Everything posted by SteveJ

-

71z but L28 engine, could someone tell me what I have?

While this doesn't directly answer your question, it's still a good (and short) read:

-

SU flat top bowl drain screw

Nope. No drain screw, at least not on the set I had handy. There was a heat shield on the bottom. The shield covered this: Still no signs of a drain screw, so I took off the bottom of the float bowl. Nice and gunky! Here's a side view of the floats. And the float bowl chamber. No penetrations on the sides that I could see. I'm thinking that valve is TOAST. Anyway, when putting it back together, note that 1 screw is shorter than the rest. The short screw goes where there is an indentation on the bottom cover. Don't dismantle unless you have a new float bowl gasket on hand. And don't buy the cheapest kit since that kit does not have as many gaskets. (2 needed) https://www.rockauto.com/en/catalog/nissan,1973,240z,2.4l+l6,1209170,fuel+&+air,carburetor+repair+kit,5964

-

Fuel tank evap hose leak and tank fuel level question

Yep, those work great. I even used my impact gun to raise/lower the jack.

-

78z Fuel Gauge is not working

Is there any chance that the dash harness to body harness connector was disconnected?

-

78z Fuel Gauge is not working

Was the key in ON?

-

78z Fuel Gauge is not working

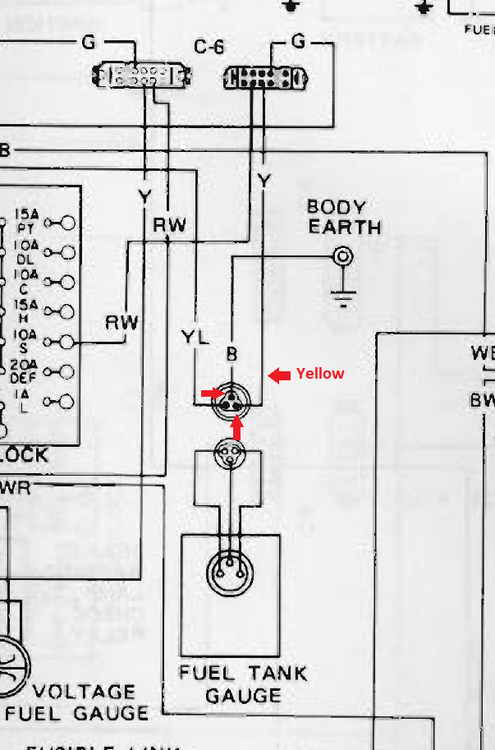

You have to use a small piece of wire to jumper the black and yellow terminals where the wiring connects to the sending unit at the tank.

-

78z Fuel Gauge is not working

This test should only be done with the gauge in the car. The voltage regulator needs to be connected for the gauge to function properly. @gotham22 Here is a video of setting up a bench test. Follow the wiring exactly. If you're not sure how it should be wired, stop and ask questions, otherwise, you could damage a gas gauge. I have not been able to ascertain the state of your sanity.

-

Impossible Oil Leak?

Just because I like resurrecting old threads every now and again, I wanted to add a product review. I put the gasket @Zed Head linked in post #26 in this thread on my ebay watchlist. A couple of weeks ago, I got a "special offer" that knocked $2 off the price. I figured I could spend the roughly $6 to get one of these printed gaskets, and it arrived today. It is much more pliable than the old gasket. The reproduction is 2mm smaller diameter than the gasket on my spare oil cap. It's also not quite as thick. Does it matter? Probably not. It will mate to the sealing surface of the valve cover, and I don't think there would be any gaps. The cap with the new gasket is on the left.

-

Testing Pertronix Ignition Module

It would explain why they fail.

-

Xenon 3125 Spoiler Install - 1975 280Z

There are little retaining clips you can put on the pins of the emblems to help hold them in place.

-

Let's show vintage racing pictures. I'll start.

I wouldn't be surprised if Randy Jaffe has a copy of the photo if it exists.

-

1971 HLS30-14938 "Lily" build

That would be 0.030" in freedom units. 😁

-

Fumoto drain valve

@dpascual1986 hasn't been on the site in over 4 years. You probably won't get any feedback.

-

280Z Fuel Injection to Carb Swap

Are you swapping in a 240Z or 260Z engine? If not, you have to open up the window in the head for the mechanical fuel pump, and you'll probably need to source and install the eccentric for the fuel pump. And let's not discuss the poor quality of aftermarket mechanical fuel pumps.

-

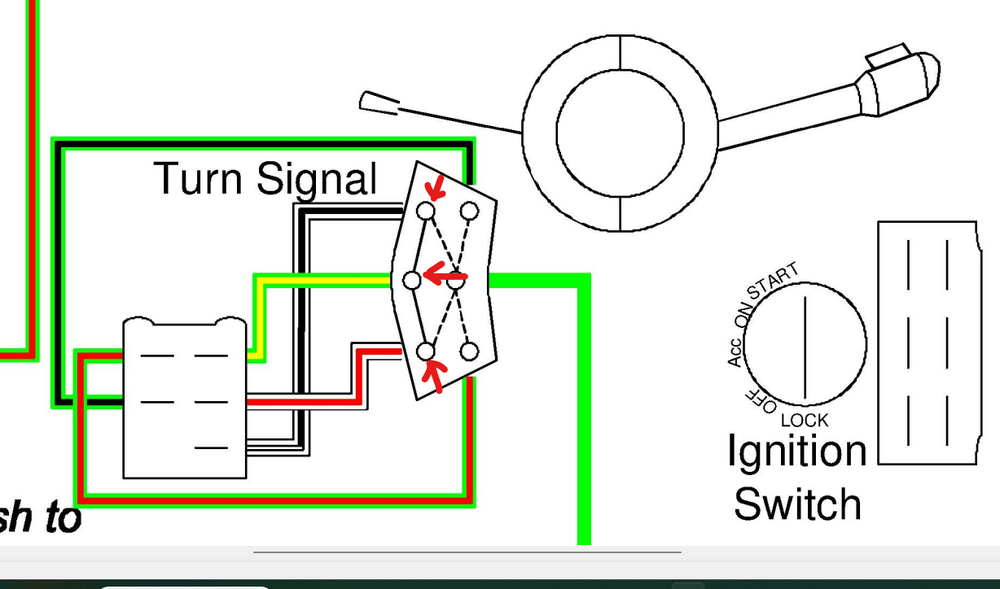

No Brake Lights or Turn Signals. Where to look next?

I couldn't pull off the simulation well enough to suit me. First, look for corrosion. Where? Look at the PDF I attached. I indicated 4 areas to focus on, numbered in red. Inspection Points.pdf This is a visual inspection only. You're meter isn't designed to ferret out this kind of problem. For the fuse box, examine the contact points of the fuse holder, and you may need to remove the fuse box to examine the back side of it. Just be sure to pull the negative terminal off the battery before you attempt to do that. Sometimes disconnecting and reconnecting connectors cleans off enough corrosion that the circuit will work again. You may also want to try to jumper out the brake switch to see if that is the culprit. You can probably do that with a couple of bullet connectors and a short piece of wire.

-

No Brake Lights or Turn Signals. Where to look next?

Your results don't surprise me. In fact, it supports what I said in my previous post. You have a problem in the circuit that is restricting current flow between the battery and the turn signal switch. It won't show up as a problem using a voltmeter because the voltmeter is a high resistance device that doesn't require much current. The restriction shows up as a loss of voltage when the circuit is complete. It's late for me. I should have a chance to give you some more diagnostics tomorrow. Maybe I can even make a demo video to illustrate my point.

-

No Brake Lights or Turn Signals. Where to look next?

So now it's time to look upstream. I suspect you have some corrosion, poor connection, or a loose connection somewhere in the circuit. That improper current path is a choke point, and you see the voltage drop to nothing. You could try some things like jumpering out the brake switch and see if you have brake lights. Also measure the voltage to ground at the fuse for the brake circuit before and after connecting the turn signal switch.

-

No Brake Lights or Turn Signals. Where to look next?

Take some clear photos of the 6-pin connector on your turn signal switch so that we can see the wire colors. Also, when you plug the two halves of the connector together, look for movement in any of the wires. You might be pushing a wire out. If you had a good ground, you should have seen battery voltage to ground at the green/yellow wire.

-

280Z Fuel Injection to Carb Swap

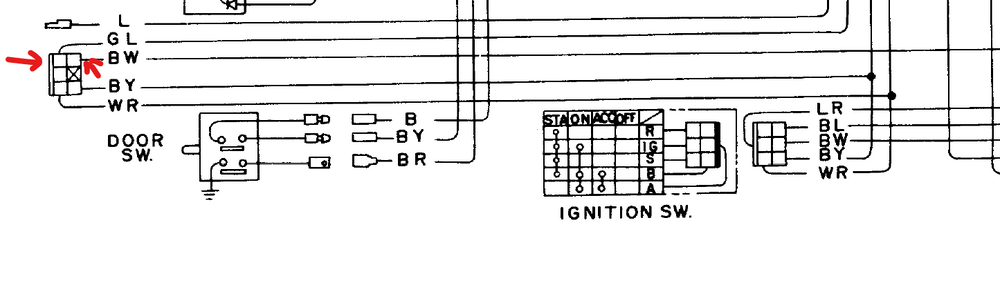

Jumper these two wires together by using an inertia switch. Mount the switch securely to the dash. That will provide power to the fuel pump at key ON. The switch should cut power if you have an accident. I think the 6 pin connector is different from the one sold at Vintage Connections. I used some that I purchase on Mouser.com. Sorry, part number for the connector isn't readily available. If you want to get an non-generic inertia switch, you could get this: https://www.rockauto.com/en/moreinfo.php?pk=3970509&cc=1427576&pt=10756 and pair it with this connector: https://www.clipsandfasteners.com/Inertia-Fuel-Shut-Off-Switch-Harness-Connector-p/a23180.htm?gad_source=1&gclid=CjwKCAjwz42xBhB9EiwA48pT73NwDLlIv8yJGuM8TKHISt7fAUw23HCsEvFF2M9k7Fhdvmvwe0MfPhoCoIgQAvD_BwE You would want to fashion a bracket for it, though. Since it has normally open and normally closed contacts, you could wire it to a light to tell you if you need to reset the switch if it has been activated.

-

No Brake Lights or Turn Signals. Where to look next?

If the switch is disconnected from the brake pedal while the turn signal switch is in the neutral position, you should see 12VDC to ground at the points indicated below. If you don't, that means the switch was not rebuilt properly. Under those same conditions, you should have 12VDC to ground at the green wire in the picture above. Please confirm that.

-

280Z Fuel Injection to Carb Swap

Fuel pump power. What year is the 280Z?

-

AC compressor 280z rebuild

You won't find a drop in condenser or drier. I haven't try to purchase either, so I cannot give you guidance. R12 is difficult to obtain since it was phased out over 30 years ago. It's probably smarter just to go with an R134a system while you're at it. Unfortunately I don't know a way to test the expansion valve in the existing evaporator. The expansion valve is another component that can fail and has no ready replacement.

-

Cruise Control in 240Z

Did you find an old JC Whitney catalog? I haven't looked at the modern systems, though your post prompted me to do a quick search. No real experience, but I haven't been motivated to look into doing it on either of my cars, yet.

-

Handy gadget

I posted a short video of the use of a magnetic finger. I bought some a few years back, and sometimes I remember I have them. They can be handy for getting washers and fasteners into tight spaces.

-

280Z Head light fender well grommets