Everything posted by HusseinHolland

-

1975 Datsun 280Z CA Market Relay Identification And ATC Fusebox Replacement

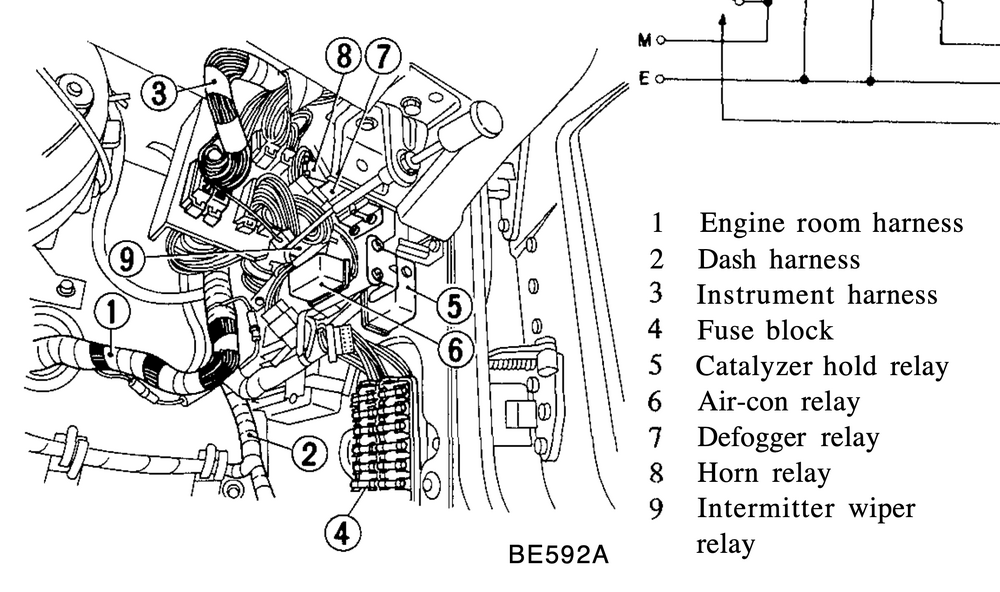

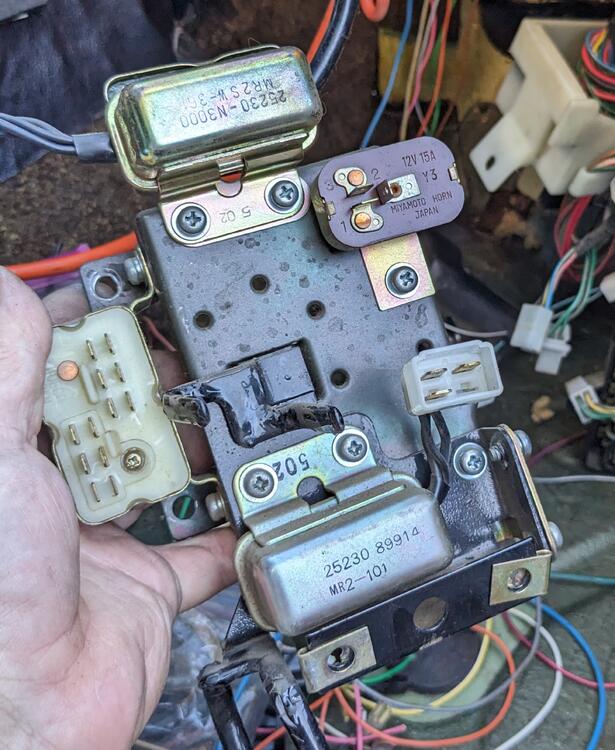

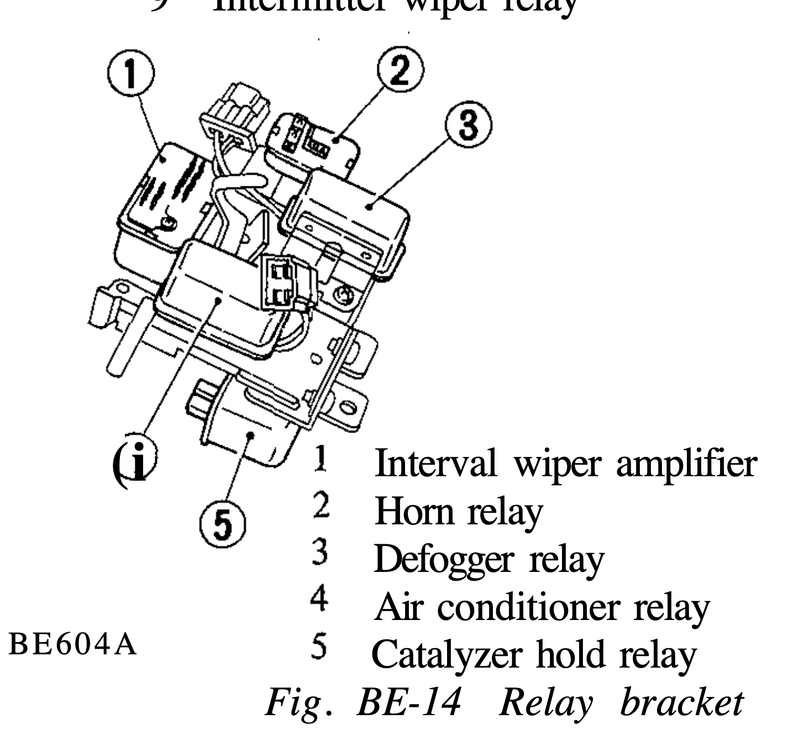

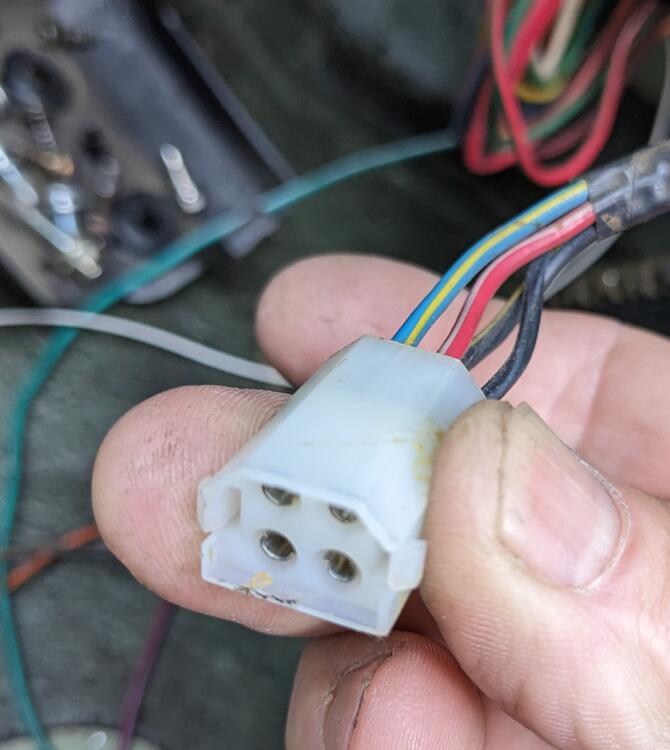

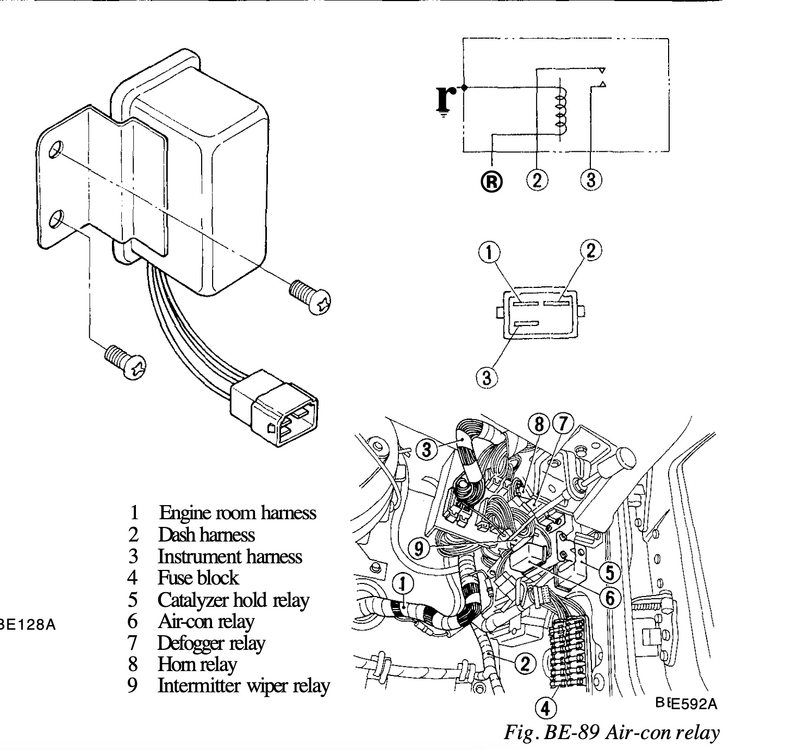

The relay diagram is somewhat confusing to deal with as a reference for what's actually there. Ultimately, the one that is unknown is the 25230-89914 relay The reality top: 25230-N3000 - should be Defrost relay top right: - Horn Relay Left: - Interval relay Bottom front: 25230-89914 ? Online says interval relay, diagram says AC relay, but mine didn't have factory AC Bottom right (back): Cat hold relay (not shown) Top middle (back): 28911-89910 Seat Belt Buzzer? Interval relay wiring doesn't match the schematic - shows 10 connections but - only 7 actual Harness side plug: Bl, Gn, Bl-Y backside, upper 28911 - 89910 harness side socket - Bl-Y, R-Wh, Blk, Blk-Y

-

75 280Z Wiper Motor Conversion W/ Variable Intermittent Wipe

Took out the fusebox & relay panel yesterday as part of the re-wire/update, so It's time to revisit the wiper interval

-

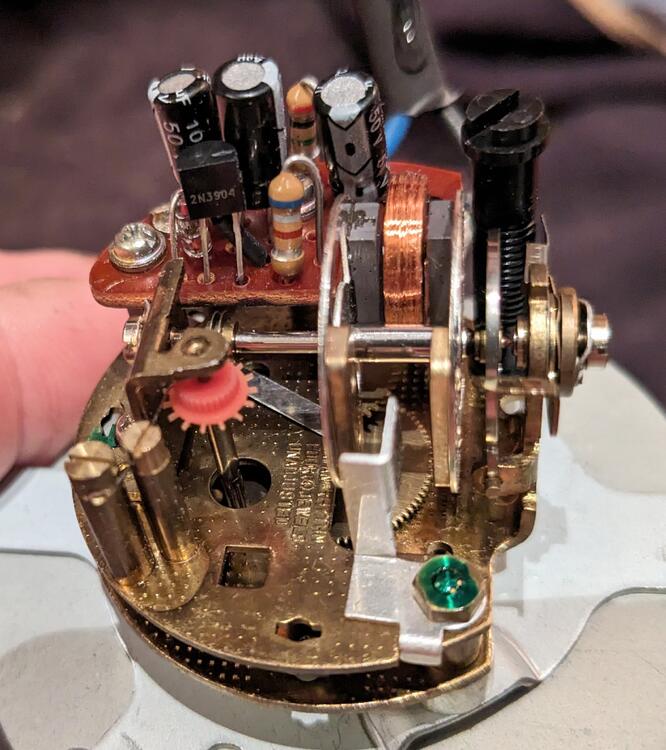

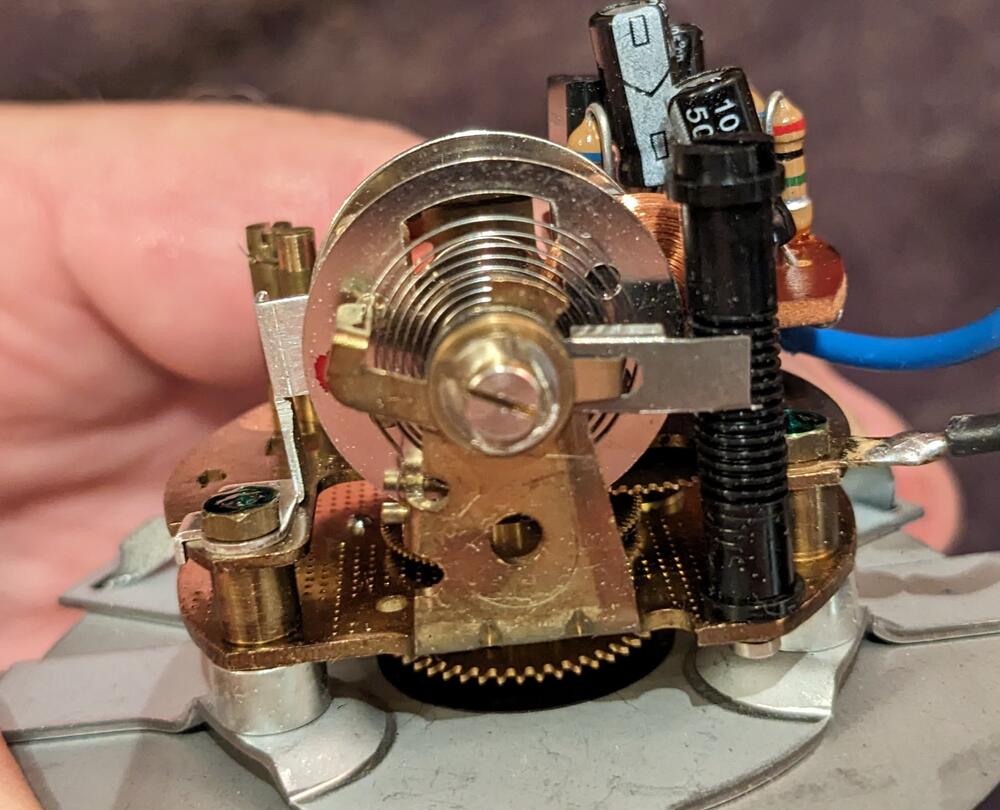

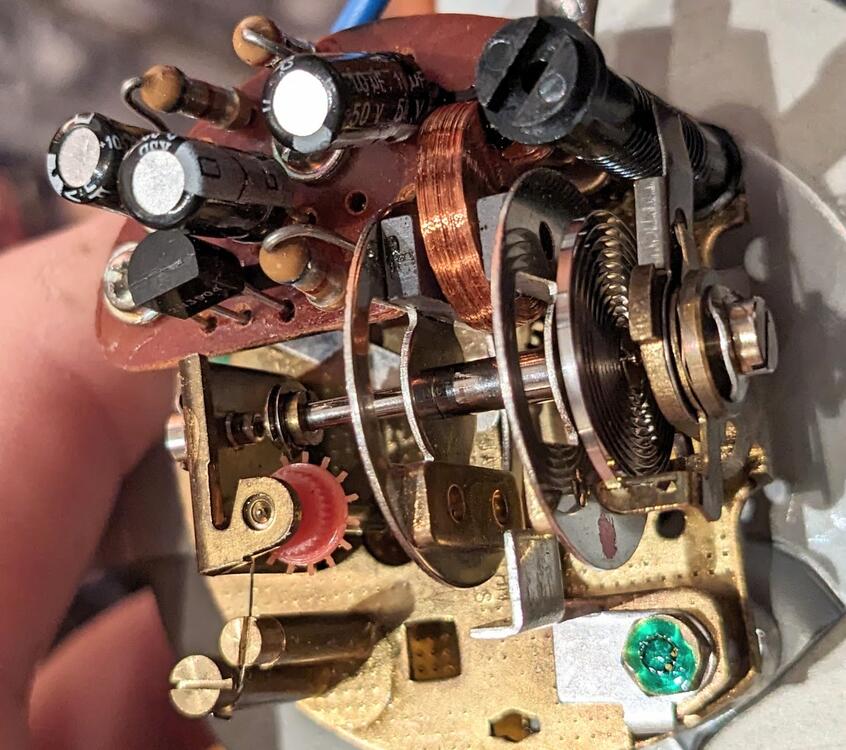

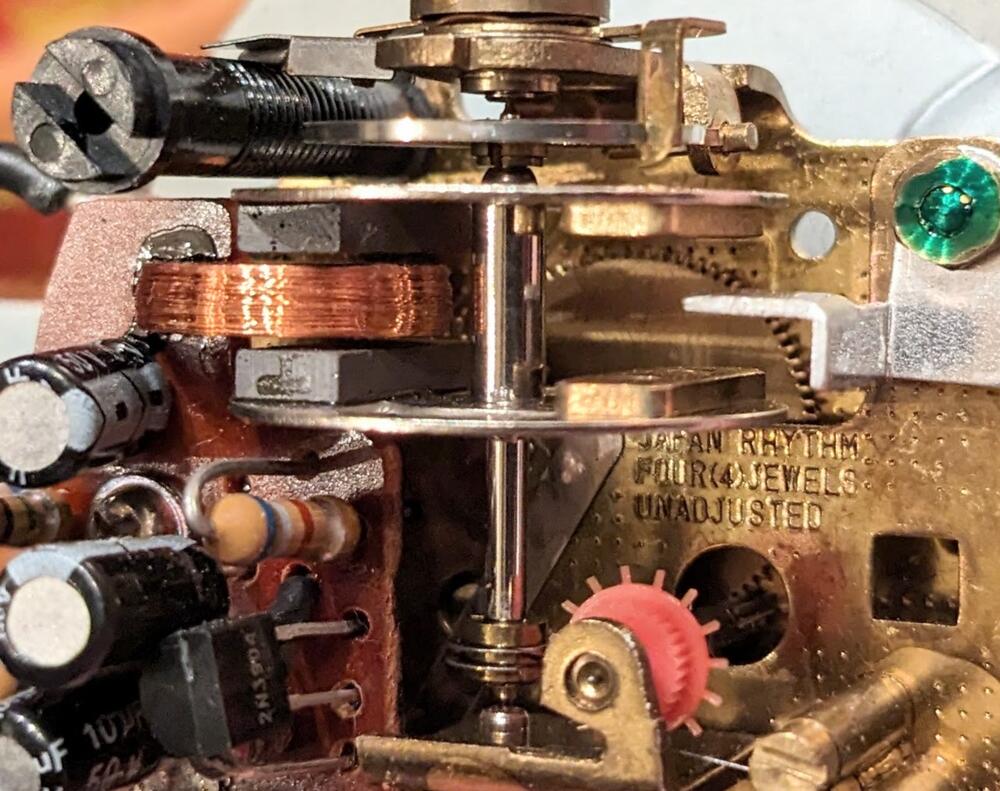

75 280Z Clock Repair?

I did look on Mouser, doesn't look like .22uf is available except surface mount. In any event, I've ordered a new OT multimeter that has the CAP feature. Should be here Friday, so I'll test the components I have.

-

75 280Z Clock Repair?

Yeah, My OTC multimeters are from the 80's. I guess it may be time to invest in newer tech. 😄

-

75 280Z Clock Repair?

I didn't test the new caps, I wouldn't have a clue how to even do that. I could swap them out for other new caps, but what I have is all from the same batch I bought off Amazon.

-

Designing A/C System Using Other Cars Parts?

-

75 280Z Clock Repair?

Thanks again for the functional description - it's nice to understand the sequence of events taking place on the board 🙂 I have some M- range resistors coming. If playing with that doesn't produce positive results, I think I'd just as soon buy a refurbished board from you.

-

Designing A/C System Using Other Cars Parts?

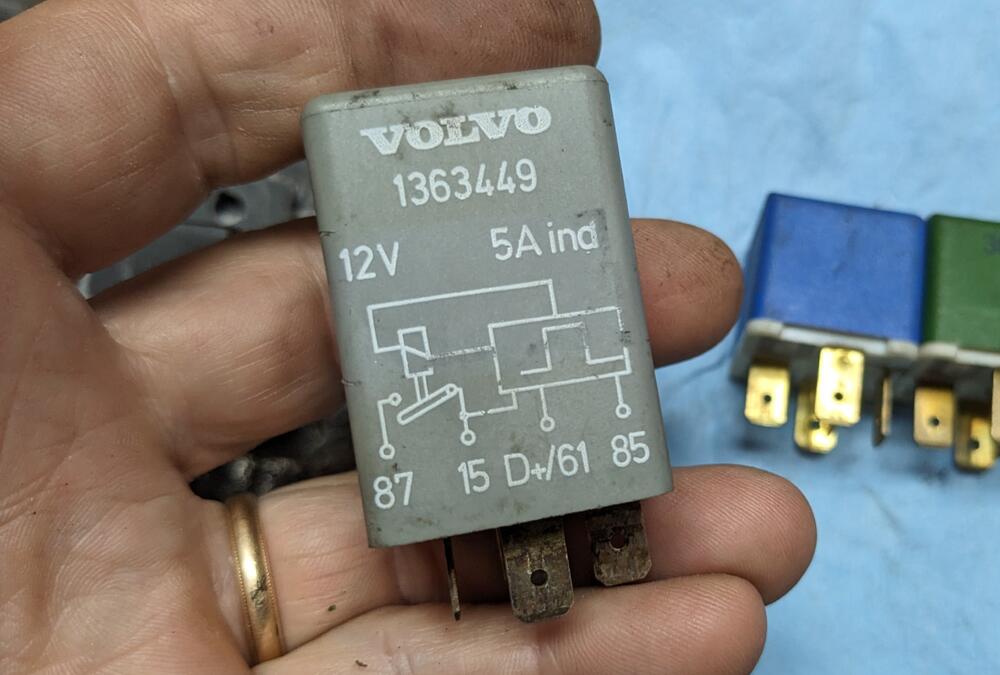

Haven't been able to work outside with all the rain. Just to keep things moving, I did a small amount of wiring inside the cabin - just the T/stat connections here, and routing wires for the delayed engagement relay VO 1363449. uses a sense signal from the alternator to only engage once the alternator is charging. The white/black wire to the V/reg (F terminal on alt) should be appropriate. Have a more compact low pressure switch that can go on the backside of the Accumulator facing the firewall, instead of the sticking out over the manifold VO 9144340 a bought a number of single pole waterproof connectors, so the bullet style will work for the D+ splice at the v/reg 6 pole connector, and at the AC compressor.

-

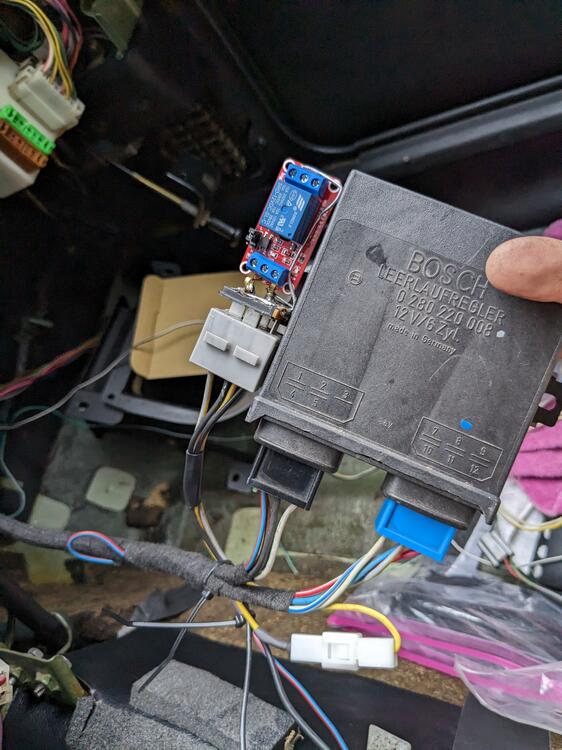

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

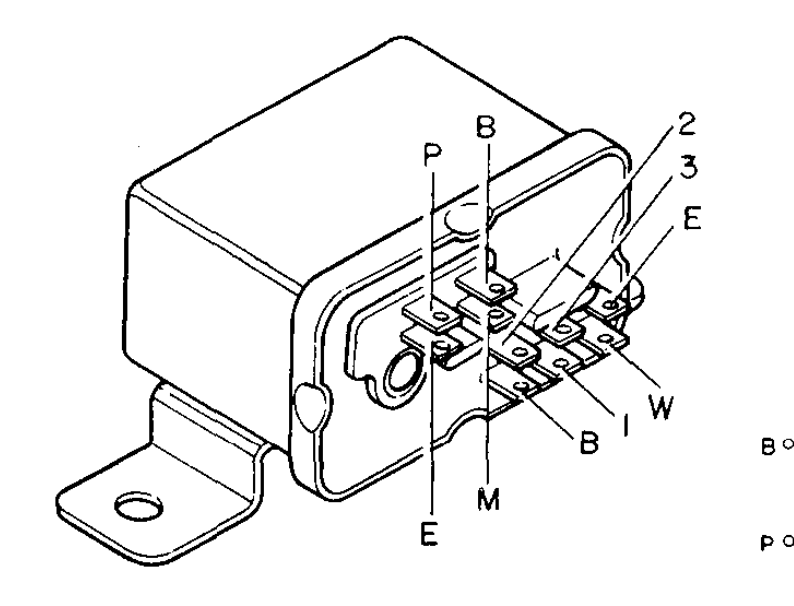

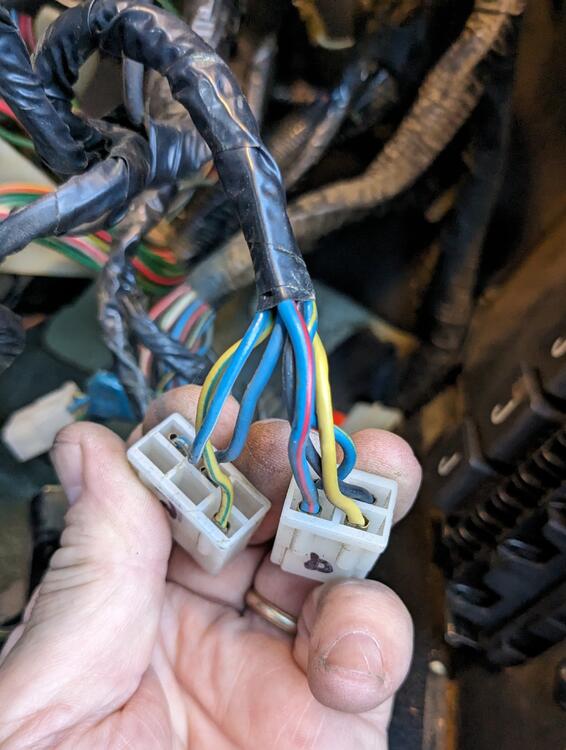

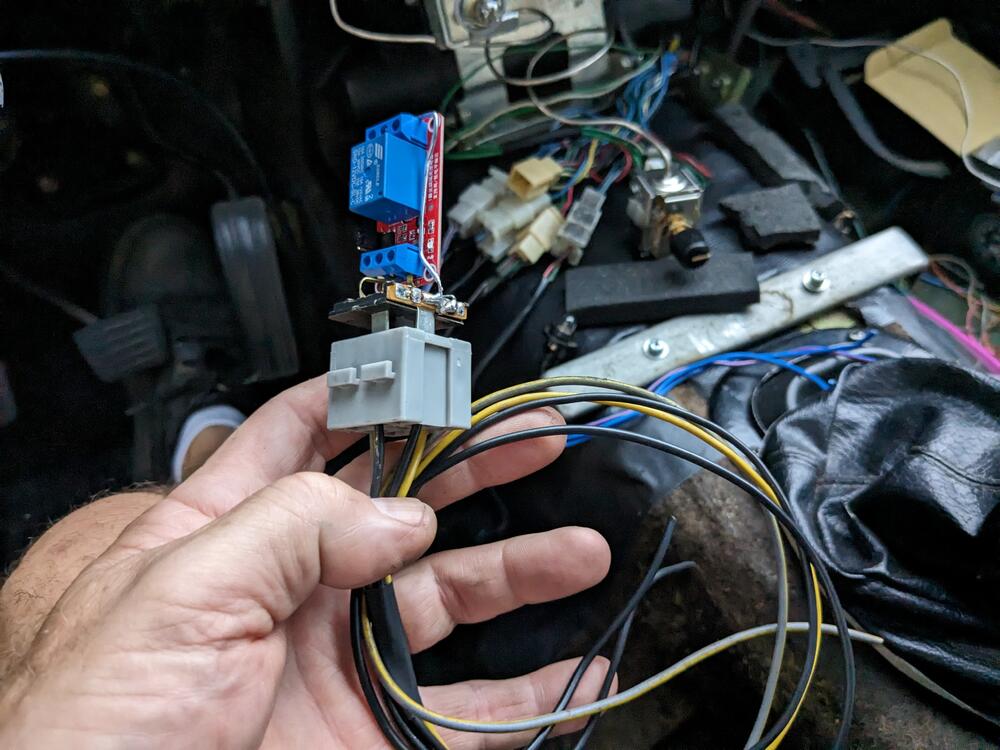

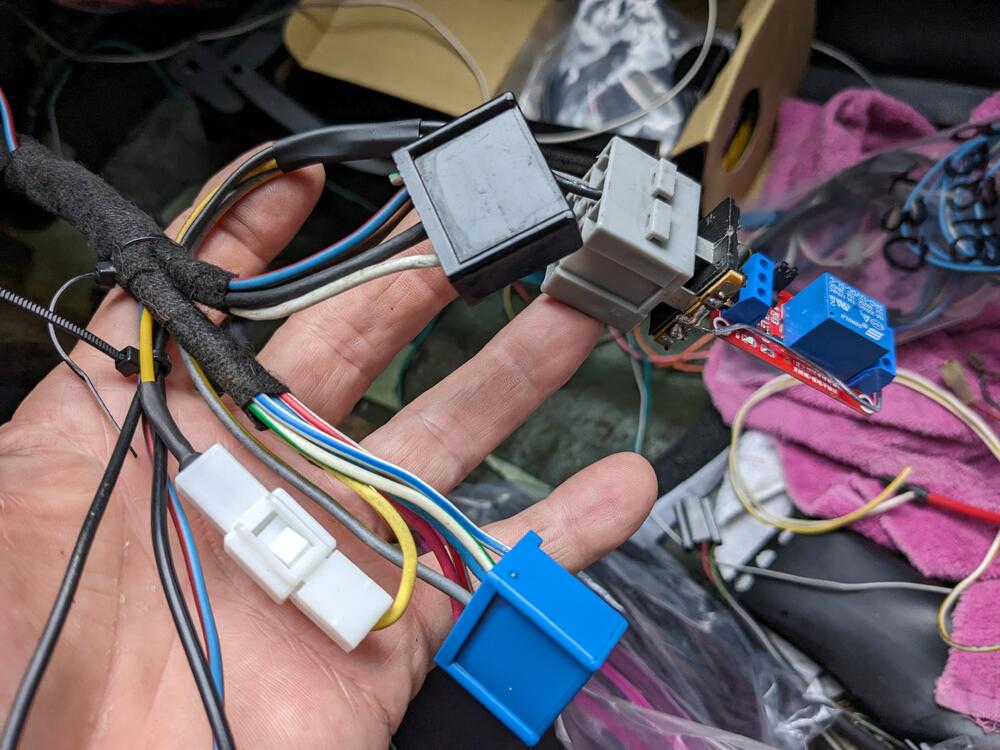

The thing is, the ECU for this is not readily available, and typically expensive if you can locate one. I'm doing it because I have the components, and my stock AAV is dead anyway. This will all only be used for a year or so, then I'm putting in a 350Z drivetrain 😁 Weather has been terrible here, so not getting much done. Did a little work on the wiring inside the cabin while it was raining harness for transistor relay for switching the stock TPS signal to the CIS module to open at idle, ground off idle. yellow wire is the signal from the TPS, so it needs to go to the relay first, then the switched leg goes back to the module it will be situated alongside the module. I will need to sleeve the relay

-

75 280Z Clock Repair?

Doesn't that mean the voltage drop would be even greater? I assumed reducing the value of the resistor would be the goal, to increase the stimulus of the transistor on the coil?

-

75 280Z Clock Repair?

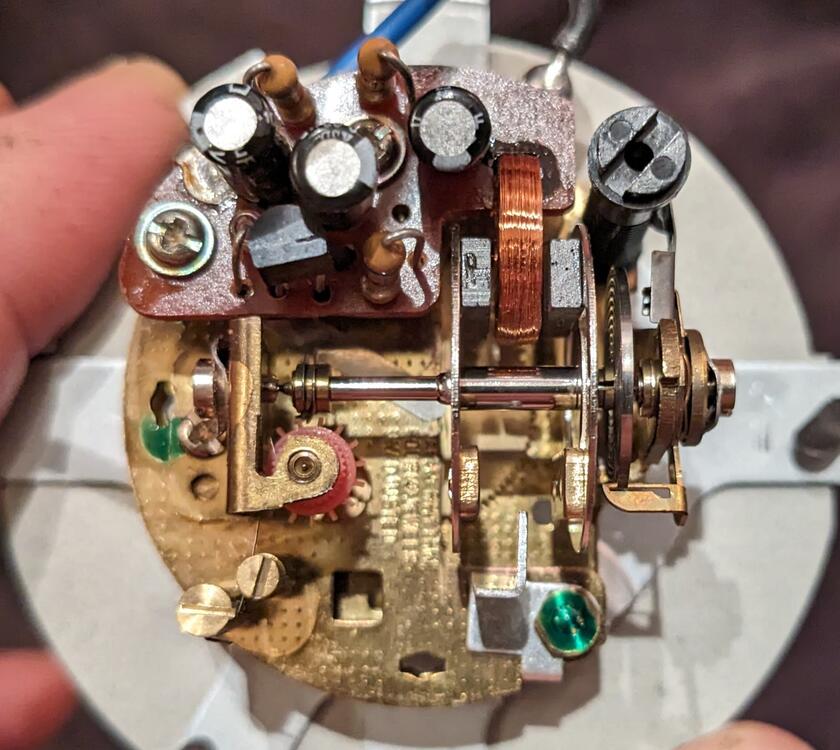

I did connect the clock directly to the car battery (inside the case), made no difference. The caps, I bought one of those sets that has a large range of values. I replaced all three - 2 x 10uf, 1 x .22uf. I presume all I can do play with the high value resistor, since I can't check the actual values of the caps.

-

75 280Z Clock Repair?

Hello Ron Thank you for chiming in I think I had to jump start it when I did the transistor. The wheel moved when power was applied (which it did not after just the cap replacements), but it did not cycle/swing of its own accord. I ran it for a few days out of the housing. I checked that the shaft/spindle was able to move freely without binding or excessive end play - I had thought perhaps the shaft might have been restrained by the end adjuster, because I had to recenter the shaft when I first took it apart & didn't pay attention to keeping my fingers away from the shaft. When I assembled it in the housing I was very careful to gradually feed/pull the two wires out through the casing as I placed the clock in the housing. There is no signs of wear or degradation to the spring, balance wheel, gears or shaft / shaft tips or pivot caps. If I spin the wheel manually, it cycles for a few seconds. I will take another pic of the clock with the circuit board in place. I was careful to center the coils in-between the wheels. I did not re-use the mis-wired transistor

-

75 280Z Clock Repair?

Thank you for the suggestion - easy enough to parallel another resistor & drop the resistance on that leg of the board. I'll give that a whirl!

-

Replacement External Door Scraper Molding (Silvermine)

Yeah, I wondered why mine seem to flap in the breeze when lowered part way, seemed unlike Nissan given the care taken with all aspects of design on this car. I ordered a pair as mine must have died years ago & been discarded - the bracket isn't there or I would have known to look further into it when I was working on the driver's door.

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

Looking back at the pic of the 78 bay I took, I realized the plug wires were not properly placed - it irked me that they were hanging out on the right side, so I took care of that & made the TB gasket EDIT - the external throttle return spring had a sleeve of some sort inside it - it was cooked, presumably from the manifold proximity, so I'm not sure of the intent. I removed the scraps & put a section of greased nylon (8mm OD) tubing inside the spring.

-

Replacement External Door Scraper Molding (Silvermine)

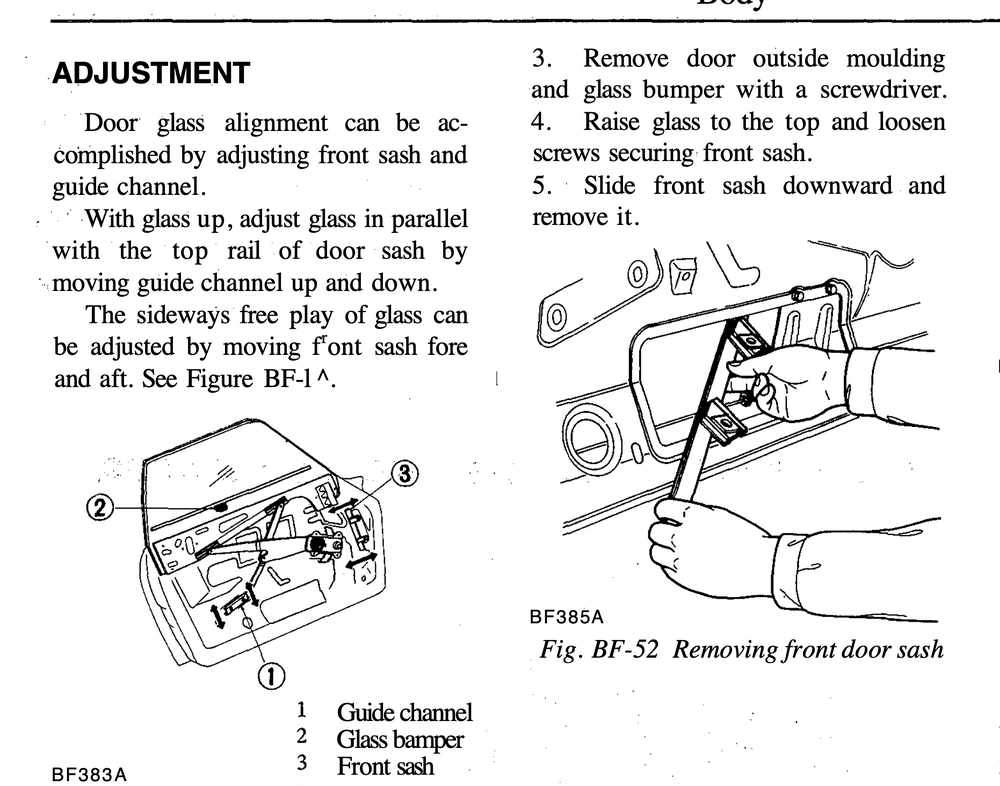

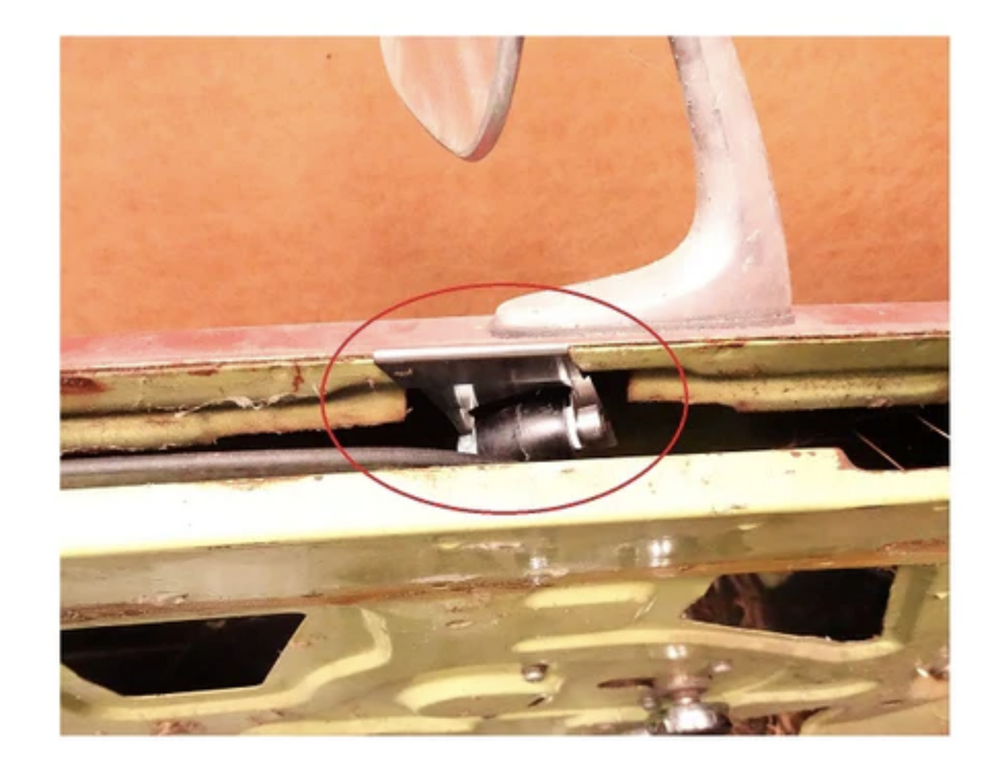

What year is yours? Mine had no extra parts attached - I'm not familiar with the extra pieces that are attached to yours at all. I see now in the manual there is what they refer to as a "Glass Bumper" looks like it's supposed to be somewhere in the middle of the door? That is MIA in my door. I had the whole thing apart when I fixed the door card. Do you have a bette picture of it? EDIT - never mind, found them on ZcarDepot - they also show where it needs to be installed

-

75 280Z Clock Repair?

Honestly, I can't recall now if I 'helped' it. I left it running for a few days off the battery & it kept good time. I'm going to assume I helped it, since it clearly won't jump start itself. Not sure where that leaves me.

-

75 280Z - Starter Motor intermittently clicks when restarting after car has been driven for several miles/in town driving

Since I had to add a power supply for the AC fan, I removed the battery & also replaced the negative cable with a Volvo part (2005 S40) that incorporates the body ground leg. I had previously treated the rust on the battery tray, so I primed & painted the area while the space was clear I added the EMS ground to the battery terminal with a ring terminal, and got rid of the old spade connection So, ground to engine, body & EMS

-

75 280Z Clock Repair?

So, I spoke too soon. The clock worked, but after I reassembled it in the case, it did not. Pulling it back apart, as long as I 'jump start" the wheel, it will run continuously after, but simply connecting it to 12v, nada.

-

Replacement External Door Scraper Molding (Silvermine)

Nothing inside the door is touched. It's pretty easy to remove - you may be able to lift the rear corner by the glass frame, and simply lever it off. There are 3-4 clips inside the channel that clip onto the top of the door skin lip. If yours won't pull off that way, you can use a putty knife with a layer of tape on it to prevent scratching the paint, tuck it under the rear edge by the door glass frame, and lever it upwards. Once you have it started, just pull it off by hand a s described before.

-

Replacement External Door Scraper Molding (Silvermine)

Yeah, I already bought the rubber squeegee & replaced one - the issue for me is that one of my moldings is damaged & I don't want to look at it, hence the full replacement.

-

Replacement External Door Scraper Molding (Silvermine)

Wondering if anyone else has purchased & installed these moldings. They are very nicely made - BUT - they are not pre-bent to the door cap curve. Website just says bend to fit, and Edan unfortunately is not good at responding in a timely manner or actually answering questions about the products he sells. All he said is that it bends easily, when I asked pre-purchase. I have tried to get more specific directions from him directly, to no avail. Since the molding is flat, I can only 'assume' the contour will correct once bent, however I'm still unclear logistically of the best way to do this. If it would bend easily, one could simply press it down on the door cap to shape it, but that is not the case. It's gonna scratch the paint at the very least. If you have removed these, you know the factory molding has both a fore-aft bow, and a 'in-out' curve to it. I don't want guess with this, they are not cheap. So, has anyone else played with these?

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

We have thunderstorms coming in, so I worked on getting the wiring & fuel hoses done so that nothing is exposed, since I have the hood off. Removed all the fuel hoses. The injector ones were too long - approx 2" - the rail was set such that the FPR was touching the accelerator link arm. Lots of worm clamps 😞 After I replaced the rail hoses with sections of 10mm ID nylon fuel tube I put the rail back in place to measure the injector hose length. I reckoned 1.75" would be more appropriate & not lift the rail Most everything back together, so now I just need to make a TB gasket, bolt the TB back on, wire a couple connections for the AC in the bay, remove & drain the AC compressor, refill with PAG46, then I can move on to all the wiring under the dash, then get the dash back in (eventually).

-

FPR project - cheaper, more available (for a while anyway)

OK - so I already installed the one 028 sensor in the cooling system, so I searched through my Volvo manuals, and found the chart - the axis is reversed compared to yours. it's much more linear though

-

FPR project - cheaper, more available (for a while anyway)

Apologies - I missed the clarification. Volvo only gives those two points. I'll put the one I have in heated water with a thermometer & get some other measurements over the next day or so.