Everything posted by SteveJ

-

Windshield washer not spraying due to electrical problem

Okay, I took a closer look. At first glance it looked like tarnished copper.

-

Windshield washer not spraying due to electrical problem

Exactly what I was trying to say. By the way, Jim, the switch I have handy this is of a similar vintage to the one in your photo has a plastic washer where yours has a metal washer.

-

Windshield washer not spraying due to electrical problem

One more clarification, last night's instructions for disassembly were for a 77-78 switch. This is why the year is important. The 73-76 has four screws on the side that need to be removed. I haven't tried to dig up an earlier switch to look at it.

-

Windshield washer not spraying due to electrical problem

By the way, create a signature and put the year of your car(s) in it. There can be other diagnostic information developed if we know the year. At least put the year of your Z in this thread.

-

1973 240z Custom Wiring From Scratch

What I did was make harnesses to intercept the wiring in the headlight circuit. At the high/low beam switch the RB and RW wire from the switch are routed to the 86 pins on the relays whereas the RB and RW wires from the dash harness are connected to the 30 pins on the relays. The R and RY wires from the fuse box are routed to the on the 85 pins on the relays. The R and RY wires in the dash harness are grounded. I landed a wire on the stud on the bottom side of the fusebox to go to fuses and on to the 87 pins on the relays. The terminals I used are for Bosch relays. Here's a picture of the other relay. The terminals are S - Signal Common S1 - Low Signal S2 - High Signal B - Battery L1 - Low Beam to Headlight L2 - High Beam to Headlight You would only need one wire from the fusebox (either R or RY) to the S terminal. You would bring the RB and RW wires from the high/low beam switch to S1 and S2. The power wire from the stud in the fusebox would go to B. The RB and RW wires from the dash harness would go to the L1 and L2 terminals. It would be easier to understand if I drew it out, but that would be for another time.

-

Windshield washer not spraying due to electrical problem

You don't need to remove the button. The switch contacts are at the other end of the switch. Here's a short video showing the contacts. You'll need to get between the copper arms and tabs to clean those surfaces. There are 3 screws that hold the parts together. Be careful removing the screws on the side because there are small plastic washers that insulate the circuit. Once you have the contacts removed, you can polish them with a dremel w/wire brush, emery paper, or dip them in vinegar for a short time.

-

1973 240z Custom Wiring From Scratch

I have mounted relays for headlights on the driver's side of the center stack for my relay solution that isn't visible to the casual observer. If you are trying to be very compact you could try a relay like this: https://www.amazon.com/gp/product/B08DD5FRSW The pros: Fuses for the loads are at the relay. This is more compact than two separate relays. The cons: I have no long-term experience with this relay. You have to replace the whole unit if a relay goes bad.

-

Lean times, and not just because of high prices and low wages.

Well, that's what I get for not suggesting looking at your ignition after I read your post. I could have looked like a stud...well, yeah, that is going too far. 😞 Of course for a sparky type, we usually suspect electrical first.

-

YPC Connectors

Well, that was fast. The connecters arrived a little while ago, and I have put them in a divided storage container so they will be ready to use. If you need YPC connectors, hi-1000ec.com is legitimate. I purchased extra male 3-pin and 6-pin waterproof connectors. The 3-pin is for wiring a conventional Bosch relay for the AC relay. The 6-pin is for jumpering out the voltage regulator connectors in 75-77 280Zs when converting them to internally regulated alternators. I bought connectors that could be used for the center gauges, too. It could also come in handy for a conversion to Speedhut gauges.

-

Heater Core Alternative - Escort Core into 260/280

I just experimented with pin removal tools until I hit the jackpot. Some of it is luck, and some of it is actual research paying off. I think I bought the Molex pin remover after taking measurements of the male pins and searching for pin removal tools with that dimension. The iwiss was dumb luck since I was interested in getting a weatherpack terminal crimper.

-

1973 240z Custom Wiring From Scratch

Well, most non-trucks have transverse mounted engines, so they aren't positioned for an engine mounted fan to draw air through a radiator.

-

YPC Connectors

I'd like to add that with the male 6-pin waterproof connectors would work for jumpering out the voltage regulator on a 280Z. It's too bad the 260Z uses a different connector.

-

YPC Connectors

I found a website that lists many of the old YPC connectors for sale. Here's a link to their YPC inventory: https://www.hi-1000ec.com/product-list?keyword=ypc&Submit=Search&page=1 The last item in the search is for a pin removal tool, too. The website whois shows a registration in Japan. I placed an order last night, and today I received an email with a photo of the shipping label and a photo of the parts I ordered bagged up. That certainly inspires confidence in ordering. This should help in making repairs and modifications to 260Zs and 280Zs.

-

1973 240z Custom Wiring From Scratch

Make sure you can bring in a 10 AWG wire into that fuse box if you're going to be running the fan from there.

-

1973 240z Custom Wiring From Scratch

Frankly I haven't worried too much about relay brands for a very simple reason. I try to reduce current flow through the mechanical switches, and I'm not adding load. The exception would be an electric fan for the radiator. If you're using a 20 or 30 A relay for an LED headlight circuit, you'll be well within the design parameters of most any relay you find.

-

Heater Core Alternative - Escort Core into 260/280

I also found this site recently that has the 2, 3, 4, and 6 pin Yazaki shells and pins: https://www.hi-1000ec.com/product/1133 They also have the waterproof Yazaki YPC: https://www.hi-1000ec.com/product-list/50

-

Heater Core Alternative - Escort Core into 260/280

Okay, I made sure I found the right part numbers. For the male pins, this extractor works: https://www.amazon.com/gp/product/B01G46DJVU The larger side is the one that fits over the male pins. For the female pins, the Iwiss (also known as Icrimp) WR01 works. I bought it with a weather pack crimping tool: https://www.amazon.com/gp/product/B07GB698KV/, but you can also get it with a couple of other pin extractors: https://www.amazon.com/IWISS-Extractor-Removal-Metri-Pack-Connectors-3/dp/B08PKLZXCX Here's a photo of the extractors:

-

Heater Core Alternative - Escort Core into 260/280

I'll try to remember to provide the tools I use when I get home.

-

1973 240z Custom Wiring From Scratch

I think @Zed Head found them a long time ago. I ordered some about 7 years ago.

-

1973 240z Custom Wiring From Scratch

Yes. https://www.amazon.com/gp/product/B00JS8OU9M

-

Replacement Windshield Options

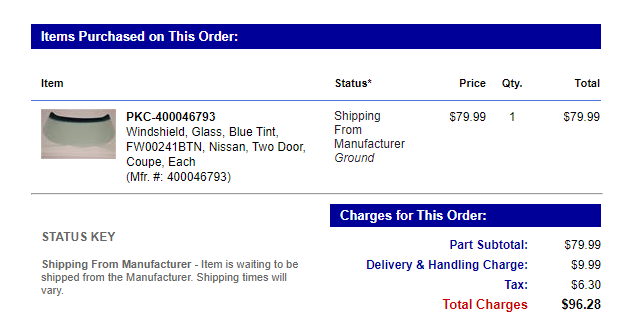

And I found the email after the order. Look at that price. 😞 I think one of the Jims posted about finding it 5 years ago. Nope! It was @Zed Head. The good news was that I did get a windshield 3 years ago for a great price thanks to a hook-up from a friend.

-

Replacement Windshield Options

And I checked my email archives to find the cancellation from Summit (5 years ago). It had the part number, so I looked it up.

-

Replacement Windshield Options

I think Summit Racing used to list the Pilkington windshields. I tried to order one, and the ship date kept moving out until my order was cancelled.

-

71 240Z High Beams Work Low Beams Don't

Correct, the high/low beam switch on the turn signal stalk.

-

71 240Z High Beams Work Low Beams Don't

Considering it's both headlights missing low beam, the most likely problem is with the switch.