Everything posted by HusseinHolland

-

Replacing All Large Opening Seals & Hatch Small Seals

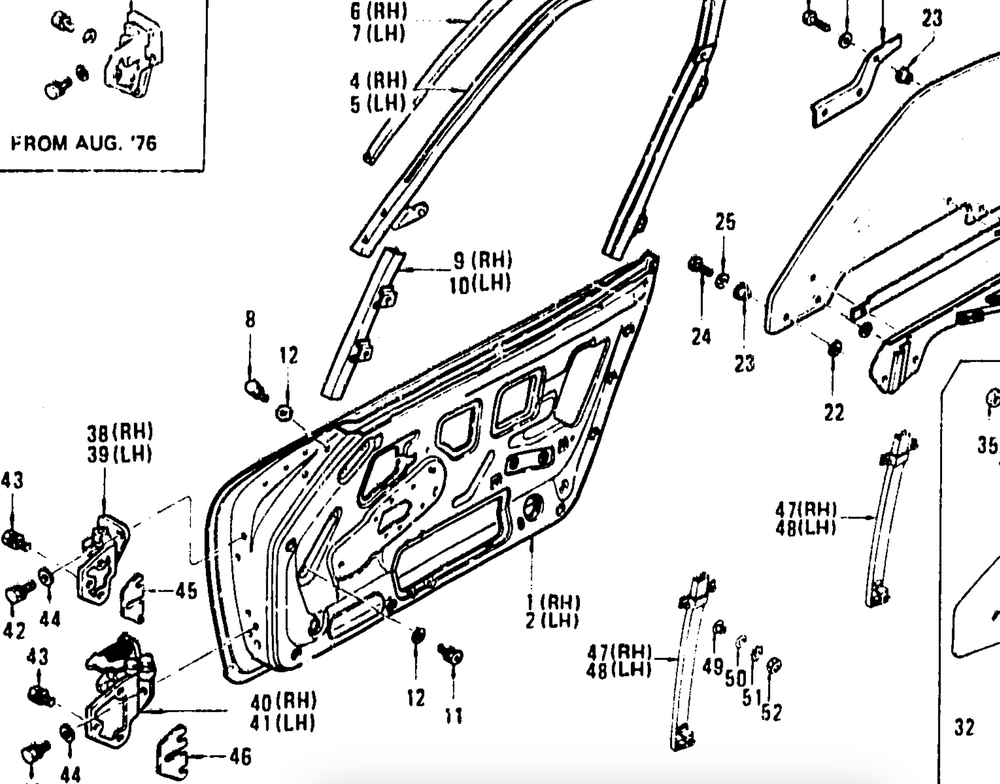

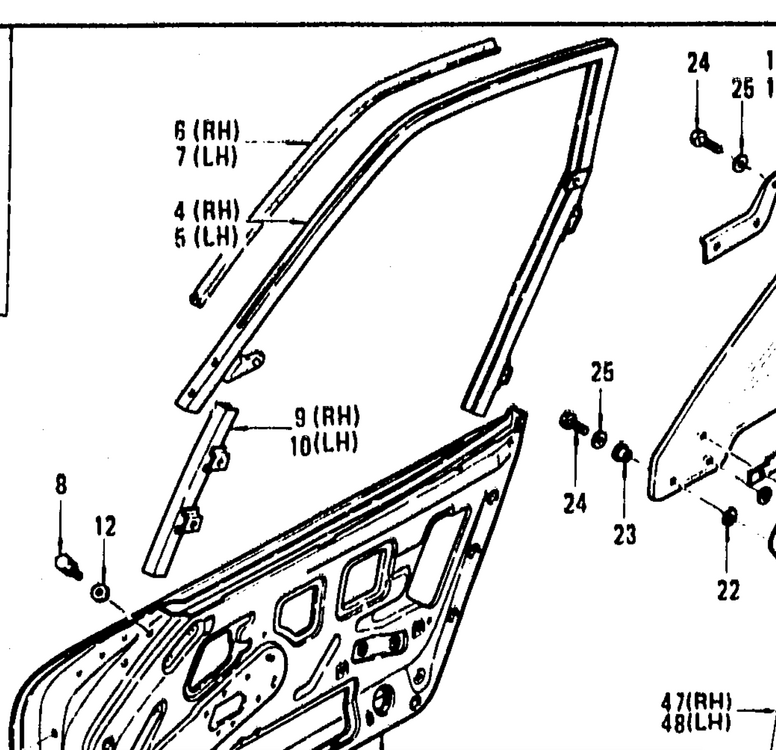

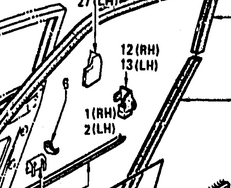

OK - looking at pics of a 77-78 frame and the earlier frame - the later frame has a separate lower section #47 & #48 in the catalog Only one bolt at the front inner instead of two on the earlier style. Rear ends a few inches below the 2 vertical mounts that likely align with the 2 on mine, and has two additional horizontal bolt points. If I can get the later lower guide channels maybe I can make it work

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

So, having driven the car to work Tues-Thurs, the starting time is not that bad. It's really only the cold start in 40ºF temps that is somewhat lengthy. I think I maybe being a little picky for an almost 50 year old drivetrain. I dunno. It's pouring rain today, and forecast the same for tomorrow, so Sunday I'll get back to it. Thank you Zed Head The primer kit I knew about, as some Volvo PPL have used it. Personally, $70 for that is way too much, plus it's bulky (and tacky) 🤪 - so, I'll figure out a more discreet primer some way shape or form.

-

Replacing All Large Opening Seals & Hatch Small Seals

Thank you. Unless the door inner skin/structure was also substantially altered and/or the glass shape also changed, I can't see how it couldn't be made to work. I just can't find any detail pics, besides the threads where the discussion revolves around fitting later doors to to a 240Z Not sure that matters, unless you mean perhaps the 76 version would be more likely to fit a 75 door? I'll have to look again in the parts catalog, I would expect there is a chassis break listed for the frame change

-

Replacing All Large Opening Seals & Hatch Small Seals

Got the last window seal done today - passenger 1/4 glass & frame seals. Cleaned up & painted the bracket weld areas on the frame as with the DS

-

Replacing All Large Opening Seals & Hatch Small Seals

Question - will the later frames fit the 75 door? Same attachment bracketry built in the the frame? (4 mount points at the front, 3 at the back vertical, 1 facing inward top rear of door skin) I'd just as soon update mine to the later version, especially since the coating on mine is compromised & has surface rust. If the frame with physically fit the door, and it's just the brackets that are different, I could always cut them off the old frames. Also, if you have a pic that shows the channel w/seal - can't tell from the part manual exactly where it goes. The seals I bought don't appear to be long enough to go the full length

-

Replacing All Large Opening Seals & Hatch Small Seals

I did find that the smaller vent hose grommet was torn - so I sealed that for the time being Also, I had removed the bumper shock & bracket on the DS, that left 3 holes that fed directly into the muffler cavity. Filled them with sealed plugs

-

Replacing All Large Opening Seals & Hatch Small Seals

Thank you - the antenna drain I plugged sometime ago, the PO put in a manual antenna mast. I'll look at where the EVAP lines come through the floor, and the harness grommet. T/light gaskets are coming... Today I got the door sealed back up & put the door card back on. I need to find a grommet for the lock button Found this in the bottom of the door yesterday - the tab has no tension anymore, so just as well I bought complete new ones Before I put the door all back together I massaged the two dents as best possible, used a heat gun on the outside & a screwdriver handle to work the metal from the inside. Lower dent was between the visible dot & the belt molding Fitted the Volvo 240 crank handle, and a replacement armrest - this one I found in black, so I didn't have to paint it/

-

Replacing All Large Opening Seals & Hatch Small Seals

OK - so the one (of several) annoying things about driving this is that is smells like exhaust in the cabin. When I drove it earlier in the year, I just left the windows wide open to negate it somewhat. I've already replaced the main door seals & hatch seals, and the driver's window channel seal. I hadn't replaced the passenger door channel seal, so I did that late this afternoon. I'll find out tomorrow if that helps at all. Besides that, the only other thing that I can find info on that can cause it is the tail light gaskets. Apparently fumes will get sucked in past those. I ordered new ones, I need to remove the rear panel & lights anyway to redo the chrome & grey metallic on the panel, so I'll do that when the gaskets arrive . Took the passenger door apart. Didn't have time to document much on this side, it took me about 2 hours, and the Mrs was getting testy Have to put the interior panelling back together tomorrow also drilled & tapped the window winder M5 x.8 to accept the Volvo 240 crank handle. The Volvo shaft has twice as many splines, but it fits snugly on the shaft, so I'm not going to have to cut & weld as I did with the DS EDIT - I did shove the rear molding in place between the frame & door - but I couldn't tell from the form factor exactly how it was supposed to fit. Any chance someone has a pic with theirs in place?

-

Purs like a kitten...

Trans is definitely whiny - but it does have 250K on it. I only have to deal with it for a year or so, after that I'm doing a 350Z drivetrain conversion with the 6 speed. Should be all good after that.

-

Purs like a kitten...

The motor feels strong as it is. One reason I changed the TPS WOT setting was I could see the AFR's get really fat just revving the motor in the driveway. After driving around & coming to work today, about 20min local & highway- the enrichment values seem pretty good under load. I reduced the ECT resistance value a touch as the cruise AFR was a touch rich. Now I have the wideband I do see that the system goes kinda rich right off idle before it levels out, but my old Volvo does much the same. I think I should just put in the 250A breaker, as the first couple revolutions hot cranking with the 125A seemed slightly sluggish before it blew, and less so with the 175a, so perhaps the initial starter draw is high enough to strain the lower amp breaker, and actually induce the slow crank, I dunno. It just seems to crank better now than yesterday. (EDIT - excessive draw was due to faulty rebuilt starter, replaced) I do still need to redo the compression test, as the one I did back in the Spring prior to any valve adjustments had one cylinder well over 10% deviation - 140ish vs. 165 range on the others. Valves were very tight on that one. Overall engine feels pretty darn smooth now it doesn't have a lean condition, for sure.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

It has varied. With the nylon fuel tubing on the rail & the stock FPR, It held pressure (close to 30psi) for a day or so. After I took it apart again to look for debris, I switched back to standard (Volvo) 7mm fuel hose for the rail junctions & added the Volvo FPR pod. With this setup, pressure typically drops to around 20psi within 4 hours or so, and overnight is down to no registered pressure.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

That's impressive. Since many vehicles have a prime feature (for example, my newer Volvo does), I would still say long term residual rest pressure is not expected.

-

Purs like a kitten...

Got the replacement clutch slave installed, and wheel I had the car jacked up, I took care of the speedo drive inner & outer shaft seals. No pics. I drove the car around, went to Harbor Freight & Home Depot to get some extra dot 3 brake fluid & regular antifreeze. Once the engine is hot then parked, it seems that it cranks slower. When I got home, I shut it down, then realized I didn't pull up far enough in the driveway, so went to restart it. Blew the 125Amp breaker on the starter cable again. I've replaced it with a 175Amp breaker. See how that goes, I'm going to drive it to work tomorrow. It's done much idling in the driveway while I worked the kinks out, so it's definitely. due to have the snot beaten out of it. One drivability issue is that I keep trying to upshift into (non-existent) fifth when I get up around 65-70 when accelerating.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

that search actually just brings up my new thread & few presumably related to fuel pressure issues. In any event, I'm likely going to add a momentary contact switch for the time being. As it stands, I only need it for cold starts. Though, having said that, it is likely to change 😞

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

Fuel pressure will always leak down overnight - I don't know how long it is designed to hold, however I've never seen any 'old' EFI maintain rest pressure for more than a couple hours, if that. I put fuel pressure gauges on all my old cars, so I know from personal observation that even with new fuel pumps, regulators, injectors, etc., long term rest pressure is not part of the design.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

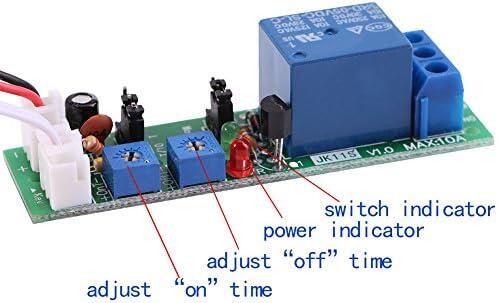

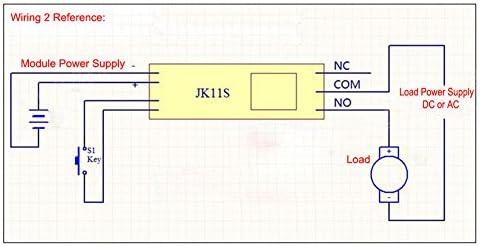

Wondering if anyone has done this. I found a thread on HyridZ where the main suggestion was to simply bridge 36/39 w/key on to engage the fuel pump. That appears to be a viable approach, if it comes to that. I need to do this as cold start definitely is impeded by lack of system prime. Hot or warm starts are pretty rapid in terms of cranking time What I was thinking was more along the lines of a timer/delay circuit that would run the pump for 3-5sec when the key is turned, anywhere in ACC or On, so that no additional input is required. I've found a range of timer relay/circuit boards that would possibly do the trick, the issue seems to be making it only run once with the key on signal & not cycle. Couldn't find anything on here, but maybe it's hidden like the AFM/Pot thread. Example:

-

Designing A/C System Using Other Cars Parts?

Painted & reinstalled the dash vent panel today, and put the steering wheel back. No horn pad, as I don't know yet if it's centered exactly. Can't drive it until the new clutch slave arrives & replaces the blown out one.

-

Purs like a kitten...

Did a number of things today. Replaced the ECT with a new Beck Arnley 158-0134 sensor. With that, (ambient temp 50ºF) it started well (after the initial delay with priming), and during warmup. AFR's stayed nice & fat, which was not the case with the old ECT. Once it got closer to normal operating temp, the AFR"s went lean again (16's). So, I put in the 1.1K ohm resistor in series with the ECT. With that, warm AFR's are to rich (13.4-13.7) - so I don't even need 1.1K resistance added to the ECT circuit Pushing very slightly on the AFM lever fattened it up a touch, and smoothed the idle quality So, I lessened the wheel tension by 1 tooth Also adjusted the WOT enrichment TPS settings - the factory position brings it on around 30º opening, so I moved it to closer to 50º Stock adjusted Reset (lowered) the base idle closer to 800rpm, with those changes the AFR was sitting around 14.2 So, I installed the 2.2K potentiometer, wired the 1.1K as well, but decided the 2.2K would give me more range. Since 1.1K puts AFR's at idle around 14.2, I need somewhat under 1K to get the AFR's in the 14.7-14.9 range at idle. Bolts to the left dash frame support Used a 2pole HD090 series connector to join the pot to the ECU. Removed #13 wire from the ECU connector, now that goes into the pot, pot output goes to pin13. Set dial on POT so that 1K ohm is with #1 at 6 o'clock where I can see it Full value (2.2K) puts dial @ just over 5. Unlikely I will ever need to use that end of the scale. Connector tucked up above ECU Warm engine, setting dial to 0 brings AFR's to 14.7-14.9. I'll see how it starts & warms up with that setting tomorrow after work. Still can't drive it to see how it performs on the highway cruising, due to the blown out clutch slave.

-

Bad air flow meter??

I don't have to worry about that - I'm going to do a drivetrain conversion on mine 😄 So, I made a couple of resistor plugins - one 2.2Kohms, the other 1.1K ohms. I'll try them tomorrow & see which runs better. I ordered a couple of POTs, one 1K & the other 2.2K, so depending on which resistor seems to run it better, I'll add the pot so I can tweak the value to make intermediate adjustments. I guess I could just use the 2.2K POT, but I don't know if makes a difference to sensitivity of adjustment.

-

Purs like a kitten...

Thanks to @siteunseen for linking this in the bad AFM thread - bumping it so I don't have to search for it, as I'm going to follow her layout, wiring the pot at the ECU harness just have to recheck the two pins for the sensor - 13 & the ground - looks like 16, 17, 35 & 5 all tie together so I'm not sure it matters which I use Edit - never mind, forgot that this is placed in series, not parallel 🤪

-

Bad air flow meter??

Reading through the whole thing - she gets to the POT input at post 57, after all kinds of futzing with the AFM. Seems like I should leave the AFM alone, and just do the POT. Important details, post#66 Edit - forgot to say - I wish RadioShack still existed - I used to get all my electronic projects odds & ends from them. I guess there just were not enough of us to keep them afloat 😞 EDIT - in post 57, she says: "Anyway, I ran upstairs and grabbed a 5k variable resistor and plugged it into the temp sensor connector. That let me tweak the mix manually. I found that the best mix was achieved in a warm engine with a resistance of 2,550 ohms, while the temp sensor's resistance had dropped to 240 ohms. Thus the mix could be richened about right by adding 2,310 ohms in series with the sensor. Interestingly, I think I remember the value of the previously added resistor being 2.2k, so apparently someone else had been down this road before me. I'm sure at one time it made the engine run very well, and then it got wonky again with age and deterioration." I only ordered a 1K pot, I'm wondering if I should get one that goes at least into the 2K range....

-

Bad air flow meter??

Thanks for the input. It definitely does not feel right at all, you can feel the lean miss, so I don't want to drive it & possibly damage the engine. The POT should be here tomorrow, along with a new ECT. I can run the motor with the Volvo ECT pressed against the t/stat housing & get AFR's in. good range overall, but it doesn't feel 'right', so I'm going to use the correct ECT, check the AFM values & wire in the POT. Hopefully Sunday. Tomorrow is gonna be rain all day. 😞 If I have to, I'll mess with the AFM adjustment. I don't want to spend too much $$$ on components like that, as the whole mess will go away when I do the VQ35DE conversion in a year or so.

-

Designing A/C System Using Other Cars Parts?

Back to the duct work. Had to do this before the steering wheel & glovebox got back in. This is the diagram I found for the AC ducts Driver's side doesn't match the vent I bought listed as being the driver's side, and no way the one I bought will work on the DS. The one I bought listed as pass side is correct for the DS - I found two captive nuts set into the over steering column section of the dash frame. The duct is significantly shorter than the illustration, which threw me off while I was trying to figure out where either vent could fit. pass side ducts. I will have to mod the glovebox, as the AC duct sits into the glovebox area, due to the offset of the non-factory evaporator box width Trying to fit the vertical port on the right - just not going to work so I need to locate another horizontal vent bracket the the vent is supposed to attach to found a pic online of what the right side bracket for the vent should look like

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

It's way too lean, you can feel the lean miss. To stop this HEI thread from going even further into left field, I started posting in the existing AFM / lean running thread. Thank you for the link - I'll look at adding a POT - that seems like a practical way to make adjustments to the eng. temp ECU input

-

Bad air flow meter??

Adding on here for AFM related concerns - I'm going to go through the EFI resistance tests of the AFM, and then have a go at adjusting the AFM following the AtlanticZ Guide With the engine running at idle, the AFR's are too lean, and gently pushing in on the counter weight definitely evened out the lean condition. I couldn't do that and watch the AFR's, so I don't know how much it actually enriched the base value, however it was a definite improvement. I've ordered a new ECT, so I will swap that out when it gets here. EDIT - also looking at ZedHeads suggestion for adding the temp signal POT (ordered 1K pot)