Everything posted by HusseinHolland

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

So, I shouldn't have declared it resolved. 😞 Started fine cold, but as the engine warmed, pretty quickly the AFR's climbed back into the 16 range, so it would seem possible that there is an issue with the ECT. I tried plugging in a Volvo ECT, and with it pressed against the t/stat housing the AFR's were where I wanted them to be - 14.5-7 range at idle, so I swapped it out after the engine cooled. With it installed in the cooling system, the AFR's went even leaner. I'll order a new ECT, just to safe. I'm going to have to investigate a thorough functional test of the AFM also.

-

Designing A/C System Using Other Cars Parts?

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

I did both openings 1/8" NPT & M5x1 Fixed the running issues! https://youtu.be/pvHhBw-u9Ro First I checked the ECT (cold, 70ºF) - 2160 ohms at the sensor at the ECU : 2180 ohms Normal OP temp 263 ohms. Values within normal range according to Datsun chart (thanks, ZedHead) I could swap it out for a Volvo one - & make it (marginally) fatter when cold.... Might need to do that depending on how the cold starts are now. Anyway, after that I went back to thinking about what could cause the hunting. I realized that when I did the TPS trigger signal, I didn't confirm that the relay I added had diode protection to prevent interference with the stock circuitry. I simply added a diode inline from the TPS to the relay to test the operation. With that in place, the hunting at 2.5K went away. So that aspect was resolved (YAY!) (Thanks also to @Captain Obvious for questioning the off idle interaction . The system still runs lean though. I don't know if all the cleaning out of coking in the TB & clearing other passages has made it leaner. I certainly didn't feel the lean running condition before I started all the mods. I looked at the AFM adjustment, and that made no meaningful difference. Manifold vacuum at idle is good. Regulated Fuel pressure is good While I cogitated on how to address this, I added the AC switch plate and added carpet mat stays So, I decided that instead of futzing with the AFM to try & tweak the AFR's 2 whole points richer, I decided to just raise the regulated pressure to 3bar - using a Volvo regulator of course As you can see form the video above, that brought the AFR's right where they need to be. new regulated fuel pressure under vacuum. Rises to 3bar with vacuum removed. Having confirmed the pressure is consistent & vacuum works I installed a nylon feed line & quick connect in the intake. Old FPR location is bridged with new hose above it. Bay Now I know the system is fully operational, I will revise the return setup, it is overly long - didn't want to cut down the hose that had to connect to the rail return until I knew it would work. With the fueling resolved, I'll switch the HEI module back & see if I can get that aspect resolved

-

Designing A/C System Using Other Cars Parts?

I did deal with the AC switch plate. I realized a rivnut would make the perfect shoulder nut Determined 14mm is the depth I need to seat the T/stat. Cut down a couple rivnuts until I got one that was right. Filed down the OD a touch re-threaded to 10x1, drilled out the cover plate to fit, notched the cap so I can tighten it down. should fit like this

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Thanks Z - good idea. I'll do that tomorrow. EDIT - I need to recheck the TPS setting as well - I had that off when I blocked off the BCDD. Need to verify idle/off idle switch point I did remove the rails & hoses, blew out the lines. No sign of debris, but at least I've ruled that out. Also pulled the plugs & checked that. They're not old, and they look pretty even The only other thing I'm wondering about, is the AFM - the cover is not fixed, and I've knocked it off several times. I'm wondering if I somehow messed up the sweep. Can't tell if it's actually making contact with the board. Does seem like a stretch, though. EDIT - looking closely at this pic on the large screen at work, I can see two track marks on the circuit.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

I believe it, the issue is that the condition was not present prior to all the recent work, hence the need to revisit the fuel & ignition work I did. I have not touched the AFM, except to rewire the connector, but that was back in the spring & I drove the car many times after that w/o issue. I'll consider making adjustments to the AFM clocking, but not until I've ruled out any issues I may have created.

-

1975 280Z Using Voltage Regulator Wiring (L terminal?) To Add Charge Indicator Lamp

-

Center Console Install/Hardware

Thanks CptO I have the front lower two secured, along with the 3 countersunk head M5 screws inside the rear tray. I guess I'll make a cross brace to unify the "wings" I don't want them potentially flapping around.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

OK - so here's the problem: AFR's are way WAY to lean, even when stone cold, it started around 14 & went leaner from there. Normal op temp idle AFR's were 16.5-16.7 range. I disconnected the CIS system, and predictably it made no difference. Regulated fuel pressure is steady @ 36psi, and gets higher as vacuum decreases (when revving the motor off idle). Unplugging each injector in turn, affects the running. I'm going to pull the rail & check for any restrictions.

- 75 280Z - Another Interior Innovations Seat Upholstery Thread

-

Designing A/C System Using Other Cars Parts?

Found I have another (minor) issue - the T/stat can't be bolted to the console - the threaded section is too short for the depth of the console. I made a face plate using a Volvo 240 part. What I'm going to need is a shouldered nut, basically a top hat.

-

vintage dashes 280z

Center opening gap difference Left to Right Didn't notice with the original center console whether the dash aligned with the uprights. or if its staggered like this EDIT - forgot to add pics with the LED bulbs illuminated AS SteveJ mentioned somewhere the Tach lighting has reversed polarity sockets, so I use conventional bulbs there. Not quite as bright.

-

Center Console Install/Hardware

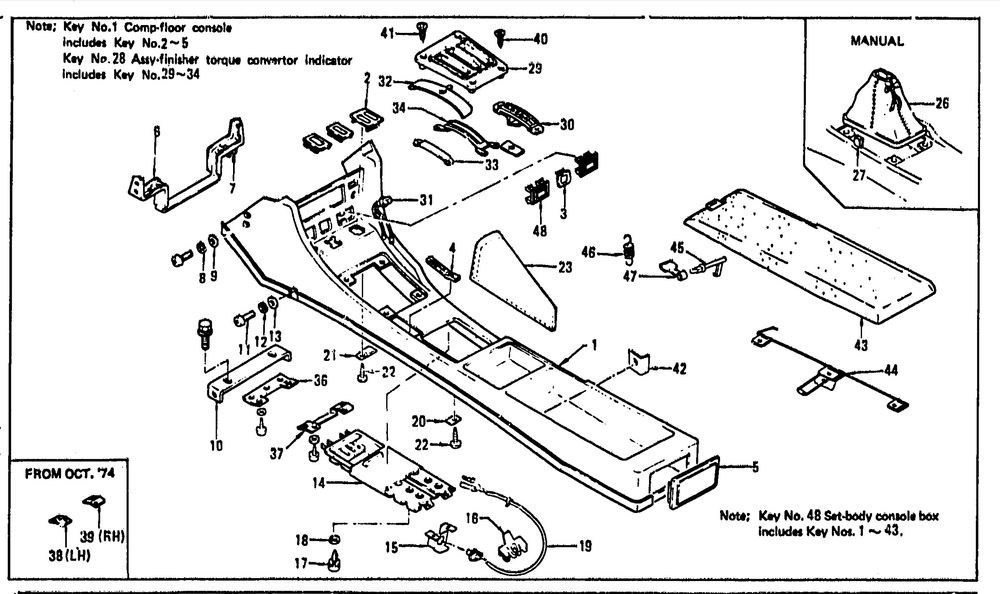

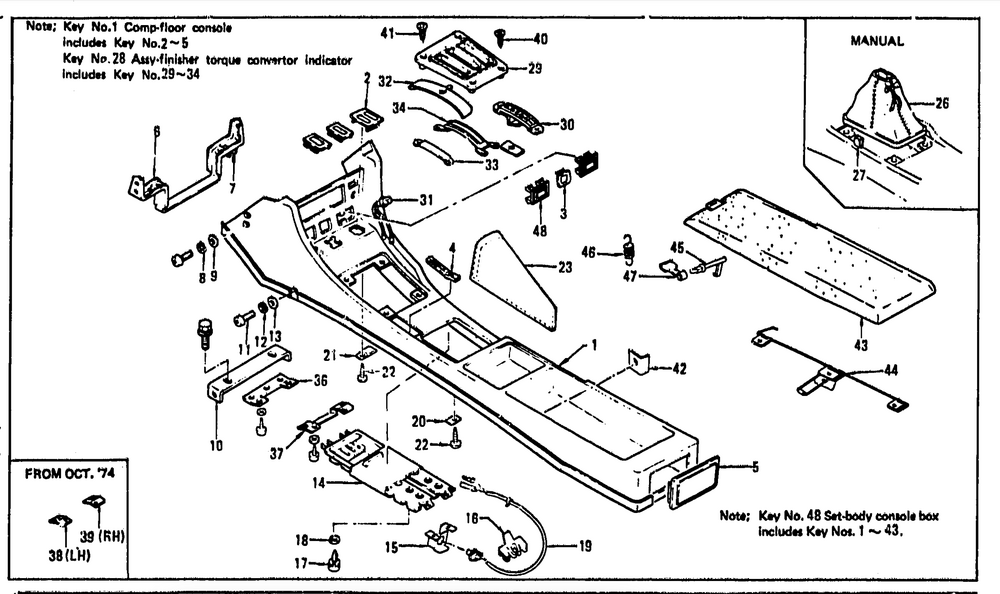

So, I installed the console today - and I don't have anything for the forward upper portion to attach to. I had a bracket that I thought was it - but it was just the tie plate that is secured with 2 M5 screws at the base of the center opening, that the HVAC control sits on. I can't figure out from the part catalog what would even constitute the support, unless it's the 'Radio Bracket" 96915 - N4200, #6 in the diagram Not really happy with the shifter boot fit - the opening is way too large for the stock shaft. Too much work to cut & resew.

-

Center Console Install/Hardware

It's Leaf Green with regular black interior - I didn't get custom stitching when got the seat upholstery

-

Center Console Install/Hardware

-

Center Console Install/Hardware

It's a shame that so many ppl don't think to add pics that would clarify so much. I installed a leather boot in mine, getting ready to put the console back had to cut a clip for the rear, the full width don't fit the aftermarket leather boot

-

Center Console Install/Hardware

Perfect. I'm also replacing my center console with a new piece, and the original was missing all the mount hardware. I looked in the fiche - and had to 'assume' the forward screws were self tappers, since they are not described or assigned an item #

-

vintage dashes 280z

Finally getting the Vintage dash back in. Fit is very good, however there does seem to be excessive gap on the vertical surrounding the center console trim. I'm wishing I hadn't precut the excess vinyl to match the factory in this area. I'll add a pic later to illustrate. I left much of the excess material in the glove box area, I'll deal with that when I'm actually ready to install the glovebox. Have to deal with all the HVAC ducting before that happens

-

75 280Z winder mechanism & release mechanism

Forgot to add the door glass rollers (ZcarDepot) went in - another thing I didn't know I was missing

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Yes, good point. I will do that next, before messing with the fuel rails. I can just disable it entirely (after warming the engine) by unplugging the module. When the IACV is shut, minimal air can bypass, so plugging those shouldn't be necessary for testing the 2.5-3K rpm condition

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

There is an ongoing issue with the HEI setup - I have the stock system in it now, as the last time I switched it back to HEI, I had the no start/slow crank condition return. I assumed the battery was low/ drained from all the start attempts, so I trickled charged it over a day to rejuvenate it, but that wasn't the cause. In any event, I ordered a genuine AC Delco HEI module, so eventually I will swap that out & see what happens. Since it starts/ runs as one would expect with the stock module, I'm leaving ti until the load condition is resolved. The only system aspect left to revisit is the fuel delivery at the rail, to check the FPR and tubes for any debris. The Volvo system takes the TPS idle signal for base line. The CIS Module uses an ignition pulse taken from the negative side of the coil to know what the engine speed is. If it were somehow interfering with the stock EMS, I would expect it would be across the board, however I can disconnect that wire from the coil to confirm that. I have the WBO2 controller ready to be connected to the car, just have to wire the power/ground - that is the main thing delaying the restart / testing at this point, don't want to foul the new WBO2 sensor. Hopefully the rain will stop by Sunday, and I can get back to it.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Thanks for the input, CO. Yes, timing only fluctuated in conjunction with rpm. Yes, either ignition module/setup I don't see it being related to the BCDD block off, that only caused a high base idle condition, there's nothing in there that could be flapping around. The CIS system is fully operational - the easy test is to crimp off the feed hose from the low vacuum external side of the tb, and that will negate the IACV, dropping the idle to whatever base value is set at the butterfly & idle compensation (bleed) screw. As soon as the hose is released, if the system is functional, the IACV will surge the idle to around 1200, then settle at the controlled value of approx 850. Turning on the AC raises the idle about 100 rpm, so I'd have to say it's fully operational. I did all the mods without the dash in place (so no wiring to EMS, etc), so I did not run the engine after each set of mods as I would normally do to function test the work. So, fuel rail hoses, HEI mod, CIS additions, were all done without post-testing each individually. Basically, Murphy's Law has struck me for not following my usual protocol 🤪 I've almost got the dash/console back together, so once that's complete (mostly need to wire the WBO2 controller, so I don't contaminate the LSU9 WBO2 sensor) I will run it again & see what's up. The reason I'm leaning to a restriction is in part due to the fact there were hose particles evident when I removed the lines, and currently the system pressure does not drop off within the usual time frame (typically within a hour), it holds pressure for HOURS. I'm just going over the things I fiddled with to double check my work.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

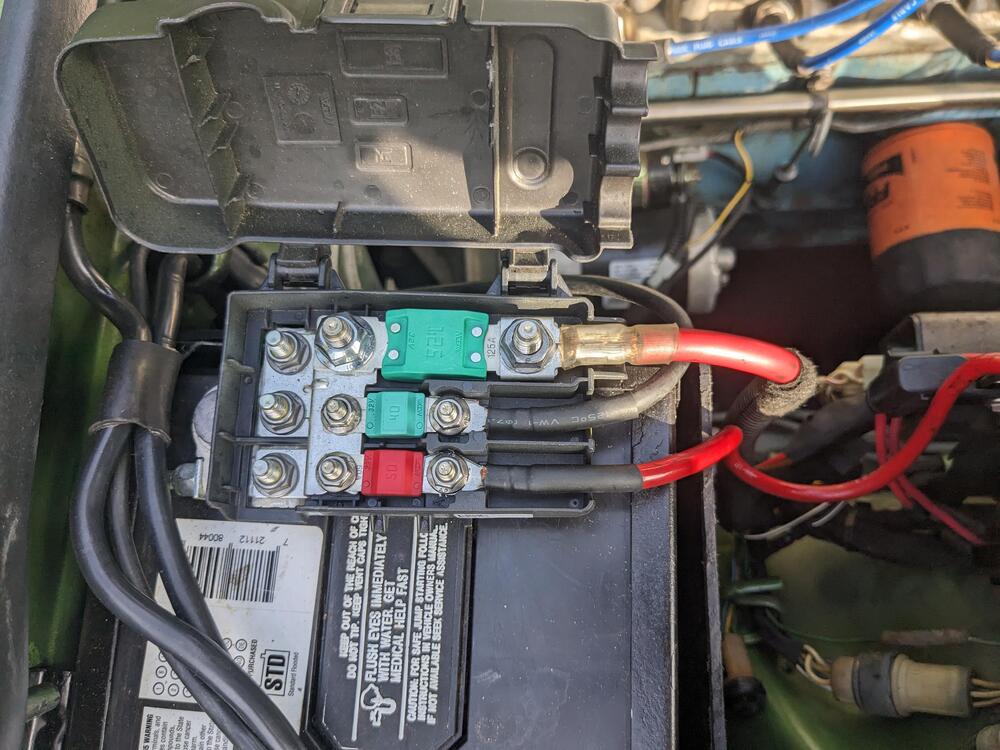

Apologies first of all for cluttering your thread with my problems! I'm still going to remove the rail & flush it. I have had situations where regulated pressure indicated was in range, but volume under demand was not. I'll have to see if I can record line pressure somehow on this system. Sorry for the confusion with the coils & ballast. I am NOT using the ballast with the HEI setup, that was when I switched back to the stock setup to test. The coil is relatively new (old stock), however I did try a couple others I have, no change The 125A breaker is on the starter feed, so the current draw with dwell/timing out must be very high. I can switch it out for a higher rating, but that won't resolve the cause. I've left this alone for now so I can get the interior /dash reassembled. I've also installed the WBO2 for the AEM controller, so I can see what the AFR's are doing when the symptom manifests.

-

1975 280Z Using Voltage Regulator Wiring (L terminal?) To Add Charge Indicator Lamp

wired my relay feed to the L terminal via a new charge indicator bulb. Circuit works exactly as @SteveJ described. repurposed rear defogger lamp for charge indicator Bulb holder w/spade terminals

-

Designing A/C System Using Other Cars Parts?

The point of getting the car running right now, was so I could vacuum & charge the AC system, to make sure there are no leaks - so I can put the dash back together & reassemble the interior... I found that one crimp I had made was insufficient. The high side line fitting to the orifice tube leaked with the system under pressure. I re-crimped it, and was able to then fully charge the system. Pressures seem OK for an 80º afternoon, and it blows cold. Condenser fan doesn't come on until high side hits about 250, but then drops pretty quickly. Anyway, I now know the AC system is functional. blurry pic of recrimp. Fortunately it was a fitting I could access & didn't have to remove the hose to do the job.