-

Posts

305 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by zclocks

-

Tachometer Swap : 280z into a 240z series 1 housing

zclocks replied to 240260280z's topic in Technical Articles

You have two different problems. The back lights could be a ground to the lights or you lost pwr for the lights . Turn signal could be the same kind of problem . -

Motor man. I've tried the Equus conversion and it's not as easy as the author makes it look. However, The dash looks very nice. How long did it take to have the dash recovered? . Zclocks

-

Tachometer Swap : 280z into a 240z series 1 housing

zclocks replied to 240260280z's topic in Technical Articles

I know it's been a while since this article was written and it's very good. Including the photos makes it a lot easier to understand. I've made this conversion several times without problems. The one comment I have is the 280z unit that was used is from a 77 or 78 280z. The 75-76 280z has the same font and face plate as the 240 including the 6500 red line. If you use a 75 or 76 280z tach for this swap you don't have to touch the face plate or needle. Makes things a lot easier. Zclocks -

I WTB your 280zx, or 280qtz clocks. Please let me know the condition,quantity, and price. Contact: ron@zclocks.com Thanks

-

I now have New Rally Clock Oscillator box by Zclocks. This photo is the first one out and currently taking orders., It's a plug and play if you have your own circuit board or I can supply a complete working oscillator . Contact me at :ron@ zclocks.com for pricing and info.

-

Dave, You got real lucky with just a cap that was bad. In my experience the tran goes bad all the time and the two coils do drift to the point that they are not usable. Nice wording on UBER careful when soldering around the coil wires, that can't be stressed enough. They are about 35 gauge and easily to overheat. I haven't seen a Simpson 260 for years and loved the one I had when I was in the service. Good job!! Ron

-

The 2-knob Rally clock box I'm building will really look nice as soon as It's plated. Not sure on the price yet, but you can e-mail me at : ron@zclocks.com if interested. Thanks.....

-

I'm fairly new to this web site and have seen several articles on clocks. This is of particular interest to me as I do have some experience with total clock reconditioning. I've been repairing, refurbishing and specializing in 70-83 Datsun /Nissan clocks for the last 8 years and thought I would pass on several bits of trivia and technical information. I never really thought about NOT using oil on a clock as that seems to be common knowledge until a friend came to me years ago with a 240Z clock. Bill knew I worked on all sorts of electronic hardware and was soliciting my input. His problem was that his clock had stopped (like it was the only 240 clock that didn't work). I have a 75 280z and my clock has always worked. I was wondering why bills didn't? I took has clock apart and began to understand why. Bill said he had removed the clock and flushed it out with WD-40? and then lightly oiled all the components. The clock worked for several months and then quit and this was the second time for this occurance. After I looked at the clock in detail I could see why. The automotive environment is very tough on all the components and the most critical parts are hermetically sealed. The first generation 240Z Datsun clocks were not hermetically sealed and susceptible to all the dust, dirt, chemicals, humidity and temperature. JECO, the Datsun subcontractor, who built most of the Datsun clocks never used oiled for good reason. Oil attracts all the nasty contaminants that can wear out critical clock components and eventually grinds the clock to a halt. I know I know everyone always uses oil on their grandfathers clocks. If you think about it we change our engine oil which is filtered for the very same reason, so that the engine will last longer and not wear due to....the dirty oil. The first generation clocks (240z) have what's called a "NO LOAD" motor which keeps the main spring of this clock contiguously wound. The rest of the clock consists of gears, paws, and bearings that rotate and work in unison to move the clock hands. The problem is that any gear or bearing that produces friction slows the entire clock and if sever enough the clock will stop. Are you beginning to see a pattern here. Oil that is used to lubricate (all oil) coats the surface of moving parts and eventually starts to collect contaminants. Eventually this causes the viscosity (on a micro level) to thicken and produce resistance to the overall clock operation. In addition the change in temperature alone will change the oil viscosity. Believe me when I say it takes very very little resistance in any of the clock parts to stop this mechanism. When solvent other than alcohol is used to "flush" the clock all your doing is removing the contaminants, but when you apply oil you start the process all over again. If you don't mind removing your 240z clock every year or so then I guess that's ok. After helping Bill reinstall his clock I'd opt for a clock that would work forever (we did but that's another article). The 240z guys and girls have a rough time compared to rest of us removing and installing their clock. That is unless the dash is removed. This is what I have found works the best, denatured alcohol. You should remove each and every clock part, clean all parts with an artists brush, inspect the cleaned parts, and reassemble (NO OIL). Let me say that again...NO OIL.This can be a rather daunting task and is not for the weak of heart or those with limited patience. I know this works because I've cleaned way to many 240 clocks and I still have one of Bills 240Z clocks on my test bench. It works and it keeps pretty good time. It doesn't get much outside time, but that's why it's still working. If I get enough interest I'll write a weekly article on "how to" for each of the four generation clocks. Like what goes wrong, how do fix it, what's interchangeable, how do I clean it, what kind of paint to use and so on. Hope this was helpful and please give me feedback. Thanks.........Ron

-

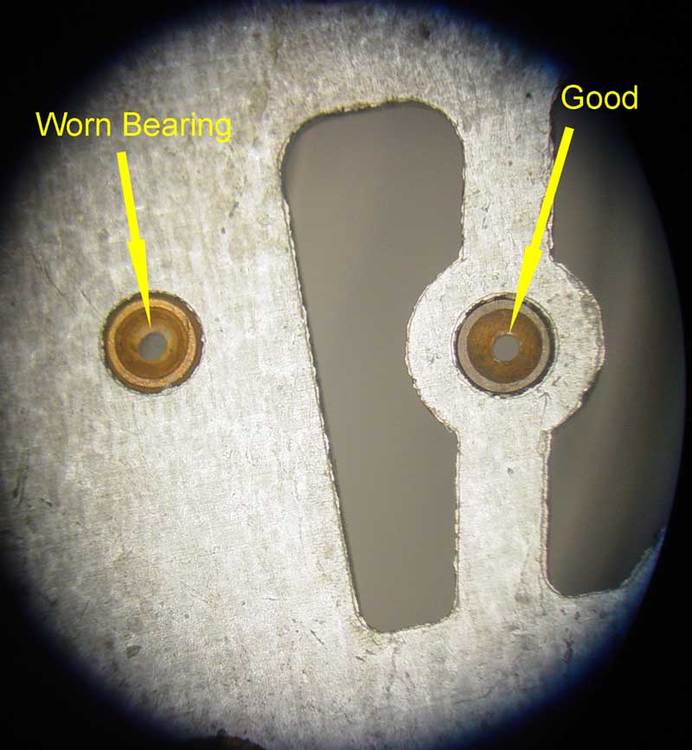

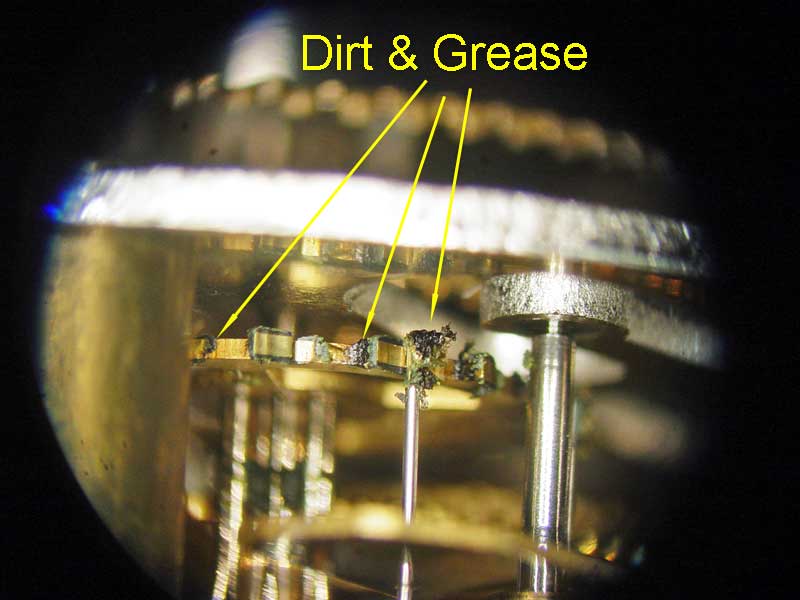

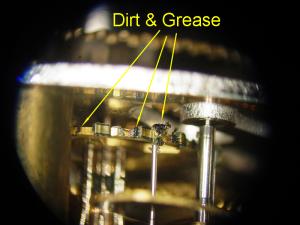

dhayes5, Deoxit is basically a contact cleaner and should work. However, most of the 240 mechanisms I have seen look like the attached photos . Most cleaners are not aggressive enough to remove all the grease, oil, and dirt. The other problem is bearing wear . The best way is to completely disassemble the clock , clean , and inspect for damage. Hope this helps

-

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

zclocks replied to dhp123166's topic in Open Discussions

I have both the parts you are looking for. You can contact me @ ron@zclocks.com The 3D printers do not have the detail to hold the tolerances required for the motor gears. Ron -

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

zclocks replied to dhp123166's topic in Open Discussions

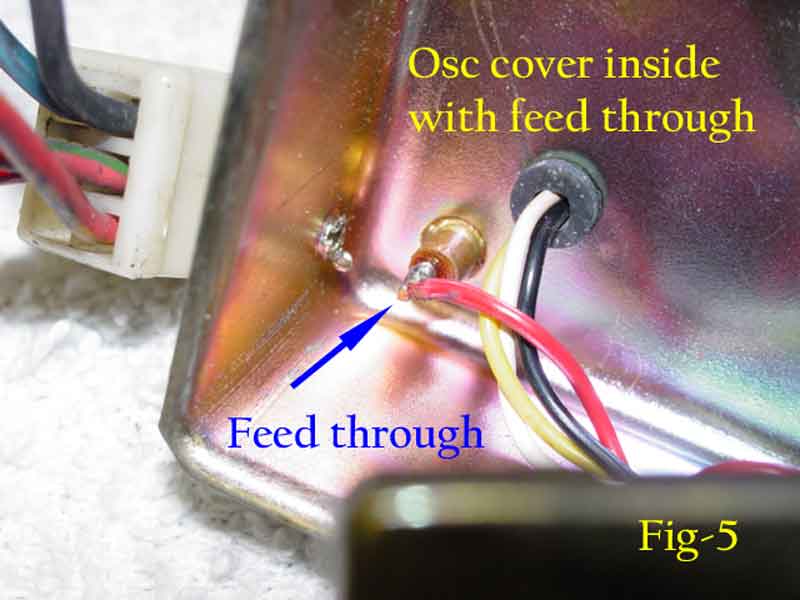

Hey d3c0y, If you measured the feed through to ground and it was shorted then one can surmise that the capacitor internal to the feed through was shorted. However, I have not seen one that was shorted , but I always measure the case to feed through just to make sure. One question I still have is what is the capacitance of this feed through and what noise is trying to be eliminated, frequency? I'm not sure this feed through is relevant to the OEM ckt bd as there are several internal caps on the subsequent ckt bd(s) that take care of this potential problem. The OEM ckt boards have 3 revisions , C_D_E over the years, and I have tracked each trying to understand what they , JECO, was trying to do. Not sure if this feed through was very useful after the first revision other that a convenient place to connect the power wire (red) to the (green) motor power. Not sure if it's relevant to your ckt bd , but what I have observed on the OEM bd is that there is only an input resistor for current limiting and a Zener pull down to clam the voltage. In my opinion if Jeco was concerned with noise then why didn't they address this in a ckt up front and the voltage, full wave rectifier. Subsequent clock manufactures , Kanto Seiki and Citizens both have DC filtering on their clocks. One of my pet peeves is that Datsun protects the clock on a 10 amp fuse? Most clocks only require 15- 20 mili amps so why put it on a 10 AMP ckt!!! By the time the fuse blows the clock will be a puddle of metal. .The only protection in most clocks is a simple resistor that has to melt before it protects the ckt. I've seen this in the std clocks, calendar and the 2-knob rally clocks. The clocks in my cars are all fused on 1/4 amp fuses and that is still high .Not that there is a problem, but come on 10 amps! All the 240 and 280 clocks are fused on 10 amps by Datsun . Anyway. enough of my ranting. Hope this was of interest to someone. Ron (Zclocks) -

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

zclocks replied to dhp123166's topic in Open Discussions

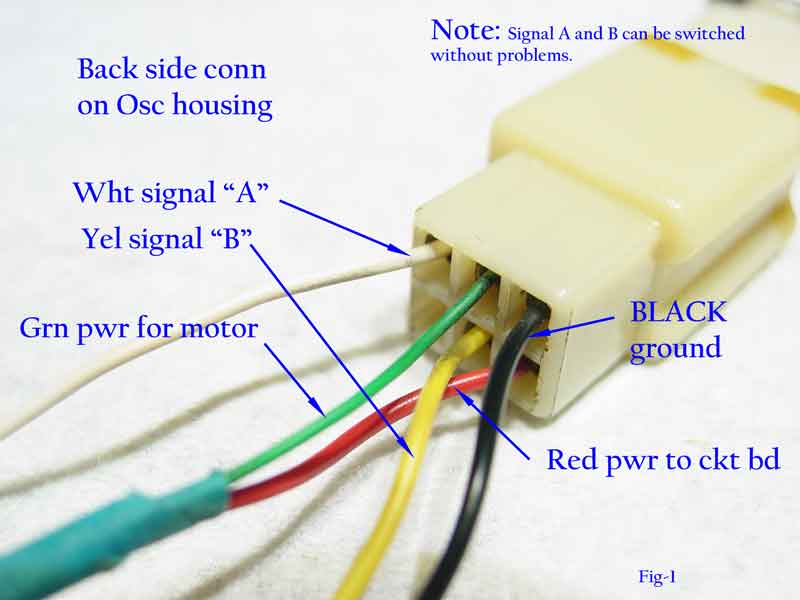

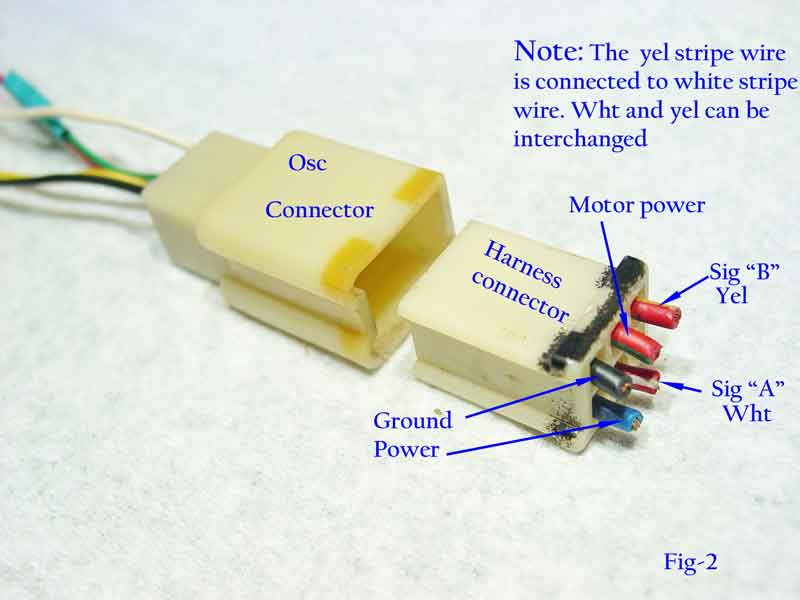

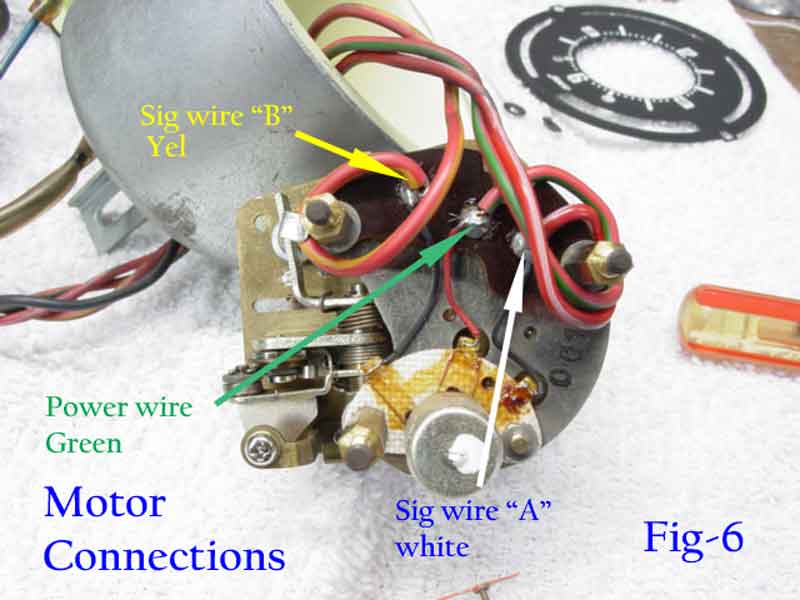

Back from vacation and looked through my photos of the RC wiring. When I mention POWER in the photos it's 13.6 vdc . Also, this is the wiring colors for the original OEM osc, harness, and motor. The color stripe on the wires match up with the same solid color wire on the osc connector. The exception to this is that the signal wires , White and Yellow, can be interchanged. ie: white strip can connect to the solid yellow wire and visa versa. The signals can a be reversed and not cause a problem. Let me know if you have any questions on the photos. -

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

zclocks replied to dhp123166's topic in Open Discussions

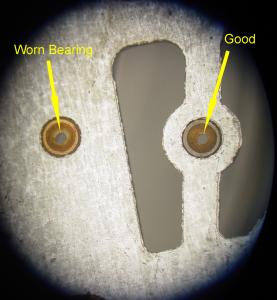

Also, failed to mention that the two motor bearings wear over time . Again this is another part that is bad about 98% of the time. These bearings are very critical and SUPER small. I have to make these from nylon on a mini lathe. If you use anything other than nylon you risk damaging the shaft that supports the motor magnet and the flywheel. In addition, I see where Capt Obvious is going with the feed thru. I have eliminated the feed thru in several osc' without problems , but again I don't have a way to test for hi freq RF. If you replate the cover the acid plating bath destroys the feed thru, causes the center terminal to short to the housing. Something to think about. Ron Ron -

Pricing 240z Rally Clock w/ Fully Functioning Oscillator?

zclocks replied to dhp123166's topic in Open Discussions

I just received this from Gavin and guess I will give my input. Basically Monkeyman has the correct color code and wiring diag for the original Osc box and clock body, Aug 30 posting. There are 5 wire colors in the harness and I would and do keep them original. This way we can all be on the same page. Black-- ground blue-- 13.6 vdc red wire/ green stripe---13.6vdc for motor red wire/white stripe--signal for motor (A) red wire/ yellow stripe--signal for motor (B) There is a power feed thru on the Osc cover and this is where the red wire for power to the original ckt bd is attached. Also the green wire is attached here and provides power up the harness to the motor, motor power. The feed thru is isolated from the case of the Osc. Not sure what this "Com" is on the purple board , but please tell me what is it's function? I'm currently on vacation, but when I return I will lay out a RC clock , harness, and Osc and show where everything goes. There are also other items that can prevent the clock from functioning after you get the wiring sorted out. The main motor gear in most of the clocks I have seen are cracked or missing teeth. The OEM gear is casting wax. It can't be repaired and needs to be replaced. No one makes this gear and I ran into this problem so many times I had a mold made and manufacture my own. My gears are made from a very hard plastic. Another problem is the clock lever or pawle(sp) which keeps the motor running in the correct direction. What goes bad are the two nylon disks that act as friction disks. If they are very bad they affect the motor speed by causing excessive friction. Just my 2cents Ron -

WTB: Analog clocks, (quartz and mechanical) from 240z--280zx clocks. Please contact me with what you have and price. Thanks...ron@zclocks.com

-

If you have 77-78 280z quartz or 79-83 280zx analog quartz clocks please contact me with quantity and price at: ron@zclocks.com Thanks ..... Zclocks

-

Also, hr369 I did measure the pulses from the ckt board years ago and they are determined by the design. I don't recall what the count was but if the clock is slowing down or has a hard time starting then the transistor or the caps are the problem. Don't know why you asked but if you try to change the design or add additional pulses you will over drive the transistor and cause a failure. The original article I wrote was for the 240 clock which is 98 % mechanical and has no electronic ckt .Oil / contaminants are the main failure cause. Oiling any of these clocks is a NO-NO. There are metal and nylon (self lubricating) gears in all the clocks. Oil only causes problems unless you want to pull your clock every 6 months for cleaning and re-oiling. Hope this helps....

-

let me see if I can answer this without getting in toooo much trouble. If you have tried the adj screw and it doesn't work then you can have one of three problems. 1) the adj clamp on the main spring has slipped, 2) the screw on the main spring is loose or broken. 3) the ckt board is failing and needs to be rebuilt. What might have happened is that you didn't wait long enough after you made and adjust to see if the time was correct. Adjustments should be made in very small increments and you should wait 4-5 hours before you decide to make further adjustments. If you set the clock 15 min ahead of the correct time and it continues to loose time in 24 hours then you have a problem as I just described above. Setting the clock ahead of time doesn't compensate for anything. What I have learned over time is that we seem to think there is one problem when there is really 2-3 or 4. Clocks are not magic but it can seem like it.

-

Another problem I have seen lately is that the bearings, and there are about 5, can become worn and cause problems. What happens is the shafts attached to these bearings will start to wobble and the associated gears bind and lock up. Again the wear is associated with the oil that attracts the dust and dirt and reacts like sandpaper on the bearings / rotating surfaces. Replacing the bearing(s) is the only solution. These are very small and difficult to work on. I do have refurbished 240 mechanisms 4 -sale on my web site, zclocks.com/sale-items.html Hope this helps....Ron

-

The attached photo goes to the post I made in 2005. This is what oil does to the gears in the 240 mechanical mechanism. If you can remove all the contamination as shown you have a chance of getting the clock to work , that is if the motor is good.

-

HI, The knob from the 280zx digital clock will not fit the RC clock. The hole in the 280zx is larger and the screw is larger in dia. I have a screw that will fit, correct thread and pitch, and I can modify the knob to work. Email ron@ zclocks.com for pricing. Ron (zclocks)

-

You need to send your clock to zclock.com for conversion to a quartz unit. Zclocks

-

EuroDat, Your clock is removed through the glove box which doesn't involve the dash cap. Zclock

-

Also, just wanted to mention that there was an excellent article in Aug 6, 2008 by E. Bettio of Australia on the 280 clock. I reversed engineered the 280 in 2000 to fix my own clock but this guy put in way to much time, but did an excellent job. http://www.classiczcars.com/forums/attachments/tech-pubs-howto/23622d1212753644-fixing-your-z-clock-how-fix-your-260z-280z-clock-rev-1.pdf This is on the classic site and and shows up under " Monkey Man" but he credit should go to Bettio. It's a very good article for those who want to see what the electronics in the standard 280Z clock is about.

-

Thanks for the support and yes I guess I did miss the forest. Seems that when I input on other sites I get less than a positive response. Your right about the zener on the 75-78 clocks as they are 5.1 volts. I was thinking of the 2-knob rally clock which has an 8 volt zener.