair & siding, and leave the drainage until later on. Rained all day - so I got the receptacles wired (GFCI at the start of the run, shown earlier) & added a waterproof housing & switch for the new exterior door lighting Cover didn't arrive in time for me to add it before this pic This sucka is bright!

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

This is the first time I've tried them. I've never had an issue with the twist nuts, and I have plenty of them, so I will likely continue to use them. Yeah, I'm glad I didn't realize they were there in the warm weather. Since rain is in the forecast, I decided to dig off the south side of the garage, where I had just removed that plywood. So that I could figure out how bad it is. This is as far as I got before my back said that was enough.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Wired the overhead LED for the new space Added a GFCI receptacle & switch for the light. The other receptacles will be fed from this one Wired the outside receptacles Added a shelf here - I'm going to use the right side for my laptop removed the 4x8 sheet of plywood behind the press - cut in half, I'll be adding pegboard above. I'll have to address this mess from the outside, so I won't screw the plywood back in place for now found this above the door when I removed the plywood to run conduit for an outside light fixture above the doorway I like these push-lok connectors - so much easier to confirm connection than the old twist nuts

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

It was in the 20's this morning, but the sun was out. I framed out the casing on the window, and got the rest of the siding up & primed before it was time to clean up for the day. I cut the sill to 12º, and back-caulked everything. Have to get done with the exterior soon, I'm tired of looking at the tarped wood pile

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Small things again today. Primed some stuff inside, added some pegboard near the door, and since the sun was out the past couple days, the snow cleared outside. I started putting the siding up while I can, even if it was only 30ºF in the sun. Supposed to rain later in the week, so I'd like to get it done before then

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Thank you - the garage footprint is only inches over 18' sq. I'm used to constantly moving stuff around anytime I work on a project - that more than anything I'd like to reduce. Adding the 4' on the back helps immensely (given the scale) - moving forward I'm going to draw up plans to add on to the North wall, again, not much because I don't want it to be too obtrusive going in towards the house/deck. Even if I add just a single floor 6' additional width over the 18' depth, it would give me room to clear the main floor completely as a work space, which would be great, and it wouldn't overly impact the side yard. I still prefer to work on the cars outside if the weather permits, but much of late winter & early spring is either too cold or too wet...