Everything posted by gnosez

-

Doing laps *incar videos*

Some of that is Wilwood comp pads and the other and primary source is the left LCA (just) touching the rotor under heavy braking. I moved the LCA pivot points to reduce bumpsteer so take a look again and see how little I need to saw the steering wheel back and forth. LCA has had a visit with the grinder (again) but it can't be tested until I get to The Glen next week.

-

Doing laps *incar videos*

SCCA-NER/HRG at Thompson (all comers vintage race). Chasing a very nice 280Z part3thompson.MP4

-

Fibreglass Hood

I have a FG hood from the early 70s that has the same workmanship. I need to go look at more closely after seeing this pictures.

-

Fasteners for L30 intake/exhaust

I agree with the blue (as opposed) to the red lock-tite. Belmetric is my go-to place but then they're located 15 minutes from my house. Great people.

-

Differential fluid

I have used the jack and wrench/vise grip trick a few times but mostly on the fill plug for the tranny. I once had the car start to lift off the jack stands the plug was so tight. Heat was the solution.

-

Differential fluid

A 1 inch piece of flat stock about 10 inches long with a 1/2 inch bar stock piece welded to the end. The I/2 piece was measured to allow it to just fit between the mustache bar and the diff for a normal cover. You can also just weld the short piece of 1/2 bar stock to 10 inches of 1/2 stock. The extra capacity cover has a side filler and is somewhat easier to get at with a 1/2 inch extension.

-

Crankcase breather?

I'm not a fan of sending dirty air from the engine back into the engine so consider a knockout catch can with a drain valve.

-

Let's show vintage racing pictures. I'll start.

https://www.bing.com/images/search?view=detailV2&ccid=%2fCyyKzce&id=D6DF55F4D0DE0A24FF9C5ADF54D5414B597764CE&thid=OIP._CyyKzcev0tcEueNbDozmQHaE7&mediaurl=http%3a%2f%2fwww.conceptcarz.com%2fimages%2fDatsun%2f70-Datsun-240Z_DV_10-WG_06.jpg&exph=681&expw=1024&q=bob+sharp+racing+images&simid=607987100539618427&ck=B4108861B6E062FA12492BE08D672707&selectedIndex=96&ajaxhist=0 Same car with different flares and wheels?

-

Let's show vintage racing pictures. I'll start.

https://www.billstoler.com/#/gallery/2019-watkins-glen-vrg-event/wg2019-8881-ca247/ This is John Willey's very clean and well prepared 280Z. I ran against him and he is a very good driver.

-

Safety announcement: Check your steering mechanism’s safety, especially if a little sloppy.

Whether it's at the track, prepping for the next race or at the end of the year, there's always at least one nut or bolt that was loose that would have made for a very bad day. The number of wire-tied, double nutted and new nuts and bolts increases every year. Every bolt/nut has a paint mark to verify it was torqued and a similar reference mark to show if it moved. The plug wires are individually zip tied to the distributor cap and the dipstick has a spring to keep it in place. Everyone of these things came loose at one point. Peace of mind.....

-

Strut Tower Brace experience?

I found a better picture. We bolted it in and backed up the metal inside the cowl area. On a separate note, once we added the bracing similar to ones used in the GTU car we had to come up with a way for the wiper arm to work since it's path was blocked by the tube connecting the driver's side strut tower and the upright tube in from of the shifter which ties into the cross=member under the dash. That side is higher to allow clearance for the carbs. We cut the lower wiper arm and fabbed an upside down "U" which was bolted in. It's hard to get a good picture but i think you're get the idea.

-

Strut Tower Brace experience?

Here's the one we have used for several years on the race car. This winter we expanded our bracing but will include the tower-to-tower piece.

-

280ZX Frame Rails - Any Volunteers?

Just click on my name and it should take you to me. There's a private message button. Either day is fine.

-

280ZX Frame Rails - Any Volunteers?

PM me for my phone number

-

78 280Z rear strut removal

Sometimes you can remove the strut from the shock (as opposed to the other way around) using a hat or large washer, a 2x4, 2 clamps and a hammer.

-

Rear Spindle Pin

I'd like to mention that in addition to the race car not having a wedge bolt neither does my street car which has had the Arizona Z Car RCAs installed since 2006 which has not been wire tied or pinned. Freedom of movement is key in suspension parts. Remove the lock pin and rotate the strut and RCA. Put in the pin back in and try again. But hey, if you feel more safe with it there fine.

-

Rear Spindle Pin

There is no reason to put the locking pin back in. In fact a threaded rod works just fine instead of a spindle pin. I have the T3 RC arms in my race car which has over 180 track days. The threaded rod that came with the RCA is still working fine and I see no reason that a similar rod couldn't be used in a set of stock arms.

-

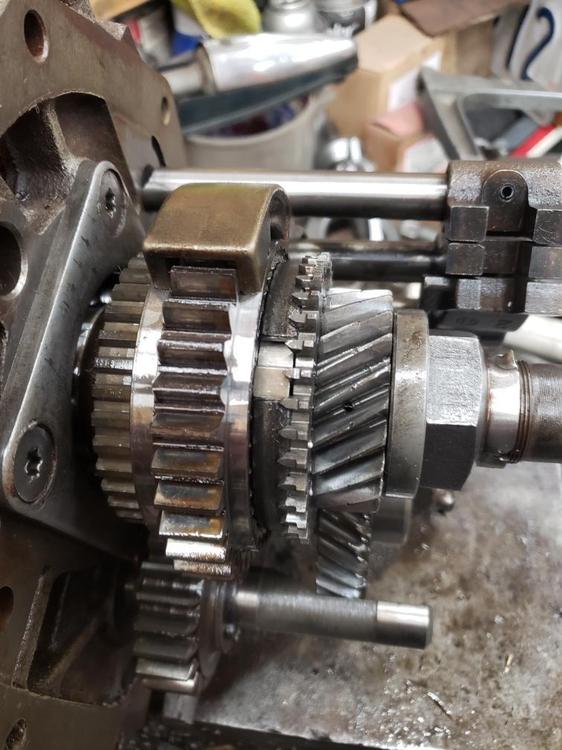

280Z early 5-spd 1st gear

But why is it there?

-

280Z early 5-spd 1st gear

I have never opened a truck 4 or 5 spd. This one has a different fork, gear and has a spring to push the syncro into place.

-

280Z early 5-spd 1st gear

-

Rear Valence/bumper fit

The indent also adds strength to the piece.

-

MSD ign box

Thanks. I was hoping it was an analog box and I could trade you for a new digital one I have.

-

MSD ign box

Is it an analog or digital MSD box (6AL)?

-

Parts for Sale: Hitachi KM-1520ZC AM/FM Radio

I have one but need to verify if it is in working condition....

-

"New" Bad Dog Parts

Bad Dog Parts has been working on several new parts and before they are offered for sale, we need your help getting the fitment dialed in. For these parts we would ship a prototype to a willing Z owner who would trial fit it on their Z and report back to us any modifications or changes required to ensure they fit correctly. In return we would provide a free set for your efforts. Here is a list of our current prototypes: · 280ZX frame rails (coupe and 2+2) · 280Z frame rails for aftermarket floor pans · 280Z optional rear frame rails (for stock and aftermarket floors – similar in design to our optional 240 rears) Note: Pictures of these parts will be posted once the Design Patent application process has been completed. As our rails are made from 13-gauge steel we recommend folks who want a stock thickness rail to get them from Zeddfindings instead. Ours are made for those you have added more HP, torque or drive their cars hard. In addition to these we also have several other parts close to final production fitment in the next 30-45 days: · 7-gauge frame rail prototypes for S13 and S14 drift cars · 280Z seat brackets · Toyota Tacoma (Standard Cab) frame rails reinforcement pieces If you wish to assist us please send an email to: john@baddogparts.com Let us know the part(s) you can test fit and the year of your Z(s).