Everything posted by Seppi72

-

Frame Rail dismemberment 73 240z

I agree with heyitsrama, spot weld cutter(s) and a spot weld chisel or panel knife. I had to remove the entire radiator core support from my '72 when I crashed it back in 2010. Took a while and a lot of swearing, but it came out. I also had to remove the right front frame rail as that was bent too.

-

Question on early S30 brake pressure warning device

In looking at the FSM drawing I posted back when I created this topic, it appears that your piston only moves a few millimeters in response to a pressure differential that will overcome the opposing spring force. The "full diameter" part of the piston then makes electrical contact with the sensor and the warning light goes off on the speedometer. Once you release the brake pedal, the spring forces "should" return the piston to its central position, breaking the contact and the light will go off. Without the sensor, it does not look to me as though the piston can move so far as to shut off either brake circuit. So, I agree with EuroDat and would look for something else that is clogging the system, most likely on the inlet flare fitting of the front brake circuit or in the line coming from the MC..

-

DIY FOAM Build

I'm sure this is exactly how Nissan did its development work back in the late 60's, the history books be damned.

-

Countersinking Weber DCOE throttle shafts

If I were still working the 9-5 job, I'd model this on some fluid dynamics software and see what happens.

-

Countersinking Weber DCOE throttle shafts

Thanks. Frankly, that's the answer I was hoping someone with more experience would provide. None of us need more work to do.

-

Countersinking Weber DCOE throttle shafts

My 40 DCOE carbs do not have countersinking on the throttle shafts. Consequently. the tops of throttle plate holding screws stick out into the air flow, like little pill tablets. And, while I can readily get replacement screws, I'm wondering if changing to countersunk screws might be a good idea now that I have the carbs all disassembled. So, some questions: 1. Seeing as how I shall very rarely have the car at WOT and using a 6000 rpm limit, how much difference will my "tablet" screw tops make in the airflow compared to countersunk screws? 2. How hard is it to turn my current throttle shaft into one that would accept countersunk screws? Frankly, if I go this route I'll probably have a machinist do this. 3. What size countersink is necessary?

-

New Member,New to Z's

Welcome to the fold, SJZ. I'm an original owner on one of my cars. You've got a nice car on which to start a project. There are a lot of us "midwestern" S30 owners who will be happy to assist you with experiences and advice and then hope to see you in our areas once she's drivable.

-

Fiberglass glove box

Has anyone ever seen someone make a new glove box insert out of fiberglass? The OEM unit is simply "cardboard" that is stapled and glued together with a lot of right angles and "sharp" corners. I figure that if I make a plug of the inside of the box using expanding polyurethane foam in a polyethylene film bag I could then fabricate a decent and more robust box from that. In fact, if I wished to, I could then continue to shape the plug so I could make modifications that would allow for an even deeper and perhaps compartmentalized box that would still accommodate my Vintage Air A/C lines.

-

Brake Booster/Master Issue?

I just bought a new Beck Arnley 072-2694 Brake Master Cylinder on Amazon for $77 and free shipping.

-

Brake Booster/Master Issue?

Power Brake Exchange lists two different prices for '70-'74 Z cars along with two different core charges. I called and the more expensive one ($194) included the master cylinder. But the fellow in San Jose told me they don't do MCs anymore so that leaves just the rebuilding your booster for $109 plus a $50 core charge. There is nothing in inventory so you need to send in yours - I would assume the core charge is then waived - and wait for them to get the work done.

-

Parts Wanted: Dashboard finisher panel (damaged)

View Advert Dashboard finisher panel (damaged) Looking for a dashboard finisher panel that has irredeemable damage to the heater control area. I'm installing a Vintage Air Gen II StreamLine control panel in my '72 and will be cutting that section out to do the mounting. My panel (see pix) is in very good condition and I really don't want to hack up such a nice part as many folks are or will be doing restorations and will likely need such parts in the future. So, I'd rather use one that is beyond repair - at least in that area. Advertiser Seppi72 Date 10/02/2021 Price Category Parts Wanted Year 1972 Model S30

-

Brake Booster

There is a method for checking the function of your brake booster while on the car. Do a search in this forum and scout out videos. My situation is the my boosters are not now on a car so I have to try a different process. It's likely that your booster diaphragm failed and you are hearing the hiss because it's coming into the cabin along the shaft that's attached to your brake pedal. I don't quite understand why the engine would race, however. I assume you have SU carbs and are taking vacuum off that manifold.

-

Brake Booster

Hissing sounds like a vacuum leak somewhere. Surprized you can hear it in the cabin. Does it feel like you get any assist on the braking?

-

Time to Speculate : Coil Spring Breakage

I'm inclined to agree with Jeff G 78. If the mud packed at the bottom of the spring, then the free portion would be carrying the entire load at that corner and it would eventually cause flex fatigue. I'll bet the second break came soon after the first one. Poor little spring.

-

Zedyone back on the boards

Yeah, but the beach scene in Boise is indescribable.

-

Zedyone back on the boards

Glad to have you back, buddy.

-

testing brake power booster off the car

I know how to check for a weak power booster that's on a working car and there are many videos on how to do that. I have several boosters from various cars that I've amassed and want to know how many, if any of them are still functional before I go to the trouble of refreshing one or more of them for my restomod. What I'd like to know is if there's a way to determine the "goodness" of a power booster that is off the car. I have a vacuum pump, tubing and gauges and figure that I could draw an 18" (or so) vacuum, shut the pump off and then watch the vacuum drop over time. I could do the same with the installed and working booster on my other S30 to establish a baseline. Does this make sense to those of you who might be familiar with this? Or, is there another way to make such a determination?

-

Car crash, car show, Bozosudoku video thread - find the old Datsuns

Thank goodness none of us were doing dumb things like this when we were younger !!

-

Question on early S30 brake pressure warning device

After sitting in Kroil for the better part of four days, EuroDat's "heat it and beat it" method worked to dislodge the piston in my switch. About 40-60 seconds of heating with a propane torch along both sides of the main chamber axis and then tapping it hard on the flat of my bench vise did the trick. Thanks, buddy.

-

Triple carbs for stroker motor

I certainly did not know that. Are there any equations for making a determination of the effect? Or, do you just have to put different configurations on a dyno?

-

Triple carbs for stroker motor

I've looked at a Pierce manifold and it's about the same size as a Cannon.

-

Triple carbs for stroker motor

In reality, I'm thinking of mounting Weber 40 DCOE carbs on a Mikuni 44 manifold. I put a carb and spacer on the near end of each one to illustrate differences. I roughly measure the distance from the tabletop to the highest point of an air horn as 295 mm for the Cannon and 240 mm for the Mikuni. That gives me almost 2 inches to play with for installing an air box. However, it also brings the carbs that much closer to the headers. But, putting in a heat shield is not an issue for me.

-

Triple carbs for stroker motor

Thanks for the replies, folks. Here's another related question for you then: I know it's very important to "port match" the intake manifold to the head as one would obviously want an unrestricted, predominantly laminar flow of mixture going into the head. However, what about the other end of the manifold? What I mean is, for instance, suppose one has 40 mm carbs and puts them on a 44 mm intake manifold? Clearly, there will be no flow restrictions but there might be eddy currents or turbulence generated by the instantaneous change in diameter. Might there actually be an opportunity for the fuel to condense somewhat in the manifold if there is, in fact, a pressure drop from such a mis-match? Similar to the contrails seen off the rear wings of F1 cars in humid conditions?

-

Prothane or Hyperflex

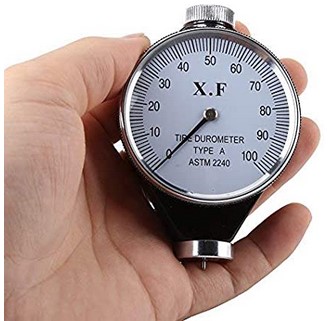

Does anyone out there have a new set of rubber bushings that are off the car or easily accessible? If so, I'd like to loan you my durometer so you can determine those initial values. It's simple to use. Just press against an included reference material (or two) and then press against a flat or reasonably flat surface of the part and see what the number is. Readings will likely be in the 70-90 range at "room" temperature.

-

Prothane or Hyperflex

Now that it's back to the workweek grind, I've asked both manufacturers the same questions. We'll see what the answers are.

Subscriber

Subscriber