Everything posted by SteveJ

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

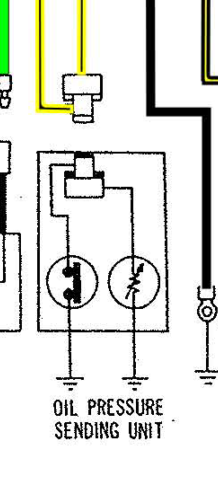

Yes, the vertical is for the fuel pump, and the top of the T is for the gauge.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Yes, you can use battery negative for ground. (Also, if you look through my YouTube channel, you'll see a video where I show how to check the quality of your grounding. Bad grounding can cause some perplexing problems.) Yes, you can check the functionality of the sensor. You measure resistance to ground at the top of the T at the sending unit. Remove the connector from the sending unit. Get your baseline resistance reading between the top of the T and ground. It should show very high resistance. You will need to ground the pin on the connector that connects to the fuel pump relay so you get fuel to run the car. Have someone start the car while you continuously measure resistance to ground at the sending unit. Resistance should drop.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

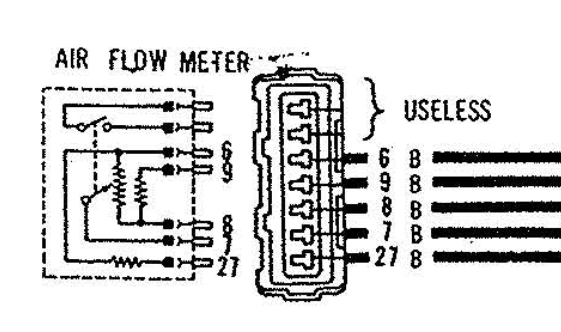

Yes, the oil pressure sending unit was changed for 78. In previous 280Zs, the flap in the AFM would close a switch to tell the fuel pump relay that the engine is running and kept power on the fuel pump. Nissan moves away from that Bosch fuel pump relay and used oil pressure as a signal that the engine is running. If you look at the 75-77 wiring diagrams, you see terminal numbers 36 and 39 on the AFM flap. This is how they documented the change on the 78 wiring diagram. So, yes, the oil pressure sender grounds when the engine is running on the vertical of the T. That circuit is for when the key is in ON.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

You can actually test to see if the gauge is functioning properly. There is a T shaped 2 pin connector on the oil pressure sender. The top of the T is the wire that connects to your gauge. You want to measure voltage to ground on that wire with the key in ON. At first, you should see full voltage, then it should start to fluctuate. A while back @Captain Obvious gave a great description of how it worked, and I bought an analog ammeter to demonstrate it. Since voltage and current are proportional, you'll see the voltage reading start to dance after the gauge warms up. Keep in mind that the oil pressure gauge and temperature gauge use the same voltage regulator, so if you don't see the voltage start to dance when you are checking the wire at the oil pressure sender, you can do the same test at the wire for the temperature sender. If one works, and the other doesn't, my first guess would be that there could be a wiring issue or corrosion at the dash to engine harness connection. Anyway, do this test and report back, and we can figure out if more diagnostics are needed.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Not needed if you only get the back part. You can get to the screws on the back using the instructions I posted.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Could it be the module on the back of the switch? Yep. It could, and I know from helping other people that the symptoms can make it look like a bad ignition relay. The nice thing is that you can replace the back of the switch with an OEM part. The part number is 48750-E7705. You can try Courtesyparts.com or Nissanpartsdeal.com. Either site is reliable. To replace: Disconnect the negative battery cable. Remove the cover from the steering wheel. Unplug the connectors from the combo switch and ignition switch. You may want to label them for faster reassembly. Remove the 4 bolts under the steering column that holds it to the dash. Push down on the steering column so you can access the screws on the back of the ignition switch and remove the old switch. Install the new switch and reverse the disassembly process. Curse under your breath if you didn't follow my suggestion in step 3. Re-attach the negative cable and test.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

The brake warning lamp is on the same fuse as the turn signals. You already established you have low voltage at the fuel gauge fuse. You probably have the same low voltage at the turn signal fuse. The voltage is enough for the light to come on faintly, but it's not enough to trigger the flashers to flash or get the gauges to operate.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Without an opportunity to poke around the car, it's hard for me to pinpoint where the stray voltage is coming from. One other test to consider doing is to remove the connector from the relay and test resistance from the W/B wire at the connector to the fuel gauge fuse. If you see 0.3 ohms again, you know the wire is intact. I've seen a lot of questionable repairs on wiring done by people with good intentions and bad knowledge. It's part of what makes distance diagnosis of electrical problems challenging. I can tell you exactly how it should work according to the factory manuals, but Bubba may have come up with a cheap fix at some time or other. Then again, it could just be a bad ignition relay with corrosion building internal resistance, dropping the voltage.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

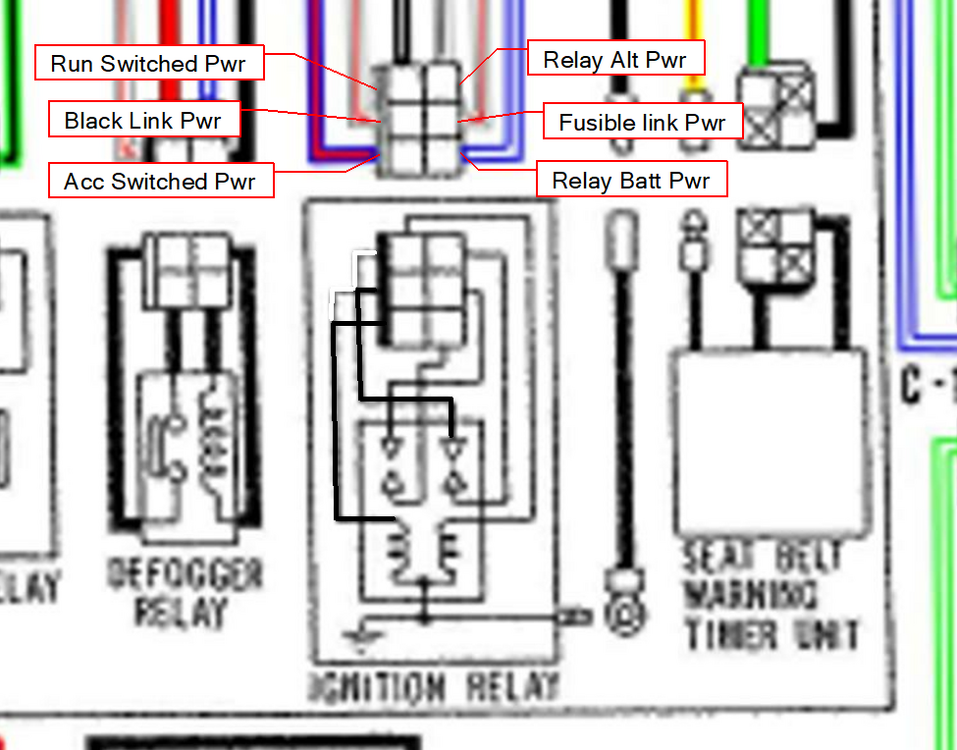

Your testing shows a potential issue with the relay. Let's verify your testing. Unplug the ignition relay. Measure the voltage across the battery terminal. (This is battery voltage.) Measure voltage to ground on each W/R wire. You should have battery voltage at each wire. I understand you had the same voltage on each wire as the battery. Put the key in ACC and measure voltage on the L/R wire. You should have battery voltage. I understand you had the same voltage here as the battery. Put the key in ON and measure voltage on the L/R wire and the B/W wire. Both should have battery voltage. I understand you had the same voltage on each wire as the battery. If all those tests pass, turn the key to OFF and plug in the relay. Put the key in ON and measure voltage at the RADIO fuse and the FUEL GAUGE fuse. Both should have battery voltage. I understand that you had voltage at the RADIO fuse but not the FUEL GAUGE fuse. Furthermore, the turn signals did not work. The fuel gauge and turn signals are powered by the same side of the relay. If you don't have voltage for the gauges at the fuse box (with a good fuse), I would expect the turn signals to be non-functional, too. I'm also betting that your reverse lights aren't coming on, either. Let's look at what all powered by the W/B wire. W/B Wire Floor Sensor Cal only Fuel Pump Not during cranking Inhibitor Sw AT only Fuse Box (IGN) G Turn Signal Brake Warn Lamp Turn Signal Power Seat Belt Warn Tmr Fuel Lvl Warn Lamp Reverse Lights L Gauges Cooling Fan Relay Fuel Gauge Water Temp Gauge Oil Temp Gauge Tachometer Speedometer Unk Func Kickdown Sw AT only Among other things if that relay is faulty, you could lose power to your fuel pump when the key is in ON. If the coil or contacts are breaking down, it would not surprise me if it was worse when the car is hot. Your engine could fire with the key in start and die shortly after when the key goes to ON due to the pump losing power. As far as connecting the relay in the wrong direction, yes it's possible but difficult. That edge should hit the piece of phenolic that is near the one row of pins on the relay. Also if the relay is attached to the relay panel, I would expect that you would have to twist the connector significantly to get it to be in the wrong orientation.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

If the turn signal (flasher) fuse has voltage but the fuel gauge does not, the first question is "Did you check on both sides of the fuse?" If it has voltage on one side but not the other, I'm thinking it's a bad fuse. Otherwise, I would have to wonder if the fuse box is damaged. Here's the back side of the fuse box. The inner columns are the supply. The outer columns are the wires that go out to the loads.

-

Changing an Amp gauge for a Volt gauge

If you're looking for a switched source that isn't going through a relay, that would be the B/W (On and Start) or L/R (Acc and On). Neither has terminations near the center console. You could get a set of male and female 6 pin 6.3 mm connectors from Vintage Connections and get the power from the back of the switch. I would advise fusing it as close to that connector as possible.

-

Changing an Amp gauge for a Volt gauge

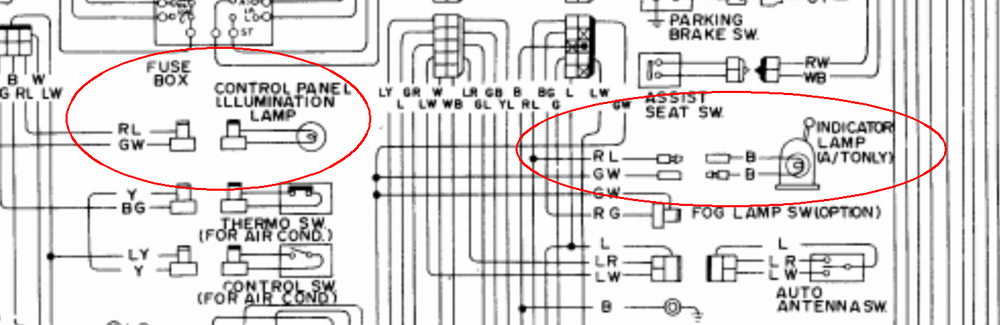

Clock power (as I mentioned in my first response) and cigarette lighter power. R/L & G/W - lighting (gauge lights, etc.) The T connector is probably for the HVAC panel. The bullets correspond to the indicator lamp for AT models

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Also, have you taken the time to download the 78 factory service manual? It's a free download on this site. There is a link in my signature.

-

Changing an Amp gauge for a Volt gauge

Test port for the BCDD. Look on page EC-6 of the 76 FSM

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

I would say those links are good. Did you ever do the tests I suggested earlier? They could go a long way toward figuring out your problems.

-

Designing A/C System Using Other Cars Parts?

I saw that on the AC controls that I have sitting around.

-

1973 240z Custom Wiring From Scratch

Looks good.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

The green fusible links are green fusible links. https://zcardepot.com/collections/electrical/products/fusible-link-wire-green-280z-1974-78?_pos=9&_sid=4a0072d4b&_ss=r Now you might need different terminals, but those are available through a myriad of sources, including Vintage Connections. That reminds me. I need to generate more content for YouTube. Wire crimping would be a good topic.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

And to add on to @Yarb's post, fusible links are designed to burn up internally and leave the insulation intact. Touch the leads together on your meter. The reading may not be quite zero, and that's the reading you should get when you measure across the links.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Keep in mind that the tests I listed in my long post will work with the car not running. Do those first. Also, post pictures of your fusible links, including clear photos of the bases that hold the links.

-

Changing an Amp gauge for a Volt gauge

I actually keep one of those handy for when I go over to help someone with his car.

-

LED Headlight conversions - My Recent take

I like Auxito LEDs from Amazon. Those are polarity independent. I have never had a problem with them, and neither has anyone else I have recommended them to. https://www.amazon.com/gp/product/B07TQLK6SH

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

First let's go over the ignition relay and what it does. That way we can trace down the problems. Note: The copy of the 78 diagram I have still shows the relay drawn incorrectly. I think I made the proper adjustments. Color Code L - Blue B - Black W - White Y - Yellow R - Red G - Green When there are two letters, the first is the main wire color, and the second is the stripe. B/W is black with white stripe. So there are two coils in the ignition relay. One coil is energized by the key in ACC or ON. That comes in on the L/R wire. The set of contacts is connected to a W/R wire that traces back to the black fusible link. It goes out as the L/R wire The other coil is energized by the key in ON, and that comes in on the B/W wire. The set of contacts associated with that coil is connected to a W/R wire from a different fusible link. It goes out as the W/B wire. I traced out those wires coming off the relay. L/W Wire Fuse Box (ACC) L/Y Air Con Blower Motor AC Relay Mag Valve Vac L/R Wiper Wiper Power Washer Pump L Radio Radio Power Antenna Sw Rear Defogger W/B Wire Floor Sensor Cal only Fuel Pump Not during cranking Inhibitor Sw AT only Fuse Box (IGN) G Turn Signal Brake Warn Lamp Turn Signal Power Seat Belt Warn Tmr Fuel Lvl Warn Lamp Reverse Lights L Gauges Cooling Fan Relay Fuel Gauge Water Temp Gauge Oil Temp Gauge Tachometer Speedometer Unk Func Kickdown Sw AT only So many of your issues revolve around the ignition relay. Is it bad? Test with a voltmeter. Note: All of these measurements will require the black probe of the meter on a good ground. Unplug the ignition relay. Measure the voltage across the battery terminal. (This is battery voltage.) Measure voltage to ground on each W/R wire. You should have battery voltage at each wire. Put the key in ACC and measure voltage on the L/R wire. You should have battery voltage. Put the key in ON and measure voltage on the L/R wire and the B/W wire. Both should have battery voltage. If all those tests pass, turn the key to OFF and plug in the relay. Put the key in ON and measure voltage at the RADIO fuse and the FUEL GAUGE fuse. Both should have battery voltage. Let us know the results. Considering you said the wipers work, the ignition relay may not be the issue. The dash lights are another issue. The red wire is for the headlights. The G/W and G/L wires are for the dash lights (and running lights including tail lights). Describe the non-start when warm in more detail. Does the car crank? It might be a vapor lock issue. Do you have an AC car? Have you checked the blower resistor? Is the turn signal flasher plugged in? It should be hiding under the dash on the driver's side. The hazard flasher is there, too. The turn signal flasher should have G/Y and W wires going to the connector.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Actually, there wasn't a wire added to the 78. The ignition relays are the same.

-

Fuel rail upgrade?

RHD Japan has it. https://www.rhdjapan.com/search/category/fuel-system_fuel-pressure-regulators/brands/sard/