Everything posted by HusseinHolland

-

280z Master Cylinder Heat Shield Picture Request

Thanks for responding. So, the lower bracket attaches to the two mount points in the frame rail (vertical surface?). Do you have any recollection of what it looks like, is it essentially an upside-down L?

-

280z Master Cylinder Heat Shield Picture Request

Does anyone have pics of the brackets that tie this shield to the inner fender/frame rail, or access to the original parts catalog so I can figure them out that way? The upper tie plate appears to be relatively straight forward, going to the same location as the bay light on my 75? The lower bracket I have no idea. I want to add that shield to my 75 280Z Thanks in advance

-

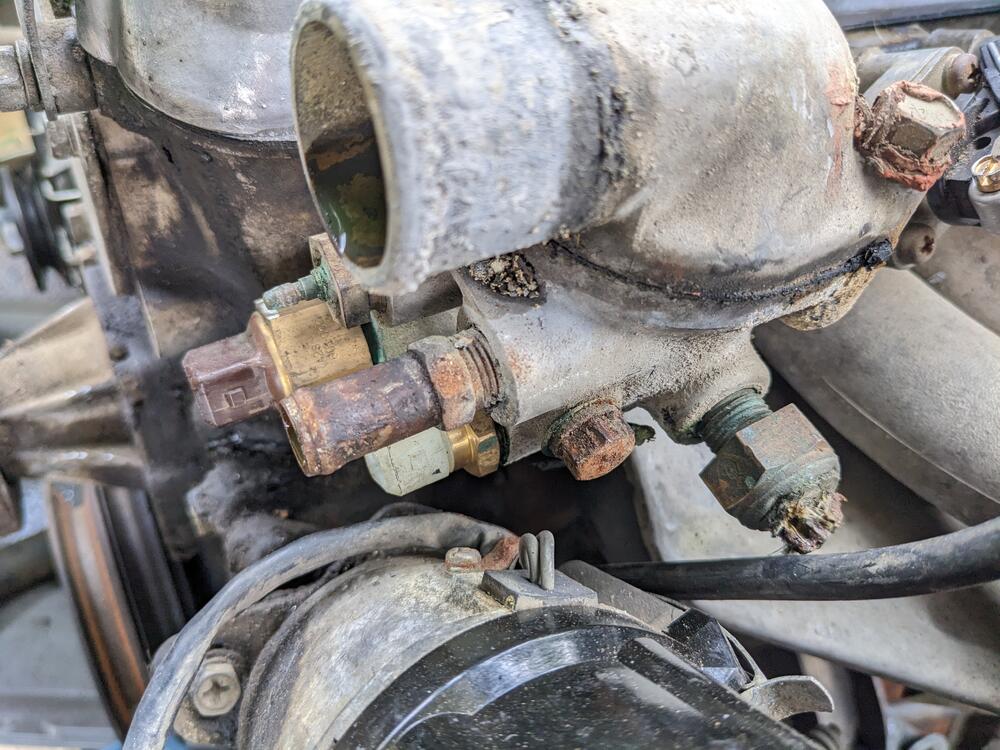

FPR project - cheaper, more available (for a while anyway)

280ZX is also 2.5bar? Volvo also used 2.5bar on most NA applications, but those regulators are not bolt on replacements (refer to Zed Heads earlier posts)

-

FPR project - cheaper, more available (for a while anyway)

I have that one in use on my Volvo 740 (first pic). I don't recall being able to drop it below 3bar. I'll have to try it at some point to verify.

-

Servicing Cooling System Questions

Thanks for the link, Steve. Unfortunately, beyond mentioning that the Ford Taurus fan/shroud can/should work, there aren't any specifics (Edit - note that in the video he is using the same Volvo fan in place of the Taurus unit). Not interested in generic/aftermarket solutions, they are always a disappointment. I've tried a range over the years on my X1/9 where eFan cooling is critical.

-

Designing A/C System Using Other Cars Parts?

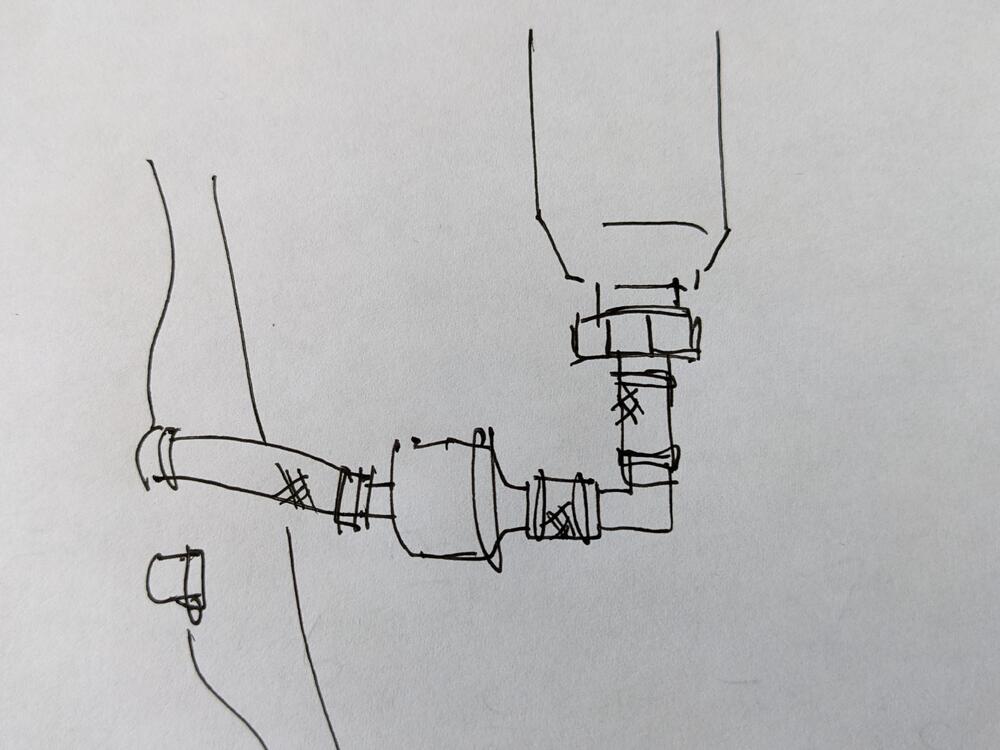

Yes, the orifice tube will be in the #6 hose from the evaporator to the condenser, in the engine bay. The expansion valve gets gutted or removed if possible. Accumulator will go pretty much where the receiver/drier was placed, but higher up. Has #12 fittings, I will step down to #10 hose. low pressure switch goes on the accumulator (Four Seasons 33197, Volvo 740 application)

-

Servicing Cooling System Questions

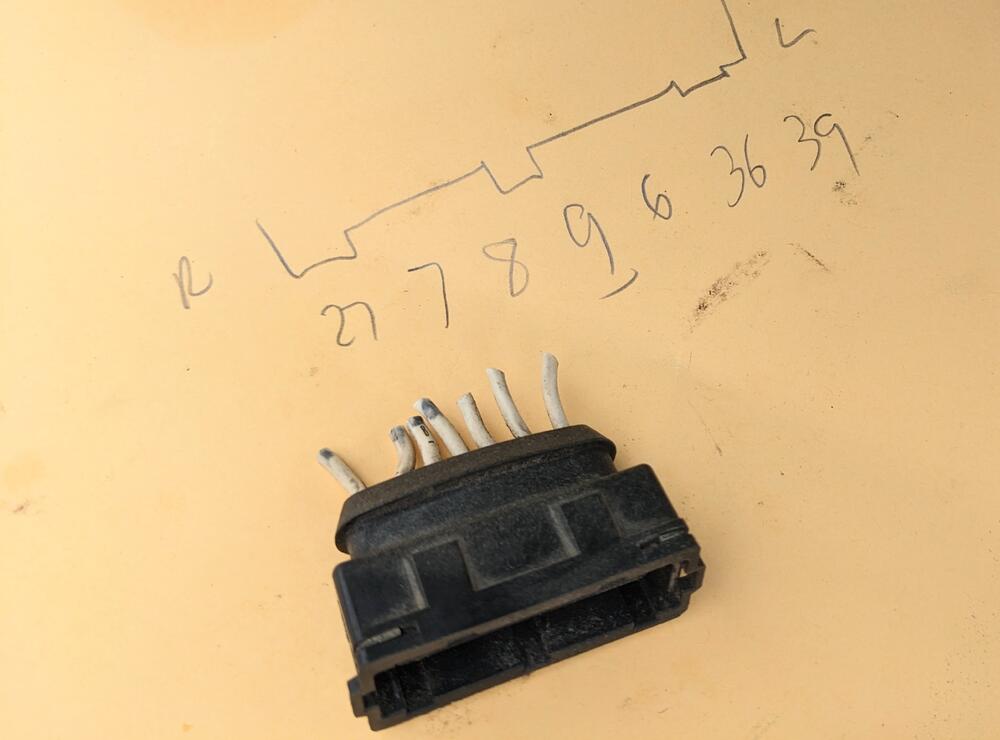

Played with the eFan. No way it's gonna work. I can't get clearance no matter what. I don't want to use an aftermarket eFan, they just don't have the pull of the Bosch units. So, I trimmed the Volvo (Aisin) fan to fit the Nissan clutch I trimmed the top half of a Volvo standard shroud to fit, I don't like the fan blade exposed. Riveted brackets to either side of the rad vertical plates to retain it ( I used 3M Velcro to hold it while I figure those out) While I was in there, I fixed the distributor vacuum line/tee connection to the TB and charcoal cannister The distributor wiring had been nicked at some point by the fan, so I re-routed that, and added a sealed 2 pole timer connection where the wire was damaged (no pic) Rewired the AFM also - blurry pic. The heat sheath below is on the dist wiring - since it is now closer to the manifold.

-

Servicing Cooling System Questions

Cleaned up around the crank, and removed the pulley & old seal. Definitely well hardened. There is a decent wear groove on the pulley seal neck, so I made sure to alter the seal depth for the new one After that I cut down the Volvo bolts to match the Nissan length (checked that at the full length they would bottom out before pulling the pump tight to the casing) New pump back on Repaired T/stat cover Volvo bolts, cut down to match Nissan original length, with 10mm heads to make it easier to access by the fuel lines, and harder to overtighten In other news, going to add a fuel pressure gauge over here And got a new throttle cable accordian boot. Not planning on driving it in the rain, but I don't want NY weather working it's way into the cabin

-

FPR project - cheaper, more available (for a while anyway)

Trying to find a schematic - typically the bottom-most port is the return - the I/O are in line with each other in the larger housing, so that female side may take some sort of push fit line, I dunno. EDIT - yeah the female is the inlet, looks like the have a designed filter pressed into that

-

FPR project - cheaper, more available (for a while anyway)

We need 2.5bar for the Z? The adjustable one doesn't drop below 3bar either.

-

FPR project - cheaper, more available (for a while anyway)

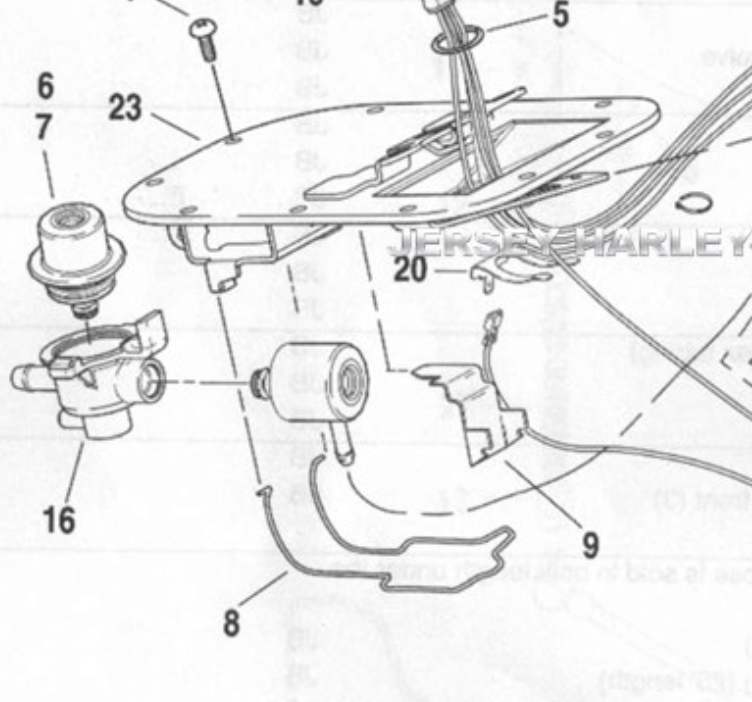

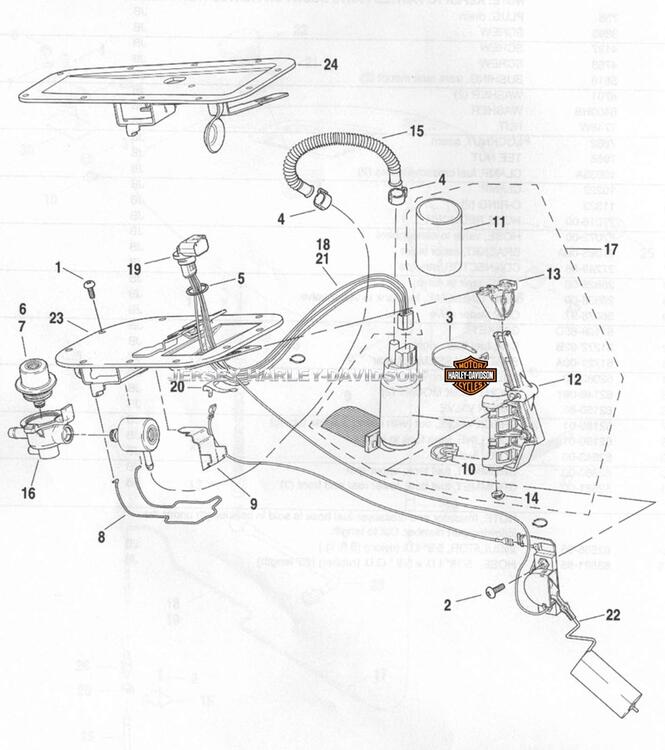

The adjustable regulator is this one: EuroSpec Sport. The standard (non-adjustable 3bar) FPR in the 2nd pic is what all Volvos & VAG came with. The black plastic pod that it sits in is a separate part that was only sold with the feed & return lines attached, so pretty much the only way to get it is to cut it from a parts car. The Volvo 3bar FPR is PN 9404583 for reference. They don't go bad, so if you were going to use one, I'd get it used. EDIT - VAG # 037133035C Bosch # 0 280 160 557 EDIT - this is an aftermarket housing that accepts that style FPR. I just found that searching, so there may be other (less expensive options) This composite one for a Harley also accepts the same design FPR, don't know if the ports are useable

-

FPR project - cheaper, more available (for a while anyway)

Both of those types are common on Volvo 240 / 740 / 940 series, depending on year. There is a 2.5bar version of the first style (o-ring). The o-ring fitting is the same dimensions as any composite injector, so a universal injector bung could be modded for use. The last one you posted was used on all Fiat/Bertone X1/9's with EFI - 1980-87. There are FPR pods used on 90's Volvo (850, x70) & VAG models that has a removable FPR. Those you can buy Adjustable FPR's for, which would allow changes depending on tuning & other mods. I used one on my old Volvo converted to pickup truck when I +T'd it Downside is you can't buy the pod - it comes with nitrile/nylon sheathed lines attached. I cut them off and/or cut them down & make my own lines Gm also used this design FPR on LS motors - I know because the one I'm putting in my pickup truck has a housing that has the Bosch FPR. So there may be other options. I think using the 3 way Volvo style would work the best in terms of compatibility with the rail, since it has input, return & regulated output . I have another I scavenged from a parts car many years ago, so at some point I can test in on my '75 rail...

-

Servicing Cooling System Questions

T/stat cover came off without too much drama. I had to block sand both surfaces, they were both pitted Chased the threads in the housing, to clean it up. There is pitting in the underside of the cover neck, but the inside is clean. I can only presume coolant has been seeping past the (crappy) Gates upper hose, that wasn't quite the right ID. Cleaned up the pitted area with a Dremel wire wheel, I'll fill it with JB Weld Water pump bolts didn't feel great coming out, so I worked them back & forth fair bit. Mating surface mostly cleaned up here The original hardware for the water pump cleaned up OK, but I think I'll use newer hardware. The T/stat bolts are nasty. The Volvo bolts have integrated flanges & are higher grade While I was in the bay, I added an 80's Fiat brake line clip to replace the broken hood prop retainer (and put some primer on the area where the rad sits up against the panel Checked the fit of the Volvo fan shroud on the rad - should work OK, the center of the fan motor will be offset to the left, and the water pump sits offset somewhat to the right. I'll test fit it once I figure out a suitable method of retaining the shroud flush to the rad core motor.. Have to locate mating pins and/or water proof housing for the eFan connections - pretty sure they are Furukawa or Yazaki ? EDIT - Yakazi 58 Y series EDIT - assuming the shroud & fan clear the waterpump snout, I will wire the fan same way I did on my old Volvo

-

Servicing Cooling System Questions

Is that Good luck (not likely to work out) or Good Luck (I hope you are successful in the attempt) 🤪

-

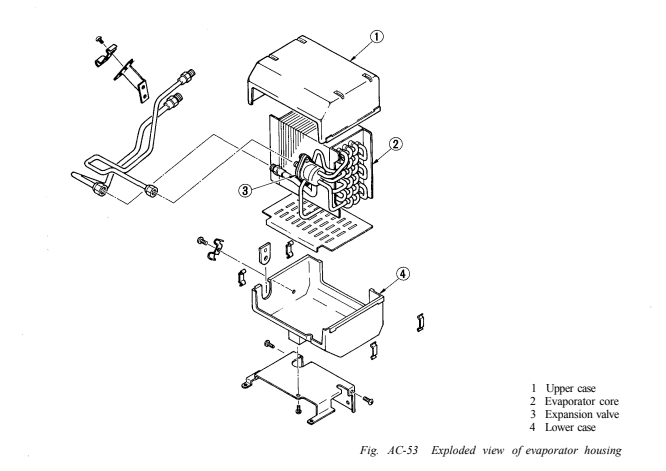

Heater Core Alternative - Escort Core into 260/280

Hi Steve Thank you for the offer. I think what I would need to explore this are the OD and thread pitch of the Male fitting and the ID of the Female fitting, where the lines exit the firewall, and the two male fittings on the Evaporator itself - if that's what you have handy. I took this image from the eBay listing. I need to establish if they are all metric or standard. Judging from the other pics, the line fittings are flared (JIC perhaps?), which is not standard for any US type o-ring style fitting (MIOR, MOR, FIOR, FOR, etc.,) This may not be worth the effort if I have to make lines that go into the casing to attach. I don't see any way to convert the outer fittings to o-ring style, unless someone sells repair ends that can be silver soldered to the existing hardlines. There are standard (#6, #8, #10) male & female flare beadlock fittings, but they will definitely be SAE thread, not metric.

-

Heater Core Alternative - Escort Core into 260/280

Thank you - those make it very clear. I am thinking of buying a used factory AC box with evaporator, since every other part of the dealer AC install is sloppy, I can't imagine the evaporator install is any better. The issue there would be dealing with the factory line fittings. I have no idea if they are standard or some funky metric size/version fittings that will be difficult to find.

-

Servicing Cooling System Questions

Thanks gents. I think I'm just going to remove the cover. I don't need to tempt fate right now. Hopefully the water pump bolts don't snap on me. @Yarb indeed - I will be doing that as I mentioned above 🙂 Seems easier to do it whilst the rad is out the way & I can get a puller on the crank pulley.

-

Servicing Cooling System Questions

So as part of the general overhaul I'm replacing the leaking water pump, and the t/stat cover gasket. I wanted to remove the entire housing to give it an overall cleaning & replace the mount gasket. The issue is the long bolt feels like it's going to snap - I only tried to loosen it slightly, and it just felt wrong. If you've ever snapped a stud I think you know what I'm talking about. The question is, is that a thing that happens with these? It is a relatively long bolt, so it is possible it's twisting somewhat as it turns. I just don't want to have to remove the head to address a sheared off bolt, so if it is fairly common for these to snap, I'll leave well enough alone & just replace the cover gasket & check the T/stat. Any input would be much appreciated front crank seal is also obviously leaking, so I want to address that now as well Fan blade has multiple stress cracks - Volvo used Aisin fan clutches & blades through early 90's on some models, so I have a new fan blade, just have to mod the ID to remove the 'tangs' that will be in the way I will see if I can fit an electric fan & shroud first. All the Volvo (Bosch) ones I have are around 3.5" depth off the rad, which is deeper than the clearance I measured. They work really well. It may work for this install as the fan is offset in the shroud. I'll experiment with that. If so, I'll add a thermoswitch in the lower hose (again using a '80's Volvo coupler intended for this purpose) as there is no rad provision for one.

-

Blower Motor Upgrade - Not a Honda

Just found this thread. Very useful! I've ordered one of these off RockAuto, still a good deal at just over $40 for the 4 Seasons 35086.

-

Heater Core Alternative - Escort Core into 260/280

I made a line to serve the purpose. Fiat EPDM hose at either fitting, then a Volvo shaped bleed hose with quick connect fittings to make it easy to service without messing with the end fittings

-

Designing A/C System Using Other Cars Parts?

I'm going to piggy-back on this existing thread, rather than start a new one, if that's OK. I asked a related question in Captain Obvious's heater core thread I'm going to revamp the non-factory AC in my 75 280Z, using the accumulator/orifice tube system rather than the antiquated & less efficient expansion valve & receiver/drier setup found on most older (pre mid-late 80's) imports. I've already done this successfully on my Bertone X1/9. The main difference here is that I don't have the factory control head, so I'll likely need to use one of the aftermarket rotary t/stat w/capillary controllers to regulate it. I've bought a universal 12x25" condenser, orifice tube 'repair' kit (Santech MT0669) and a GM accumulator (Four Seasons 33197) typically found found on all 700 Volvos. I will probably use a Sanden or Diesel-Kiki compressor, since that's what I'm familiar with from Volvo applications. I may have a new one in my basement. As long as it has the 4 mount ears I can make it fit. The clutch can be swapped out for a V-belt version. If I keep the current line routing, rather than the factory layout with the receiver drier on the right inner fender, it will greatly simplify the layout. Question is whether I can fit the accumulator on the left side - the receiver/drier is currently stashed down on the inner fender near the manifold/downpipe. Not ideal. I may need to route the lines around to the right & put the accumulator on the existing bracket used for the vacuum tank (I presume) on right inner. That would mean much longer AC lines, so I'll have to figure that out. I have the AC beadlock crimp tool, so making lines from scratch is not a problem. My Z currently has a 14x20" condenser, and I think having a slightly larger overall surface area (approx 300 vs 250 current) can't hurt as a side not, why the heck did Nissan route the distributor feed harness along the rad hose?? Seems like a recipe for diaster. Mine clearly got clipped by the fan at some point

-

Heater Core Alternative - Escort Core into 260/280

@Captain Obvious - I'm hoping you can clarify how the heater box unites with the AC section - the manual is very unclear to me - does this entire box attach to the one in your picture where the foam seal is located on the left? I'm trying to figure out the layout before I take mine apart. Since it''s not factory AC, I'm wondering how the evap is mounted if the housing is not normally present on Non-AC cars. Can't seem to find a schematic that clarifies that.

-

75 280Z Skillard Tall Grille & Skinny Bumper Install

Thank you. I made that last year - took about 3 months to do the cut & weld work on it. I wanted to keep the gate functional, and keep the flow of the factory body lines as much as possible. On the bumper install, I removed the rear bumper yesterday. I was surprised to find that my valance is a bolt on desgin - I've seen many YT where they had to cut spot welds to remove it. Perhaps that is only the late 280z? I need to drop the tank so I can get the bumper shocks out before I test fit the rear bumper. While I was on the back end, I added M5 rivnuts and some closed cell foam as a surround for the hatch louvre, that got rid of the rattles & open holes that will only be rust magnets now the car is in NY climate

-

Rewiring the 75 EFI harness

Just to add to this - the cold start & warmup cycle is MUCH improved - takes less cranking time & throttle response is better than before. Still need to address the fule pump & feed, as the ppl that worked on it previously loved to run much longer hoses on everything, so there is a crimped loop in the feed to the pump, I would expect that is creating a delivery issue at anything over idle load. In any event, I need to drop the tank to remove the rear bumper shocks, for the skinny bumper install.

-

280z 1976 fuel pump saga

Can you simplify the input side? The feed is very convoluted. Have you had the same setup since the first pump you installed? Perhaps the elbow right off the pump, so the filter is more inline with the tank outlet. I dunno. Looks problematic to me.

.jpg.0ddbfa2223e62f42c16e2f7ed5434265.jpg)