-

Posts

305 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by zclocks

-

View Advert Datsun quartz clock 77-83 Wanted : Datsun analog quartz clocks, 77-83. Must be in fair condition and working condition not required. Just to make this add clear I'm only interested the analog QUARTZ CLOCKS from 77-83. If you have a quartz clock(s) of the years pictured and only those that says QUARTZ on the clock face please PM me. Thanks....Ron Advertiser zclocks Date 02/17/2022 Price Category Parts Wanted Year 77 Model 280z

-

THIS ADVERT HAS EXPIRED!

- WANTED

- USED

Wanted : Datsun analog quartz clocks, 77-83. Must be in fair condition and working condition not required. Just to make this add clear I'm only interested the analog QUARTZ CLOCKS from 77-83. If you have a quartz clock(s) of the years pictured and only those that says QUARTZ on the clock face please PM me. Thanks....RonAsk for price

Seal Beach, California - US

-

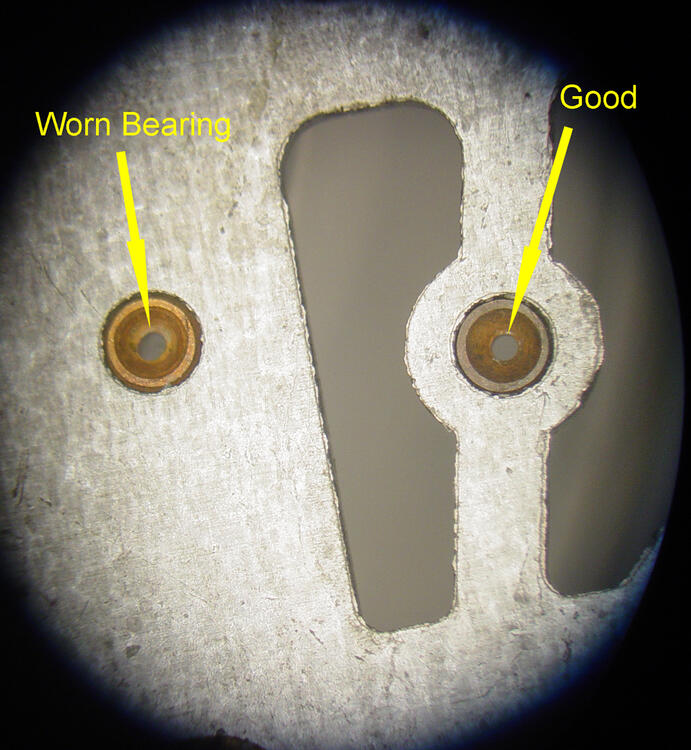

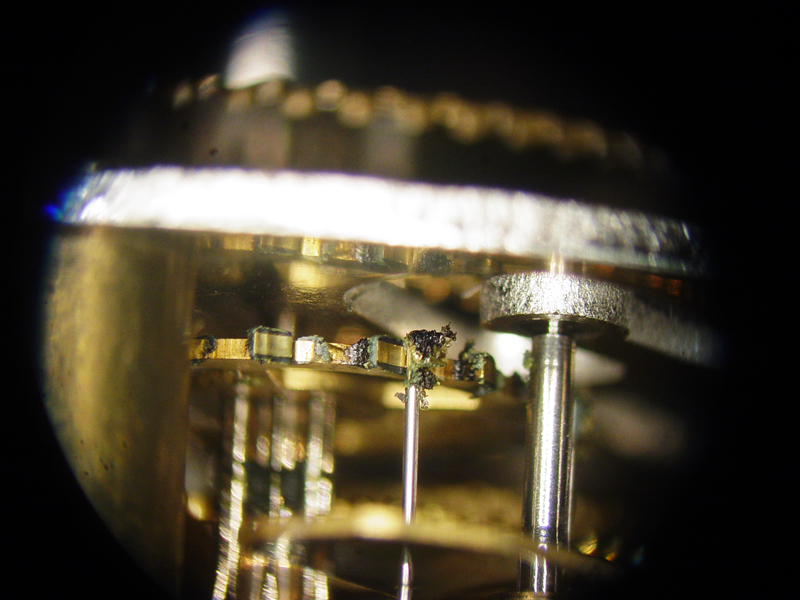

I noticed this tread and have a couple of comments. There are three clocks talked about here which are all different and have unique problems. The 74 260z was delivered with two clocks. Very early 74 the clock was the same as the 240zand the later clock was the 280 version. So we have the 240, 280 and what appears to be a VDO clock that are all different. As far as the 240z goes if you put 21volts on any of the clocks you will cook the parts. This clock is very sensitive to dirt, grease and oil. If you look at the enclosed you will see what oil does to the clock gears. Oil collects dirt like a magnet and turns into grease. This is what stops the 240 clocks. Disassembly and cleaning is the only way to put the clock back in service for many years. Also, inspection of the bearing points in necessary or you will be disassembling the clock within a short time. Again the enclosed shows a worn bearing and this part needs to be re-bushed. All the oil in the world won't help this condition. The 280z mechanism has very few bearing points and does not need any oil. The caps on the circuit board are the main problem and the spring is the second as well as the pink gear (missing teeth) on the enclosed. The other problem is the coils on the circuit board. Either of the two can be open,shorted, or incorrect resistance. As far as cleaning DO NOT use the cleaning solution as mentioned. This is an old clock makes formula and is VERY VERY caustic / dangerous. This is as dangerous to your lungs as using epoxy paint without a respirator. The cost to make such a formula is about $60--80 depending on where you can get the items. Also, the ammonia(20%) can only be purchased at a chemical supply house and runs about $35 / quart! Also, this formula will destroy and degrade the nylon and plastic of your clocks. DO NOT use it. Isopropyl alcohol is the best solvent and yes it takes a little elbow grease, but it works. I am not a clock maker, but I have repaired , cleaned and refurbished many grandfather clocks as well as hundreds of 240- 280 clocks. Oiling is something you should due for a grandfather clock as it has weights that drive the mechanisms that weight several pounds. With this kind of force on pivot points and bearings need to be oiled. Our Datsun clocks do not have this kind of force on the pivots. The 280z mechanical clock has several bearing that support pivots that are plastic and they do not need to be oiled. The correct way to oil something, if you must, is one drop of oil on the bearing/pivot and wipe off all visible oil. Clock oils today are synthetic and have a much higher load and degree of temperature resistant than organic based oils of the past. Hope this helps. Ron

-

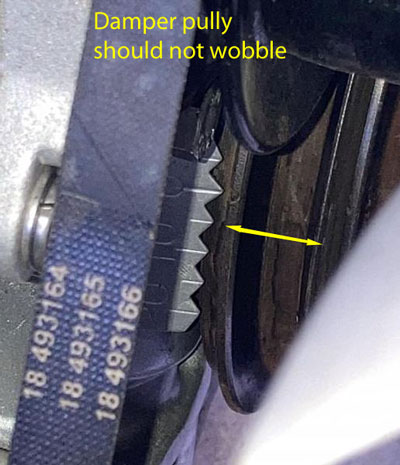

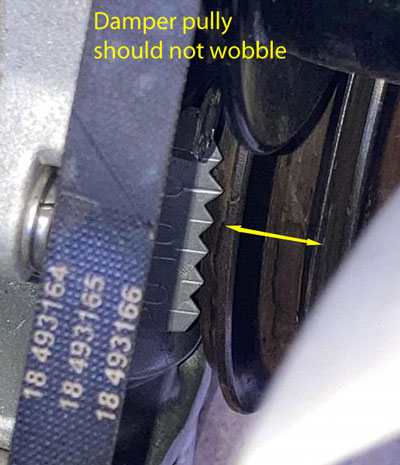

If ZKar doesn't have one I have a couple of other sources that might. If you do find one I would have it rebuilt. There's a good place in nothern CA which charges like $190 , but they do a really good job. My damper looked go after I removed ,but the rubber was cracked. On the car it was wobbling about 1/4 in.

-

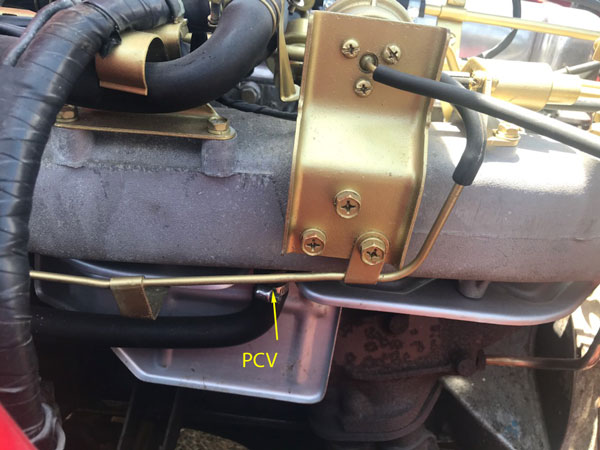

Location of PVC. If in question easy to remove and clean with solvent. If you can shake it and it rattles then it's probably ok.

-

So you had a internal oil cam and spray bar? I was told by a Z mechanic if you used both you wold have very low oil pressure. Ron

-

Good pix of the cam. Looks like you have so damage. Could be the oil galleries in the spray bar are plugged. I would remove the spray bar and make sure they are not plugged. Also check the holes in head that attach to the spray bar to make sure they are open. Also, I think there are gaskets the the spray bar attaches. Make sure these are not leaking. As a note: I'm not sure that the 77 had a spray bar. My 75 cam was damaged (loud lifter noise/couldn't adjust out) I replace the cam with a 77 or I believe it was a 77 cam. The new cam was used and had holes in the cam lobes . This eliminate the need for the spray bar. Maybe someone else can chime in on this.

-

When that happens I usually say" I 'm here to take the secretary out to dinner! Something else I saw in a previous thread about damper pulley. This is near and dear to me as I just had to do mine several months ago. The damper should not wobble.

-

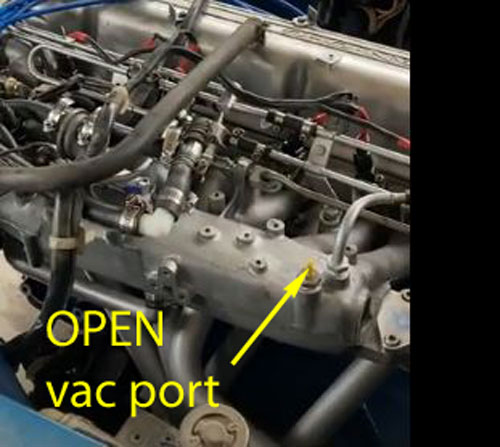

I snipped it from your video , but couldn't tell if it was plugged. A couple of vac sources are all vac lines suspect due to age, dip stick seal, pan gasket, maybe, cover plate, like where yours is plugged off on intake manifold. and valve cover gasket.

-

-

I've tried to follow this thread and it appears you a have a lot going on. Been there and done that . Don't give up you have to work one problem at a time and you will get there. The valves should not make that much noise. If they were adjusted correctly you should hear an even clatter. If they are tooo tight they wouldn't make much noise. In an earlier thread you mentioned spray bar gaskets. Do you have a spry bar on this car or do you have an oil hole in each lobe? you can't do both or you will have very low oil pressure. If you have a very flat lobe you can not adjust out the noise. Second it appears that you have NO vaccuun if i'm reading your gauge correctly. Where are you connecting the vacuum gauge? Third did you check the fuel pressure? The way use started the car it appears the pressure was low and it took three try to reach the 30 psi to start.

-

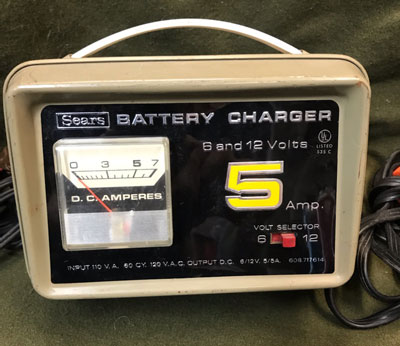

Patcon, Yes, I think most of the time the chargers can be repaired. Their not like a clock....LOL Ron

-

This is a great topic especially if your looking for a trickle battery charger or one to replace a dead charger. I had the tan 5 AMP charger pictured for over 40 years and it finally died. Well my neighbor helped by hosing down the charger with water. Anyway, Instead of replacing the diodes I just tossed the charger and started looking for a new one, what a shock. I tried three new charges that died before I went looking for a SEARS unit like my old charger. I found the two Sears charges as pictured on eBay. The 5 AMP is my " go to" and the 6/2 AMP is a backup. These are very heaving duty, work all the time and never overcharge the battery. I had to change the power cords and the battery clamps, but this is the only charger I will use. You can find them on eBay for no more $ than the newer chargers that are JUNK! SEARS use to contract different company's to build quality products , but that time has long passed. The garbage we see today is from CHINA! end rant

-

-

-

View Advert Quartz clocks If you have either of these two Quartz clocks and would like to sell them please contact me at: ron@zclocks.com or PM me . Thanks Advertiser zclocks Date 03/06/2021 Price Category Parts Wanted Year 0 Model 280

-

-

View Advert Clocks wanted If you have either of the 280z or 280zx Analog Quartz clocks shown please PM or email me. Thanks....Ron Advertiser zclocks Date 11/19/2020 Price Category Parts Wanted Year 77 Model 280

-

-

Ha Ha!! I'm laughing cause I have the same problem and I'm older than you. Thank god I have a pull out radio.

-

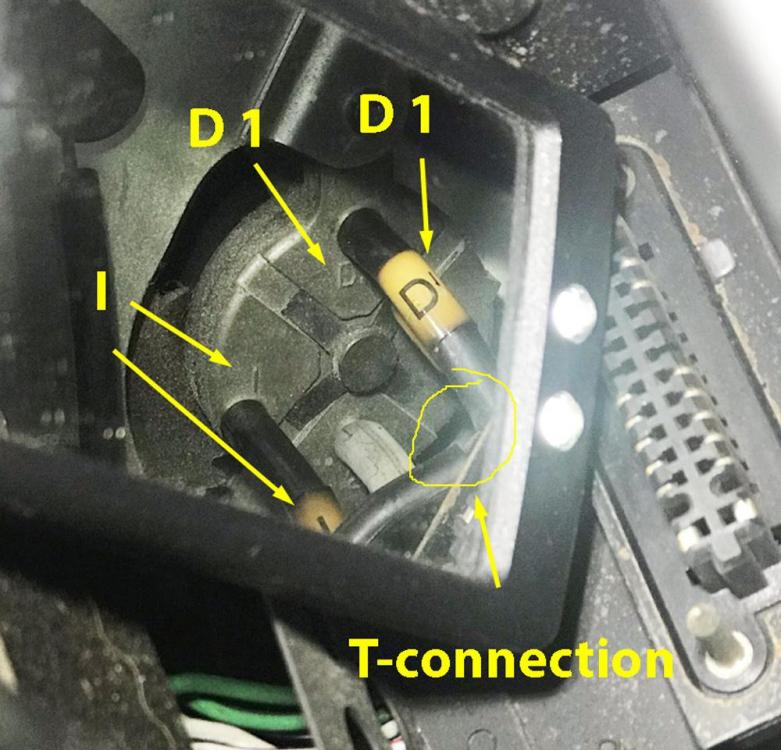

Looking at the two side by side looks like the the switch labeling is different in Z Excellence car than mine. Mine matches my manual.

-

I did get a photo after mega contortions, but my 75( 1/75) is connected as per the manual. D1 hose to D1 on valve and "I "hose to " I "on valve. "T" connection is from D1

-

If you can remove it maybe it can be repaired. Never heard of one going bad , but after 44 years who knows.

-