Everything posted by HusseinHolland

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

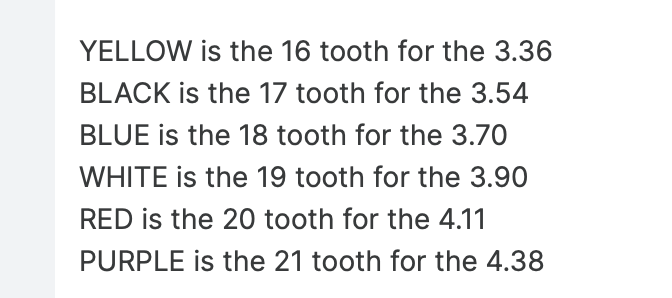

I'll count the teeth on the 75 one when I pull it - according to the linked page the white one I have is 19 teeth. Hopefully mine has only one or two more teeth than that, which in combination with the 5 speed drive gear should slow the speedo cable enough to make it more accurate at highway speeds. Wife & I tested positive for COVID at the local doc-in-abox this morning - we've been playing tag with whatever virus I got at school for the past 2 weeks, but she is in much worse shape than I. So, not much getting done car-wise, just don't have the energy. 😞 EDIT - found this - so I may as well leave the 19 tooth in, as it has 2 more teeth than the black one in my 75 with 3.54 FD

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

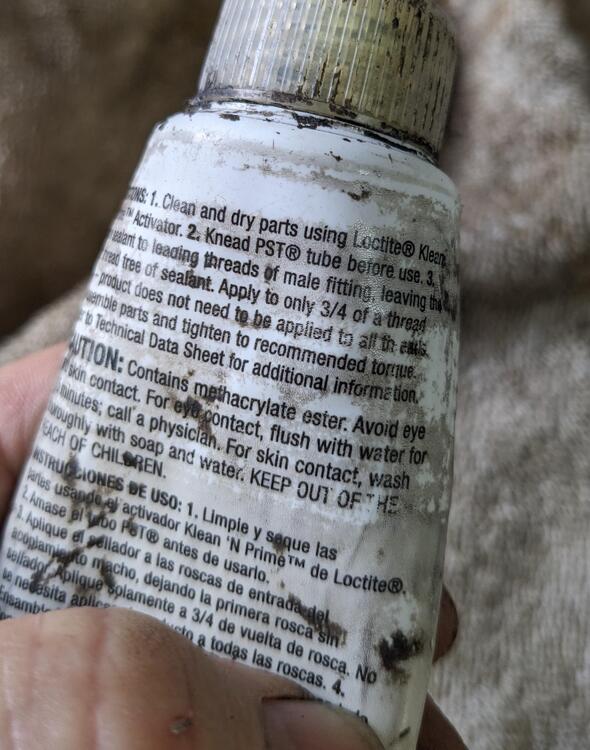

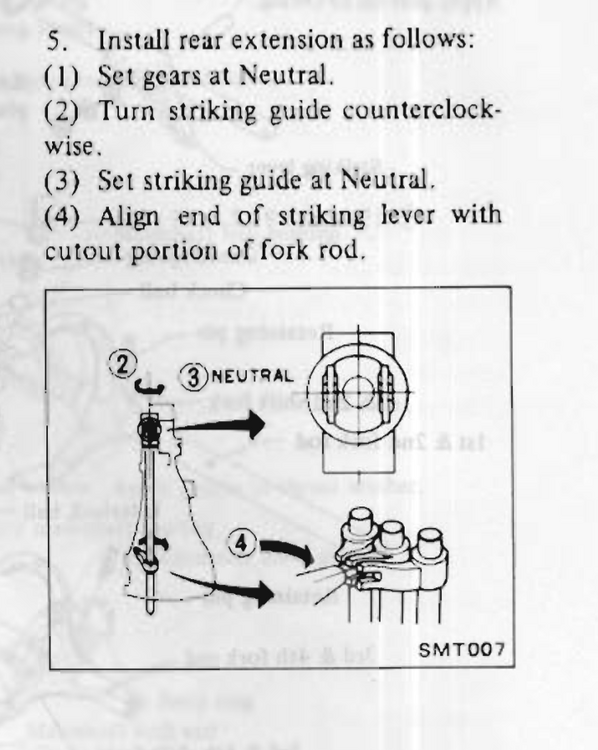

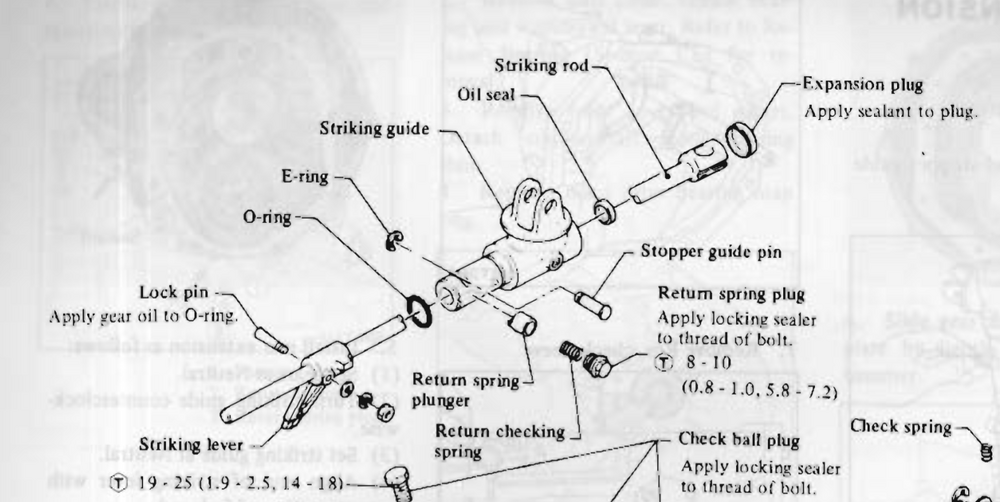

I ordered 2 quarts of the GM 10-4014 Friction Modified Synchromesh - now I can't find the the thread where fluid options were discussed - I know I ordered it for a reason. EDIT - chickenman mentions it here @Dave WM - thank you - I'll make guide dowels. A similar issue happens with the Fiat X1/9 transaxle where the input shaft splines can be a bitch to engage/align, a similar approach with guide pins is used there also. I'm just gong to print you post, so I have it on hand for reference. Had fun getting the rear casing back on today, after replacing the shaft seal & housing oring I had to watch through the reverse check sleeve hole to see if I was getting the 'striking lever' into the fork slot. Took a bit of back & forth & up & down to get it in place. Couldn't photograph it clearly Mopar transaxle casing RTV- since I had it on hand, I decided to use it casing bolts cross-pattern torqued to 13ft/lb Used Honda clutch shaft grease for the T/O sleeve, fork pivot & shaft splines Noted that the Loctite I'm using is 592, not the 567 otherwise mentioned. I'll have to look that one up. Also need to figure out the speedo gear - I think the normal route is to swap the existing one over - but.... mine isn't accurate anyway (with the 15" wheels and tires it's over by more than 10% by 65 (displayed) and goes up from there. I'm wondering if this one will possibly bring it closer? Have to research that.

-

'75 280Z - preparing for '06 350Z 6 speed drivetrain conversion

Putting this here before I forget (again) Both cars have the 3.54 FD ratio. another tidbit from NewZed - 75 280 R200 has different flange than later years

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

So, question for those who've removed the trans- can you disconnect the shifter at the base from beneath the car, one video I saw it appeared that he just lowered the back of the tranny, and then disconnected the shifter from underneath rather than removing the entire console. Is that in fact the case? Would make life easier for sure. If anyone can confirm that that would be great.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I was going to replace the T/O bearing carrier, however the replacement I got off RockAuto (listed & illustrated correctly on the site) - came as the wrong part form factor & dimensions are all wrong. I just cleaned mine up & replaced the bearing. No evidence of wear in it, or on the input shaft sleeve

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Had to take another day off work today, the cold I had, I gave to the Mrs, and she gave it back. She just finished a round of antibiotics, so that's next for me. Hopefully tomorrow I'll feel up to working on the Z.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Thank you - I also use Loctite thread sealant on pipe thread, and only snug the plugs. 15 years back when I was modding the crankcase vent system on my 500AWHP Volvo wagon, I used a bunch of 3/4 copper pipe & 1/2" NPT fittings as part of the block vent (occupies much less space than AN fittings of similar ID) - I used to use teflon, but I found it didn't always work well with oil / vapor connections, so I switched to the Loctite 567 😁

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Thank you for the detail - I don't need them, I have both my fill and drain plug, it was more just I couldn't find a direct answer & enquiring minds want to know, ya know 😁

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

That makes more sense - also the OD of the NPT bung is oversize by about .010" - doesn't thread as far in by hand without more effort

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Measuring the fill & drain plugs - it appears they are 1/2" NPT - 14tpi gauge fits better than metric 1.75 pitch. Comparing with 1/2" NPT copper pipe & cast iron plug

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

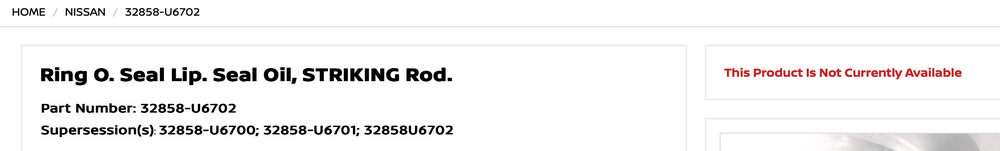

Thank you EuroDat. I got confused checking against your parts list, as the header says for the 'B" (early 5 speed?) trans, and only notes the "C" in regard to the stubby version footnoted (EDIT : note - I have conflated the "C" suffix with the C,W, designation). Anyway, I went with a seal listed as 70A NBR oil seal, that I could get in a day (arrives today), all other options were 1-2weeks delivery. I found this 240Z life trans id page last night, which I used for reference to figure out what I have. You could amend the parts list header to include FS5C71B, and note the 32858-U6702 as now NLA? Dave WM noted the Omega Machine bushing above - I also searched for it last night & found the listing. I'm going to leave what I have - don't want to wait a week or more for another part - I "reamed" it to remove raised burrs, and the tailshaft sleeve is still a snug fit with no discernible 'slop'.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I did make sure the oil hole lined up with the squished end of the oil gutter. I'll look online for Omega Machine. If I can get one promptly, I'd just as soon change it out

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

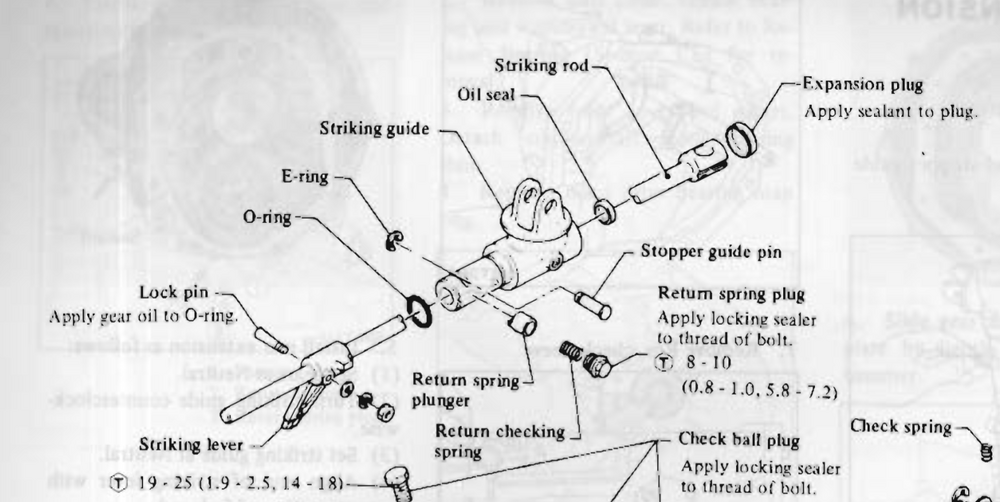

More dismantling. Striker shaft seal has dimensions on it - 5x 14x 20- found some online. Tailshaft bushing is pretty gouged . I pressed it out, and considered installing a Volvo AW71 bushing, but it's about 1/2" shorter, so I cleaned up the original to make sure there are no burrs, and reinstalled it. The trans has been dismantled in the past, I'm not going to take it further apart. gear & synchro teeth look OK pressing out bushing - needed a drift a hair under 1.5" to not bind in the casing Datsun (BW T5?) vs Volvo (AW71) Pretty hairy in there cleaned up front flange, new seal, gasket back in place ground down square nut so a 19mm 12 point fits - it was all kinds of mashed up. I presume they used a pipe wrench on it evidence of restaked nuts dismantled striker rod remnants of a bearing - found this in the speedo drive channel, presumably why the trans was dismantled in the first place. No evidence of any current bearing issues striker shaft seal muck gutter running to tailshaft bushing reinstalled original bushing after cleaning up the scoring

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I did - he said it's NLA (32858-U6702) . If Nissan listed seal dimensions in the catalog like Honda, I could at least search for an equivalent .

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Dave - did you dismantle (and document) the shifter (striking rod) to access the oil seal & oring?. Can't find a diagram of that aspect in the manual. Also the oil seal is NLA from Nissan, wondering if you are aware of a viable alternative? EDIT - found your videos in this thread - unfortunately (for me) the oil seal was still available back then you did it in 2016 - so I'm assuming no measurements of the old seal were ever taken for reference 😞

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

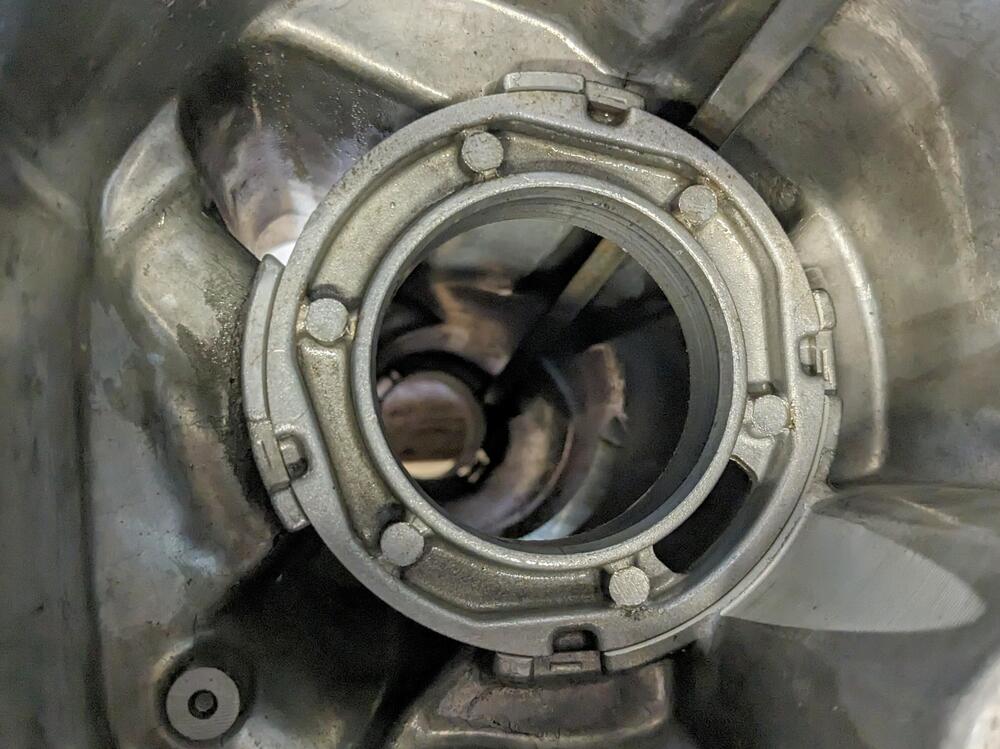

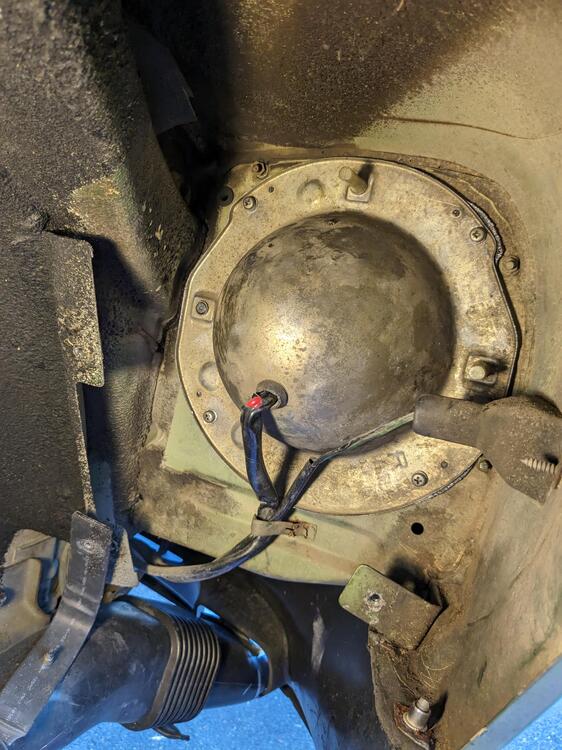

Now I've started feeling better I worked on cleaning up the 5 speed Bleed hole in front cover? There was much fluid in the shifter cavity - I think I'll have to remove it & see what's up. The end oil seal (32858-U6702) is NLA - I could only get the shaft Oring. After degreasing, I started cleaning up the casting lines - a bunch of them were pretty sharp - I'm prone to accidents, so don't want to risk slicing myself when handling the trans for install

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

So, they (Eibach) sent out ONE spring to replace these(!) Now I'll have to wait another week or two to get this resolved... updated the vent tank setup - posted in the Vapor Tank thread Been sick for a week now, so some days I haven't done much of anything. I spent a little while placing the outlets along the south wall, and figuring out conduit. The east end (left side) conduit will run upward to connect to the 240 outlet going on the center post between the garage doors. The west end will connect to the new conduit runs coming over the west wall behind the press. Need to finish the bottom plate in the soth wall area before I can put the inner wall back together, and then run the new electric in the conduit. got another small bench grinder from a salvage emporium in upstate NY - paid $20 for it. Just needs a little cleanup.

-

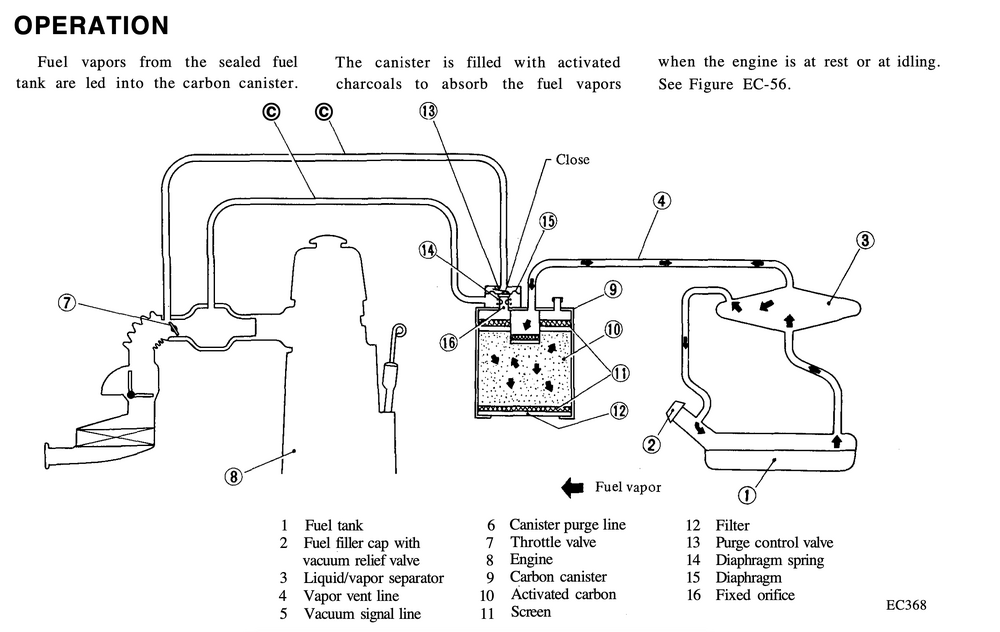

Vapor Tank Question

Been trying to recall exactly - now I'm thinking the fuel in the vent line at the charcoal canister was AFTER bypassing the vent tank, but before playing around with the charcoal canisters (when I saw the fuel) - this pic is from Monday, the day before. There was an elevated loop in the line, however it was isolated from the 5/8 filler neck / fuel tank vent. SO, I think it is fair to surmise that if the vent tank had been in place, there would NOT have been liquid in the line. Now I have the two circuits combined again (previous post), I'll know during the week if it is resolved.

-

Vapor Tank Question

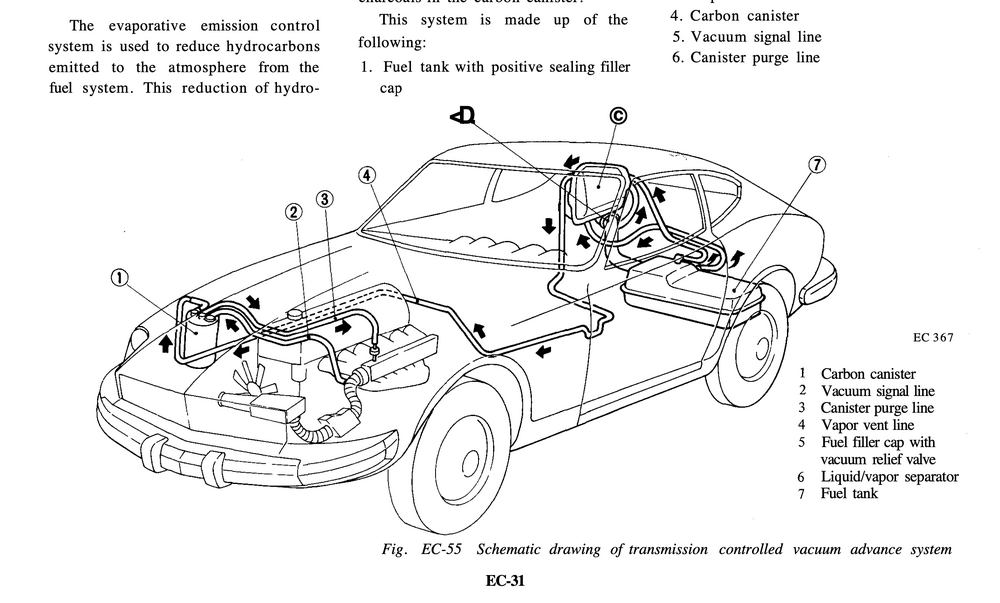

OK - I'm cautiously optimistic about the revised setup I made today. Pondering the factory diagram, and those of the several generations of Volvos I have owned, I surmised that my main mistakes were: 1) running the 1/4 vent hose below tank level 2) separating the 1/4 and 5/8 circuits. So, in my continued effort to NOT put the vent tank back, I revised the 1/4" vent line to connect with the 5/8 line. This way, if any quantity of liquid either makes its way up into the line, it will drain back into the filler neck connection, as it would with the factory setup. The 1/4 vent then continues in a loop, and goes back out to connect to the factory line up to the canister. The underside of the canister was still damp with fuel from the prior setup, however after I wrapped up & drove around for a bit, went to Home Depot, left it sit, came home, the canister was emptied of fuel condensate (bottom of canister felt dry to the touch). I'll check it again tomorrow before I reinstall all the hatch trim. Tank end, elevated the vent hose elbow coming out of cabin Tool for installing these fittings, makes it much easier 4 way connector is from a Volvo tank vent setup

-

Has anyone tried these extended headlight buckets for LEDs?

Indeed! I didn't even take any pics of the inside prior to installing the rear cover - there was nothing to remark upon, everything went very smoothly.

-

Vapor Tank Question

I see that it is described that way - but it appears in practice that the drain back feature seems implausible, given the height of the 5/8 fittings on the upper side of the vent tank - it would have to be full of fuel for that to happen Yes, to be clear there was liquid in the line at the charcoal canister with the vent tank in place - I could smell the fuel at the original connecting hose - which had cracks at the canister end. which is why I didn't think removing the vent tank would make a difference in that regard. What I experienced today was a deluge out of the canister - quite a different story from a little liquid sitting in the line. EDIT - to add to this - Prior to fixing the ruptured 1/4 elbow hose at the tank, I had only filled the tank once - which was how I discovered the leak at the tank - after that I had not ever filled the tank beyond 1/2 full. I do not recall getting a gas smell at the charcoal canister, and since the vent circuit was open at the tank, that would all make sense. Timeline: I "fixed" the hoses at the back, leaving vent tank in place. After that, in checking the overall system, I noted fuel odor at the charcoal canister. Drove 500 miles to Carlisle PA & back. No evidence of fuel vapors. Fuel smell developed in cabin . Decided to bypass the vent tank. Replaced the short hose from vent pipe to canister. Noted liquid fuel in vent pipe at charcoal canister. Swapped out Nissan Canister for Volvo Canister Still had slight fuel smell in cabin - - which was the improper (permeable for fuel) 1/4 hose I ran from the gas tank to the vent tank Reroute new 1/4 vent hose beneath. Fill tank. Fuel subsequently drips from charcoal canister. I'm going to have to put everything back to stock configuration & see if there is liquid fuel in the line with a full tank of gas after that. The way I have it now, the 1/4 vent line is below the level of the vent to the filler neck. The factory setup has the 1/4" vent line as the highest point in the system, above the filler neck vent. The 5/8" and 1/4" vents also combine at the vent tank. I have them completely separated. With a full tank, actual fuel must be sloshing into the 1/4" line.

-

Vapor Tank Question

Thank you - I'm second guessing whether removing the vapor tank has caused the problem - however I don't know of any other car that had such a contraption, and the later Z's don't have it, so it would seem something else is the cause. I filled the tank yesterday afternoon. Today, the car was in the sun all day & early evening I drove around for 5-6 miles at low speed (25 mph zone, heavily policed) with the Mrs, and the we got home & she got out, she could smell raw fuel. I turned it off & could see gas dripping out the charcoal canister base, running down into the splash pan(!) I could add a check valve, but that wouldn't alter fuel/vapor running from the tank to the canister. I can reposition the vent line at the tank, so it runs elevated relative to the 5/8 vent, right now it angles downward off the tank nipple. I'll add the vent tank back if I have to, just rather not. diagram

-

Vapor Tank Question

I insert the gas filler nozzle completely , and stop when the nozzle check shuts off supply. I don't keep adding after that. I also had never filled the tank prior to fixing the original ruptured vent hose a couple weeks back.

-

Vapor Tank Question

Seems plausible in theory. I wouldn't expect there to be enough vapor to fill the vertical hard line off the rail up to the canister though. I'll pull the hose off the hard line after a few tank fulls & see if it reoccurs.

-

Vapor Tank Question

I have made changes - I removed the vent tank, ran. the 5/8" filler neck hose directly to the tank fitting, and ran the 1/4" vent line directly to the charcoal canister hard line bypassing the vent tank. That was all after finding the liquid fuel in the line though. There is no check valve that I can see between the vent hose, hard line & charcoal canister that I can see, unless it's tucked up above the fuel pump mount bracket where the vent hose clamps to the hard line, which I doubt.