Everything posted by HusseinHolland

-

SpareTire

-

SpareTire

Resurrecting this thread. I have the MilkFab rear disc conversion, and the ZcarDepot front larger brake kit - after my Volvo C30 broken wheel on the NY Thruway construction zone, I'm paranoid about driving the other cars with no spares. I'm going to Ohio in August in the Z - at this point I'm not longer comfortable running with no spare. Before anyone mentions it, I do have AAA, however being stuck for hours due to a flat is not something I'm willing to experinence (again) Some ppl mentioned using a Honda Accord spare - (I'm assuming '05-'06 range based on date of original post). EDIT - looking on line '02 was the last Accord to have a 4x114.3 bolt pattern. I have no access to JY, so I'll need more concrete input if possible, since I'll have to order one off eBay if I go that route. I would rather not get a full size wheel & tire spare, as that will not fit in the well on my 75

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Getting the truck ready for another Ithaca trip, and a short one to Kingston, NY tomorrow - I got a new windshield installed today - the old original one was so pitted driving at night was a nightnmare New wheels & 2 new Bridgestone Potenza T005's for the C30 came - so I got those mounted. Need to check the toe old one new This is what I drove home on last Sunday

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Lol - my co-workers were singing that to me - emphasis on "Schools Out Forever" 😁

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

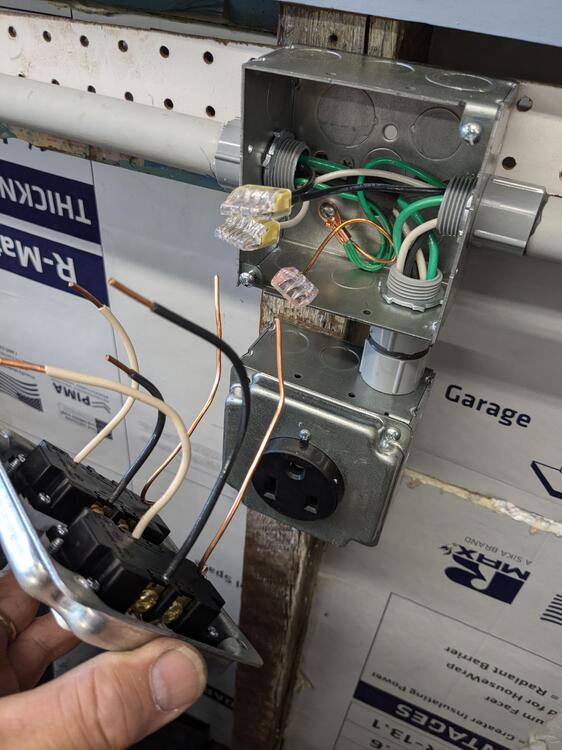

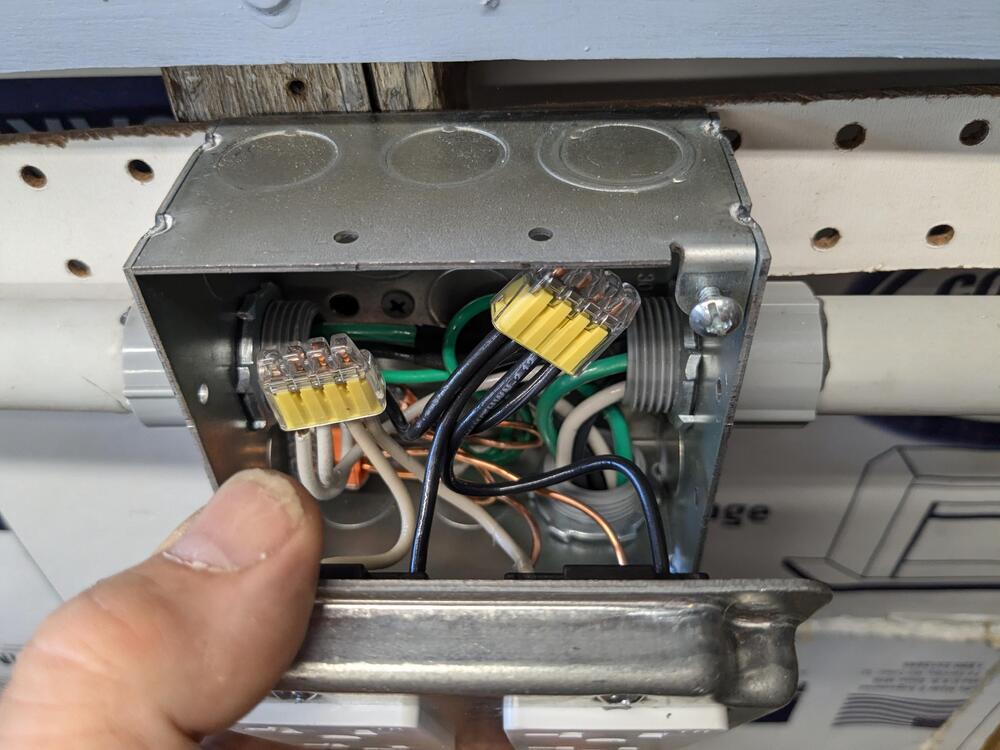

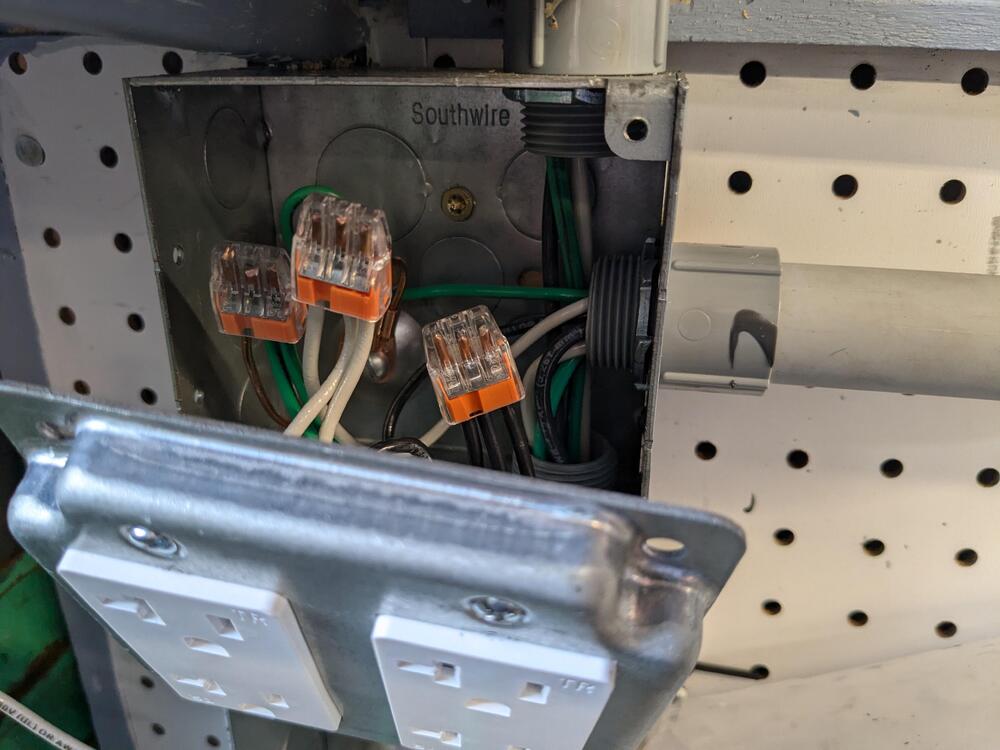

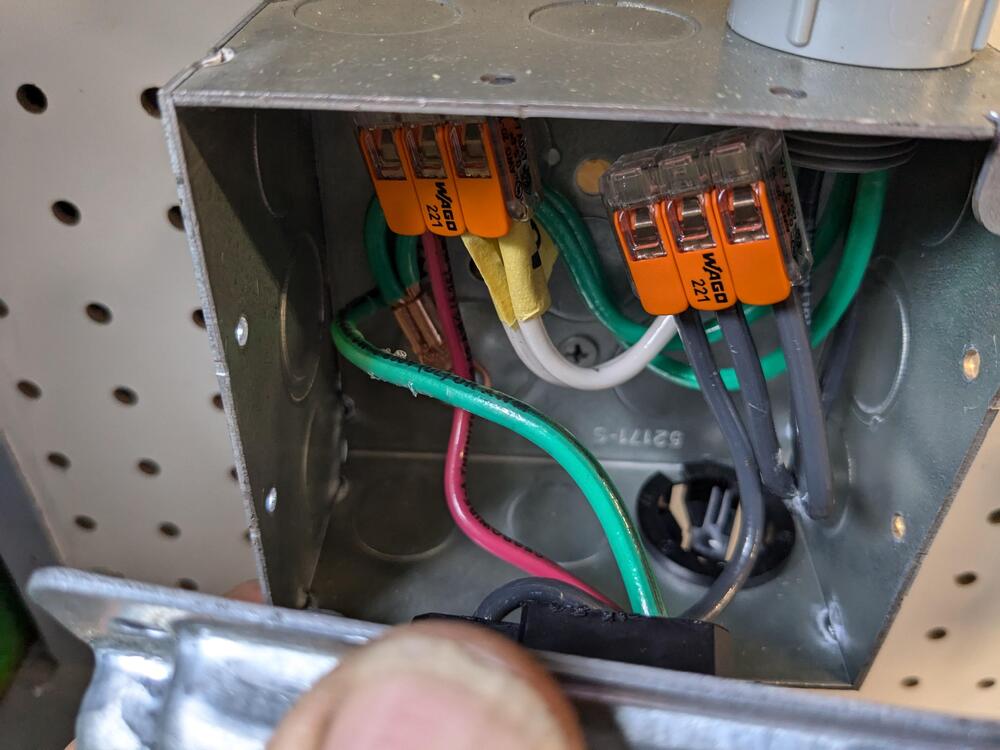

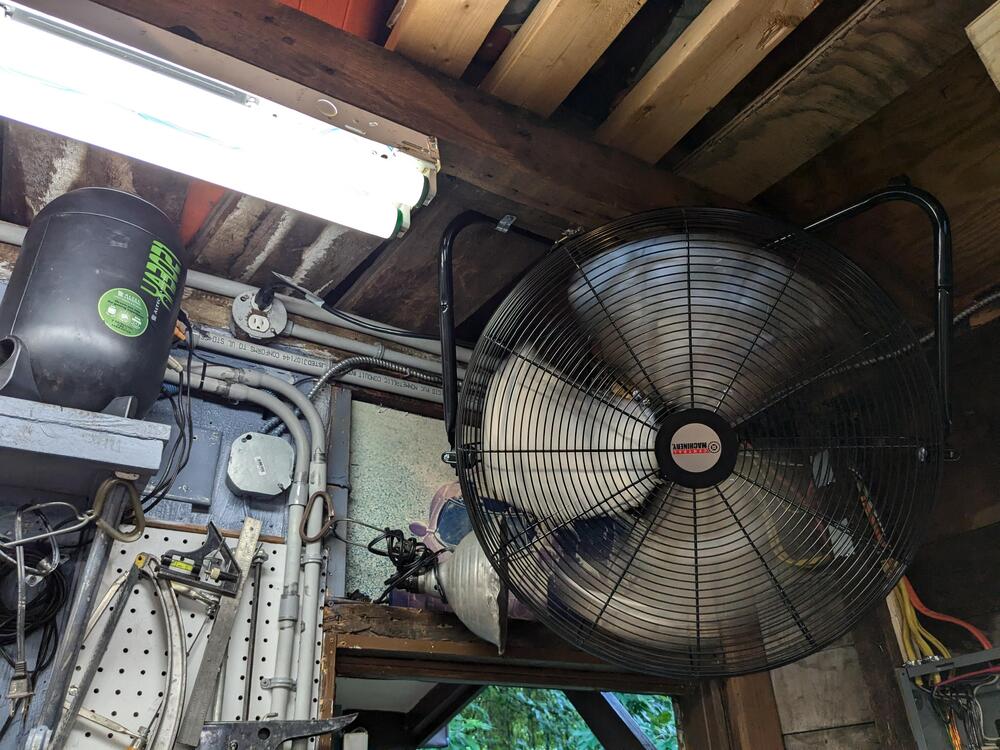

Today was the last day of my teaching career. I'm officially retired 🤪 Got a little wiring on the south wall - finished up the wiring of the 240 & 120 receptacles Used crimp eyelets for the grounds wired each receptacle separately rather than bridging them 12AWG for the 20A receptacles Made sure they were the right version 240V outlet this time 10AWG for the 240V 10WGA Junction that feeds the East center post receptacle

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

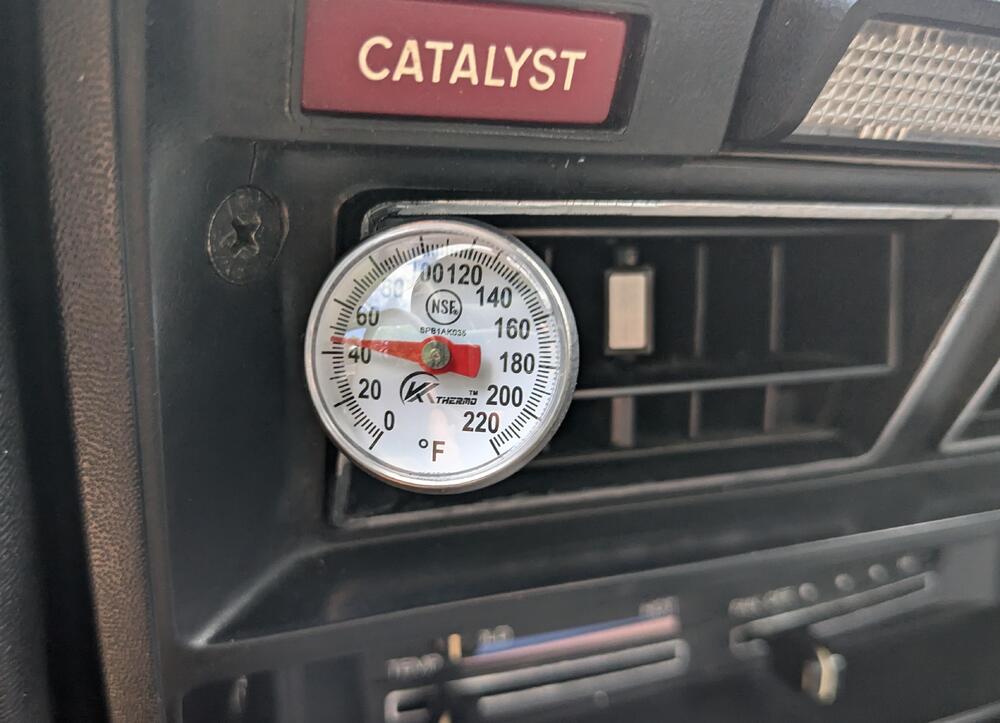

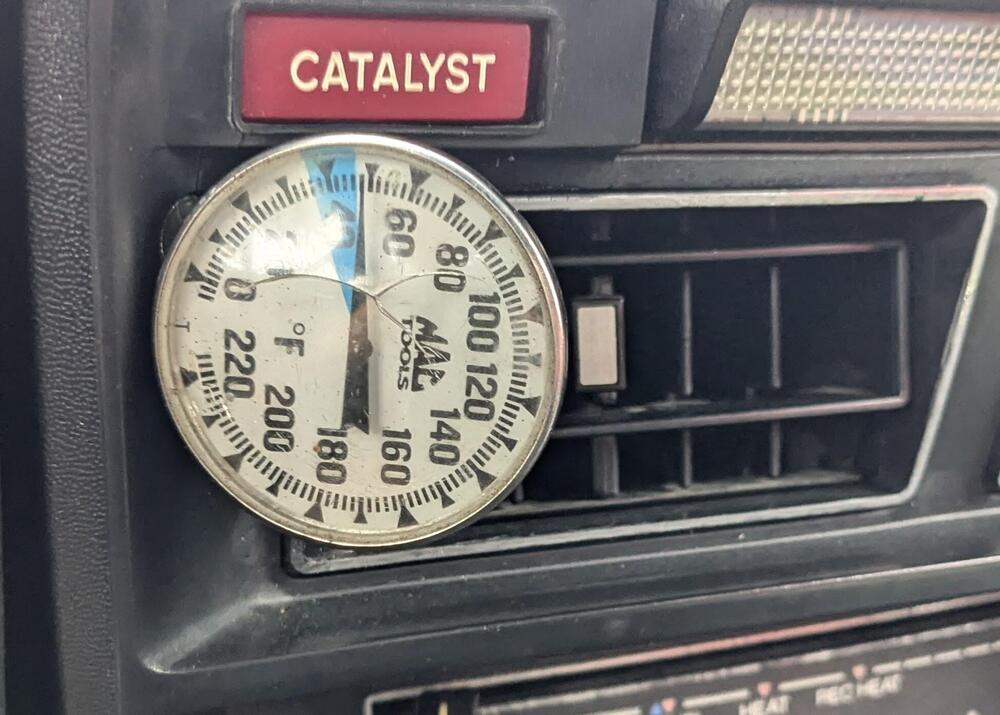

Got the Z in for it's annual safety inspection this afternoon - after driving around some more AC is running around 45ºF - very happy with that

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

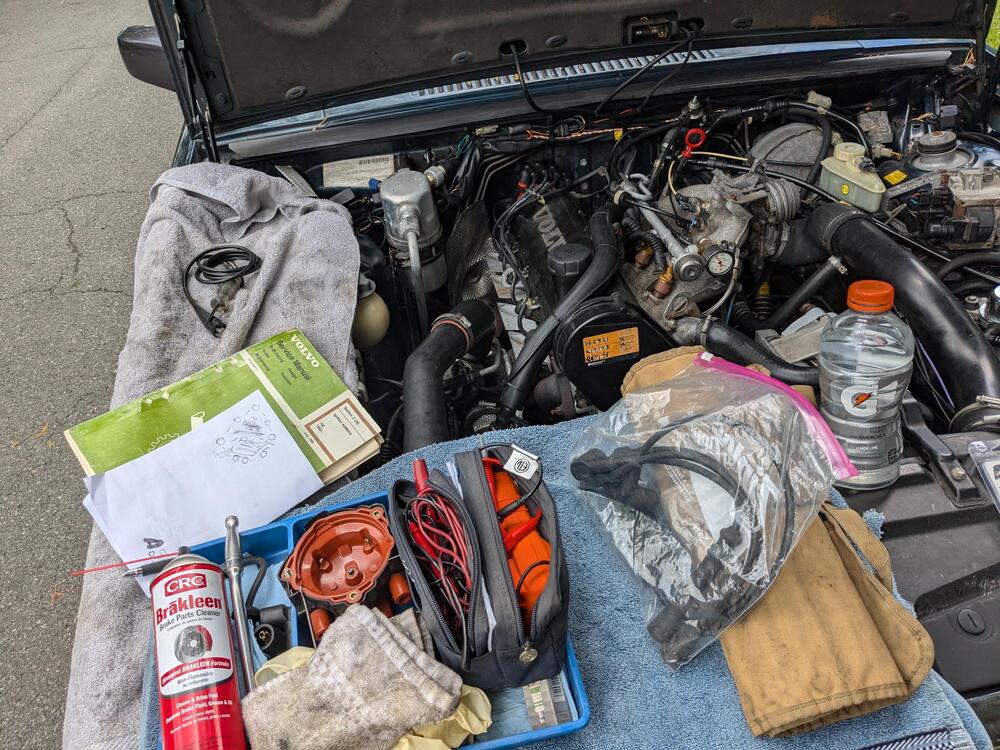

The meet was awesome, I'm glad I went - not so much the actual travel to & from... The pickup issue was pretty straight forward - no spark to the plugs, but spark present to the distributor. I didn't have a spare cap or rotor, or I probably could have fixed it on the road. Ultimately, I replaced the rotor & 2 of the wires that didn't have positive lock on the plug anymore. Actual resistance values of the wires were OK. Plugs were all OK, gaps OK. I had just replaced the cap & rotor a few days prior when I removed the distributor to address the leaking shaft seal. I should have just left the old ones on, they only had maybe 5-6K miles on them. I re-installed the Bosch ones, just cleaned up the contact points Dead (non-Bosch) rotor on left Plugs OK, gap OK (WR7DC) checking spark on each wire after running again , stable idle

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Space saver after 100 miles with extreme camber Bent tube removed Have to keep it 45 or lower to avoid drivability / handling concerns. Made it back to Deposit, NY where the accident happened. took me over 2 hours to go the 90 miles. The remaining 140miles will take about 3 hours, on a replacement same spec space saver (mid 00's Volvo S60Rs came with big brakes - so they provided a space saver with a deep offset, works for my setup.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Hell of a day today. Left home with the Mrs. at 9am to head upstate for the annual Volvo car meet. We got about 30miles north & then the pickup died. I tried to fix it, but there was no spark & I had no parts to fix it on the spot. SO, we got towed back home around noon. I still wanted to get up to Ithaca for the meet, so repacked the C30 & left on my own, the Mrs. had had it. I got about 2 hours or so into the drive & then this happened Single lane traffic through a construction zone, basically we were all on the shoulder. Section of roadway heaved, broke the Tesla in front of me, I moved over as far as I could without hitting the concrete divide, and got the broken wheel & a bent strut tube Just a little extra camber I put the space saver on it & drove the remaining 90 miles at 40-45mph. That was excruciating, but at least I made it, and ppl up here were able to source a strut tube, so I can change that tomorrow, if all goes well. I'll have to drive downstate on the space saver, which won't be fun, but at least I won't need to be towed all the way home.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

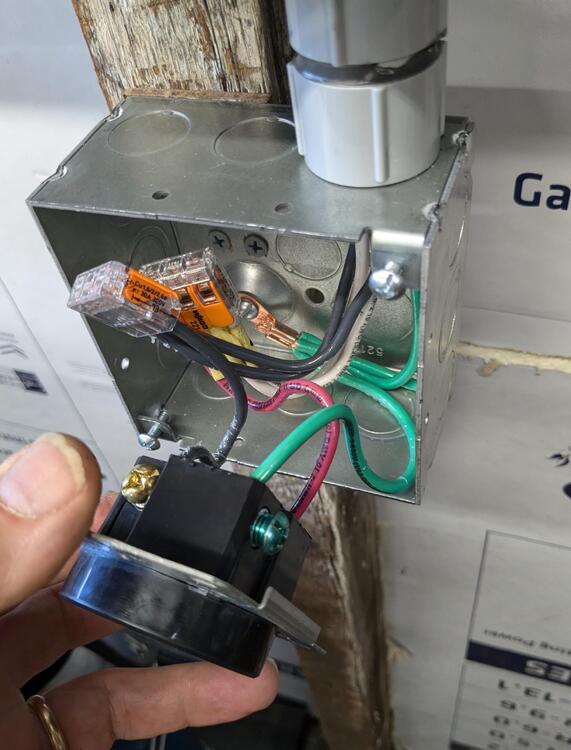

Chipping away at the wiring runs. Added an outlet up high (that I forgot earlier) to plug the fan into running the 10ga & 12ga in the conduit along the south wall 4" deep box sitting above will be mounted below existing for the 240v receptacle, like the East end boxes above, Ran out of 3/4" threaded ends

-

Designing A/C System Using Other Cars Parts?

-

Designing A/C System Using Other Cars Parts?

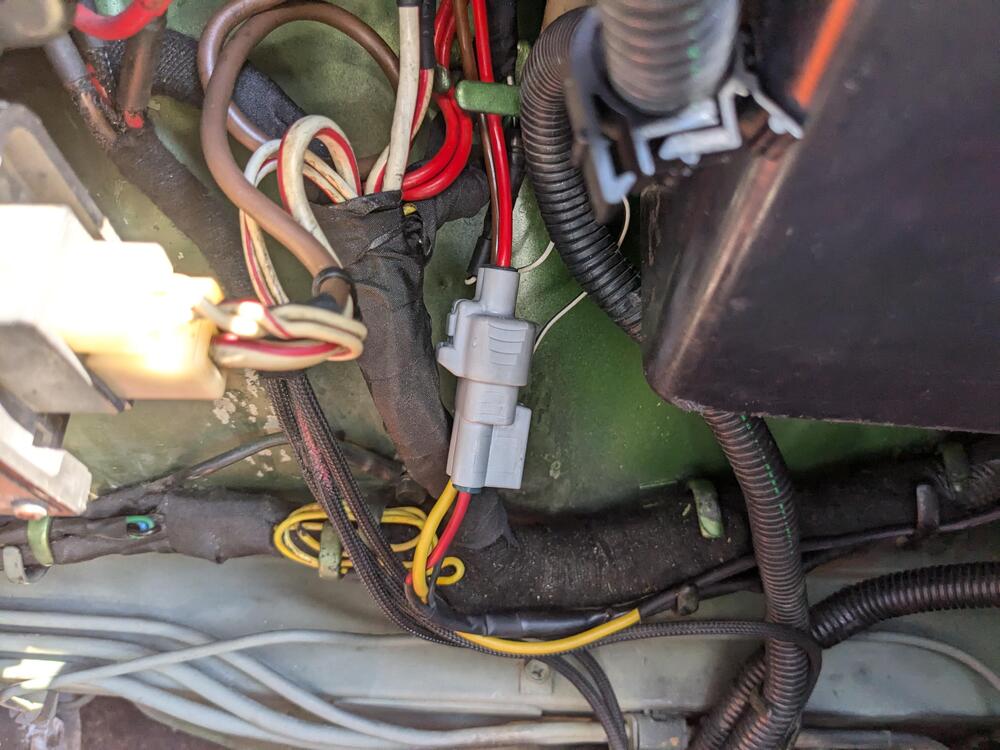

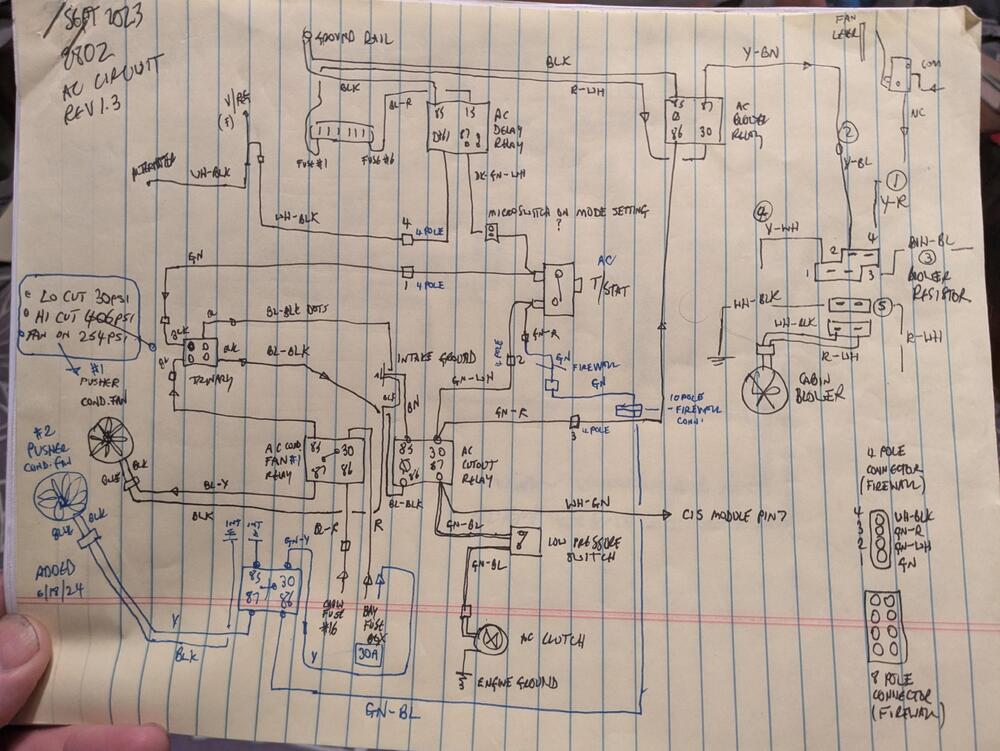

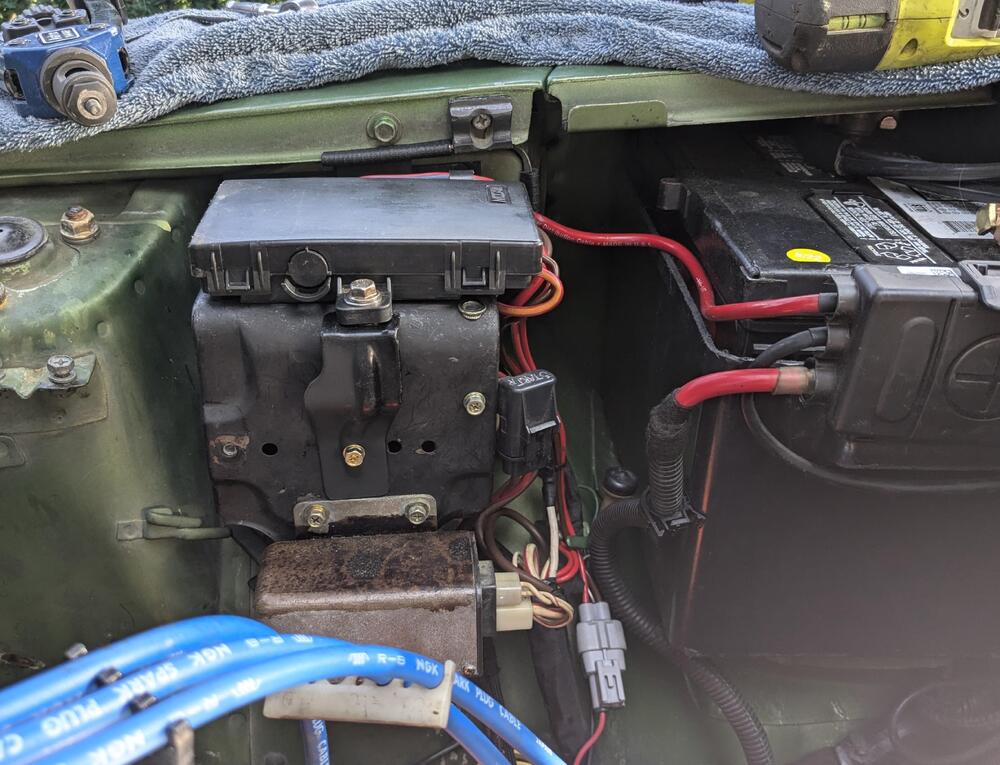

Did the wiring for the 2nd fan. Took awhile. I ended up running a completely new circuit instead of tapping into an existing. Relay connections Racetronix SPST (Delphi components) relays fused power (Y) Switched power from AC T/stat (Gn) 90ºF outside - duct temp 55ºF, not bad. I do need to recheck the system pressures. May need a little more freon (R134a)

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

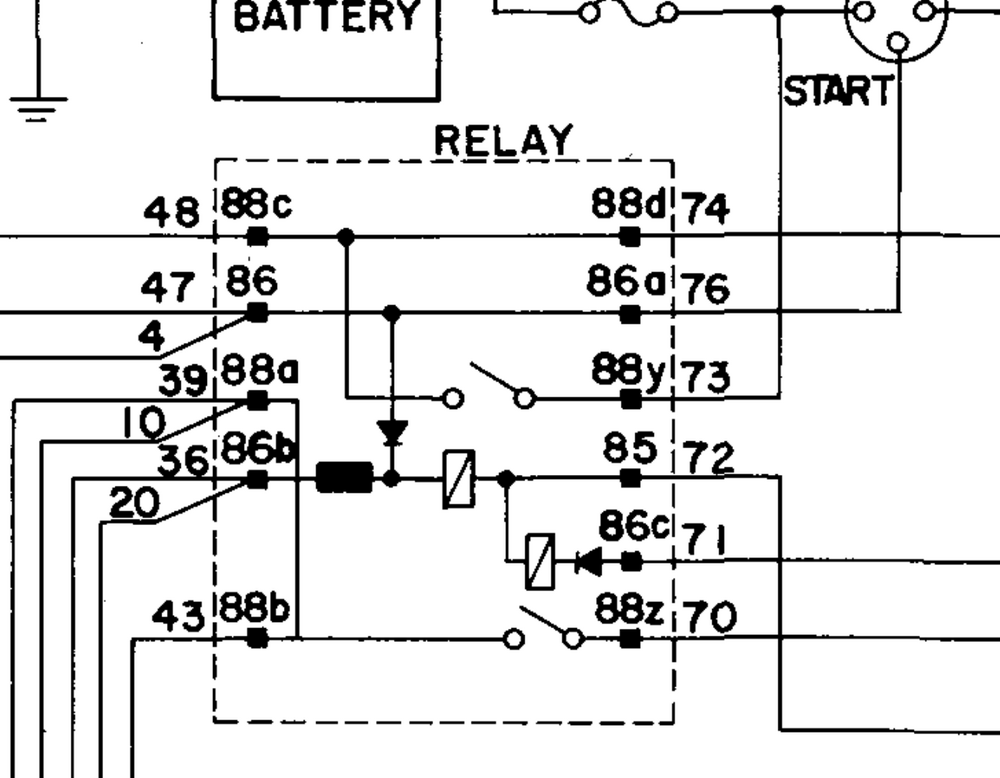

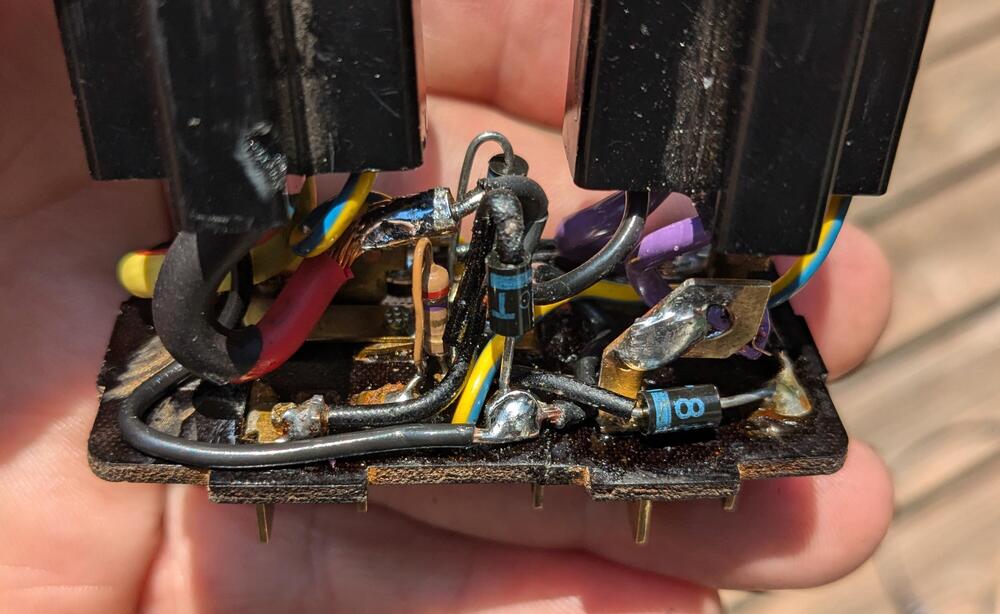

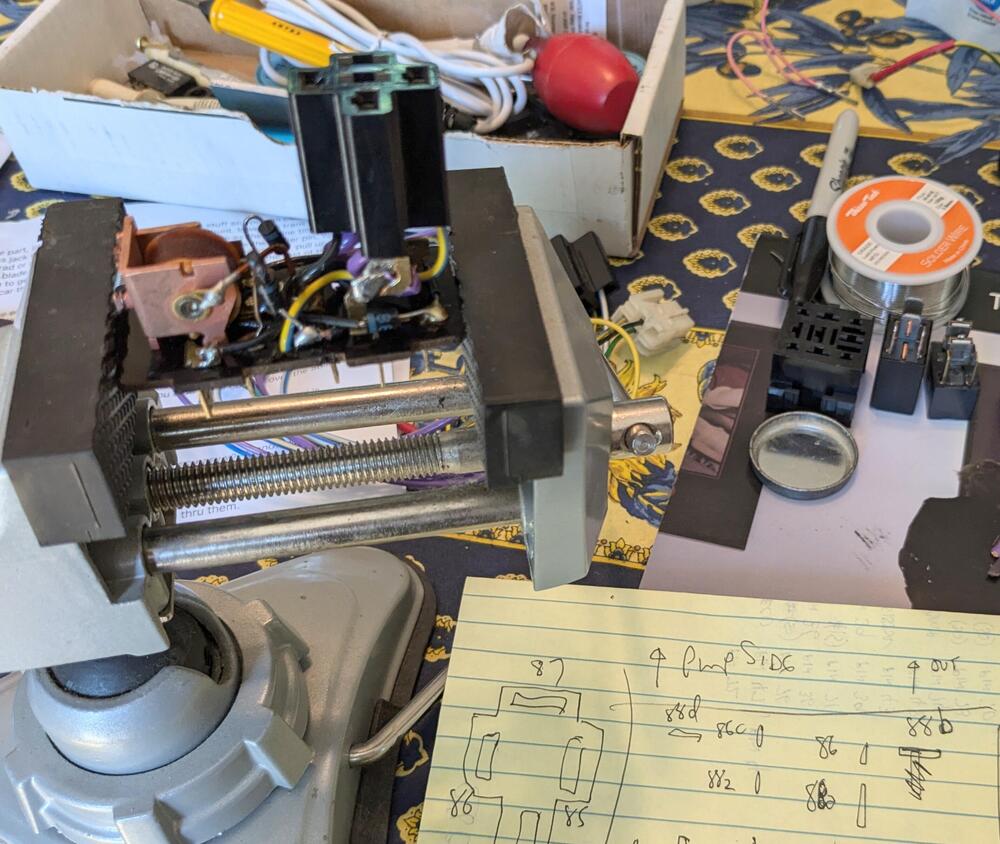

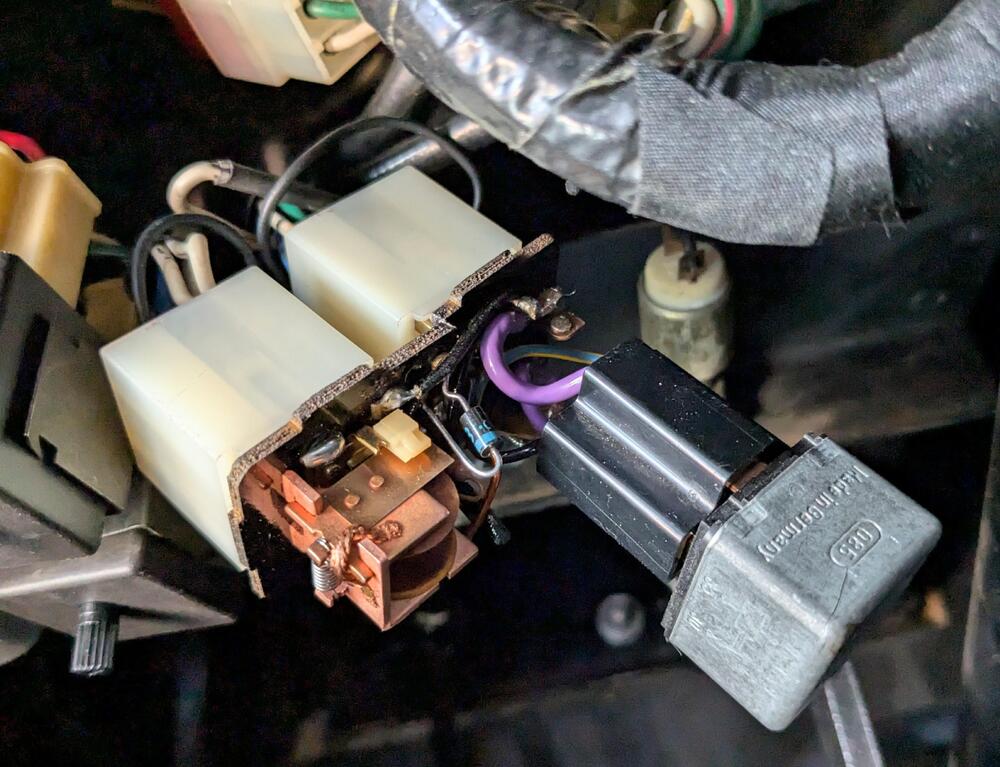

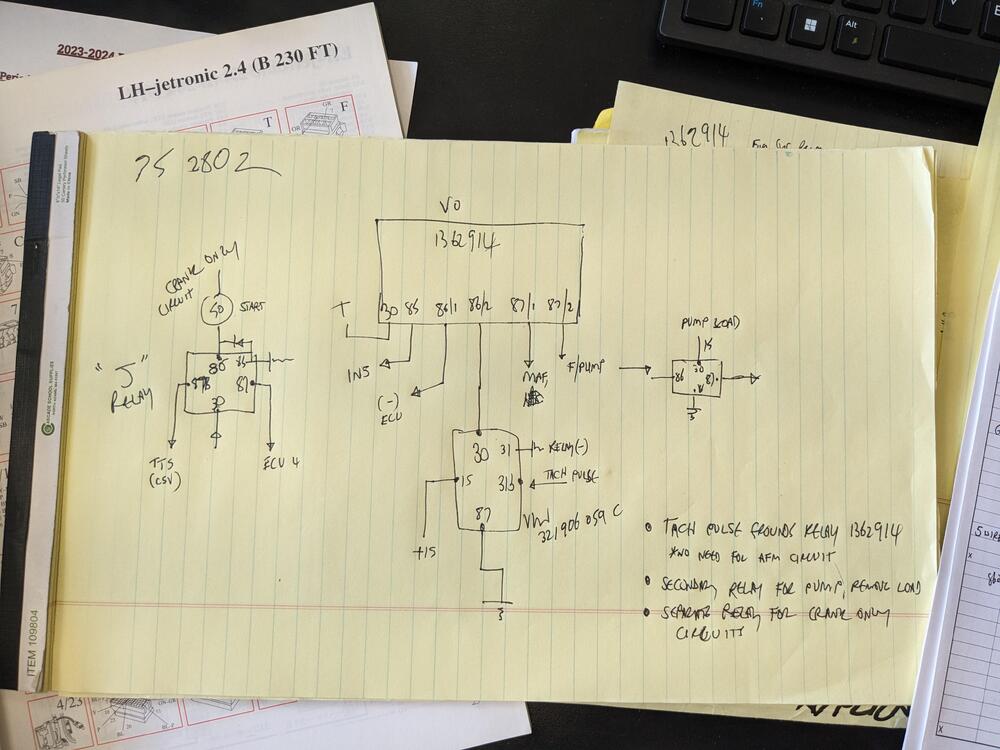

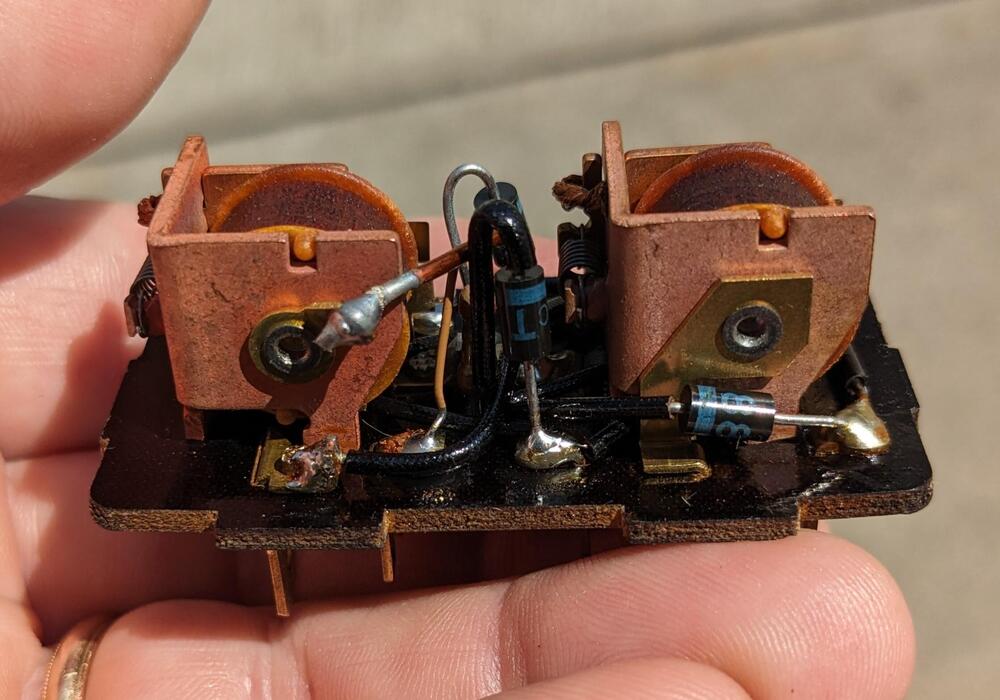

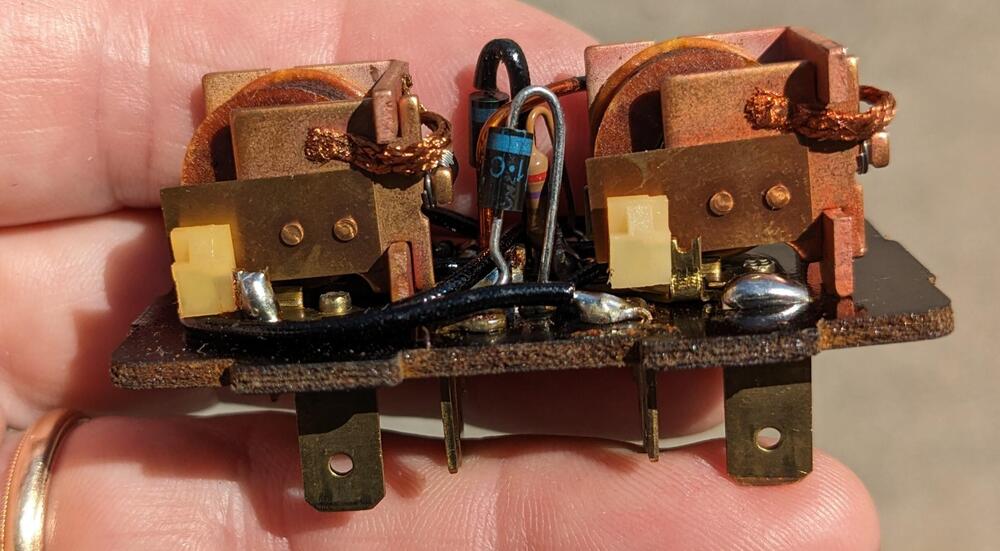

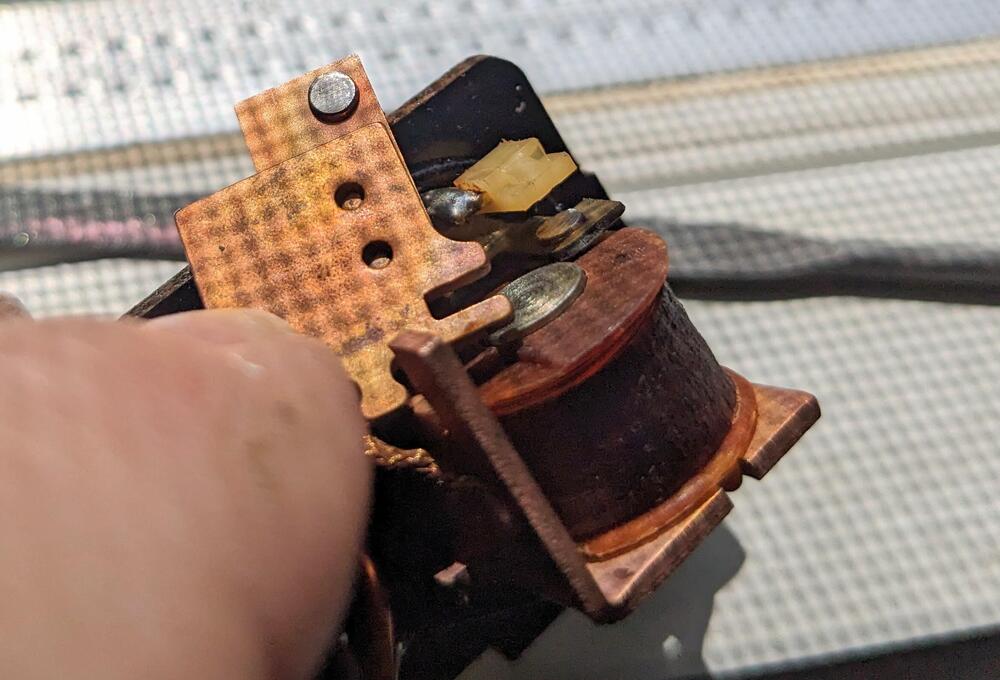

Odd that the diagrams all only show 2 diodes - the one for the crank only enrichment circuit, and the one on (+) 86c - there is another on the combined ground leg (85 terminal) Horizontal mounted diode is on the (50) crank only enrichment /pump signal circuit. Diode on top right center is on the ground leg (85). Diode on bottom right center is on the power relay coil feed (86c)

-

Designing A/C System Using Other Cars Parts?

Driving this afternoon, I got stuck in heavy highway traffic for about 20min. With the A/C on, idling, the coolant temps started to creep up over normal. I don't want to have to turn the A/C off in such situations, so I'm adding a second condenser fan that will run as long as the A/C is on. The existing fan ONLY comes on by way of the Trinary switch, which is set to engage it when pressure exceeds 254psi - which basically means it doesn't come on very often, definitely not when I need it to. On the Volvo pickup, I had rewired the fan onset when the stock pressure switch died - it made the A/C keep cooler & lowered the high side pressures. Added rivnuts to the AC condensor riveted anchoring plate at the top 2nd Fan installed, now I just have to fiinish wiring it

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

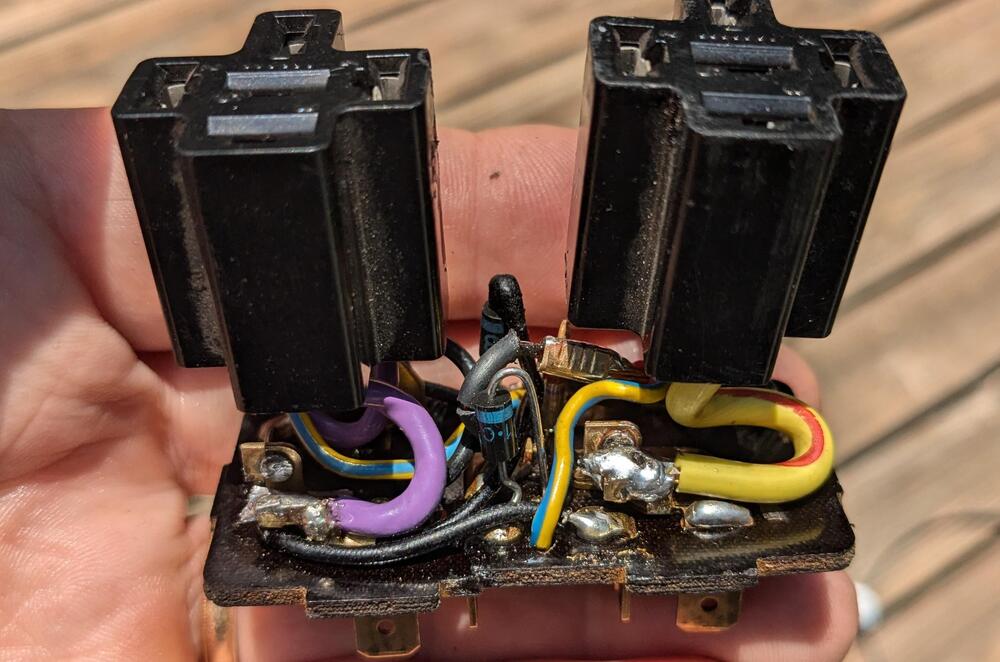

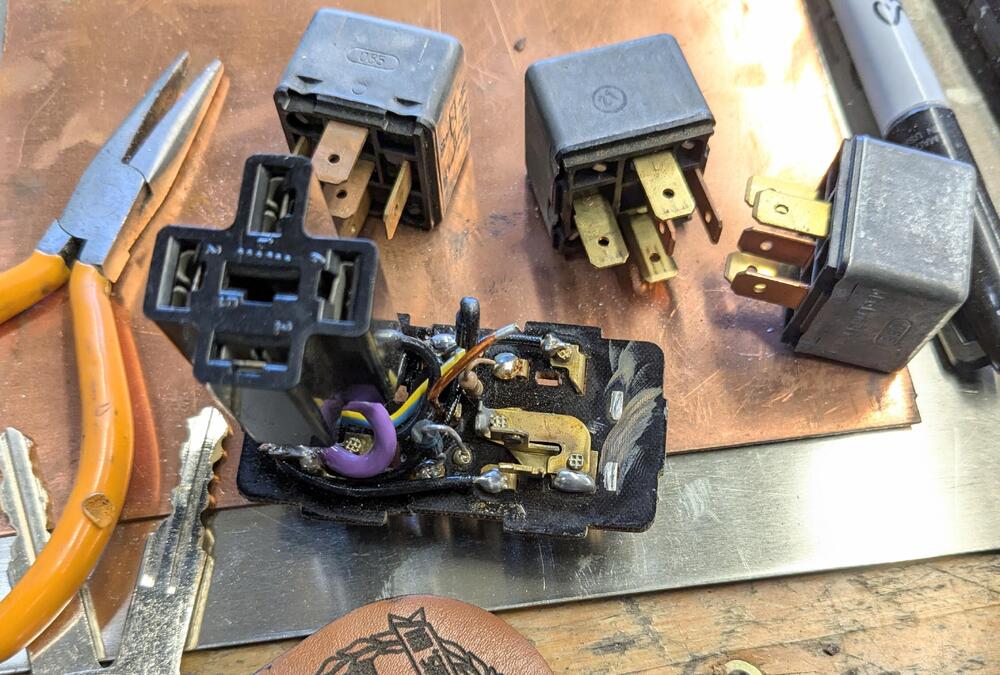

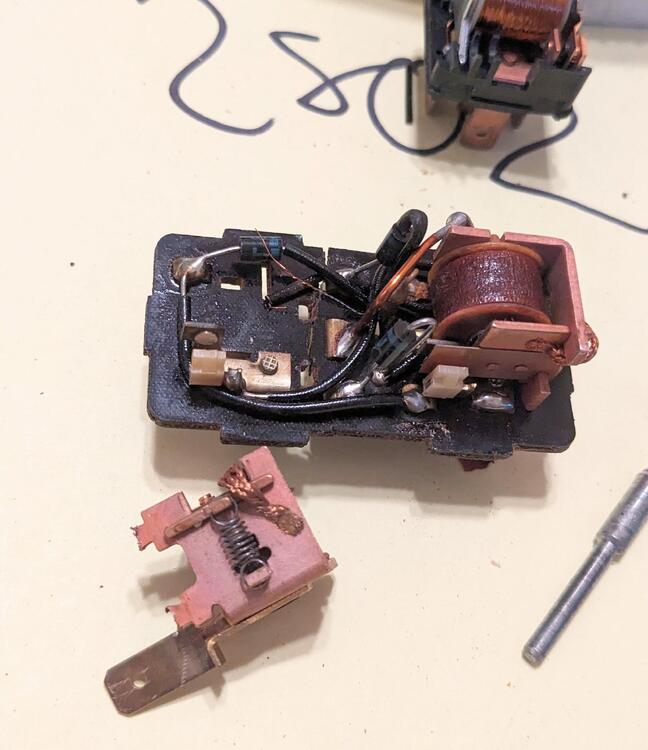

Finished the 'adaptor' socket Ran the switched coil feeds through to the underside - not enough room to solder them on the component side After I tested it in the car, I epoxied the base after - I had cracked the base when I pried off the first coil, so I wanted to make sure nothing was going to move. Put the cover back on to retain the new relay sockets

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

I decided to go a easier softer route - used the factory base, adding standard cube relay sockets that will be secured in the factory relay cover, so easy to replace the part that could wear, without dealing with rewiring the harness Plugged in to test - make sure my wiring is correct before dealing with the other side Cutting the cover Removed the 2nd coil, more to come.

-

Vapor Tank Question

If you haven't located a good cannister that will fit without modifications, I could sell one of the two I have - both work. I don't need 2. I'd want more for the original Datsun, vs. the Volvo/GM version. May depend on where you live as far as shipping goes, it's quite large & weighs a few pounds. You can message me if you are interested.

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

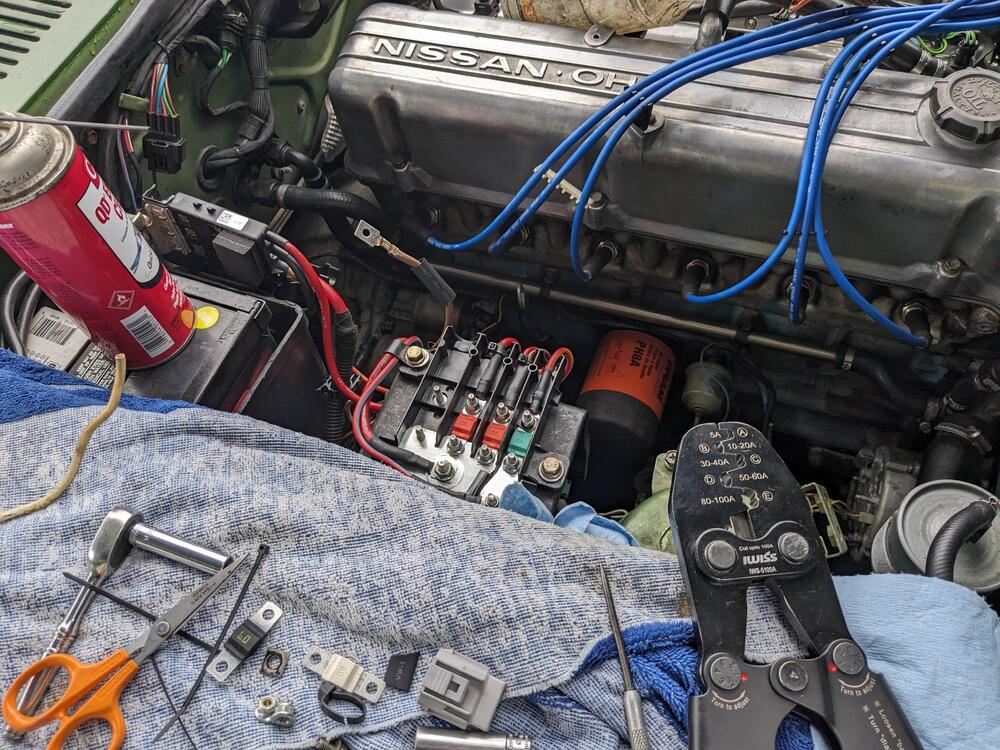

Good point - that load alone accounts for more than half the rating of the fuse I had installed, coupled with under-rated wire gauge. I'm planning on re-wiring the EFI relay to use a couple of standard cube relays for the crank & pump circuits, with a (more readily available) Volvo EFI system relay to govern it. The pump relay will have a separate fused feed. Since I won't have the floating ECU ground normally used to control it, I'm going to use a VW relay that requires a tach pulse to switch the main relay ground. With that, I can do away with the AFM circuit. The goal is to shift the load from the complex relays to the (Volvo/Bosch "J" cube relays that are intended to carry up to 50A loads, and are easily available. I'm driving this to a Fiat meet in Ohio in August - I don't want to drive that far relying on a relay that is essentially unobtanium. along these lines

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

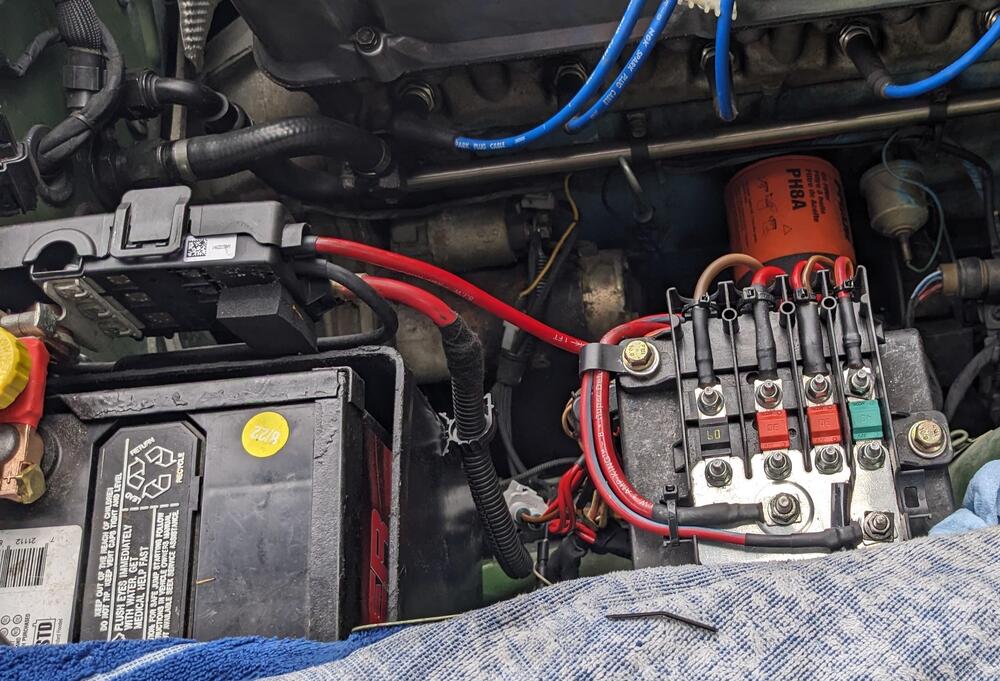

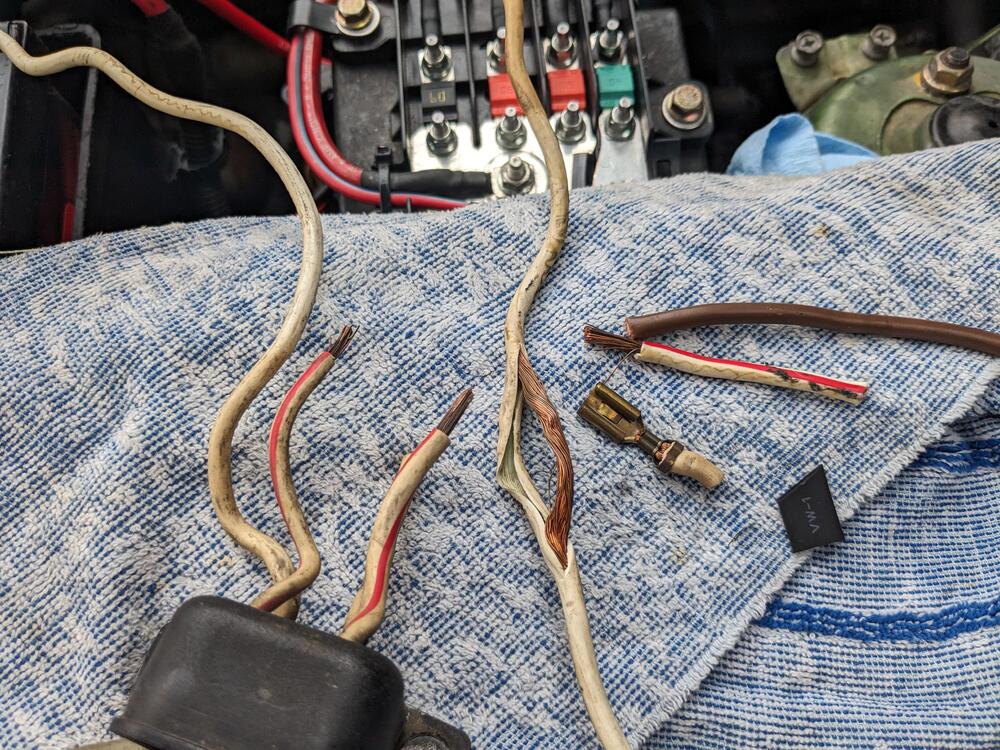

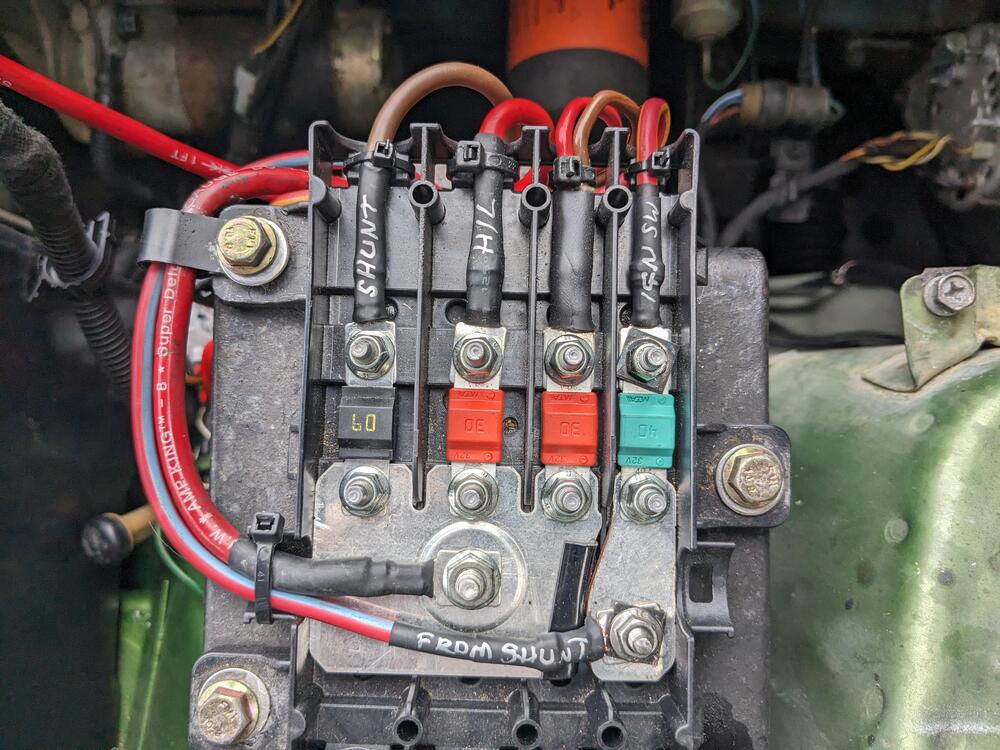

I don't know. I did determine that the fuse holder I used was actually the version rated at 20A (based on the AWG) - I must have swapped out the 20A for a 30A fuse, so maybe the combined draw of all the consumers off the switch was just too much, it definitely overheated. So, I've re-wired the Ignition switch feed (from Shunt) via the Midi fuse block. Using a 40A fuse to match the value of the fusible link previously replaced with the inline blade that melted. Sectioned the supply plate Approx 3mm wga Red/Blue to match original ignition switch feed (Red-White) from shunt to 40A fuse MTA Midi fuses & power supply crimp terminals Replaced (White) feed wire from fuse block to Shunt, approx 3.5mm wga Brown - mine looked iffy. Sliced it open to look at where the wiring was kinked. Actually in better shape than the insulation appeared. I had bought some 7.8mm Female spades of the type used on the Datsun, thankfully. Used 60A Midi fuse - original link was 80a, according to chart. Feed line from main fuse block is 80A labelled so I don't forget what feeds what (have to figure out what the 3rd one is for) l

-

Vapor Tank Question

There is no (no aspect of the system is designed to pull a vacuum on the tank) vacuum pull on the vapor line from the gas tank/vapor tank circuit. Vacuum only operates on the cannister. The large vacuum line on the purge valve from the intake is the draw, the small vacuum line from the TB is the "switch" that opens the port to allow the large line to pull fuel vapor from the cannister off idle.

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

I think I found a problem today, car hiccuped & then died, and this time it was dead - the maxi fuse melted. I'm assuming it's just poor quality. Got to bobby pin from a student, but that melted right away, clearly not good for 30A . So I broke a keyring in half and shoved that in there so I could drive home. This was the replacement for the fusible link between shunt and ignition switch.

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

Yesterday, I drove the car with the Mrs., and it acted up - no throttle response & cut out a few times, stalled. Restarted every time. I thought maybe I was actually out of gas, as the (cheap) new gauge seemed pretty inaccurate. Anyway, that wasn't it. Today I took apart the old relay & cleaned the contacts to retry the relay. It didn't a make a difference, the coil is the problem, it overheats & cuts out as before. Took a bunch of pics of the relay, so I could try replicating it. resistor for AFM circuit is 2ohms. I'll probably just make a new relay setup, just didn't want to cut the factory harness at this point. pitted contact after resistor value 2ohm tried to cleanly remove the coil, cracked the board in the process I also added an extra heat sink for the HEI module, as it did seem to be getting pretty hot So, in the end, I didn't find anything conclusive, and after the initial glitch/hiccup in the driveway, I took a short drive this evening & flogged it hard to see if I could make it act up. It ran just fine.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

I had done the siding then the trim, but I had to go back & touch up the siding. for the stuff that's left (up above the entry) I'll do the trim first, seems to work better. Zonked again today - slept in. I think I did too much yesterday. Back to work tomorrow, I only have till Thursday with my (art classes) students, then it's Regents Exams, so no regular class attendance. They all need to finish their art finals, and I was out all last week, so I know many will have elected to coast in that time without me there to motivate them.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Last few days I've just been futzing on small things - not enough energy to pull the trans Tuesday - after napping most of the day away, I had to get something done so I replaced the 3 kitchen counter receptacles with GFCI - been meaning to do that for years also got another coat of paint on the garage bump out, and started cleaning up the trim. I'm not great at cutting trim Today I added an 8' LED light on the left, 2 fluorescent units on the cross beam Fixed the base of the attic stairs - old base sheet was 1/4" - I changed it with 3/4" and bonded the tie plates to it. Much more rigid & secure now. The other thing I'm always missing is a secure place to put the odds & ends I end up working with - I made a frame to retain 3 trays I have -instead of having to have it in the way on the bench, or under