Everything posted by montoya_fan01

-

Front Pulley removal

I'm wondering if your car had A/C installed at one time. The 240z's that I've owned have had a "two groove" pulley that was manufactured of an inner and outer piece bonded together, but which could not be separated without destroying the part. The spare L24 I picked up had this same pulley, with the addition of a "3rd groove" like you describe bolted onto the front to drive the dealer installed A/C system. After removing the additional "3rd groove", I couldn't get the original pulley off the crankshaft snout by hand, so I used a pulley-puller to avoid possible damage to the pulley itself, or the woodruff keys.

-

What do Original 240Z Wheels Look Like?

"Fun In My Z" posted a link to a picture of a car with the black steel wheels which are hidden behind the Hubcaps that you see in that picture. FWIW, the mags (actually aluminum wheels) on the car in the other picture "Fun in my Z" linked to are in fact on "26th Z"'s car. I don't see that "26th Z" posted any pics of mags.

-

E88 not the best head?

Neither side of things should exclude the other IMO. Driving Schools (the good ones) aren't cheap either, and it is easier to learn to drive faster in a car that performs consistantly well than in one that consistantly doesn't. One thing that none of us has mentioned is that some people just love to work on their cars and regardless of any possible performance advantages, they just "want" to tinker and make their car better in their own eyes. "Different stokes for different folks." "Somebody has to win, and somebody else has to lose." "Focker OUT!"

-

Is this a Centerforce I or II? Does it matter?

Walter: The P/P in your pic looks exactly (including the color) of the Dual- Friction Centerforce II shown in the current MSA Catalog (Page 93). When I bought my Centerforce I, it was not orange, but did have the ring of counter-weights. You didn't post a clear pic of the disc that you have which should show obvious signs of two different friction materials used in it's construction. See MSA Online Catalog Page Yes, dowel pins are important in my opinion, and should be easy to acquire. As for the collar, I've always heard that you had to use compatible fork and t/o collar, but that is with OEM clutch parts. Is the height of the CII pressure plate different than a stock 280Z unit? I think I'd try to contact Centerforce to inquire further. Might be that they could advise,

-

E88 not the best head?

but if your competition has been to all of the schools and you have also, AND he's still a better (naturally gifted) driver than you, can you afford to ignore more power? I don't think so, not if you're competing to win. If the competition doesn't take advantage of everything available to help him win, then perhaps you can afford to do the same, but I say WHY would you want to? Certainly 10HP isn't going to replace driver skill, but if your competitor has BOTH, you had better have them both as well otherwise you're wasting your time competing.

-

E88 not the best head?

I won't flame you but I submit that even at the lowest level of grassroots competition (street racing for bragging rights, or autocross for example), any potential advantage is worth exploring. A competitor will use all the power (and driver skill) at his command to beat his opponent. If someone is serious about winnig he cannot afford to ignore any potential advantage. It's true that there is no substitute for driver skill, but an additional 10HP is nothing to sneeze at either.

-

Strut... bushing thingy?

What is wrong with the bearings? Do you see or feel something wrong with them? It's not like the rotate millions of times like wheel bearings, so they are a very low wear item and almost always can simply be washed in solvent and regreased. As for the spacers in the rear, they seldom need replacement either as they are pretty well protected from weather, but on the other hand they don't cost much.

-

Clean 240z w/ 27k Miles in Ft Lauderdale

The "wrong green" Z also has (shudder) Mud Flaps installed front and rear. :sick:

-

Strut... bushing thingy?

damn, I'm a step behind you guys this morning.

-

Strut... bushing thingy?

Dave: Which catalog are you looking at? I have the current (I think) MSA catalog and I can't find the part # you mentioned. (cover is gray and has purple 240Z and 350Z on it. It's only a year or 2 old) I did find PN # 23-4196 on Page 97 which is for a pair of Urethane Bump Stops @ $15.95 EDIT: On Pg 118 I find the part number you mentioned, but it is for the actual roller bearing that allows the strut assembly to rotate to make right and left turns

-

Strut... bushing thingy?

:stupid: Guess I took too long to compose my reply.

-

Strut... bushing thingy?

Nate: What you have discovered it that the "bump stop" that is integral to the upper spring seat has dried out and turned to dust over the years. It is meant to keep your strut inserts (cartridges) from bottoming out and being destroyed. It's a common thing to find this 35 year old part to be gone. It is not available separately as an OEM part, you'd have to replace the entire upper spring seat to get it back to OEM. However, it IS available in Polyeurothane from MSA and other places like Black Dragon (VB), etc.

-

Compression Check and Valve Adjustment

With compression number like you are posting, I'm guessing that you don't have a L24 equipped 240Z. Why did you pull the hood? Never heard of that being necessary to do a compression test and valve adjust.

-

E88 not the best head?

Absolutely ! !

-

Save S30-0002

I hope you are right, but that car sure looks rough.

-

E88 not the best head?

FWIW, I don't think this info was posted on CZCC by Paul Ruschman, I think the poster was referencing info that he found on HybridZ.

-

Save S30-0002

its probably beer cans by now.

-

Where can I find a tach

before you start buying a replacement tach make sure you are buying the correct one for your car. There are 2 tachs in 240Zs. 3 wire, and 4 wire. Which is yours?

-

Heat/Mustang race

First, you need to find out if it IS or ISN'T overheating. Buy a Candy Thermometer (Kitchen section of Megalo-Mart or ? ? ? . Then you can actually see what the real water temp is when your water temp gauge is reading at various points. That will help you to know when or if a problem exists. Right now you are just throwing parts at it, so you need a plan to track this down logically or you may end up replacing everything when it's possible/probable that only one part is at fault. Do you have a FSM? or Haynes? Often you will find a Troubleshooting page at the back of each section that might help you in this regard. FWIW, home flushing of a radiator (if that is what you did) is not a substitute for having it professionally cleaned ( it's called "rodding out") when the radiator is boiled, pressure back flushed, opened up, and then rods are run through the cooling tubes to clear them of packed crud & gunk that can plug the tubes. I wish you luck, keep us informed of your progress.

- only 1 set of 240Z LED Tail lights for sale!!

-

Any Takers?

Yes, sadly there must be. :nervous:

-

What years came with the speedo that starts at 10MPH?

i don't think bill was flamin you or the car, just pointing out that with all the repair it needs, that you've got quite a lot of work ahead of you before worrying about the speedo becomes "the next step" in resurrecting this car. I ain't flamin you or the car either.

-

Any Takers?

at least he did it to a ZX and not a real........................

-

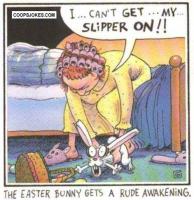

Easter

should be a slow day for you. who wants fried chicken and que papas on Easter? or do you guys sell fried rabbit also?

-

Thinking of installing an 81-83 5 speed

The adjustment at the slave sets the amount of gap between the p/p-disc and the flywheel when the clutch is disengaged. That is one place to adjust point of engagement, but IMO it's not the right place to do it. (you of course are welcome to do it in whatever manner floats your boat) The only other place to make an adjustment IS at the master cylinder/pedal interface. I always set the slave adjustment (my early 72) per factory spec. so that there is positive disengagement but not an excessive gap, and then adjust the pedal height so that the clutch engages when the pedal is about 1" above the floor which is where I like it to be. This method works equally well for a 73 with the "self-adjusting" slave/fork. (I've owned one and used this method)