Everything posted by HusseinHolland

-

75 280Z Clock Repair?

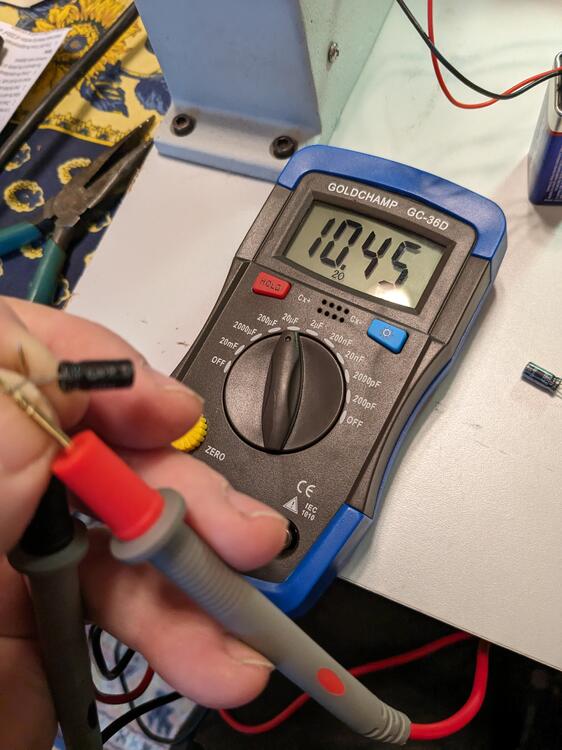

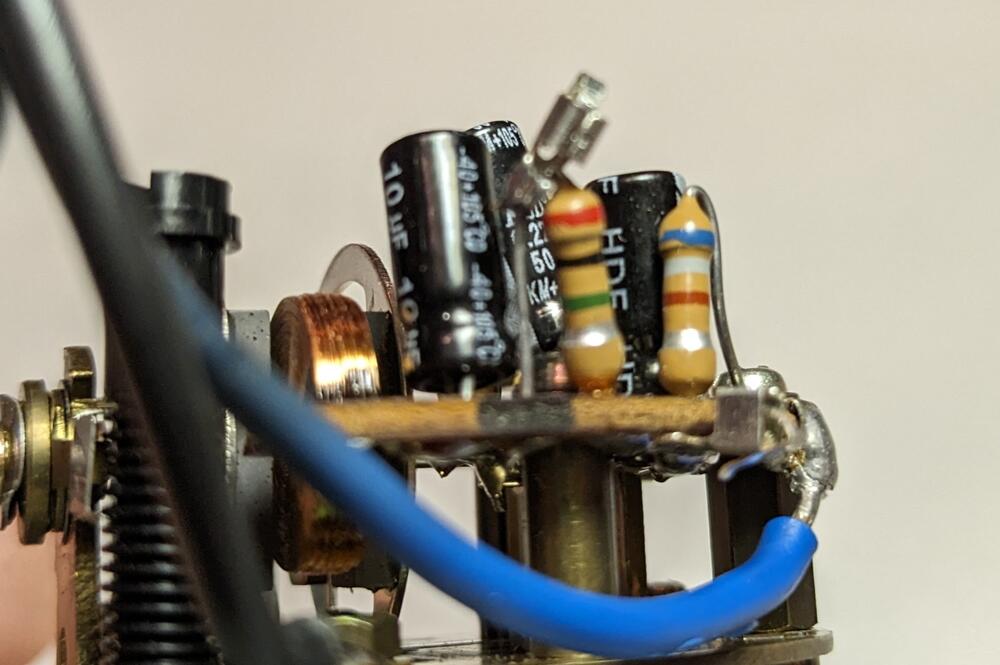

Been raining all weekend. Since I can't work outside, I got back on the clock repair. First, I checked some of the remaining caps rated at 10uf. Most of them were 8-8.3uf (!) , others were 10.5 or higher. The .22uf caps were all under 2.1, most were .2 or below. I removed the .22uf (read as .20) and one of the 10uf (read at 10.45) from the circuit board. The other 10uf read at 10.3, which was closer than most. I found one .215uf and one 10.1uf cap, so I installed them.I also added 2 sockets (not in focus, sorry) to allow me to plug in various resistors if needed to adjust the resistance of the 2M resistor Turns out, I didn't need that - with the replaced caps, the wheel was triggered & the clock runs. It's been keeping time since 2pm, so I'm hopeful that's that.

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

So on yours, you use a TPS wired into the stock EFI to set the integral IACV high flow mode off idle? I haven't seen anything like the BCDD on any early EFI Volvo - I'm curious why they went to such elaborate lengths to limit high vacuum on decel - don't they have oil control piston rings that would limit oil and unburnt fuel being sucked past the pistons on decel? I can't imagine it's there for any other reason than for emissions. I don't recall there being an issue with that on the 70's L6 Volvo EFI (D-Jet) motors, or on the Fiats that used the same L-Jet flap meter setup.

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

The main objective is to maintain a stable idle and base rpm, regardless of varying load conditions (AC cycling, etc.,). It provides low flow mode in decel, so that would be like the BCDD in that it prevents excessive manifold vacuum, and then has a high flow mode for any throttle position under acceleration. So, 3 modes.

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

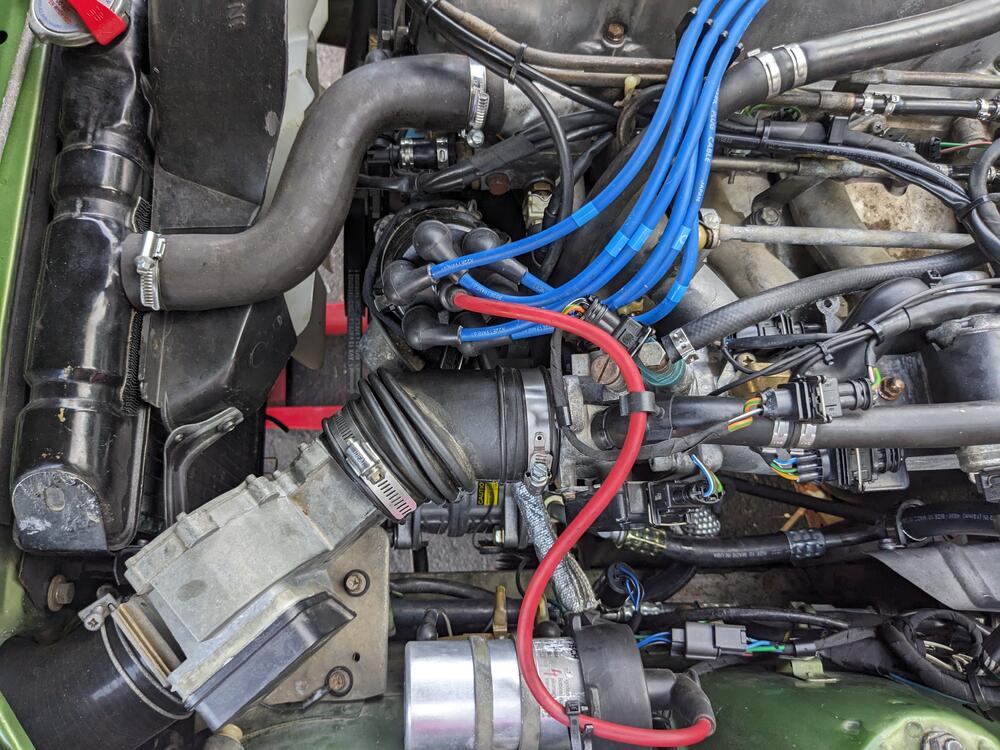

OK - so I had a break in the rain this morning, so I was able to remove the TB during one clear patch, address the ports I hadn't closed off, then get it back on during another break in the rain Larger port I tapped with 1/8" NPT thread sealant on plug tapped smaller port with M5x1, used the snapped off stud from the ignition ballast to make a plug done Back in. Ran the motor - don't have the tach installed, however the rpm's felt much more in line. A little low perhaps, so I ran it to normal op so I could check the base setting. With CIS, the easy way to do that is close off the low vacuum tube from TB to the IACV. It stalled out, so base was too low. Opened the idle thumbscrew a couple turns (I had completely bottomed it out) & got the idle what felt around 750. Releasing the tube, the idle motor cycles & the idle rises to what feels like 850-900 range. I will set it more accurately once the tach is in, but it feels good. Motor revs freely & returns to idle.

-

Blower Motor Upgrade - Not a Honda

prepped & painted The blower needs a cushion - I put closed cell foam on the housing first - that didn't work so I transferred it to the lip of the blower motor outer flange The stock bolts were too long now, so I switched to shorter M5 hardware. Bolts line up with stock holes, no mod to casing required squirrel cage offset

-

HVAC duct hose-78 280Z

I bought the Dayco 80165 hose based on this thread, however it doesn't fit the pass vent or either of the elbows - those are all approx 1.4" OD. The DS vent is slightly smaller ID for some reason - I was able to stretch the 1.25" Dayco hose over it, but no way it's gonna fit the other positions. EDIT - ordered Dorman 96030 1.5" hose to try

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

Thanks CO 🤪 By front side I meant the high side vacuum port that faces into the plenum at the flange - should be easier to plug that that the underside, as I'm using the now larger low side for the vacuum draw on the valve cover, having enlarged that orifice, I'm not sure plugging the now smaller inner/central orifice will be so easy from the underside. EDIT - I did also check the ignition timing, as I think it was mentioned that doing the HEI mod can alter the base timing - it was still around 12º-14º, as far as I could tell, not 15º-20º, for instance. Given the current high idle rpm, I'm assuming it may be slightly over normal base setting.

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

There you have it. I'll remove the plate I made & plug the front side port. Thanks CO!

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

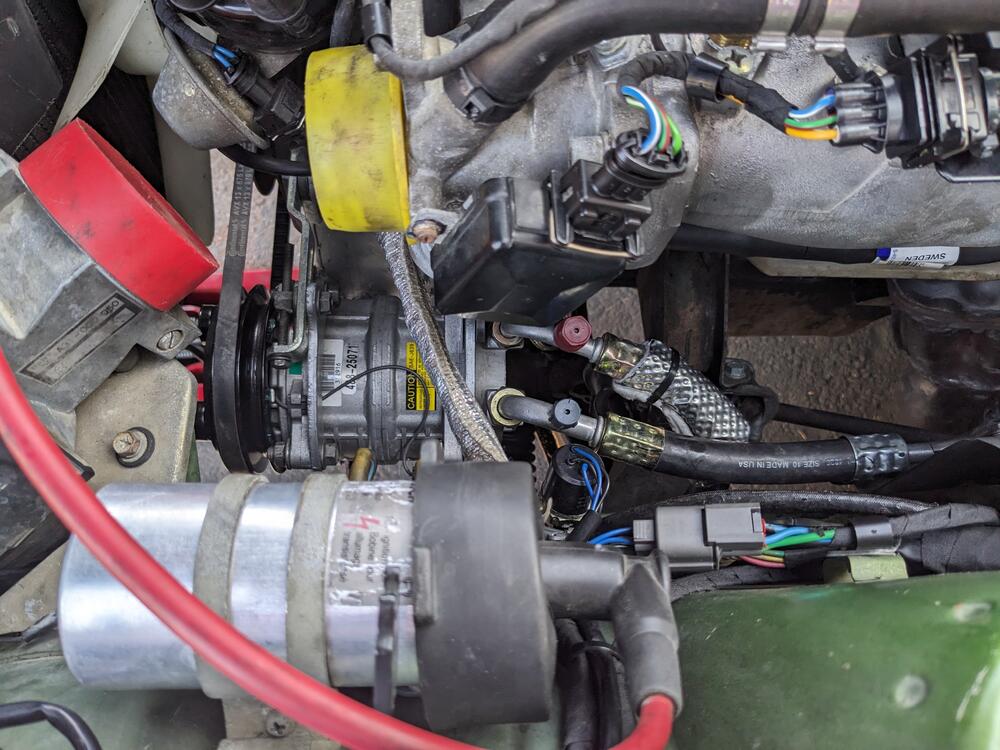

Ran the engine today, dash frame with harness in place to check systems there is a problem with the idle control - idle rpm is way too high for any modulation. Pretty sure there is a passage from the plenum side of the TB back through to the intake via the passages used for the factory BCDD system - openings in bottom area. I thought they were closed off, but too much air is bypassing the idle valve circuit. Pic from when I installed the TB - need to remove it & check the passageways

-

Blower Motor Upgrade - Not a Honda

Modded mine today - enlarged hole carefully with die-grinder & half round file to clean it up. Went to 5.7" Fan cage can be angled in place 5.75" cage OD

-

280z EFI harness hole size

If I were doing a resto & feeding a new harness, I would bite the bullet. Cutting a $49 grommet to fit around the old harness, I just can't bring myself to do it. I ordered an assortment of (ugly) generic grommets that cover the 60-70mm size range.

-

Designing A/C System Using Other Cars Parts?

Right side vent & elbow duct arrived today - gave them a good clean Ran the 3 wires for the AC t/stat through the factory harness - there were 3 empty spots Dk Gn/Wh, Gn, Gn/Wh Cleaned up & applied rust convertor to the air intake flange Blower casing together, flex coupling in place. Closed cell foam to seal each junction

-

280z EFI harness hole size

Couldn't find one on Zcar for the 280 - so I looked at the JDM link - $49(!) for a grommet, just a little pricy 🤪

-

280z EFI harness hole size

I cut mine out, after checking that the hole was 2.5" - The Volvo one measured @ 2.4" in the lip, and the original appeared to be the same, but... once cut the new one is floppy in the hole 😞 VO 3515008 I'll have to order a proper one

-

280z EFI harness hole size

Are we talking about the large grommet that the main harness passes through into the bay? Mine is torn, so I've been figuring out if I can use a Volvo grommet I already have. I would say the ones linked from Mouser are less than ideal - the factory grommets have a tube of sorts that allows for harness movement & also a downward angle on the bay side, to help keep water from tracking through to the cabin. I'm considering slicing the grommet, as I'm NOT removing the harness to feed through a new grommet. Not ideal, but better than a grommet with the torn 'tube' section.

-

Designing A/C System Using Other Cars Parts?

pulled the compressor today, drained & flushed the Mineral oil out, added 5floz of Pag46 DS AC under dash vent arrived Bought Dayco 80165 1.25" ID hose (found it suggested on another Z forum) to cut & fit for the ducts

-

Blower Motor Upgrade - Not a Honda

OK - thanks Steve Same overall dimensions as the 4 seasons one, so mine is not a quirk.

-

Blower Motor Upgrade - Not a Honda

OK - I 'll mark it up carefully & see how it goes.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Did the resistor bridge today, and installed the Bosch coil original center post snapped off, so I riveted the spade tang to the bridge. Doesn't really matter since the coils gets full battery voltage at any of the connections

-

Adding Forward Foot/kick Panels to a 75 280Z

I see - my 75 didn't have any under dash panels, period. I was interpreting the schematic as illustrating complex bracketry for the floor panels - that would have sucked 😄

-

Adding Forward Foot/kick Panels to a 75 280Z

Thank you, Steve. Certainly better than nothing, just not clear Eurodats' pic from his 280Z

-

Adding Forward Foot/kick Panels to a 75 280Z

I've seen pics of interiors that have the trim panels under the pedals & covering the wiring on the right (for example in EuroDat's HEI conversion thread, pic showing his ICM wiring). I'm going to add them to my 75, I just can't find any pics that show the mounting point itself. Are they secured directly to the floor/bulkhead, are there raised mount tabs? If anyone has pics with the carpet out where the mounts are visible, that would be awesome. There are 3 mount points per side.

-

1975 Datsun 280Z CA Market Relay Identification And ATC Fusebox Replacement

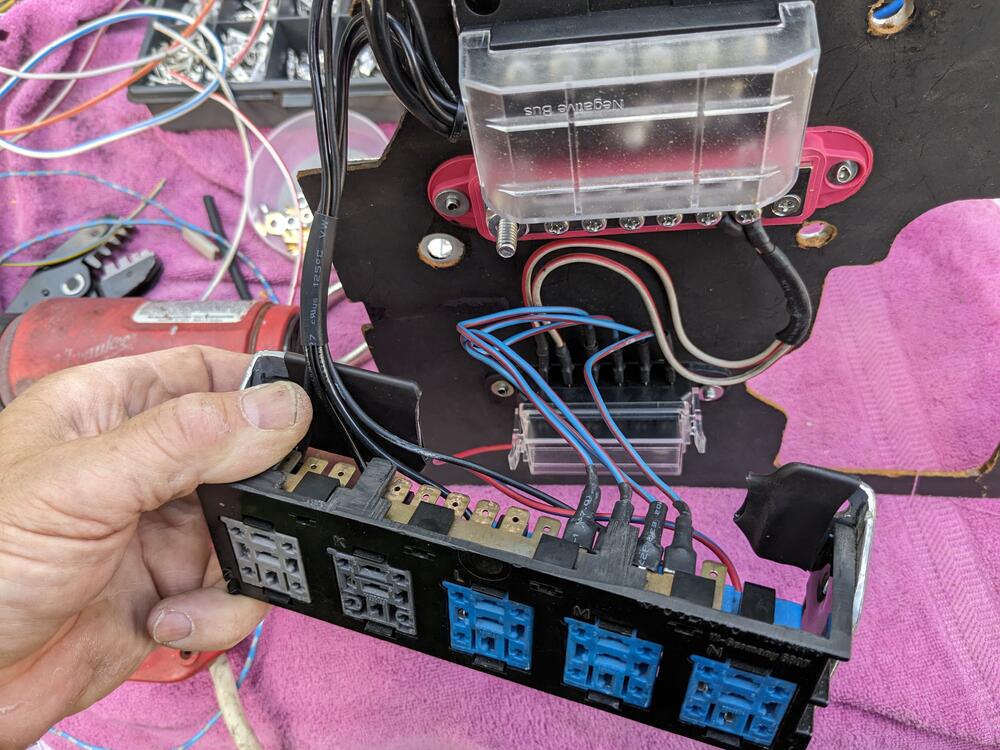

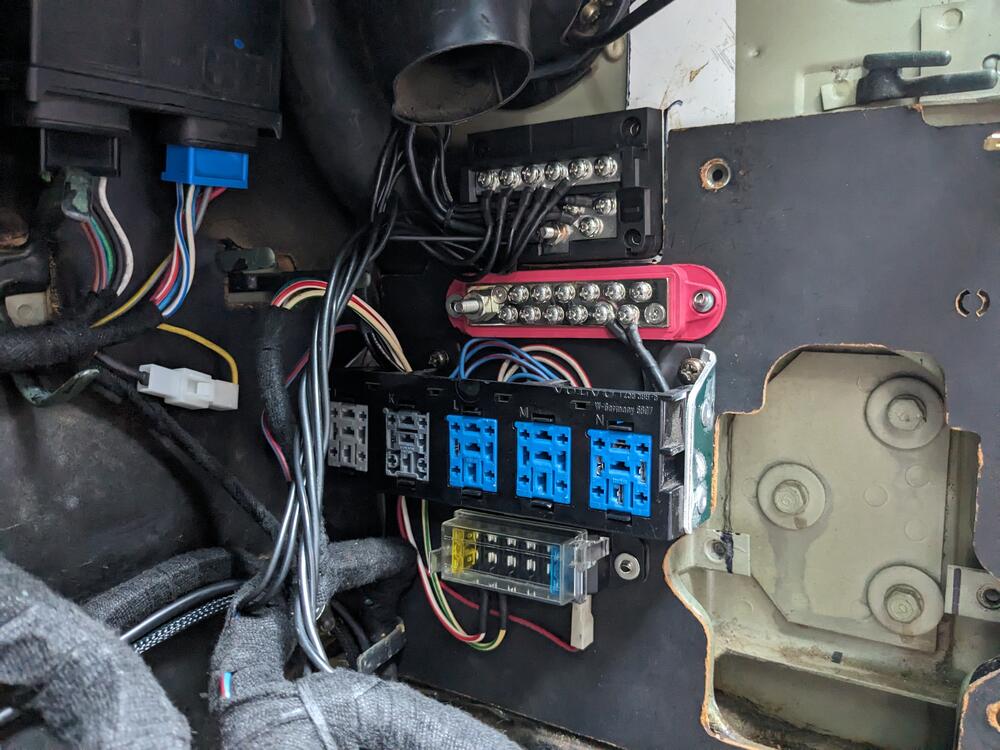

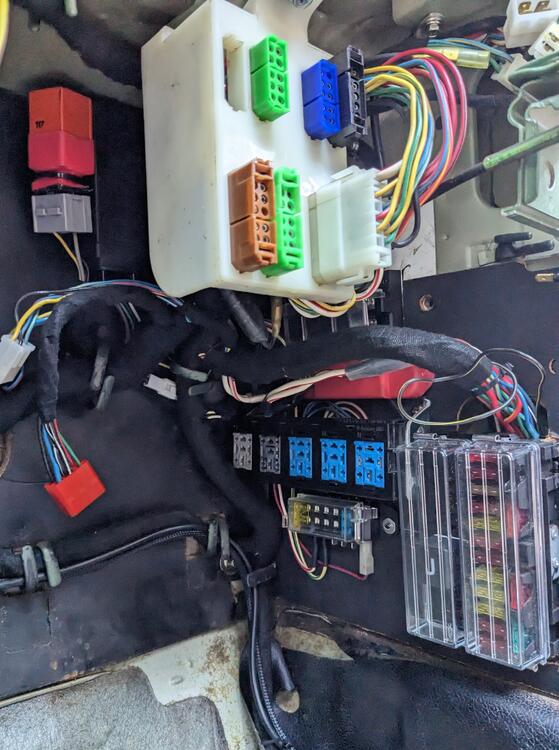

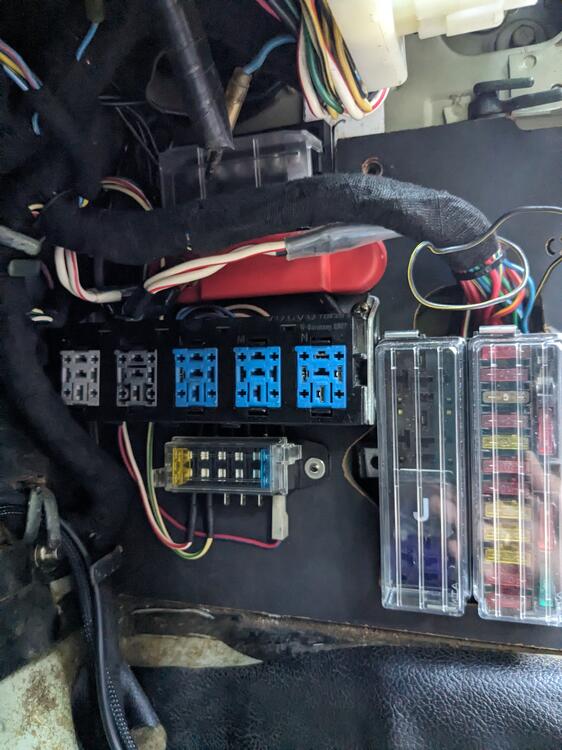

Worked on the power circuits today Organizing additional wiring, relay grounds Wired spare relay sockets with power & ground. Only 2nd from bottom is needed right now (AC-on blower fan override) Wiring secondary relay panel, additional 6 fuse panel, ground, 30 & 15 rails 15 rail is part of relay panel. Volvo inserted 3 rails in the relay/fuse panels. I kept this one. making sure that everything can be removed, and has enough cable slack to move out of the way as needed test fit again, re-wrapped harnesses, place CIS module

-

Blower Motor Upgrade - Not a Honda

Pics of my box opening, stock motor cage & Kia (4Seasons) cage. Cages are not interchangeable, shaft design varies 5 3/8" opening Stock cage just under 5 1/4" Kia Cage 5 3/4" (!) 1/2" is too much meat to remove - the wall is pretty shallow in the 2 o'clock area above

-

Blower Motor Upgrade - Not a Honda

The cages are not the same form factor. I'll take some pics of what I have. Perhaps different brands vary, the 4 seasons motor is much lighter weight, smaller motor than my 75 Z version, cage is larger.