Everything posted by SteveJ

-

Time to replace the rear suspension bushings in the 260Z

With the end link nuts being stubborn, I had a couple of more opportunities to use the induction heater. On the first top nut, I got the end link hot enough that the bushing caught on fire. For the other end link, I thought it would be a good opportunity to shoot a demonstration video. If you're not familiar with the induction heater bolt removers, I have a positive impression so far.

-

Time to replace the rear suspension bushings in the 260Z

I have to admit that I am reassembling without touching the spindle pins. I want to know if I corrected the toe with the new inner bushings.

-

Time to replace the rear suspension bushings in the 260Z

The inner bushings are off. They definitely show 48+ years of wear. @Captain Obvious, I can see how the distortion could lend itself to letting the toe change. I'll put the inner bushings together and check on the spindle pins. So far, aside from the one end link on the sway bar, everything has been cooperating. If the new poly bushings don't fix the toe problem, I'm going to try the eccentric bushings from MSA.

-

77 280z Restoration

John, is it plastic or metal on the back side of the HEI? If it's metal, I would say go for broke and use conductive paste. I'm thinking the two holes in the unit for mounting may be the path to ground they want you to use. If it's plastic, use the silicone adhesive and bolt the unit securely to the heat sink. Then the heat sink should be bolted securely to the body. Check resistance between the mounting bolt of the HEI and the negative of the battery to make sure you have a good path to ground.

-

Time to replace the rear suspension bushings in the 260Z

So far things are working out in the disassembly. I had one end link on the sway bar that didn't want to cooperate, and I was rounding the nut. I figured it was a great time to break out the induction heater. I heated up the end link a couple of times, getting it cherry red, put a smaller socket on the impact gun, and spun off the stubborn nut with ease. The rubber in the bushing was smoking a lot, and I wondered if it was going to ignite. On the other hand, the torch would have almost definitely ignited the bushing. I am happy with the induction heater so far and would suggest someone working on a bunch of rusty bolts should consider getting one.

-

Time to replace the rear suspension bushings in the 260Z

Good to know. I also purchased a ball joint press. I could experiment with that, too.

-

Time to replace the rear suspension bushings in the 260Z

I'm only working on the rear at this time. It's almost impossible to get rubber anymore.

-

Thermostat/Oil gauge

It's a tiny meter, about 1.5 inches by 1.5. The nice thing is that if I blow it up, it was cheap.

-

Time to replace the rear suspension bushings in the 260Z

Yes, sir. I am putting poly bushings in. This may be interesting.

-

One-Family 1972 240Z Restoration (HLS30-93069)

For future reference, you can put the fuel pressure gauge on the line between the fuel rail and the carburetor. I found it easier than trying to connect it to the fuel pump.

-

77 280z Restoration

The heat sink should be bolted to the fender. That should be an adequate grounding.

-

Time to replace the rear suspension bushings in the 260Z

I have a 20 ton press and plenty of sockets. I may be able to push out the old rubber. I did see videos on using fire to have one's way with those bushings.

-

Time to replace the rear suspension bushings in the 260Z

On the advice of a friend, I bought a transmission jack from Harbor Freight to hold up the differential. The nice part is that my 20% off coupon was good to use for buying it. The coupon said jacks were excluded, but I guess it meant hydraulic jacks. I also took the opportunity to buy a set of 3/8 impact sockets, and at Home Depot I picked up a compact 3/8 impact gun. Now to find what bolts are uncooperative.

-

Sexy? or sacrilege?

I'm kind of thinking it reminds me of a Dino with fewer curves. Maybe it's just the orange.

-

Acceleration Stumble

I actually saw that helping a friend with his 280Z. He bought a fancy FPR from the company that employs Corky Bell. The fancy FPR was supposed to work with the stock FPR to increase the fuel pressure even at higher vacuum. Well, when my friend got someone to install the FPR, the installer didn't bother reading instructions (Sometime instructions aren't for sissies.) and removed the stock FPR. When my friend brought the car to me, he had Corky's number, and I confirmed what was needed. My friend got a stock FPR, and I installed it, but I didn't put a vacuum reference on it at first. On the first test drive, the car stumbled at tip-in, and I could even see it with the AFR meter. I found an available port for the vacuum reference, and the car ran a lot better.

-

1977 280z Radiator clutch fan engaged too frequent

And the oil pressure looks good, too.

-

77 280z Restoration

Use a conductive adhesive between the HEI and heat sink. https://www.amazon.com/Conductive-Adhesives/b?ie=UTF8&node=401542011

-

Acceleration Stumble

@siteunseen was referring to the return side of the fuel pressure regulator.

-

Acceleration Stumble

YouTube does that to videos under a minute now.

-

77 280z Restoration

Here is what I suggest to help your project. For the terminations, either for the HEI or matchbox, buy a kit like this: https://www.amazon.com/HUAREW-Connecto-Terminal-Insulating-Electrical/dp/B098DX41Y8/ and a crimper like this: https://www.amazon.com/ProsKit-300-035-Multi-Purpose-Crimping-Tool/dp/B002PI8D4K I like open barrel terminals more than single crimp since they clamp onto the insulation and the wire. With the proper crimping tool, the open barrel terminals rarely come off. The kit includes insulators so you can reduce the chances of shorting something out.

-

Time to replace the rear suspension bushings in the 260Z

I purchased the Energy Suspension bushing kit a LONG time ago. (I'm thinking it was about 8 years ago or so.) I put the car up in the air earlier this year, but I realized the scissor lift made it where the exhaust was in the way. I finally put the car up in the air with the QuickJacks. (Don't buy a lift that has a crossmember at the top.) So I was looking it over carefully since this is definitely not an area of expertise for me. I sprayed some Kroil on various bolts and nuts that will need to be turned, and I think I worked out my plan of attack. Lower the exhaust and support it out of the way. Remove the rear sway bar. Attack the moustache bar. Attack the crossmember, supporting the differential with a jack as needed. Remove the inner LCA bushings Replace the bushings on the mustache bar, crossmember, and inner control arms. Pray and contemplate developing a relationship with alcohol. Attack the spindle pins. Assembly is the reverse of disassembly. (In the Haines manual tradition) Thoughts, criticisms, advice?

-

Acceleration Stumble

Let's start with the obvious. The car isn't getting fuel at tip-in on the throttle. Has your friend thought about getting the injectors cleaned? What is the fuel pressure during this time? Is the vacuum line connected to the fuel pressure regulator? I couldn't pause the video in time to see.

-

1973 240z Custom Wiring From Scratch

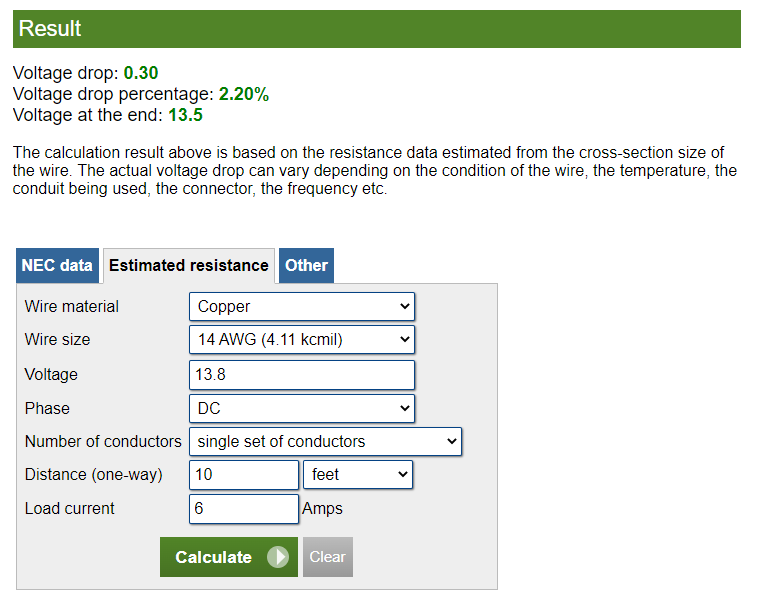

Just be aware of what gauge wires your terminals are designed to take. Doing some quick resistance calculations, you are upsizing a lot of wires with little to no benefit. You may end up with an issue getting your engine harness through the hole in the firewall. (Keep in mind that it will probably be easier if you put the pins in the connectors after you get the harness through the firewall.) You may want to check out a voltage drop calculator like this: https://www.calculator.net/voltage-drop-calculator.html Choose estimated resistance. I did a quick calculation for the headlights with a swag for the distance and used incandescent sealed beam ratings. The voltage is 13.8 because that is toward the low end of operating voltage while the car is driving. Many of your circuits for the engine harness are grounded close to the load, so this calculator would overestimate the voltage drop. The battery/charging system are your highest current circuits, so the larger gauge can easily be justified. No other circuit comes close especially if you change the parking light circuit to LEDs, as that is probably the biggest continuous draw you would see. Other high draw circuits: Fan (14 AWG is fine, but you might be better off with 12 AWG) Fuel pump (This is about 10 A or less. 14 AWG would work.) Headlights (depending upon whether or not you switch to LEDs. LEDs would drop this circuit to about 3 A.)

-

77 280z Restoration

Low impedance would translate to more current. More current means more power. More power means more heat.

-

Koito H4 Headlight Housings

Search many dealers. Some say NLA, and others say they have them. Here's a Google search on it: https://www.google.com/search?q=toyota+81110-60P70&oq=toy&aqs=chrome.0.69i59j69i57j69i59j46i131i199i433i465i512j69i65j69i60j69i65l2.4904j1j7&sourceid=chrome&ie=UTF-8 Here's one dealer that says they have them: https://parts.toyotasouth.com/oem-parts/toyota-headlamp-assembly-8111060p70