Everything posted by HusseinHolland

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

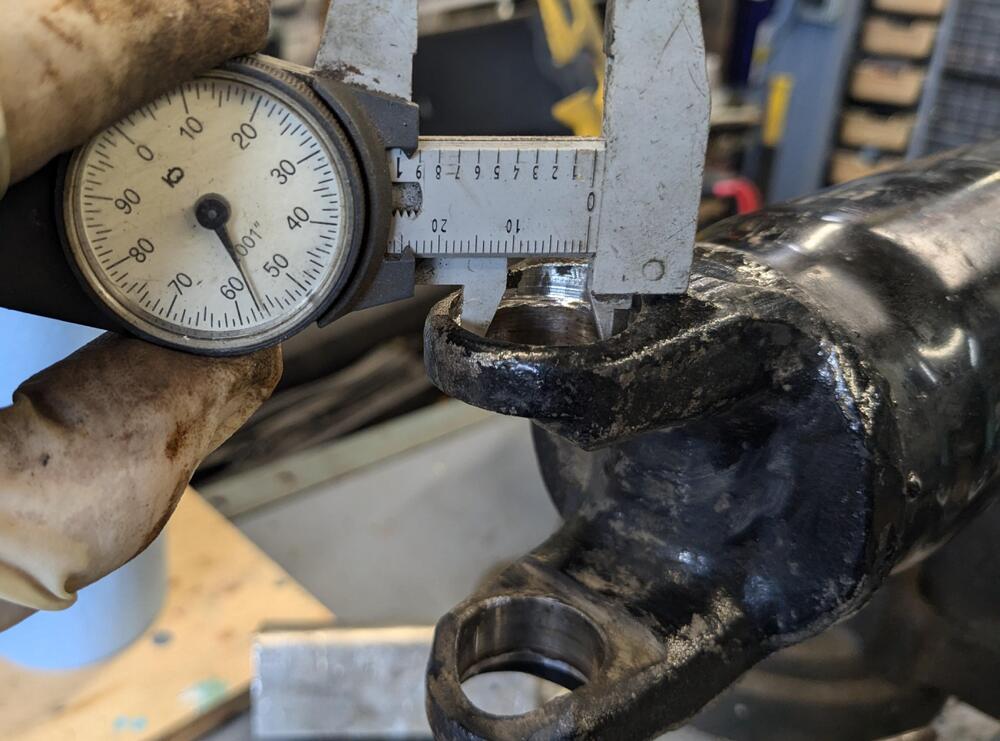

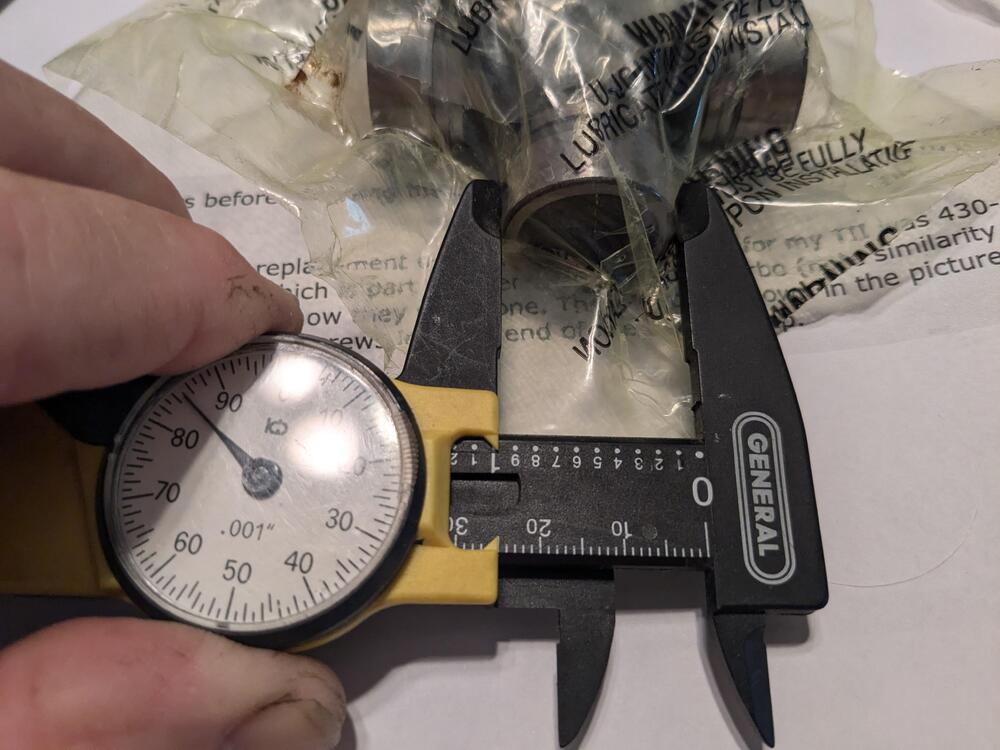

On to the next area of frustration. I ordered a joint (Dana 5-1501X) off RockAuto for the prop shaft. When it appeared that wasn't going to arrive anytime soon, I ordered a pair of 430-10 based on the posts in the other threads. Neither version is the correct size for the prop shaft on my '75. My joints are 2.575" from outside of cap to outside of cap, and have .947" OD bearing caps. The Spicer 5-1051X is 2.525" outside, and has .985" caps (same as replacement listed on ZcarDepot) Caps are TOO big, joint is undersized The TUS-10 (430-10) is 2.34" outside, and has .875" OD caps - WAY too small all around. Removing the factory joint - some ppl mentioned a stake ring that can be removed - there is no such thing on mine. I ground the stake area out, and removed the UJoint using the same process as for a standard external snap ring style remove the caps holding the yoke to the shaft then remove the caps holding the joint to the yoke Yoke to shaft orientation is marked inner land where the lock ring will presumably sit ID of yoke - approx .955" - no way a .985" cap is going in that Datsun cap to cap (measured at 2.575" / 65.5mm?)when holding the caliper, have to recheck that # Datsun cross end to end approx 2.405 / 61mm Cap OD approx .947" / 24mm cross shaft OD approx .702" / 18mm TUS-10 5-1051X

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

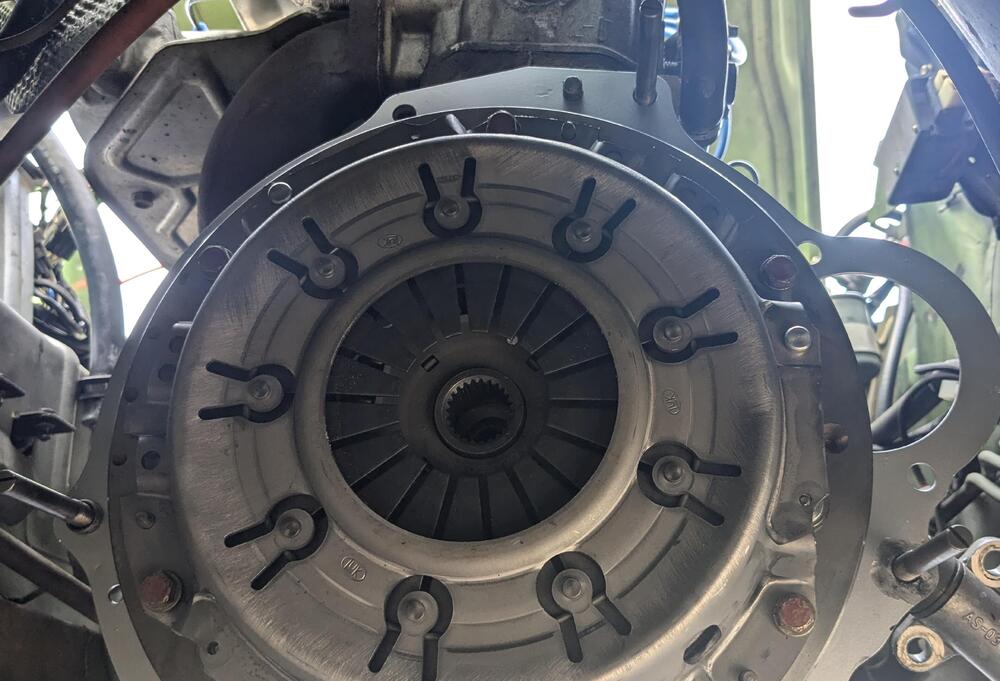

Lever offset - approx 4 /34" with new clutch Going to the old trans & setting the fork to the same offset, then extending fork 1" rearward fork to sleeve contact at 1" extension Sleeve offset at the 4.75" setting I guess I could mod the pivot pin (move it forward/extend the seat) so that the lever is moved forward. That would reduce the travel of the sleeve & move it back closer to stock. I honestly don't know why the new clutch setup (intended for 81 280ZX NA) has a different stack height than the old clutch & T/O. I'm not going to take it all apart, as no matter what I find I would have to return / replace the clutch to hopefully find a resolution to the issue of the changed lever offset.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Since I still have the complete 4 speed with fork & bearing/collar, I could measure the revised fork rest position & then observe the fork/collar contact over the 1.25" or so travel required to disengage the clutch. I might out of curiosity's sake. As long as it lasts a year or so, that's really all that matters. As the clutch wears the fingers will move rearward, reducing the fork throw anyway - but, I am unlikely to put enough miles on it for that to come into play before the whole mess comes out for the V6/CD009 swap.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I did install the longer slave push rod from the Volvo - that one fit perfectly, and pedal feel & travel is good. I used the Honda boot - had a little more travel allowance

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Waiting for Z parts. Getting ready for a retake of the Ithaca trip in the pickup. Yesterday my wife pointed out that there was a bad noise coming from under the passenger side - the cat was disintegrating. I don't have another cat to put in - so today I modified a resonator to fit Test fit - cut the flange and extension pipe off the dead cat - tacked to resonator welded, added bung for O2 all good. good offset on the O2 Also had to fix my Mum's weed whacker - the lower shaft wouldn't stay in the main body, so I just drilled it & put a set screw in there

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Thank you for finding that - I have more than 1.5" off the backside of the fork to the back of the casting opening. I need about 1/2" extra rod length to take up the slack. I don't see any difference in PN listings for the slave cylinder between the 280Z & the 280ZX. I know ZcarDepot sells one with an adjustable rod, so I assume this has come up for others. The new disc is substantially thicker than the worn one, I want to say at least 1/6th inch, which would draw the fingers in, since they move rearwards as the disc wears. Not seen this symptom on any other car I've installed a clutch (that was listed/intended for the vehicle in question) on though. I'll play with a longer rod & see if it disengages as expected -have to put the exhaust, etc., back on to test it running of course. Hopefully it's not all coming back apart.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

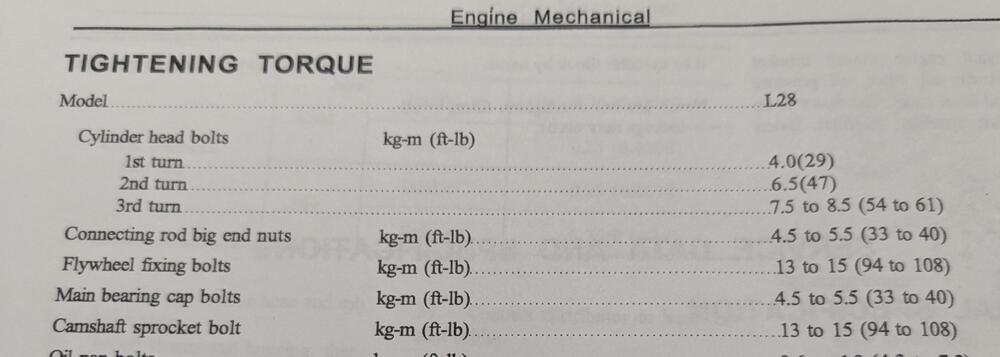

I went through my collection of hydraulic clutch components. Datsun Hnoda Volvo 700 Fiat X1/9 The Volvo one may be just long enough. It also has a wear resistant head. Otherwise, I mod the Fiat one. Old clutch The old disc is significantly thinner than the new - I didn't check the stack height of the whole clutch though Cleaned up the spacer plate and heat sheild New rear main installed installed & torqued the flywheel - 105 ft/lb . Volvo flywheel lock tool from the 70's Disc centered, PP torqued to 15ft/lb New PP only uses 6 bolts like the original 3 Guide pins made it easy to set the trans on the motor. That was a nice tip Shifter attached. I had to shave one of the top hat bushings to get it to fit in the fork Trans in place, mount set. Took a bit with that, I had to leave the mount loose on the trans to get everything to align as it was lifted into place. Think I had it backwards first time around Speedo cable attached, all new seals Reverse light switch swapped over from the 4spd. Cleaned & primed the left frame rail - looked like brake fluid must have stripped all the paint at some point

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

New issue - I don't recall anyone mentioning an issue with the slave cylinder but the offset is wrong on mine. I used the clutch complete intended for the 81 300ZX, and the throw out lever, pivot and bearing. Anyone else experienced this? I'm assuming the operating throw is the same, just a longer rod required?

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I've ordered a set

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

That's how I ended up cracking them free

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I didn't read through your entire thread, however I'm just replacing one U Joint, and I'm not getting involved in re-balancing the prop shaft. I don't want to over complicate this - I've never had or heard of the need to re-balance a Volvo prop shaft, or even considered it a requirement when replacing u joints, and that setup is 2 piece, 3 joint with a carrier bearing. I find it hard to believe the Nissan spec is that sloppy that replacing a joint would throw the shaft balance out. I do make a point to mark & install the yokes as they came out. Ultimately, I will be modding the prop shaft for the CD009/VQ35DE conversion, so I'm only replacing the front joint so it doesn't put undue strain on the bushing in the tailshaft, or the trans bearings.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I see. I missed your second reply (above) with the link to examples of the Nissan setup. I have never seen such a complex setup for installing a UJoint. Typical Domestic & EU Spicer joints rely on a recess groove in the outer portion of the yoke, which the retaining ring/clip will seat in once the UJoint is placed. There is no adjustment - that part is quite confusing, given that Nissan seems to be a stickler for precision. Having so many thicknesses of clips implies that the production tolerance margins for the yokes (and/or the joints) must be pretty loose. I have replaced many a standard U-Joint in the past - Volvo used 2-piece driveshafts with 3 1140 or 1310 joints on all their RWD models, and worn joints was a pretty common thing. in my experience it's mostly been a question of tapping the cross back & forth a smidge to get the right 'feel' in the joint before installing the clips. With the provided info you have given, I will have to pay close attention to the fit.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Interesting! Do you have any pics of it installed? They don't have any directions or install pics I can find on their website. I have seen a couple of cars at the Carlisle Import Show in PA that had steering rack Tie rods modded to fit also.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Yes - I found a couple threads linked off HybridZ with horrendous photography, however the description was clear - cut a recess/land for the Cclip to seat Lightened this pic I found to show grinding for clip

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Interesting. The bolts in there do seat against the flange lip - there is no way to rotate the bolt. Perhaps they swapped out the factory bolts when they did the clutch at some point in it's life. Couldn't recall the Datsun name for the part - Volvo used a similar design, just called it a caster rod, since it affects the caster 🙂 I've found that Rockport 430-10 is the replacement U-Joint, I just ordered the Dana version off RockAuto as it will get here much quicker than the other options I could find. Apparently the replacements use a C clip that locates on the insides of the yoke, rather than the traditional clip in a groove on the outside of the cap. Stakes have to be removed first, of course.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Finally got to pulling the transmission. Removed the fan clutch/blade, and disconnected the throttle linkage at the firewall. Removed the 2 upper bell housing bolts, and removed the starter motor Removed the front exhaust pipe and heat shield. Manual doesn't say to remove the rear swaybar, however there is no access to the driveshaft flange nuts with it in place angle is all wrong, until I dropped the sway bar. Made guide pins to ease the re-install . M10x1.5 threads cut a screwdriver slot in the ends got the shifter pin/clip out cleaned up the area where I had pounded the tunnel to fit the 350Z seat Tranny jack in place Out. Took some leverage between the bell housing & engine to free it. I'm gonna say the last tech to work on it (new clutch at some point) was not happy with putting back the worn trans Only one sleeve guide on the lower left guide pin on the upper right Found that the relatively new caster rod rubber bushings are already toast. Other side is the same Also found the forward U Joint is binding - it doesn't look like it is serviceable. Have to look into that I didn't note which way round this was installed - has two notches on one side

-

SpareTire

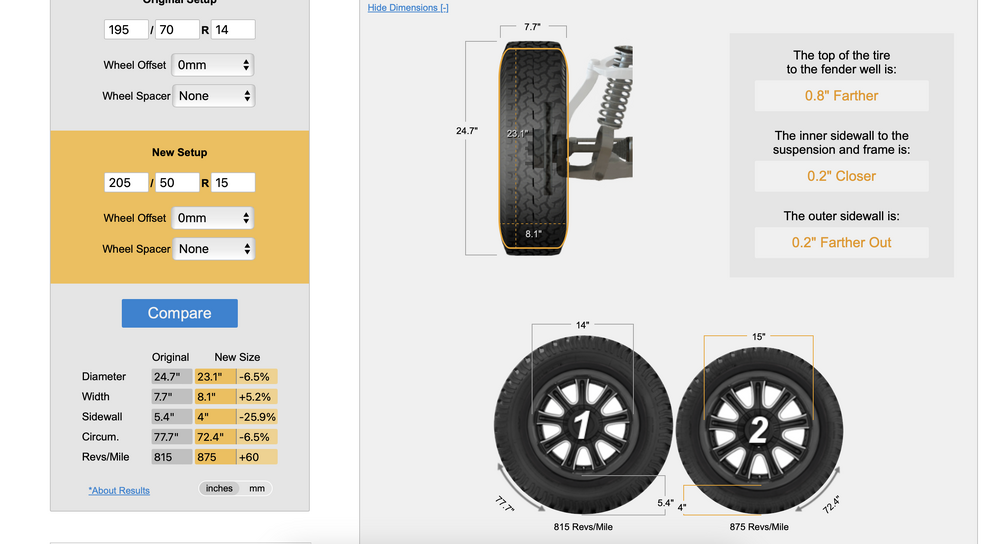

I had to go find the tire size I used, and look up the OE size - for some reason I didn't document either. I don't recall the spare being full size though - I discarded it not long after getting the car. The problem with most wheels (such as the Honda suggestion) is that the offset for FWD is not going to clear big brakes, I believe Searching for a spare also brought up a range of other 15" wheels I wouldn't mind - I liked the Rota's I had on my X1/9 - that brand has a 4 spoke 4x114.3 - but it's 15x8 - I don't know if that will clear the strut tube. I really don't need another set of wheels & tires to play with right now...

-

SpareTire

-

SpareTire

Resurrecting this thread. I have the MilkFab rear disc conversion, and the ZcarDepot front larger brake kit - after my Volvo C30 broken wheel on the NY Thruway construction zone, I'm paranoid about driving the other cars with no spares. I'm going to Ohio in August in the Z - at this point I'm not longer comfortable running with no spare. Before anyone mentions it, I do have AAA, however being stuck for hours due to a flat is not something I'm willing to experinence (again) Some ppl mentioned using a Honda Accord spare - (I'm assuming '05-'06 range based on date of original post). EDIT - looking on line '02 was the last Accord to have a 4x114.3 bolt pattern. I have no access to JY, so I'll need more concrete input if possible, since I'll have to order one off eBay if I go that route. I would rather not get a full size wheel & tire spare, as that will not fit in the well on my 75

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Getting the truck ready for another Ithaca trip, and a short one to Kingston, NY tomorrow - I got a new windshield installed today - the old original one was so pitted driving at night was a nightnmare New wheels & 2 new Bridgestone Potenza T005's for the C30 came - so I got those mounted. Need to check the toe old one new This is what I drove home on last Sunday

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Lol - my co-workers were singing that to me - emphasis on "Schools Out Forever" 😁

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

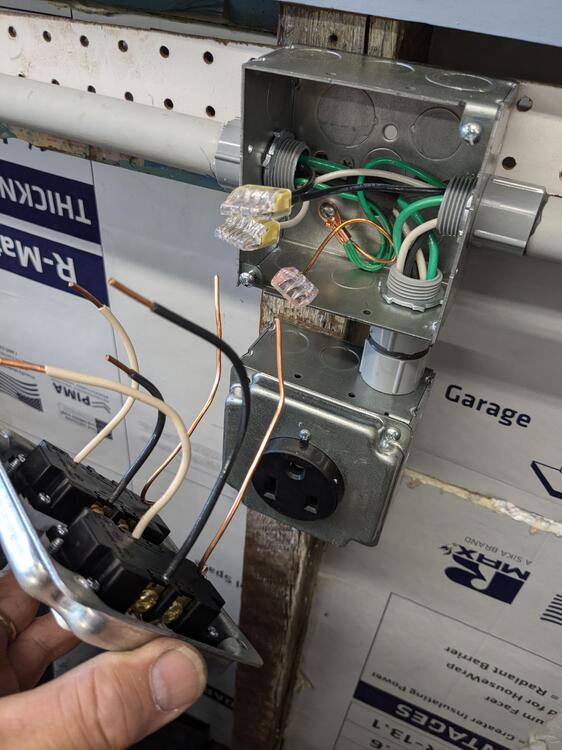

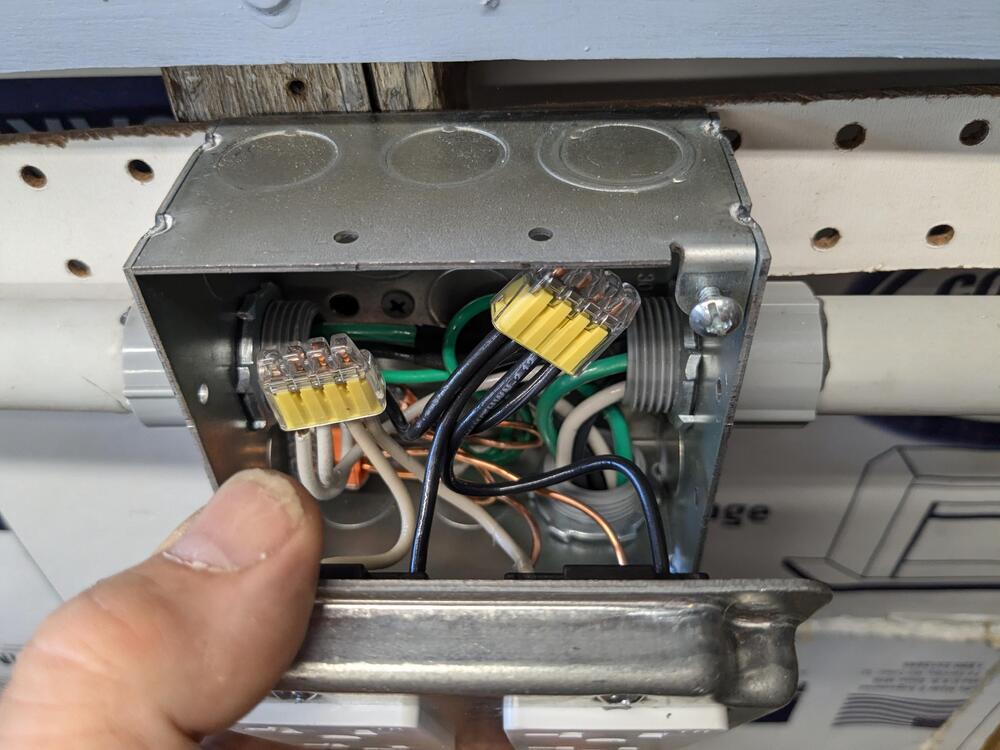

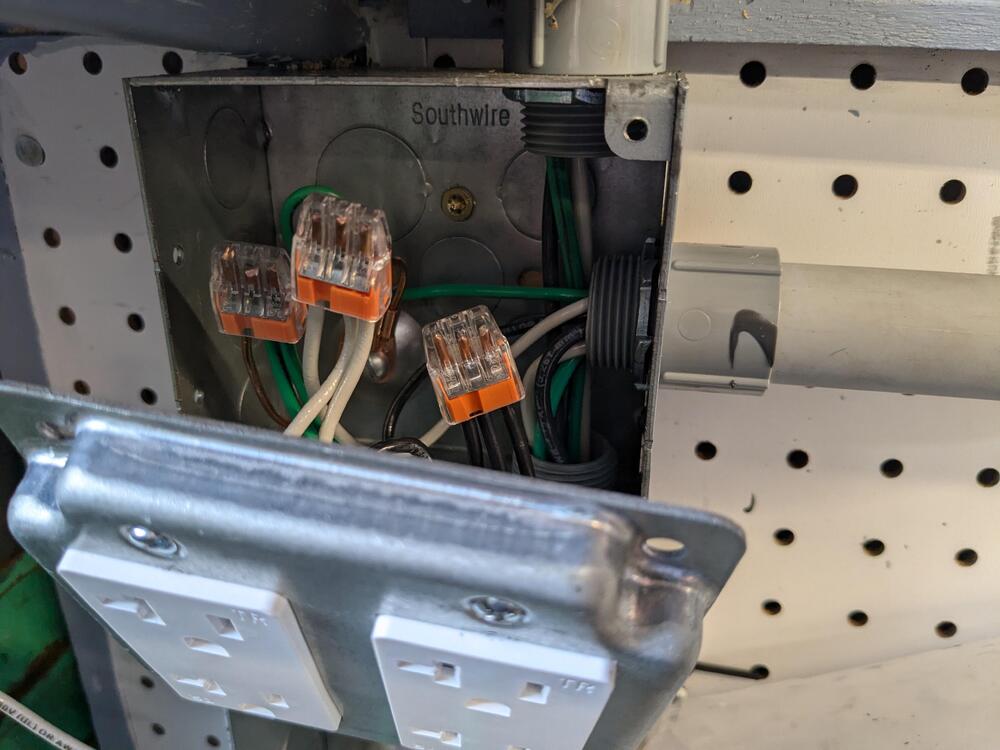

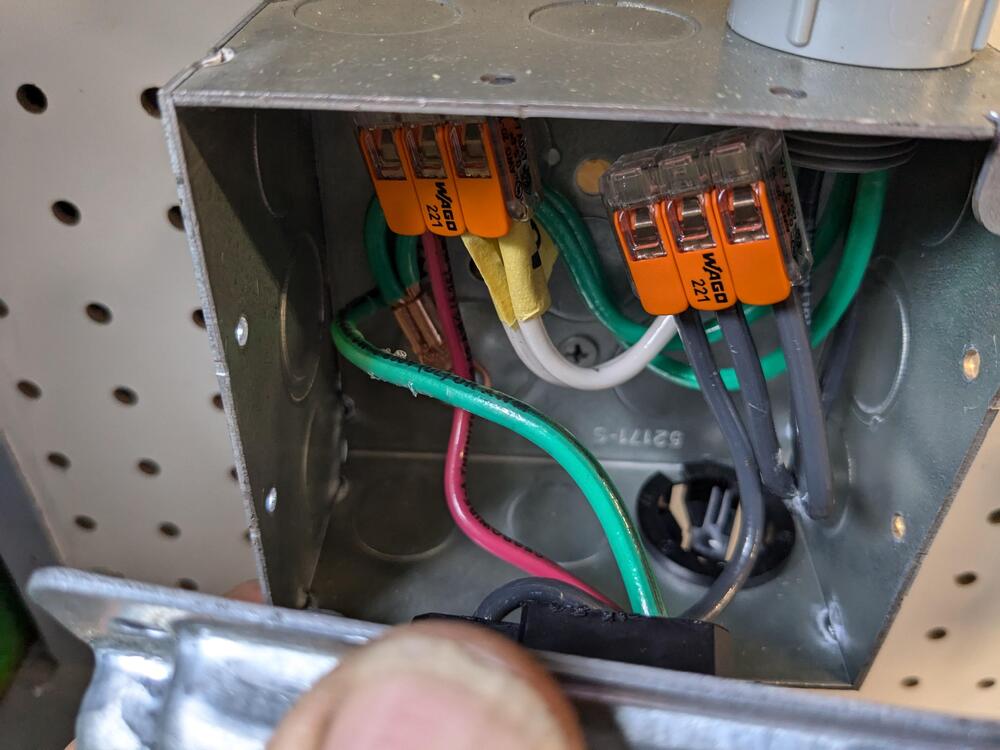

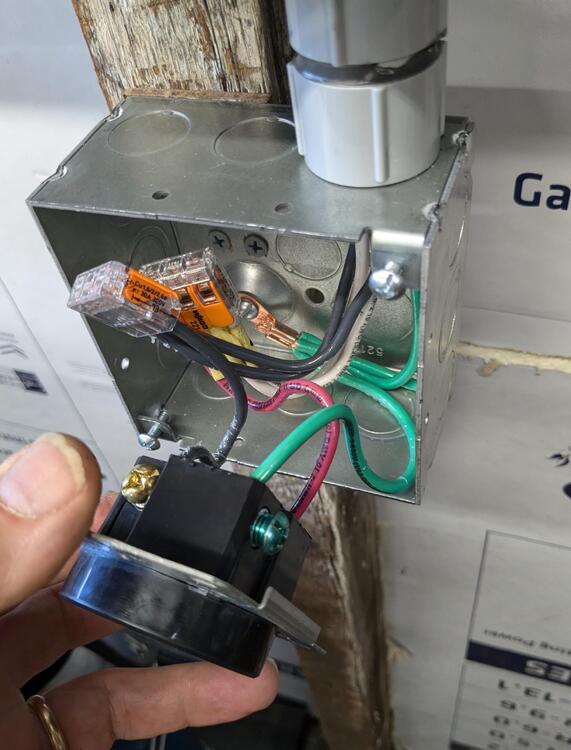

Today was the last day of my teaching career. I'm officially retired 🤪 Got a little wiring on the south wall - finished up the wiring of the 240 & 120 receptacles Used crimp eyelets for the grounds wired each receptacle separately rather than bridging them 12AWG for the 20A receptacles Made sure they were the right version 240V outlet this time 10AWG for the 240V 10WGA Junction that feeds the East center post receptacle

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

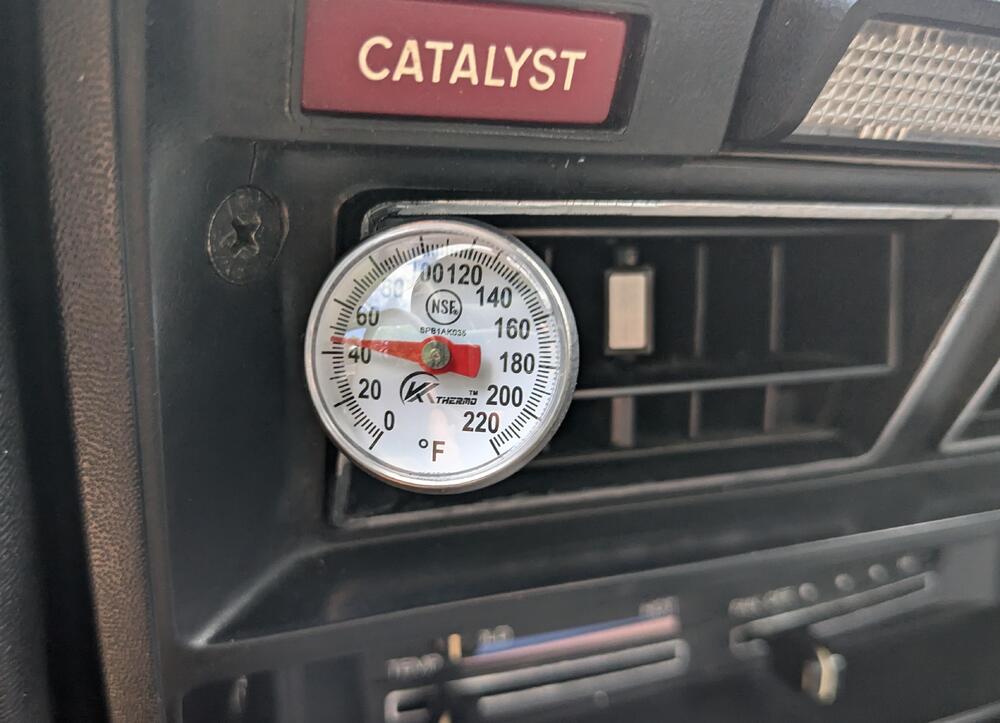

Got the Z in for it's annual safety inspection this afternoon - after driving around some more AC is running around 45ºF - very happy with that

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

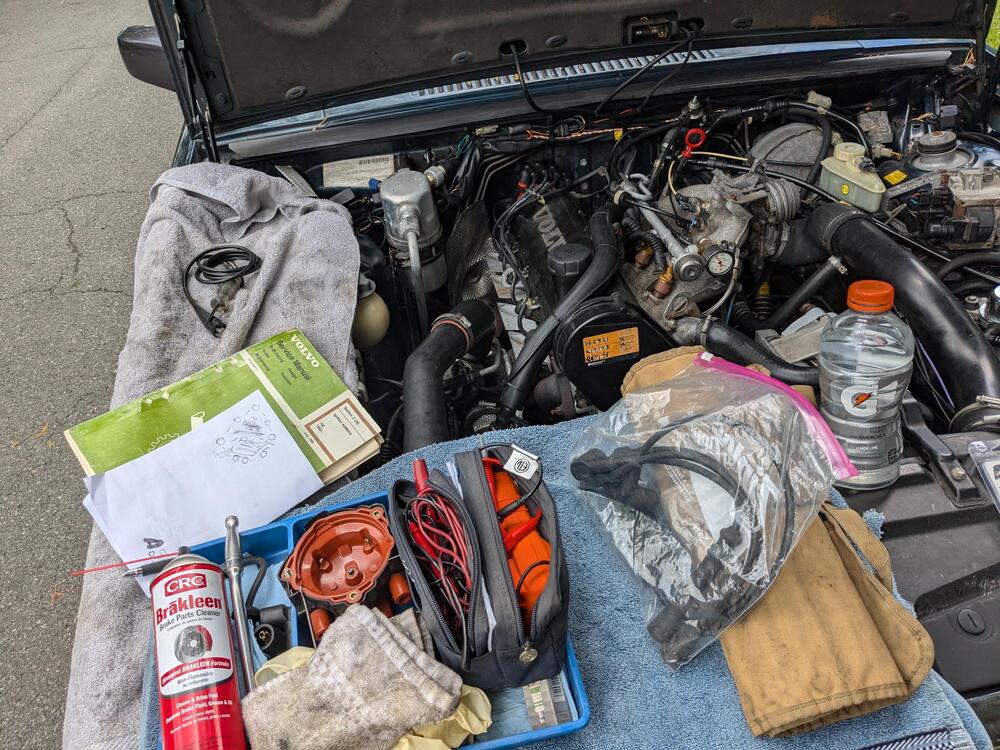

The meet was awesome, I'm glad I went - not so much the actual travel to & from... The pickup issue was pretty straight forward - no spark to the plugs, but spark present to the distributor. I didn't have a spare cap or rotor, or I probably could have fixed it on the road. Ultimately, I replaced the rotor & 2 of the wires that didn't have positive lock on the plug anymore. Actual resistance values of the wires were OK. Plugs were all OK, gaps OK. I had just replaced the cap & rotor a few days prior when I removed the distributor to address the leaking shaft seal. I should have just left the old ones on, they only had maybe 5-6K miles on them. I re-installed the Bosch ones, just cleaned up the contact points Dead (non-Bosch) rotor on left Plugs OK, gap OK (WR7DC) checking spark on each wire after running again , stable idle

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Space saver after 100 miles with extreme camber Bent tube removed Have to keep it 45 or lower to avoid drivability / handling concerns. Made it back to Deposit, NY where the accident happened. took me over 2 hours to go the 90 miles. The remaining 140miles will take about 3 hours, on a replacement same spec space saver (mid 00's Volvo S60Rs came with big brakes - so they provided a space saver with a deep offset, works for my setup.