Everything posted by SteveJ

-

Amp meter pegs all the way right

I talked to Guy. The alternator in question was rebuilt. He swapped in another alternator, and it worked fine. I guess that someone did a less-than-stellar job of rebuilding the alternator, probably not getting the field wire hooked up right.

-

Amp meter pegs all the way right

I responded to your PM, but just to share with everybody else... My first thought would be that the battery is undercharged. Think of an ammeter as a flow gauge. Not only is it telling you the volume of electrons flowing, it's telling you the direction of flow. Positive is toward the battery, and negative is away from the battery. I looked through the diagnostics in the EE section of the 72 FSM. It confirms this as one possibility. I kept looking through the FSM and noticed something on the VR diagnostics, too, on EE-26. Excessive output could be from 1. A broken neutral (white) wire. 2. A bad VR 3. Poor grounding of the alternator. 4. A broken ground wire. If you have a multimeter, you can check continuity of the wires and grounds (1, 3, & 4).

-

6-Prong, Male End - Anyone have a spare?

I have that type of connector, but I won't have time to get to the post office to send it to you until after the national convention. That said, if no one else comes through, you could try Vintage Connections. Go to the price list and order a HP6N Non-Latching Set. You may want to order extra terminals as well. I have done business several times with Del. He is a stand-up guy.

-

Leak at the fuel sending unit

I also found this link about petroleum jelly and nitrile (See post #7): http://www.candlepowerforums.com/vb/showthread.php?113228-Nitrile-Buna-N(O-Rings)-vs-Petroleum-Jelly(Vaseline)

-

Leak at the fuel sending unit

Vaseline is not compatible with latex rubber. The O-rings are another form of rubber. Latex wouldn't stand up to gasoline, either. If a product holds up against gasoline, I would guess it would hold up to vaseline. Gasoline is an excellent solvent, after all.

-

Leak at the fuel sending unit

Thanks for all of the advice. I received a new O-ring yesterday, and I took much greater care in the re-installation. I cleaned the sealing surface of the tank with a soft toothbrush and carb cleaner. I then applied vaseline to the sealing surface of the sending unit to hold the O-ring in place and lubricate the O-ring. I spread a thin coat of vaseline on the O-ring, too. I eased the sending unit back into the tank and made sure the notch on the sender fit right around the key on the tank. I put the retaining ring on and rotated it with two pairs of pliers to ensure that the ring rotated around it's center. (I had used a screwdriver to push it before.) With my wife watching the tank, I added plenty of gas. There were no leaks. Unfortunately I was able to confirm that my gas gauge has given up the ghost. If anybody has a spare one that he/she can part with, send me a PM. I'd love to get my hands on one quickly.

-

ground wire

Sam, I see three loose wires in the picture you posted. Two are black with ring lugs attached and the other is a light color with a bullet connector. Which wire are you concerned about?

-

Another bumper question

Stock bumpers had a rubber strip toward the end of the bumpers, but they weren't end pieces. There is no filler. As for reference pictures, try CarDomain.com.

-

low oil psi

Are you getting your oil pressure off of the dash gauge or with a mechanical meter at the engine? If you're not using a mechanical gauge at the engine, you might want to try that before spending the money & sweat to make changes.

-

Barn find on ebay

It looks like the Sun-Moon-Star model was used as a starting point. I have one on my desk at work and one in my home office. Of course, whoever created that missed the biggest feature of a distressed Z. The dash isn't cracked at all.

-

240z front on a 280z

The bodies are completely different, and I think that includes the major dimensions. You can't just swap parts over. There will be a lot of fabrication and fiberglass/bondo. If any of your mates has a 240Z, take some measurements. Unless you're really good with body work or have access to someone who is, you'll also run into issues when the lines change between the front guards and the door as well as at the bonnet and the base of the windshield. In my 18 years of being around Z cars, I can't recall ever seeing such a swap. By the way, while you may like the look of the 240Z better, you do have better aerodynamics with the 280ZX.

-

naps for a 280z

At Zcar.com, the topic comes up from time to time... http://www.zcar.com/car_talk_forum/what_is_this_manifold-naps_831617.0.html http://www.zcar.com/70-83_tech_discussion_forum/l28_naps_896835.0.html Search over there for more info.

-

1978 280z w/no headlight power. HELP.

Search through the electrical section. I know that I've described the headlight circuit in great detail.

-

Leak at the fuel sending unit

Thanks, Jim. The old ring was a little corroded, but not too bad. Fortunately, I found a new retaining ring in my parts stash a few minutes ago. If I was organized, I might actually catalog all of the stuff I've been accumulating. I did not look at the sealing surface at the tank, though I imagine it's pretty nasty. I cleaned the gunk off of the O-ring with carb cleaner, and it passed my cursory inspection. That doesn't mean it was still up to snuff. Thanks for the info.

-

Leak at the fuel sending unit

I replaced the fuel sending unit on my 74 today. I thought I had a new O-ring, but I couldn't find it. When I removed the old sending unit, the O-ring appeared fine, so I decided to re-use it. I tweaked on the retaining ring a little because I wasn't smart enough to leave well enough alone. It puts plenty of pressure against the fuel sending unit and O-ring. However, when I tried to put in some gas, it leaked at the sending unit. I got the gas level below the sending unit and worked on it some more. I think the first time I put the ring back on it may have slid over to the side some and not remained centered in the opening. I put the ring back in place again, carefully ensuring the ring was centered properly. A friend slowly added gas, but the leak remained. I went ahead and ordered a new O-ring and retaining ring from MSA. I hope to have it around Thursday or so. I'd like to hedge my bets, though, and ask for input on any other reason for the tank to leak at the sending unit besides not centering the retaining ring or replacing the O-ring. Thank you in advance for any suggestions.

-

interior screws?

You're welcome, Sarah. Sometimes it's not so bad to pay extra for the correct screw. My two cars have suffered from benign and not-so-benign neglect over the years, so if I can replace someone's kludged it-works-for-the-most-part fix with a proper fastener, it's worth it to me. The link really pays off for finding parts commonalities.

-

interior screws?

Look at the parts manual link in my signature. Find all of the part numbers. Go to Nissanparts.cc or Courtesy Nissan Parts, and put in all of the part numbers. They will let you buy anything that is still in the system and let you know what is NLA.

- clutch on a 260z

-

clutch on a 260z

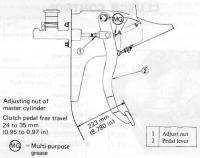

Step 1 - Chill cold beverage of preference. Step 2 - After Step 1 is complete (beverages must be cold), park the Z so that you can open the driver side door as much as possible. Step 3 - Contort yourself as much as possible to get your head and shoulders close to the clutch pedal. Step 4 - (I prefer using a pick with a hook end for this.) Remove the cotter key from the clevis pin that holds the clutch pedal to the push rod head on the clutch MC. Step 5 - Remove the clevis pin. (Note: Make sure you leave these parts some place where you can find them later.) Step 6 - Loosen or remove (I can't remember if you can get away with just loosening the bolts.) the bolts that hold the clutch MC to the firewall. Step 7 - Move the lock nut on the clutch MC push rod toward the reservoir. You shouldn't have to move it too far. Step 8 - Move the push rod head to butt up against the lock nut. Step 9 - Align the push rod head and the clutch pedal so you can put in the clevis pin. Step 10 - Get some of that cold beverage because you've probably worked up a sweat. Step 11 - Tighten the clutch MC to the firewall. Step 12 - Test travel of clutch pedal. DO NOT TAKE THE CAR FOR A DRIVE, YET. Step 13 - Readjust the pedal if necessary. Step 14 - After getting pedal to your liking, put the cotter key back in the clevis pin. Step 15 - Finish consuming cold beverages.

-

260z duel flat top carbs.

While gasket kits are available, I have heard needles for the L26 flattops are NLA. A user over at Zcar.com asked me to measure the needles in my spare set of carbs for purposes of fabricating some, but I don't have time for a while to tear my spares apart. Oops, I didn't notice you weren't in America. Hmm, maybe the Aussies or Kiwis could provide you a source for the needles, or did you get your hands on an American 260Z?

-

it runs! Bad!

Be sure to use some dielectric grease in there to reduce corrosion.

-

[2011] What did you do to/with your S30 today?

Well, some of this wasn't today... I had replaced the plugs and tweaked the carbs. I had also replaced the speedometer cable and door seals (with the Kia Sportage seals). My wonderful wife helped me bleed the clutch today. (Apparently when a friend was helping me replace the clutch master, he didn't get the line quite tight enough. Oh well, the paint was bad already, and at least he didn't overtorque or round off anything.) I took it for a shakedown run in anticipation for the convention. It ran like a scalded dog. Monday, I am going to replace the sender for the fuel tank since it reads only when it wants to.

-

Compliment of the day "That's SICK dude"

-

HELP - Late 73 wiring issues

Is there any chance that there is an internally regulated alternator in the car? If you don't have a diode in the circuit with an internally regulated alternator, you can get feedback through the ignition circuit that will keep the car running. Also, it could be to your benefit to post pictures of what you have so we can see what it stock and what is not. Finally, have you looked at the FSM in the BE section to try to match up connectors?

-

Help! Car ran out of gas and won't start.

If you have access to compressed air, blow air through the line from the engine bay back to the fuel tank. Be sure to have the gas cap open when you do it. There is always the chance that there was something in the tank to get sucked in if you were running out. The only other thing I can think of (This is just a SWAG since I've never messed with this.) is that could the pickup have fallen off so that it is not able to pick up gas?