Everything posted by zclocks

-

1976 Clock

Dave, You got real lucky with just a cap that was bad. In my experience the tran goes bad all the time and the two coils do drift to the point that they are not usable. Nice wording on UBER careful when soldering around the coil wires, that can't be stressed enough. They are about 35 gauge and easily to overheat. I haven't seen a Simpson 260 for years and loved the one I had when I was in the service. Good job!! Ron

-

RHD Fairlady S30 gas pedal

The 2-knob Rally clock box I'm building will really look nice as soon as It's plated. Not sure on the price yet, but you can e-mail me at : ron@zclocks.com if interested. Thanks.....

-

Oil the Clock?

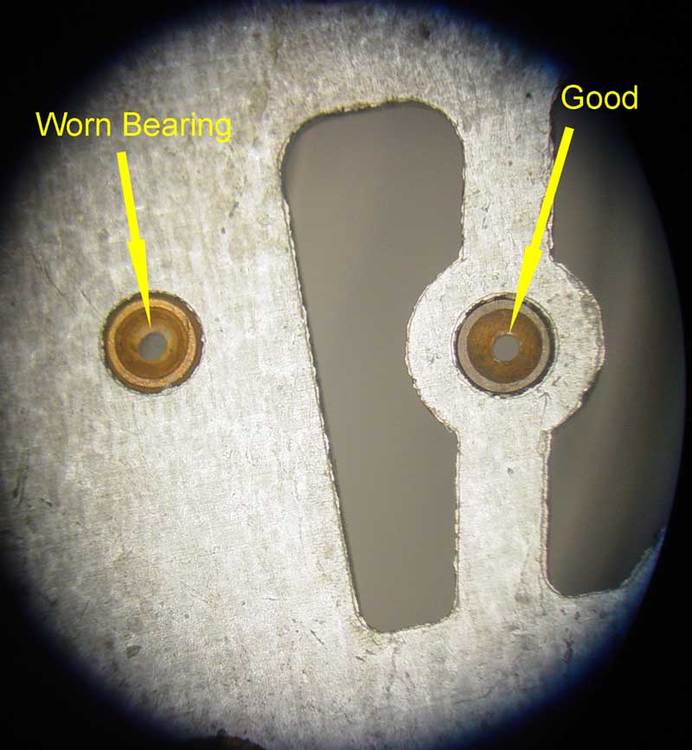

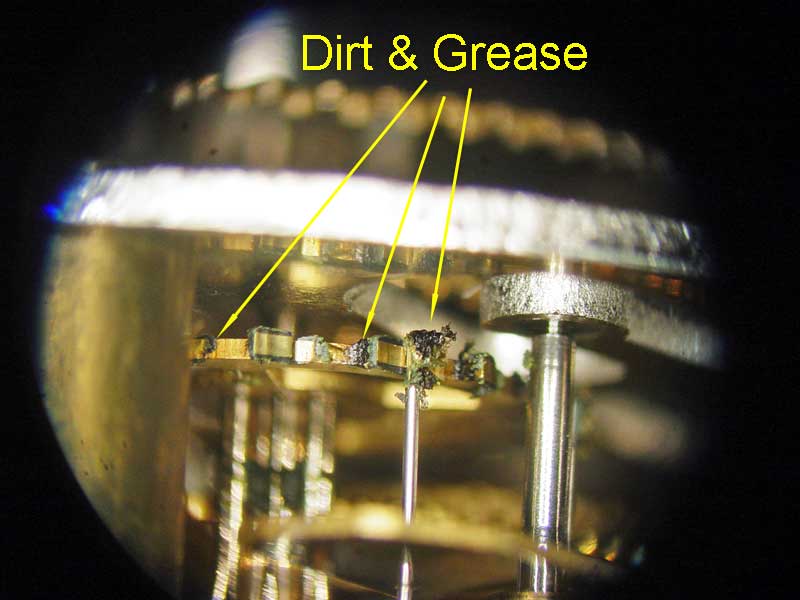

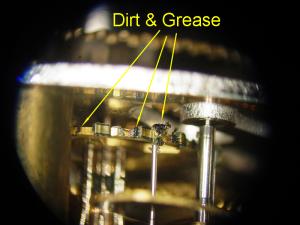

dhayes5, Deoxit is basically a contact cleaner and should work. However, most of the 240 mechanisms I have seen look like the attached photos . Most cleaners are not aggressive enough to remove all the grease, oil, and dirt. The other problem is bearing wear . The best way is to completely disassemble the clock , clean , and inspect for damage. Hope this helps

-

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

I have both the parts you are looking for. You can contact me @ ron@zclocks.com The 3D printers do not have the detail to hold the tolerances required for the motor gears. Ron

-

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

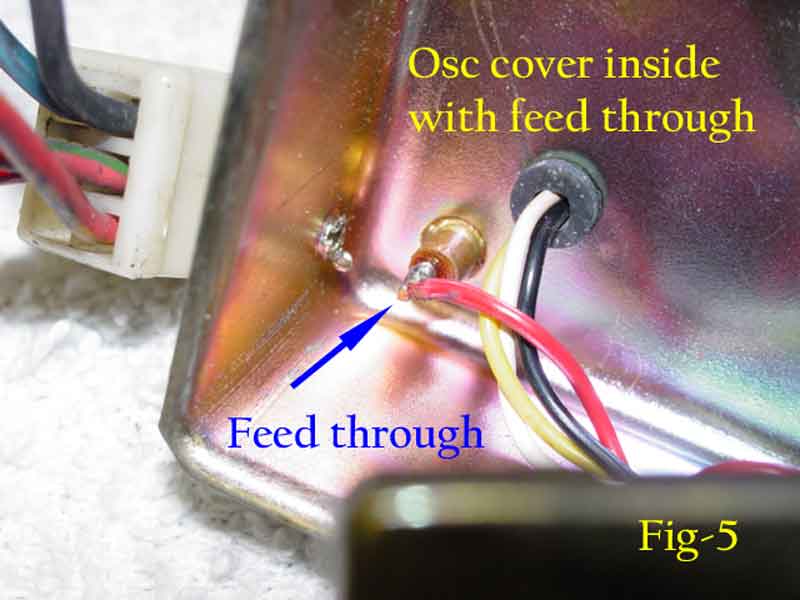

Hey d3c0y, If you measured the feed through to ground and it was shorted then one can surmise that the capacitor internal to the feed through was shorted. However, I have not seen one that was shorted , but I always measure the case to feed through just to make sure. One question I still have is what is the capacitance of this feed through and what noise is trying to be eliminated, frequency? I'm not sure this feed through is relevant to the OEM ckt bd as there are several internal caps on the subsequent ckt bd(s) that take care of this potential problem. The OEM ckt boards have 3 revisions , C_D_E over the years, and I have tracked each trying to understand what they , JECO, was trying to do. Not sure if this feed through was very useful after the first revision other that a convenient place to connect the power wire (red) to the (green) motor power. Not sure if it's relevant to your ckt bd , but what I have observed on the OEM bd is that there is only an input resistor for current limiting and a Zener pull down to clam the voltage. In my opinion if Jeco was concerned with noise then why didn't they address this in a ckt up front and the voltage, full wave rectifier. Subsequent clock manufactures , Kanto Seiki and Citizens both have DC filtering on their clocks. One of my pet peeves is that Datsun protects the clock on a 10 amp fuse? Most clocks only require 15- 20 mili amps so why put it on a 10 AMP ckt!!! By the time the fuse blows the clock will be a puddle of metal. .The only protection in most clocks is a simple resistor that has to melt before it protects the ckt. I've seen this in the std clocks, calendar and the 2-knob rally clocks. The clocks in my cars are all fused on 1/4 amp fuses and that is still high .Not that there is a problem, but come on 10 amps! All the 240 and 280 clocks are fused on 10 amps by Datsun . Anyway. enough of my ranting. Hope this was of interest to someone. Ron (Zclocks)

-

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

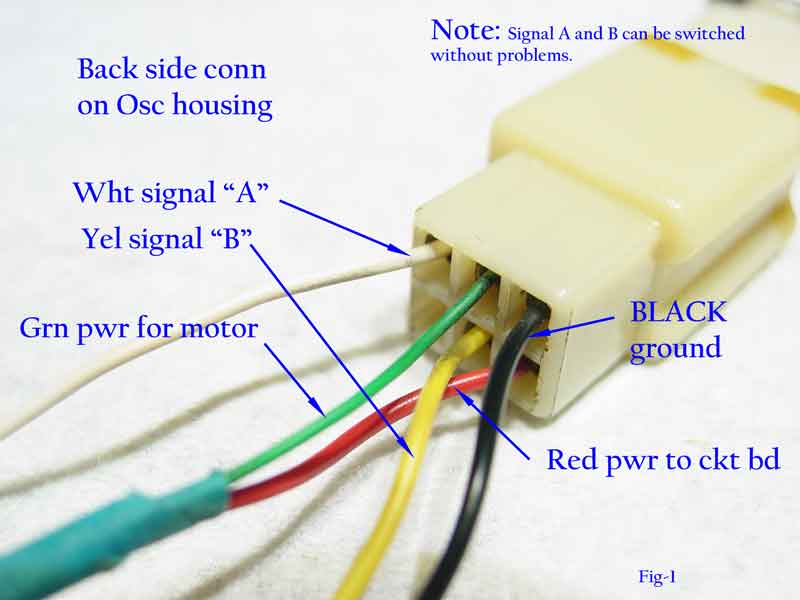

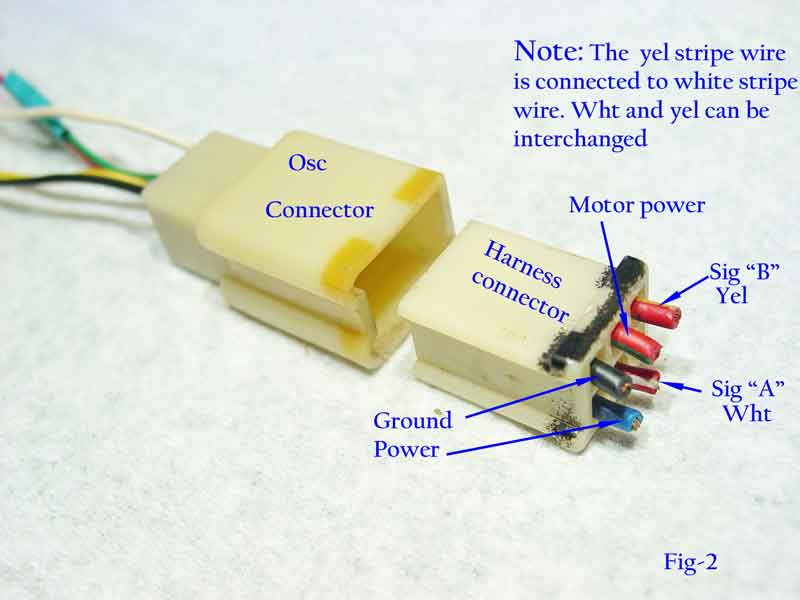

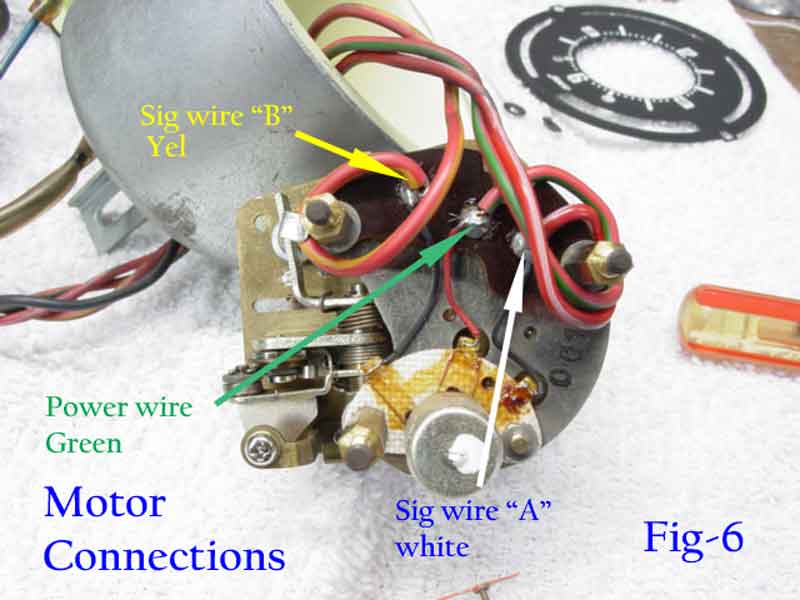

Back from vacation and looked through my photos of the RC wiring. When I mention POWER in the photos it's 13.6 vdc . Also, this is the wiring colors for the original OEM osc, harness, and motor. The color stripe on the wires match up with the same solid color wire on the osc connector. The exception to this is that the signal wires , White and Yellow, can be interchanged. ie: white strip can connect to the solid yellow wire and visa versa. The signals can a be reversed and not cause a problem. Let me know if you have any questions on the photos.

-

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

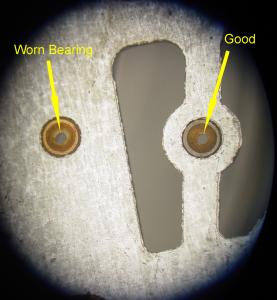

Also, failed to mention that the two motor bearings wear over time . Again this is another part that is bad about 98% of the time. These bearings are very critical and SUPER small. I have to make these from nylon on a mini lathe. If you use anything other than nylon you risk damaging the shaft that supports the motor magnet and the flywheel. In addition, I see where Capt Obvious is going with the feed thru. I have eliminated the feed thru in several osc' without problems , but again I don't have a way to test for hi freq RF. If you replate the cover the acid plating bath destroys the feed thru, causes the center terminal to short to the housing. Something to think about. Ron Ron

-

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

I just received this from Gavin and guess I will give my input. Basically Monkeyman has the correct color code and wiring diag for the original Osc box and clock body, Aug 30 posting. There are 5 wire colors in the harness and I would and do keep them original. This way we can all be on the same page. Black-- ground blue-- 13.6 vdc red wire/ green stripe---13.6vdc for motor red wire/white stripe--signal for motor (A) red wire/ yellow stripe--signal for motor (B) There is a power feed thru on the Osc cover and this is where the red wire for power to the original ckt bd is attached. Also the green wire is attached here and provides power up the harness to the motor, motor power. The feed thru is isolated from the case of the Osc. Not sure what this "Com" is on the purple board , but please tell me what is it's function? I'm currently on vacation, but when I return I will lay out a RC clock , harness, and Osc and show where everything goes. There are also other items that can prevent the clock from functioning after you get the wiring sorted out. The main motor gear in most of the clocks I have seen are cracked or missing teeth. The OEM gear is casting wax. It can't be repaired and needs to be replaced. No one makes this gear and I ran into this problem so many times I had a mold made and manufacture my own. My gears are made from a very hard plastic. Another problem is the clock lever or pawle(sp) which keeps the motor running in the correct direction. What goes bad are the two nylon disks that act as friction disks. If they are very bad they affect the motor speed by causing excessive friction. Just my 2cents Ron

-

WTB: clocks

WTB: Analog clocks, (quartz and mechanical) from 240z--280zx clocks. Please contact me with what you have and price. Thanks...ron@zclocks.com

-

WTB Datsun/Nissan analog Quartz clocks

If you have 77-78 280z quartz or 79-83 280zx analog quartz clocks please contact me with quantity and price at: ron@zclocks.com Thanks ..... Zclocks

-

Oil the Clock?

Also, hr369 I did measure the pulses from the ckt board years ago and they are determined by the design. I don't recall what the count was but if the clock is slowing down or has a hard time starting then the transistor or the caps are the problem. Don't know why you asked but if you try to change the design or add additional pulses you will over drive the transistor and cause a failure. The original article I wrote was for the 240 clock which is 98 % mechanical and has no electronic ckt .Oil / contaminants are the main failure cause. Oiling any of these clocks is a NO-NO. There are metal and nylon (self lubricating) gears in all the clocks. Oil only causes problems unless you want to pull your clock every 6 months for cleaning and re-oiling. Hope this helps....

-

Oil the Clock?

let me see if I can answer this without getting in toooo much trouble. If you have tried the adj screw and it doesn't work then you can have one of three problems. 1) the adj clamp on the main spring has slipped, 2) the screw on the main spring is loose or broken. 3) the ckt board is failing and needs to be rebuilt. What might have happened is that you didn't wait long enough after you made and adjust to see if the time was correct. Adjustments should be made in very small increments and you should wait 4-5 hours before you decide to make further adjustments. If you set the clock 15 min ahead of the correct time and it continues to loose time in 24 hours then you have a problem as I just described above. Setting the clock ahead of time doesn't compensate for anything. What I have learned over time is that we seem to think there is one problem when there is really 2-3 or 4. Clocks are not magic but it can seem like it.

-

Oil the Clock?

Another problem I have seen lately is that the bearings, and there are about 5, can become worn and cause problems. What happens is the shafts attached to these bearings will start to wobble and the associated gears bind and lock up. Again the wear is associated with the oil that attracts the dust and dirt and reacts like sandpaper on the bearings / rotating surfaces. Replacing the bearing(s) is the only solution. These are very small and difficult to work on. I do have refurbished 240 mechanisms 4 -sale on my web site, zclocks.com/sale-items.html Hope this helps....Ron

-

Oil the Clock?

The attached photo goes to the post I made in 2005. This is what oil does to the gears in the 240 mechanical mechanism. If you can remove all the contamination as shown you have a chance of getting the clock to work , that is if the motor is good.

-

Calendar Clock Knob Missing

HI, The knob from the 280zx digital clock will not fit the RC clock. The hole in the 280zx is larger and the screw is larger in dia. I have a screw that will fit, correct thread and pitch, and I can modify the knob to work. Email ron@ zclocks.com for pricing. Ron (zclocks)

-

1976 EFI Overhaul

You need to send your clock to zclock.com for conversion to a quartz unit. Zclocks

-

240Z Dash with cracks - Cap or Refinish?

EuroDat, Your clock is removed through the glove box which doesn't involve the dash cap. Zclock

-

Clock repair/restore

Also, just wanted to mention that there was an excellent article in Aug 6, 2008 by E. Bettio of Australia on the 280 clock. I reversed engineered the 280 in 2000 to fix my own clock but this guy put in way to much time, but did an excellent job. http://www.classiczcars.com/forums/attachments/tech-pubs-howto/23622d1212753644-fixing-your-z-clock-how-fix-your-260z-280z-clock-rev-1.pdf This is on the classic site and and shows up under " Monkey Man" but he credit should go to Bettio. It's a very good article for those who want to see what the electronics in the standard 280Z clock is about.

-

Clock repair/restore

Thanks for the support and yes I guess I did miss the forest. Seems that when I input on other sites I get less than a positive response. Your right about the zener on the 75-78 clocks as they are 5.1 volts. I was thinking of the 2-knob rally clock which has an 8 volt zener.

-

Clock repair/restore

I was reading these posts and thought I would throw in my 2-c worth. From my experience the OEM 240 clocks are not sensitive to voltage but are very sensitive to temperature and contaminants(oil,dust, metal fatigue). I use two different power sources( power supply and car battery) and I have not seen the difference. What I do see is the minute the temperature in my shop drops or rises 20 degree the 240 clocks start to change. The OEM clock winds the main spring by a small motor that keeps constant pressure on the spring which drives the gears of the clock. This is all good as long as the spring is new, the gears are clean, and the temperature is constant. The bigger problem is that after 40 years all the moving parts are VERY worn and it's hard to get the clock to deliver better than plus or minus 10 min. per week. Another variable is everyone seems to think oil is required, it's not. This is a short term fix and only complicates the problem. If you really want to make this clock accurate and reliable you can. What it takes is to disassemble every part, clean, inspect, replace the worn items, and reassemble. NO oil or lubricant. Also, this should be done on a yearly basis. I know this is excessive but this clock is just like your grandfathers pocket watch or wall clocks. Grandfather clocks are accurate and had many moving parts but they were all cleaned inspected, and adjusted yearly for accuracy. The hybrid clocks, 75-78, have a zener on the power line which regulates to 7 volts so power is not a factor. The quarts clocks have only 4 moving parts that are not constantly moving like the 240 clocks and there is also a zener to regulate power to 7 or 8 volts. Ok, enough and I assume I'll get a lot of flak from this post. Ron (Zclocks)

-

Clock repair/restore

Zclocks only takes one week for refurbishment and has a 6 month guarantee!!! -Ron (zclocks)

-

How to identify your clocks

The Zclocks website has been updated and two new articles have been added. 1)" How to identify your clock " 2)" Rally clock identification" The two articles should help when looking for or asking questions about these clocks. Thanks ...Ron @ Zclocks.com

-

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

I couldn't help but chime in with my 2C. Contrary to public opinion I do have 99% of the parts for the oscillator, including the ckt bd . As soon as I perfect the last two parts I can build a complete oscillator from scratch. Also, I have lens, those hard to find knobs and knob screws . I'm not into selling parts but use these to refurbish clocks. The Oscillator is a lot more than just resistors which usually don't go bad. This is 40+ year old TTL /discrete technology and usually needs a lot of TLC, especially as fragile as this clock is. Another problem is TIN whiskers, look this up as to lengthy to describe here, which is a anomaly of component leads that were not SOLDER coated. This is a bigger problem than anything else in my mind. As my wife says "you can improve a princess a lot easier than a beater". One of the misnomers of the two knob rally clock is that it draws excess battery current. This shouldn't be a problem as the standard clock draws only 12-15mA and the 2- knob rally 30-33mA. If your drawing a lot more than this then you have another problem. I have a 2-knob rally in my car and the car is lucky if it gets started once a month. I've never had a low battery problem and the car has other devices that draw a lot more than the clock. Also, excessive motor noise is coming from a worn gear/bearings in the housing. This part is not available anywhere, here or Japan. This is unique to this clock and no substitutions are allowed. Only the original material used is acceptable or you will ruin the mating gears. I make the bearings and working on making the gears. Just my 2C worth. Ron

-

Clock repair for Z's

geezer, Not sure if you can use SN to determine early or late box. SN 2032 was the later box and I have records that show a SN 2092 was an early box. In addition I have worked on a SN 0013 which was a very early box. It seems to be consistent that if the wire harness has the 6 pin plug that all the ones I've seen are the later boxes. I believed that JECO started producing the later boxes in 74 . I worked one box that had a 240 bezel on the clock housing with a 6 pin connector and another clock set that had a late 260/280 bezel on the housing that had a 6 pin connector. The connector seems to be the tell because it showed up on the late 260 and went through 78. just my 2C. Ron

-

Clock repair for Z's

Geezer, I just worked on a RC that had SN 2032 on the osc box. Ron