Everything posted by HusseinHolland

-

Replacing All Large Opening Seals & Hatch Small Seals

They are, but clearly they can still rust depending on the grade. Mine have rust "powder" on the inner surface that presses against the door seal.

-

75 280Z winder mechanism & release mechanism

-

Replacing All Large Opening Seals & Hatch Small Seals

Also - took the pass door card back off to get to the outer handle link rod - I though that was ht issue - turns out the door handle lever snapped off I'll have to order new handles

-

Replacing All Large Opening Seals & Hatch Small Seals

Cleaned up the 78 window frames (sashes) I bought. Certainly not 'excellent' condition - multiple scratches from storage. Hopefully I can polish most of them out, never tried before. He didn't pack them with any buffer between them either. Have to figure what compound may work without removing the coat. My existing frames are worn thin & have surface rust on the seal surface, which is why I want to replace them Stripped all the old inner & outer seals

-

Modern injectors, new fuel rail - no heat soak problem

10-11 is just dumping gas. Even with a high pressure Turbo, you really don't want much under 12 for good power. I was mainly checking that I had uniform values at all the injector sockets, since they all originate from those 2 wires that feed the ballast. Just to be clear - the AFR's weren't on target with the ballast in place - I had the lean condition at warm idle, and some unevenness under load conditions. It did feel better than the stock injectors, but now it feels really smooth by comparison, so I'd say removing the ballast is wise with high impedance injectors.

-

Modern injectors, new fuel rail - no heat soak problem

Warm idle, AFR's are now steady 14.7-14.8, with the pot set back at .8 (800ohm). The last few days, I had to enriched the pot value to 1, 1.1 1k-1100ohm) to get the AFR back down form 16.3-16.7 YouTube Vid EDIT - test driving under varied conditions, including WOT - AFR's are good across the board, until I go WOT, then it's way too rich (high 10's-11), so I reset the WOT TPS contact so it's not in effect until 70-75% YouTube Vid

-

Modern injectors, new fuel rail - no heat soak problem

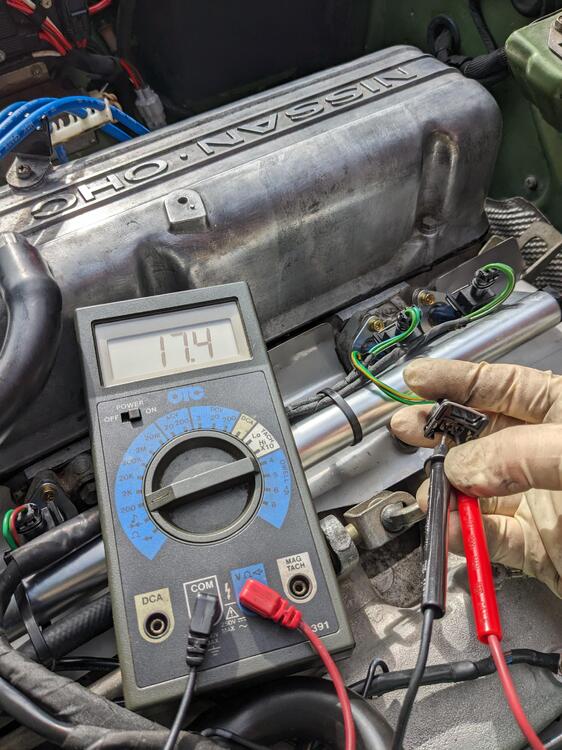

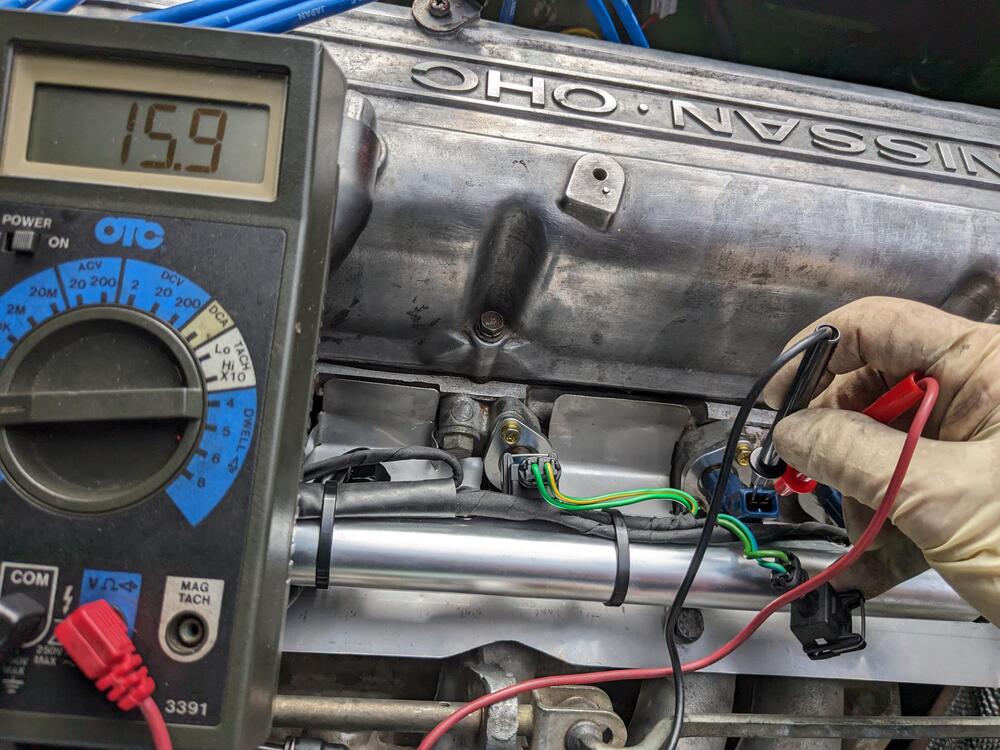

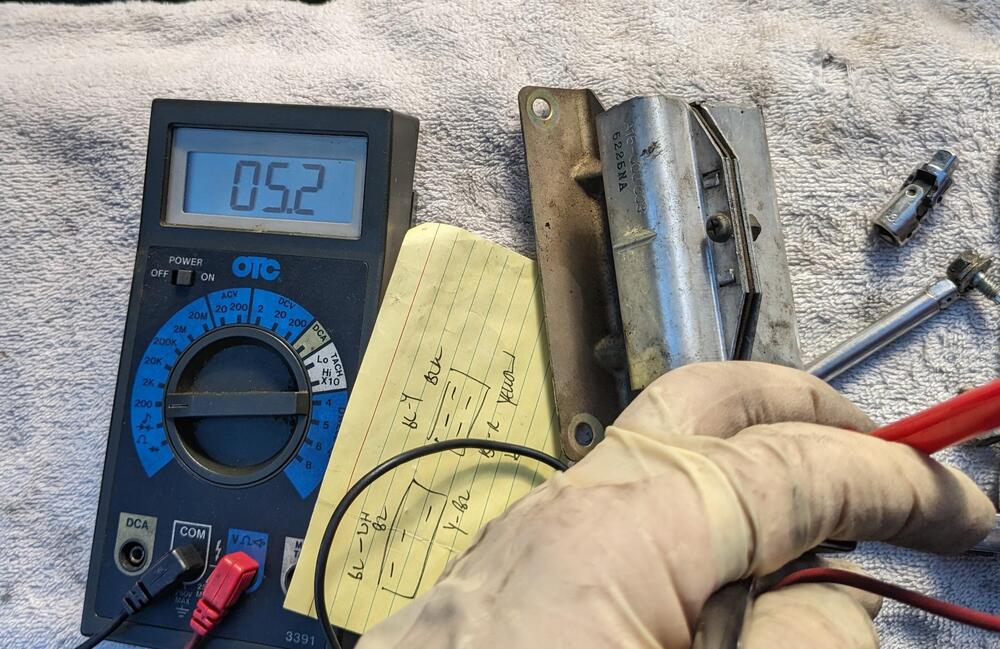

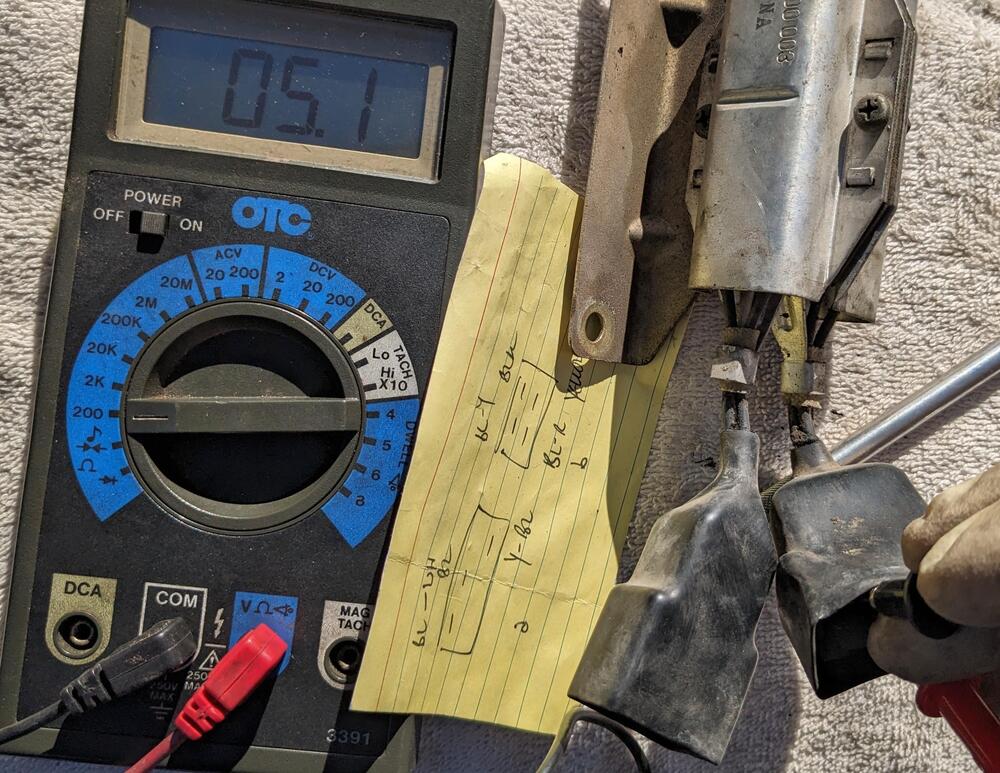

Took a number of resistance measurements today lead resistance .3ohm harness resistance, with ballast 17.1ohm (all the same) Injector resistance - All 15.6ohm stock injectors 1.9-2.0ohm Ballast pack - very clean terminals 4.8-4.9ohm Harness resistance with Ballast pack bypassed 7.6ohm 2 bypass plugs to maintain the integrity of the original harness. 4pole (3 wire) sleeved with heat shrink to approximate stock boot 6pole (5 wire)

-

Modern injectors, new fuel rail - no heat soak problem

I asked about the high/low ohm injector combination issue on one of the Volvo forums, as this applies to some early Volvo LH systems. One of the members had this to say: "sorry, you don't want to do that. If you use high impedance injectors with a resistor pack, it roughly doubles the resistance. This means the current flow through an injector is ~1/2, which results in ~1/4 the opening force on the injector pintel. This can cause slow injector opening and/or the injector not fully opening." Another gave more detailed response: "Your injectors are clearly opening; but, the injector offset (which some people refer to as injector opening time) is affected by the injector operating voltage which is now much lower than design. When you reduce the injector voltage the offset increases and the actual injector pulse width is reduced compared to the commanded pulse width. At wide open throttle or close to wide open throttle where the commanded pulse widths are large the error caused by the increased offset may be less significant although the engine will run with a slightly leaner fuel mixture. At idle and low engine load where the injector is operating with small pulse widths it will have a larger % effect on the actual pulse width. At worst, if the reduced pulse width intersects with the injectors non linear region you can cause extremely unstable idle. At best, the reduced pulse width will result in a leaner than ideal fuel mixture at idle and low engine loads." and "I assume that 205CC means 205 ml/min flow rate for the injectors. If so, that is not a particularly large injector which means that your idle pulse widths are fairly large and probably well out of the non linear region which means the increase in injector offset may have a less significant effect. So, the car may still operate right now; however, if you ever have to do a cold start on a cold day with a compromised battery you may run into a no start condition. The reduced battery voltage may result in a complete injector non opening condition at worst or really difficult starting" finally "The good news is that this should be easy to correct. This may be as simple as just deleting / by-passing the original injector resistors. What you need to do is measure the resistance of the original injector and the injector resistor. Add the values together. The 0280 155 712 injector appears to be really high resistance - 16 ohms. As long as the added value of the original injector and injector resistor is less than the resistance of the new 0280 155 712 injector it is 'safe' to just delete / by-pass the injector resistor. I suspect that this will be the case because most low impedance injectors were around 2-3 ohms with external injector resistors in the 5 - 10 ohm range so a total resistance in the 7 - 13 ohm range." I'm going to go ahead and bypass the resistor pack, after I measure the values.

-

Modern injectors, new fuel rail - no heat soak problem

Thanks -yes - having to re-do stuff due to product quality control issues is a pain in the butt. I really can't move on to other things (in my head) until I have the issue resolved.

-

75 280Z - Updating fuel feed & return lines in the engine bay

Not sure I have a chamfer bit in the correct size. I don't want to do anything to the rail until ProtunerZ makes a determination. If they ask me to send the rail back, it won't be any good if I have modified it. If they suggest I do exactly that, rather than replace it with one properly seated, I will ask for a partial refund on the part. It's already dropped $45 from what I paid, due to their Black Friday Sale....

-

Modern injectors, new fuel rail - no heat soak problem

Yes - I always check the (meter) lead resistance first - I'm used to doing that for doing resistance checks on ground circuits. My leads are usually .1-.3ohm, depends whether I'm using the probe or clamp set.

-

Modern injectors, new fuel rail - no heat soak problem

I do not. I can measure one tomorrow & post back 🙂 EDIT - looking up the Bosch # online, 16ohm is the listed resistance value So 16+6 ohm vs 2.4+6 ohm

-

75 280Z - Updating fuel feed & return lines in the engine bay

Thanks for the input, Zed Head. Yes, it should have the chamfer seat. That's the only way an ORB fitting can seal. They provide the ORB to 6AN fitting that is intended for the purpose, so it's not as if there could be an error in terms of the fitting used. The chamfer should have been cut as with the pic you found of the end seat.

-

75 280Z - Updating fuel feed & return lines in the engine bay

It's 6 AN Male (which has a 37º flare seat) on one side, and ORB-6 (o ring seal) on the other. ORB -is not a tapered thread like NPT. The seat in the rail should have a chamfer for the o r-ing to compress into. The ORB-8 end seats had the proper chamfer, I didn't take any pics of the that EDIT - ProtunerZ replied to my email - they are looking into it, they say they've not seen this issue before.

-

75 280Z - Updating fuel feed & return lines in the engine bay

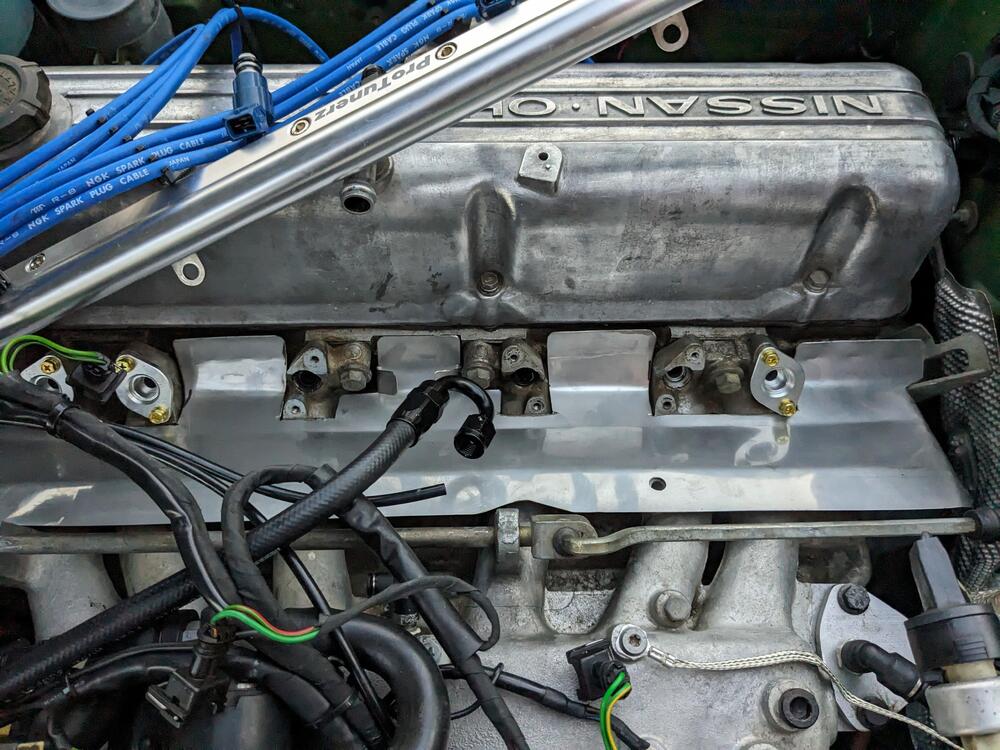

OK - so couple issues. One is that I have not been able to get the ProtunerZ rail CSV port to properly seal. They use a ORB-6 to AN fitting to seal the port. Problem is, they didn't cut a proper chamfer seat on that port (unlike the end ORB-8 ports). I've tried swapping fittings & o-rings, even adding a crush washer & thread sealant -doesn't matter it still seeps since the ring is being pushed out rather than into a recess as designed. It became easier to see today, since I now have the heat shield acting as a tray below Lack of proper chamfer seat I've sent pics to ProtunerZ, so we'll see what they say about it. The other thing was that taking the rail in & out, I damaged 2 injector lower rings. The adaptor bungs also have no real chamfer to get the o-ring started when inserting, so, unless one is very careful the seals **** in the adapter as the rail is seated on the manifold, and the o-rings get cut in the process. I didn't really notice where the slightly irregular idle beat was coming from until I had the heat shield , as that reflects the sound of the air leak & sends it to you when standing on the driver's side. I couldn't tell exactly where it was coming from (injector or base adaptor) so I sprayed them with carb clean to isolate the air leaks to two injectors I still removed the adaptors again & rechecked all the seat orings, they were all good Back together again

-

Modern injectors, new fuel rail - no heat soak problem

Just to come back to this - I was referring to the new injectors & rail with the stock ballasts. I haven't played around with combinations. I did find that the lean warm idle I have been seeing the past few days was actually due to my cutting 2 of the lower injector seals upon installation. I'll put the details in my engine bay fuel thread.

-

75 280Z - Updating fuel feed & return lines in the engine bay

There is no return on the motor, so it's not getting radiant heating as the stock system does. It's the same unit I put on my 91 Volvo pickup, which had a regulator & return on the manifold previously. Volvo started using the pod style (also used by VAG) in around 93 with the 850 series Bosch M4.3/4 EMS

-

75 280Z - Updating fuel feed & return lines in the engine bay

I think you guys misunderstand the Volvo FPR - it's not deadheaded as in the examples given in your link - it's still bypass with the return off the bottom of the regulator pod. The difference is that you don't have the return gas heating in the return section of the rail as with the stock setup. It's not going to make any difference to vaporization, since that issue is on the feed side of the stock system, not after the FPR, since that fuel is not part of the feed side equation I put pics of them in the FPR thread

-

75 280Z - Updating fuel feed & return lines in the engine bay

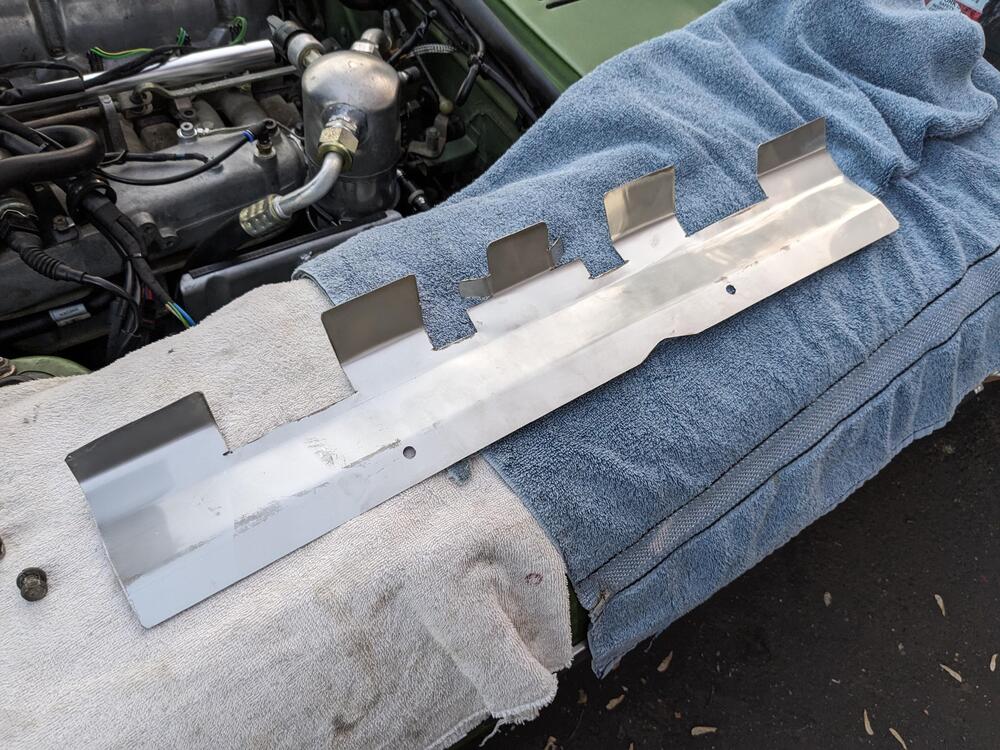

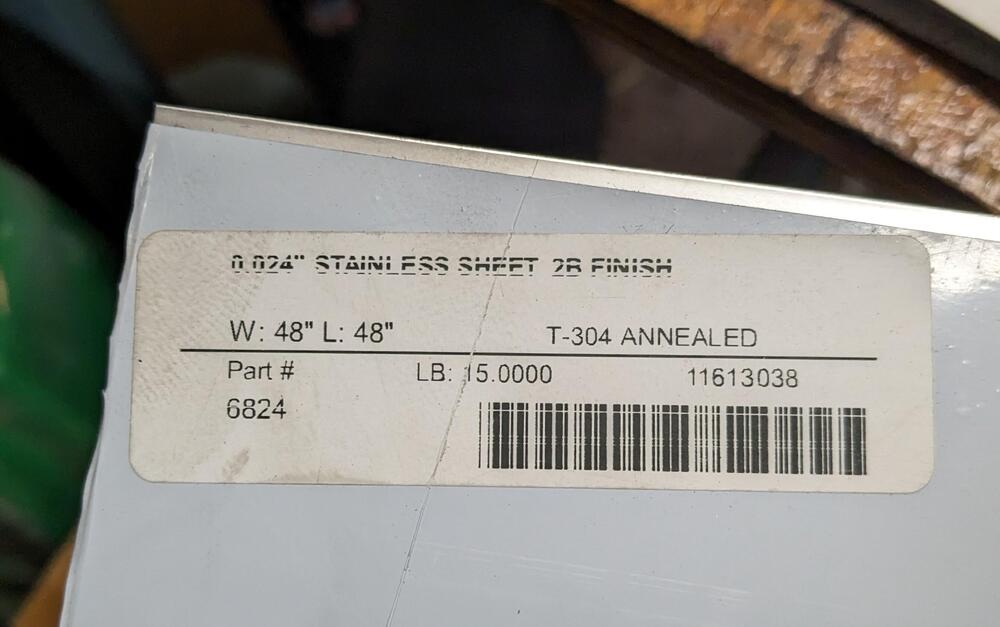

It's the same as any of the 90's-2K gen systems used before they went to entirely returnless in tank modules. Return is moved from the rail to the regulator, so only regulated pressure enters the feed and rail. Works as expected, and no additional heating of the returning fuel. Did you mean it may aggravate the hot start condition when used with a stock rail? That is conceivable. In any event, using the larger volume Billet rail seems to have removed the issue. I expect the extra material and volume within is what did the trick. Besides that, I still made the heat shield today, off the previous template. I used some left over T-304 sheet I had bought pre-covid, when the prices were still reasonable Had to chop 3" off the left end, I miscalculated that. Several in/outs to get the fitment right between the injector holders EDIT - going to have to re-wrap the injector harness to align with the new rail - not happy with the way it looks now 🙄

-

Modern injectors, new fuel rail - no heat soak problem

Good thoughts there. I can easily measure the two sets of injectors & note the resistance values. As with the Clock thread, I always get ker-fuddled when doing the math on resistance values, although in this case it would simply be addition, since the ballast & injector are in series, not parallel. Then use Ohm's Law to figure out the Voltage or Current passing? EDIT -I was just looking in the service manual, it doesn't actually give a test value for the resistor, just whether there is a voltage continuity in each individual injector circuit.

-

Modern injectors, new fuel rail - no heat soak problem

Thanks for the input - I do actually see a little leaner idle once the engine is fully warmed (15.7 range instead of 14.7) when idling after a drive. I can always adjust the potentiometer to compensate, but then it's not a hands-free system. I guess I will make a jumper for the two connectors & see if it changes that aspect. Otherwise, I don't see any reason to alter it, it feels much smoother overall, and as mentioned, the hot or cold crank times are MUCH better with this setup than the old.

-

Modern injectors, new fuel rail - no heat soak problem

@Zed Head - just to revisit this - you left the injector ballast pack in place, and ran with high imp. injectors for an extended period? Can't find any definitive on line info on leaving the system this way. I don't want to run into issues down the road due to the reduced current to the injectors. It certainly starts (shorter crank time) & runs much better with this setup. No sign of heat soak, however I'm still going to make an additional heat shield to protect the composite injectors. The only reason I am reticent to touch them is potential need for re-wiring that end of the harness due to the age & exposure of the terminals/housings (if it ain't broke, don't fix it)

-

75 280Z - Updating fuel feed & return lines in the engine bay

Forgot to add here - I had removed the Datsun FPR, and installed a Volvo FPR pod that incorporates the return, so no return on the motor I subsequently replaced the fuel rail & injectors, which meant modding the feed line I didn't care for the transition from the AN braided, and the barbed FPR port hanging out, so I reworked the feed side to tidy it up. Single 6AN braided hose from the rail to the fitting for the fuel gauge, then barbed 6AN 90º elbow into the FPR outlet hose. Not a huge fan of 90º fittings for the fuel supply, however it is all larger ID than the stock setup, and a smooth arc would have sent the line way to far forward Ignition wires need a new standoff, now the one on the stock rail is gone - I have a tie wrap holding them down so they don't rub on the underside of the hood

-

Modern injectors, new fuel rail - no heat soak problem

One of my sisters lives in Tunbridge Wells - so you are about 1/2 way between the two

-

Modern injectors, new fuel rail - no heat soak problem

I'm actually running the system setup at higher fuel pressure (3bar, w/vacuum reference), and higher ECT values (900ohm increase) to get it richer - with stock pressure & injectors my system was markedly lean - noted once I had the WBO2 in place to monitor AFR's.