Everything posted by RIP260Z

-

the journey of my fairlady.....

Very good rahail. Keep up the good work, nice to see what you are doing, as it was not clear on zclub. I do love the Magalloy wheels, and good to see someone else in the UK having them. I managed to pick up a pair, new still in their boxes... will hopefully go in the CSP when it is ready. Cheers Ian

-

Spent the day with a flat top expert and learned a lot.

Hi Blue, Thanks for the complement on my RS30. I have one pic in my garage below my avatar. I like the tool and the way of removing stuck needles, will bear that in mind. It is worth looking at/considering, the spindle the butterfly joins, it is like the SU carbs, they don't have a bearing and seal in from new, and the aluminium body and brass spindle gradually wear, leaving an area for air to be sucked in. So, it does not matter how good the carb is refurbished, if this is not done air is being drawn in that you can't control...you probably know this, but someone may not. I like the idle circuit/idle mixture diagram, but for me (I have yet to try) is have it so each carb is individually adjustable. Especially if one carb is a little bit worn compared to its partner, each carb would require a different setting, and adjusting the one idle mixture screw is always going to be a compromise. Keep up the good flat top work. Cheers Ian

-

Spent the day with a flat top expert and learned a lot.

Blue, I see the score marks on the "nut part" of the jet holder...I had that too. They seem to be "glued" in and have to be forced out. The jet either gets clogged up with carbon (soak in Brasso does the trick), or the needle wears a slot in the jet holder. Did your new Z friend have any tips for removing the needle from the bottom of the piston? Some I have come across have been soo difficult to remove without bending the needle (as new needles are NLA as far as I am aware). Good to see some in depth on the "boat anchor" flat tops

-

24th October 1969 - The S30-series Z public debut.

Hi Carl, Yes please:)

-

24th October 1969 - The S30-series Z public debut.

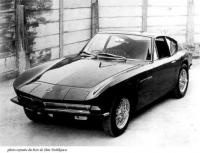

Carl, I am a little bit confused.... The first statement (taken from "who designed the S30" thread-post 61) of yours corresponds to the first photo, the second statement and photo from a few posts above on this post. I think it is now quite clear that Mr. Goertz had nothing what so ever to do with the A550-X - and that the metal prototype {pictured below} represents the Nissan 2000GT - built by Yamaha for Nissan, and which was delivered to Nissan - does in fact represent the extent of Mr. Goertz involvement. [the first photo] FWIW, Carl B. hasten to add for everyone - the final Goertz/Yamaha Prototype stayed at Yamaha, as Nissan had only contracted for Yamaha to build one working prototype - which was delivered to Nissan after the Joint Project was cancelled. That first iteration of the Nissan 2000GT, looked quite different. FWIW, Carl B. You can't give Goertz credit for helping on only one car (and only assisting) for then to say the second ("later/final") car is a joint Geortz/Yamaha collaboration. The whole project was a joint Nissan/Yamaha collaboration, with Japanese employee's of both companies first and foremost, with Goertz a minor player (given his limited time under a Nissan contract as a advisor). And on your Zhome page, you show the second car saying that it is a Yamaha A550X (using Shin Yoshikawa's book as the source).

-

Datsun Roadster Braided radiator hose will lauch soon!

Nice to know, as I was looking at a period shots of CSP311 engine bay a couple of days ago and wondering, braided hoses would be nice for my CSP311 (when I get to restoring it)

-

flattop carbs rebuilt or new dgv's

Yoshi, The flat top carbs are difficult to rebuild and set-up, especially for a novice. And from what I have seen, the re-build kits basically supply gaskets. Setting these up is crucial, and with worn components, not easy. One of the main things that need done is the throttle spindle becomes worn, and this needs addressed...not just a case of throwing on some new gaskets.... spares are NLA as well.

-

Triple Mikuni Fuel Line Set-up

Mitchell, I think I sold Chris the fuel rail... anyway, it is the same as what I have. Mine pictured is an after-market produced one, which I saw sold on Yahoo Japan. I think this is a copy of what was available in the S30 Sports option list, e.g for Mikuni, back in the 1970's. As you see I am running a return line. The return line is smaller than what supplies the carbs. I also put a reducer inside the pipe, the gives something the fuel can pressurize against (rather than running the same dia. fuel pipe) but still let fuel return. I have a small cylinder of brass pushed in, with a 1mm hole drilled through it. I am trying to replicate the system found on the end of the OEM fuel rail. Hope that helps Ian

-

speedometer not working!

I don't know about the LHD, but for my RHD S30, I just remove the tach meter (which is simple to do) and then you can get your hand in to the back of the speedo.

-

Differential breather leak

The top of the vent tube is, but the bottom that sits inside the diff/gearbox, is not. The arrow on the top cover is meant to line up with the "cut away" side that is in the diff/gearbox. If this is put in wrongly, it would not matter how the top was put on. Have you pulled the tube that goes into the diff out? Cheers Ian

-

Who actually did S30's styling? We can make it clear

Hi Kats, I found this website a year or two ago, and had the relevant section professionally translated. All very convincing/interesting, but I still want to find other corroborating evidence from other sources. Seeing what some information on the web says (e.g what Goertz has or has not done on some forums/websites, even in Japan) can be wholly wrong and I don't know the veracity of the author or his source. Currently I can only go with what I find written down, rather than the spoken word from someone in the know. Cheers Ian

-

Stuck differential cover

Mike B, I use the window putty knife method, works well, but does take a bit of effort. I usually find going in from the top of the diff where the diff casing and cover are at different heights, that way you know you are cutting through the gasket. A combination of using the point of the knife and curve blade, keeping the knife vertical and hitting it with a hammer. Just hitting the cover does not work, on all the diff covers I have taken off, they are very well stuck.

-

Who actually did S30's styling? We can make it clear

Hi Alan, Ah, thanks for clarifying, re-reading it from a blank point of view it leads to ambiguity if not pointed out which direction the statement is intended. From what I can gather so far, this is correct, maybe even finishing the first prototype on the day before the Tokyo show.

-

Who actually did S30's styling? We can make it clear

Kats, Sorry seemed to somehow miss your questions a while ago. Without sidelining the S30 thread which this is: Not according to Shin Yoshikawa's Toyota 200GT book, the Datsun 1500 Coupe project (e.g CSP311) stopped the A550x project that had been running for a few months. Why, the CSP311 project wanted to be finished to be shown at the Tokyo Motor Show of that year. And according to Shin, the A550X only started again once the CSP was nearly finished, probably the spring of 1964. (as a side note, just about when Goertz's 1 yr contact was up). Yes, need to hear directly from Kimura or someone close on the project. In Japanese Nostalgic Hero (Vol. 51 Nov.1995), which was written with Kimura's co-operation "rumours have appeared that it was Geortz who designed the Silvia and A550X" If the A550X project start before the Silvia and a few months prior, then at an educated guess, the A550X project started on the very late months of 1962/early months of 1963. This obviously started before Goertz was around, so who was doing the design? Kats, I have only scratched the surface of the Silvia design/development, so much yet to uncover...best leave it there and let the thread title discussion carry on.

-

New guy from Poland

Andrzej, Here in the UK, there are a few rust free LHD US cars S30's here. These are usually converted to RHD as a lot of original UK market 240z's have rotted away, or spent a lot of time with a welder, so you could get one before it has been converted....

-

WHO makes the best header

Bear in mind, that the header should be tailored to a specific engine spec, and as the original poster has a 2.4, (and stock?) a couple suggested could have too large primaries, and could/will loose horsepower. e.g. 1 3/4" far too big.

-

Webers on blow through turbo thoughts

Leaonard, My basic understanding of blow through set ups from a friend who was going down this route, is the carbs need to be "sealed" specially for this. The Mikuni (in the last picture) and the Dellorto 45m carb (on the Lotus Esprit turbo [i think] can stand the pressure as they (like) the Dellorto have an "O" ring on the spindle. I don't think the Webers came in a form like this, unless they have been machined to allow the likes of "O" rings on the spindles. Though stand to be corrected. There is a bit on Hybridz on this.

-

Need - Drip Rail Clips

Andrew, I was me who put the part number and picture up. I think these are now going to very difficult to find, so maybe your best bet (as you are in a dry US state) is visit the junk yards and find the appropiate year car and see if you can get some good second-hand ones. Sorry can't be of more help. Ian

-

Reputable shop to rebuild L-series engine in the Bay Area?

Rebello get my vote, they done my engine. Very helpful, and have a very good reputation.

-

Hello from Sweden!

Saw this advertized here in the UK, seller was after silly money for the 240z and the 260z 2 by 2. Hope you paid very little for it. Good luck

-

Who actually did S30's styling? We can make it clear

Or maybe Kimura "borrowed" the front styling from the CSP311 for the A550-X?

-

Kobe Seiko Rally Wheels on Ebay

I brought a set of 15" of these a couple of months ago, as Alan says, very well made. I just love them. Mine are currently off being painted. Pic. is a trial fit to see if the OEM wheel studs will do (no).

-

Who actually did S30's styling? We can make it clear

Hi Kats, Thank you for the information. All useful, I am trying to write a more correct historical (conception/design/launch) website page for the CSP311. Old Goertz dribble does not help things. Anything else you come across while speaking to anyone connected would be great. Cheers Ian

-

Who actually did S30's styling? We can make it clear

Hi Kats, I did find out Yoshida did the interior of the Silvia. I have found another name linked to the Silvia project, Ogura Hisateru, but I can't find what his role was. Would it be possible to ask Yoshida what role Ogura did (if any)? Or does anybody know? Regards Ian

-

Who actually did S30's styling? We can make it clear

Hi Carl, I was trying to hold back from saying anything, as to take away from an interesting S30 thread.... I would (as you know) take what Goertz says with a bucket load of salt. Translated (professionally) from Japanese Nostalgic Hero magazine (Nov.1995 Vol. 51). "Rumours have appeared that it was Goertz who designed the Silvia, Nissan A550X". The article this is taken from, was written with "special thanks to Kimura Kazuo" as an effort at putting the record straight for the Silvia (CSP311) design. It would appear Kimura had as much, if not more input on this (A550X) project as Goertz, especially when you include looking at his actual time in Japan (Goertz), let alone at say, at Yamaha. If you look at the timeline(s), Goertz contract with Nissan was from May 1963, for one year, thus ending May 1964. The A550X project was started just before the CSP311 project, probably the first few months on 1963, then halted (in May) to concentrate on the CSP311 prototype. The A550X was restarted in the spring of 1964. Either Goertz worked outside his contract until the Nissan/Yamaha partnership ended in September 1964 (unlikely), or gave some input, or just happened to have everything done within limited time visits before the end of his contract (one visit?)? Most likely just some input....?