Everything posted by SteveJ

- Hazard Warning Switch Removal

- Hazard Warning Switch Removal

-

Ignition Systems Analysls

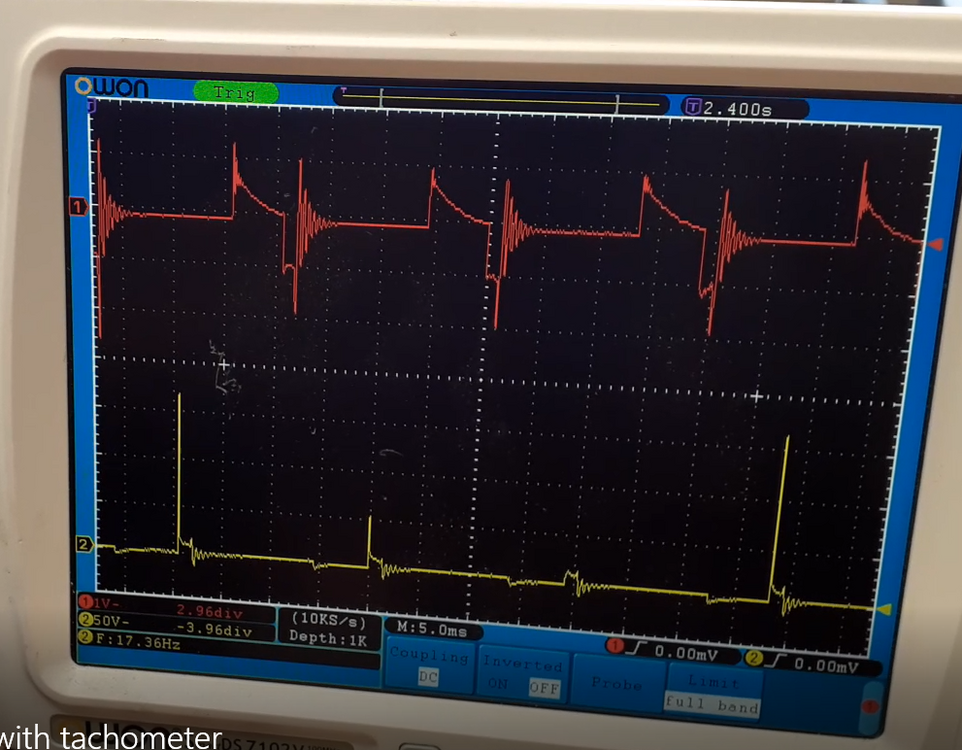

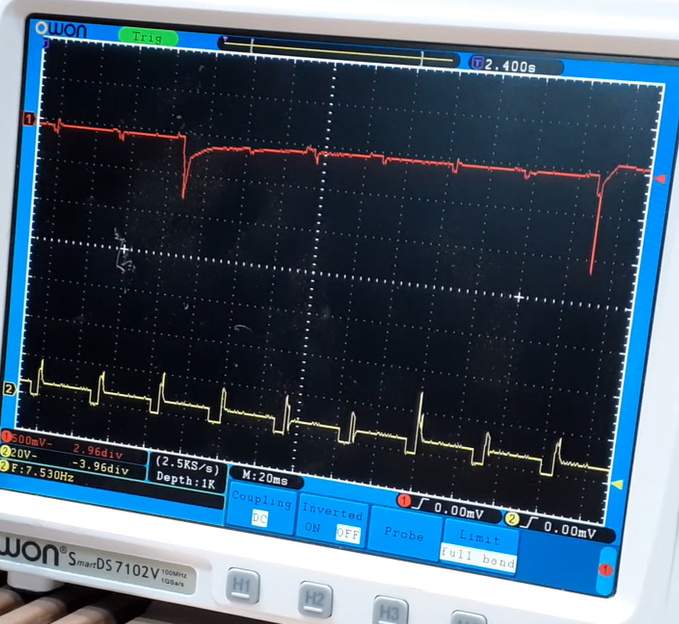

It's a good starting point since that's what most people here are running, but it would be interesting to learn more about ignition for the coil on plug systems. Just from talking with @Captain Obvious on the phone and looking at some videos he suggested, I was able to detect a potential issue with my 240Z by using my oscilloscope. The scope indicated there could be some extra arcing (having to jump more than the gap between the rotor & cap and spark gap) at the firing line of the spark at different cylinders. When I looked at the cap, wires, and coil, I found significant corrosion at the coil. Before changing the coil and wires (yellow wire is the voltage at the negative post of the coil): After the coil and wires were replaced (again, yellow trace): Next up is for me to get a current probe for my scope so I can chart the current limiting effects of some of the ignition systems.

-

tachmeter bulb replacement

I'm glad you could find green ones. I was just doing a quick search. I hope you ordered the 23mm long ones. Those will fit inside the lenses.

-

tachmeter bulb replacement

This might work for you. If you try it, let us know. https://www.amazon.com/Ruiandsion-Interior-License-Reading-Non-polarity/dp/B07JMY7Q8J

-

tachmeter bulb replacement

I have actually seen this in the wild. The Auxito H4 headlamp bulbs don't care about polarity. I installed them in a 280ZX without relays, and so did another person I know. Like the S30s, the 280ZX has one positive and two negative wires, switching the ground for high and low beam, and the those bulbs would switch between high and low beam. I even bench tested them with a 12VDC power supply and got the same results. Now could that happen with a BA9 bulb? I'm not sure.

-

tachmeter bulb replacement

I was looking through my past orders. Duabhoi bulbs were 1156. The dash bulbs I used in the 240Z were Yongming. I don't recall if I tested them for polarity sensitivity. I do recall having the issues with the bulbs back 8 years or so ago for the gauge lights in the 260Z hence my unorthodox solution. I also recall a friend having issues with converting a 280Z over to LED bulbs for the gauges a couple of years ago. I can't recall if he found a solution.

-

tachmeter bulb replacement

If the second bulb was in the speedometer, that was the problem. Incandescent bulbs don't care about polarity. When I was going to LEDs in my gauges, I ended up replacing the sockets to wedge sockets. That allowed me to flip the bulbs around if the polarity wasn't right. I didn't try to prove it out, but I think one of the bulbs in the speedometer is wired backwards. That is what provides the challenge of swapping to LEDs. Once the one diode blocks the current flow, none of the bulbs will light up.

-

[2022] What Did You Do To/with Your Z Today?

It's false Fall in Georgia. That means for a while we will have cooler temperatures for a short while, followed up with a last blast of heat before true Fall. Anyway, the conditions were great for going to a Saturday morning car meet. As a matter of fact, the weather was so nice, several others decided to bring their Z cars out, too. The two yellow 240Zs were purchased through BaT. One of the owners has been to a Georgia Z Club meeting, though I don't know if he joined, yet. I ended up diagnosing "lack of cabin heat" issues on both. The brown 280ZX and black gold AE are both owned by fellow GZC members. All I can say is that the 260Z felt great on the roads with the new inner LCA bushings. I need to consider doing more suspension work on the 240Z to keep pace.

-

tachmeter bulb replacement

Did you test them with the bulb socket re-installed? The ground for the 240Z gauges is the gauge body. Another problem could be some LED bulbs are positive ground. I found that issue early on when I started experimenting with LED bulbs. Just make sure the dimmer is turned all of the way up. However, LED bulbs tend to be less voltage sensitive than incandescent bulbs.

-

Ignition Systems Analysls

I thought this link was interesting: http://commons.princeton.edu/58-tiger-cub/wp-content/uploads/sites/75/2018/08/ignition_waveforms.pdf It talks about how to use the analyzer to diagnose the engine. If you watched the video I made, you will see the voltage at the firing line vary. I have another video where I used the inductive probe on cylinder #1. From that, I can see which cylinders have the most of the anomalies happen and possibly optimize the spark performance.

-

Ignition Systems Analysls

I hope this adds to the discussion. After watching a couple of videos that @Captain Obvious provided me links for, I bought a 20:1 attenuator for the voltage probe. I hooked up the spark induction probe on the coil wire and shot some video while monitoring my 240Z with a Pertronix Ignitor II. Maybe tomorrow I'll shoot some more video with the 260Z using the ZX distributor. Here is one of the videos the good Capt sent me: I'm not sure in my video if I'm confusing voltage kick with firing line. I noticed a lot of variability in the voltage peak at the firing line. I also noticed as the engine speed increased, I couldn't see the voltage at the coil as easily on the scope.

- 240z heater box rubber grommet

-

70 240Z, metallic clang clang clang on acceleration, worse when cold.

Maybe shoot a video so we can hear the noise.

-

73 Dash Replacement Project

Here's the follow-on question. Did the PO get the resistor installed in the circuit? The design of the tach circuit for the 260Z/280Z 3 wire has a 2.2kOhm 1/2W resistor between the tach and the negative post of the coil.

-

73 Dash Replacement Project

Yes, you have to fool the charger to get it to start. You can do that by having a jumper to a battery that you pull. However, it sounds like your method worked, so there is that. Now here's the next question. Has the wiring in your car been modified for the 3 wire tach? The stock wiring in a 240Z is for the 4 wire tach.

-

Ignition Systems Analysls

I think this link will add to the discussion: http://www.atomic4.com/dwell.htm The title is What is Dwell Management and Current Limiting?

-

1977 280z Coolant Temperature Gauge

Well, I got my old wire tracker out. At first it didn't want to behave, but soon I was getting a good tone from the end of the wire to the gauge.

-

1977 280z Coolant Temperature Gauge

I have the HF unit, and I actually used it at work...about 14 years ago. That was for wiring in a bunch of metal boxes, and I didn't get a bunch of false readings. After a while, I got to where I didn't need it any more. Does it look like your harness has been altered/modified? I might have to dig my tracer out and play with it again.

-

1977 280z Coolant Temperature Gauge

You may have misunderstood. It could be at the bullet connector. You might not be able to see it, especially if it's corrosion. Also, there could be corrosion at the connector between with engine harness and dash harness.

-

73 Dash Replacement Project

Yep, I was talking with @Captain Obvious, and he pointed out the tachometers were different. Apparently someone converted a 260Z/280Z tach to fit into a 240Z. The wing nuts were added to the tachometer

-

73 Dash Replacement Project

My friend, Google, found a link that led me to this: http://www.mgb-stuff.org.uk/tachtest.htm

-

1977 280z Coolant Temperature Gauge

It would be highly unusual for a wire to break in a wiring harness unless the harness was pinched hard or pierced. The usual suspects would be where the connectors are attached to the wire. That would be fatigue breaking the strands or corrosion. However, if you wanted to look for a break in the wire, you would need something like this: https://www.amazon.com/Electrical-Wire-Tracer-Continuity-Automotive/dp/B08L6NYQYK You would detach the C1 connector and clip the red lead to the yellow wire. Then clip the black lead to ground. You would use the probe to "sniff" the wire through the harness, and if you lose signal, that would indicate a break. The bottom line is that you should inspect the connectors carefully at both ends (C1 and at the sensor).

-

77 280z Restoration

Me! Me! Me! I want to get geeky! I even started playing with the inductive pickup I bought for my scope. I really need to re-familiarize myself with working with o-scopes. It was a LONG time since collage.

-

Thinking of selling -how do I know how much my car is worth?

I should add that for top dollar, get photos underneath the car and all over the engine bay. Also take close up photos of the rust prone areas.