Everything posted by SteveJ

-

Door Sill Benchtop

What? You don't carry a back up Z with you?

-

Door Sill Benchtop

Well, I had a chance to use the bench to work on the car today. I was about to take the 240Z to a car show, but it wouldn't start. I pulled the #1 plug and tried again. There was no spark. I got in the 260Z instead and went to the show. When I got back home, I hooked the voltmeter to the coil. No voltage in start or run. After just a moment to contemplate the test results, I determined that the tachometer must have become unplugged, probably when I was messing with the hazard light switch a week ago. No better time than the present to test the bench in real world conditions. I set it up, put the pad on it and scooted under the steering column. After groping around some behind the dash, I found the unplugged connector and put it back securely. I slid out from under the steering column and stood up with no strain on the back. I then folded up the legs and put the bench away. The car started right up. It's so nice to see a project work out so well.

-

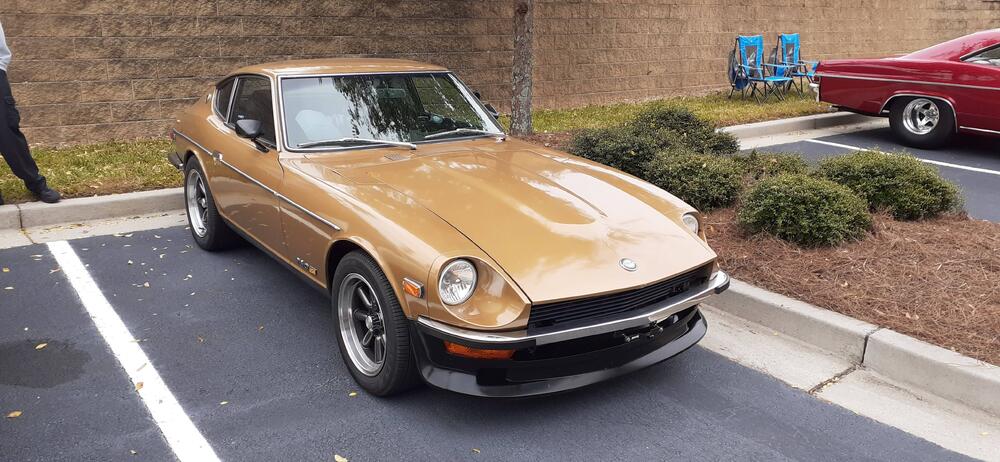

[2022] What Did You Do To/with Your Z Today?

Okay, it was Caffeine and Chrome time again. The 240Z wouldn't start, so I jumped in the 260Z to meet my friend, Paul, who drove his Black-Gold 280ZX. (I still think he needs to do the 80s 'stashe and 'fro to complete the look.) The Georgia Z Club will be the featured club at the next Caffeine and Chrome, so I used that to coax a couple of people to come out this month to check it out. This month we had 2 240Zs, a 260Z, a 280Z, a 280ZX and a 300ZX (Z1). Next month I'm hoping the missing generations show up.

-

Alternator Upgrade Issue

Back in the day, it wasn't bad to get a reman. As I mentioned before, the one I put in the 240Z was purchased many years ago. I'm not sure what happened between then and now, though I have my guesses. A friend was having issues with his 77 trying alternators and a voltage regulator. I tried to get him to do the upgrade to the Frontier alternator from the start. He spent more his way, though. The good news is that he's been happy with the alternator swap I did.

-

Power antenna wire non center tap

Or just go cheap with a DPDT switch...Yeah, I know. That's no fun.

-

Door Sill Benchtop

Thank you. It wasn't my first effort. I made another bench many years ago, but it had fixed legs and a rectangular shape. It took up too much space, and it couldn't get as close to the door sill. Eventually, it got tossed. I was actually thinking of mounting a hook to the underside of the bench so I could hang it from my shelves to keep it more out of the way.

-

Door Sill Benchtop

I did a quick search for the home made tool thread, but I didn't find it. (Of course, I didn't spend too much time looking for it.) I bought some folding table leg brackets from Amazon a while back for this project, and I finally made the time to execute. The video shows the door sill height benchtop I made for when I have to lie on my back to work in the footwell. I used 2x12 for the benchtop with 2x4 legs. I hope you find it useful.

-

280Z bumpers on a 280ZX?

@borini63 Do you still have a good collection of ZX parts?

-

Alternator Upgrade Issue

That is part of what drove me to do the Frontier alternator swap on the 260Z. I had a good ZX alternator that I decided to use in the 240Z when I was waking it up last year. That used up my reserve. I learned I could get a new Frontier alternator from Rockauto, so I went that route.

-

Picked up a 73 240Z. Need help changing all the fluids

Download the factory service manual. It has the specs. The FSM is available in the Downloads section of this board. I have a link in my signature.

-

Timing chain help

You need to support the valve. You can do with compressed air or some rope pushed in through the spark plug hole.

-

Parts Wanted: Need A Good S30 Hood

Resurrected Classics Hood - https://resurrectedclassics.com/collections/sheet-metal

-

Percussive Maintenance

I'm relaxing at home when I got a call from a number I didn't recognize. Since the caller left a voicemail, I played it. He told me he got my number from a friend. He has a 78 that he drove to the gas station, and it wouldn't "catch". He said another friend worked on the car, but that friend wasn't available. I called him back and found out that the engine would turn but wouldn't fire. Knowing that the friend who worked on the car is a very good Z wrench, I knew I had to run through possible esoteric solutions. "Beat on the ECU." "What?" "Hit the ECU with the side of your fist. Just bang on it a couple of times. Then try to start your car." "Where is it?" "When you're sitting in the car, it's by your left leg on the kick panel." "I see a piece of plastic there." "Yep. Hit it." "Oh my God. It worked." I told him he might need to replace the ECU. It looks like MSA is out of them for right now. When I told the story to another friend, he responded, "Percussive maintenance." What can I say? He's right.

-

Can someone help identify my 240Z wheels?

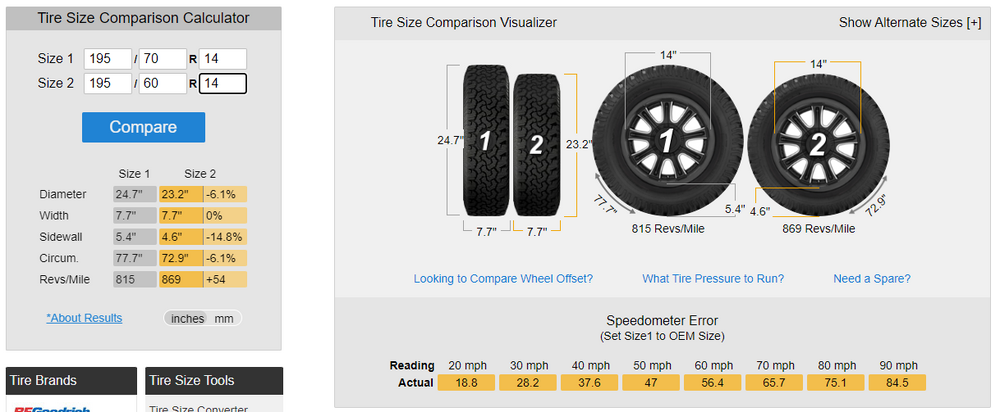

By the way, if you want to get more traction (and aren't taking the Z up to Big Bear in the winter time), consider getting some Falken Azenis RT615K+ tires. They are slightly smaller than the tires you have on the car now, but they have great grip.

-

Can someone help identify my 240Z wheels?

Yeah, I hear that at home a lot, too...except without the thanks at the end. *sigh*

-

Can someone help identify my 240Z wheels?

And here: https://www.americanracing.com/american-racing-outlaw-ii

-

Can someone help identify my 240Z wheels?

I'm not sure this is the original design, but I found it: https://www.tirerack.com/wheels/WheelCloseUpServlet?gclid=CjwKCAjwkaSaBhA4EiwALBgQaOsvTVxlScfZk2xUsLc4O6mkd_Q5sS7ms7OU0M_B2SSQM1VxT8isBhoCoUMQAvD_BwE&target=runWheelSearch&wheelMake=American+Racing&wheelModel=AR62+Outlaw+II&wheelFinish=Silver+Machined+w%2FClearcoat&initialPartNumber=AR625762SDC&GCID=C13674x012-wheel&KEYWORD=wheels_American_Racing_AR62_Outlaw_II_Silver_Machined_w%2FClearcoat_Wheels_15_In_15x7_50&code=yes&autoMake=Oldsmobile&autoModel=Toronado&autoYear=1985&autoModClar=&checkVehicle=&ef_id=CjwKCAjwkaSaBhA4EiwALBgQaOsvTVxlScfZk2xUsLc4O6mkd_Q5sS7ms7OU0M_B2SSQM1VxT8isBhoCoUMQAvD_BwE:G:s&s_kwcid=AL!3756!3!537118804928!!!u!293946777986!&gclsrc=aw.ds

-

Alternator Upgrade Issue

The test I suggested still applies. If you see voltage on the black/white wire with the key off, that's your problem. If there isn't voltage on the black/white wire, then it's on to testing with an ammeter, but I'll supply those directions if necessary. As for the ammeter gauge dancing, it means that the alternator is cutting its output. Make sure you have enough tension in the belt. What is your idle speed set to on the car? What is the voltage to ground at the yellow wire on the T connector at the alternator? The last thing I can think of is a possible issue with the voltage regulator in the alternator.

-

hard miss on #6 only notice at idle

"I'll take Fraud for $1000, Alex." "The answer is, 'Only two posts and BOTH are responding to a parts wanted ad.'" "What is the hallmark of a scammer on Classiczcars.com?" "That is correct, and you retain control of the board."

- Float-Sync

-

hard miss on #6 only notice at idle

Great point. Unless the valve seats have been replaced with hardened seats, one could have become hammered.

-

hard miss on #6 only notice at idle

By the way, on my 240Z, I was trying to re-learn how to use an oscilloscope and was measuring the voltage at the coil, correlating it to an inductive pickup on the coil wire and #1 plug wire. The waveform of the coil voltage had irregular peaks. When I reviewed my results against some Google research, I started looking for extra gaps in the high voltage circuit. Sure enough I found a corroded high voltage terminal on the coil. I plugged in a new coil, and the volume of voltage spikes decreased precipitously.

-

hard miss on #6 only notice at idle

This is where it would be great to have the ability to measure spark voltage on a scope while driving. Great! Now you have me looking at portable 2 channel oscilloscopes! Dang it, I'm spending enough money on tools already.

-

two-wire hose clamps

Is this an auction that people outside Japan can use, or does it require an agent?

-

Alternator Upgrade Issue

Unless the owner has added a big stereo, the alternator won't necessarily be putting out more current than the old alternator. On the other hand the excitation curve is improved over the old alternator, so it is putting out enough at lower engine RPMs. (I know this has been mentioned in the past over at ZCar.com. I don't know if it was mentioned here.) This can make a difference with blinkers functioning properly, headlight illumination, etc. Granted, LEDs can also help with lighting performance, and I am a big proponent for them. I have used a ZX alternator in my 240Z for over 20 years without problems, and I put a Frontier alternator (70A) in my 260Z last year. It's not an accident waiting to happen.