Everything posted by 240ZX

-

Wheel Size Question...

Tourniqet, To get the wheels to fit within the stock wheelhouse you will first have to use a coilover setup with a 8" free-length spring. The rear wheels I purchased ( I got them used ) have an offset of 35mm, so I had to fabricate custom spacers to aquire the correct position. Mind you, I have about 1/8" clearance between the inside edge of the rear wheel and the strut. It took some calculating to get it right the first time. But, as you can see it turned out well with no rubs anywhere. I forgot to mention that all my struts have been shortened 1 1/2". This is not required but by doing so you will have better usable shock travel with a lowered car. The rear tire size is 235-40 x 17 however, I've seen this setup using 245-45 x 17 with no problems. Clearances on this setup are very close. Hope this answers your inquirey. Respectfully, 240ZX

-

Wheel Size Question...

Well, The fuel pressure gauge is a Mallory 3 port (one return line to the tank). The fuel lines I made up myself from SS tubing. The electric fan was purchased from Motorsport Auto (see their cataloge). It was really fun redoing my Z, but it's much much more fun to drive!!! I never knew a Z could corner so well...and its only a street car. Can you believe the paint job, it's the only thing I didn't address. It's the same paint that was on it when I got the car, over 20 years ago. Of course it has always lived in a garage too! If you ever need advice on your project, feel free to inquire and I will assist you if I can. Thanks for the kudo's

-

Now THAT'S a sign!

-

My 240Z - title shot

Very nicely done!!! The headlight covers add a little extra class, but that's just my opinion. The bumpers look great without the rubbers, and no holes either! You should be proud.

-

Wheel Size Question...

Tourniqet, I have coilovers on all four corners, 10" free length springs up front and 8" free length springs in the rear. My wheels are 17 x 8 up front and 17 x 9 in the rear. Tires are 215-40 x 17 front and 235-40 x 17 rear. I can assure you they do not rub any where! I've seen guys with the same wheel setup as mine with even bigger tires......generally, 225-45 x 17 front and 245-45 x 17 rear. If you visit my gallery you can view my setup on my 240. The lowest part of my 240 is at 3 3/4" above the road surface. Mind you, I don't drive through shopping centers with speed bumps!!! Anyway, this setup has been successfully done by many z owners. Good luck with your adventure. Hope this helps you out a little.

-

fuel return tube

The reason one would not want to use copper lines for fuel lines is safety!!! Copper lines are pretty much in an annealed state (soft) and when subjected to movement and vibration, over a period of time, they will work harden (get brittle) and fail. A failure is likely to happen on or near where the line becomes flared, for a fastener. So do yourself a favor and use an appropriate steel fuel line.

-

fuel return tube

If you have the stock fuel system, you definitely need to have an operational return line. Fuel pressure is regulated by that little rectangular block at the rear of the fuel lines that run next to the cam cover. It has a small metering hole that provides the correct resistance to maintain approximately 4 psi to your SU's. The fuel that passes through the metered hole returns to the tank through the return line. If the return line is blocked, you will have too high a pressure at your SU's, resulting in probable float bowl overflow, because the needles and seat are not designed to handle much more than about 6 psi. The newer the needle and seats, the more pressure they will hold. Anyway, you need to get that return line unplugged or replaced. It should not be a very difficult exercise. Hope this helps you out a little....good luck!

-

I'm guessing you can trust the seller here ...

Mike, I've seen this car at a couple of shows and it is definitely a nice 280Z!!! I, myself, am not to keen on the overall styling, but that's just my taste. However, if the styling is pleasing to you, you may want to go check this one out. The best part is, is that it's all done........OK, everyone knows these toys are never really done!

-

updated 240Z website

Jason, Very nice job!!! Viewing your site takes me back to when I was redoing my 1970 240Z. Oh, the memories........ Sure is all worth it though, when its a driver again. I know what you mean about friends asking if its done yet.....do they think these cars just redo themselves over night?!! Anyway, your Z looks great. ENJOY!!!!

-

Zs by the Bay Event

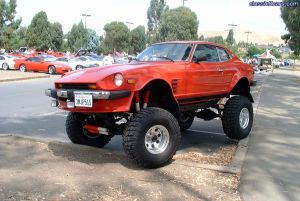

Nice photo, but why would anyone do such a thing!!! Maybe this persons next project is to turn a HUMMER into a road racer!!? Anyway, the exicution looks great!

-

Upgraded to a turbo oil pump - no start

BillD, The shaft that is between the oil pump and the distributor, has a gear on it that needs to be timed to the crankshaft so that your distributor is in the correct position (factory position) when all is assembled. On this gear, there is a little dimple that should face toward the front of the engine, when the engine is in the #1 TDC. So put the engine at #1 TDC first. If you have a repair manual, it will give you the exact details of the dimple position. Basically, you install the shaft on the end of the oil pump and rotate the shaft until the dimple is facing forward and then slide the assembly (oil pump & shaft with gear) up into the engine. When installing the pump/shaft, it is very easy to install it one tooth off. This is because the gears are helico and rotate slightly when they begin to meshtogether. You may have to do it a couple of times to get the distributor in the correct position. By the way, pull your distributor out before installing the pump/shaft. After the pump is in, then put your distributor back in. If you have timed the shaft correctly, the distributor will be correct also. I hope this all makes sences and will help you out. Have patients and good luck.

-

cam question

If I remember correctly, you will need new cam followers for your new cam, as the old followers have taken a set (worn to match) to the old cam. New followers, would mean new rockers. The actual follower is the part on the rocker that bears against the cam lobes. Maybe someone else here will confirm this information.

-

Center dash panel

The last time I checked, about two years ago, they are no longer available new. I was going to replace mine because it was less than perfect, but had to use it because I could not locate a new one. So, if you run across one.....grab it up. If not, you may try refurbishing your old one. Good luck! By the way, mine is a 1970.

-

rear vent panel for series one hatch

I would be very interested in buying the ash-tray! What do you want for it?

-

twister muffler, B.S. or does it work?

I'm not familiar with the twister, but it looks like a nice unit. However, it does specify that it's a race muffler, intended to reduce noise levels at a race track. You have to wonder if it would be quite enough for street use. If you install them, let us all know how they sound. Good luck!

-

Drag Racing Information

White94cam, I don't mean to be rude, but do 240's look like drag cars??? I think not! Do they look like sports cars that go around corners well??? Affirmative!!!

-

Carb Question's

Xargon321, That flat nut they describe is the knurled knob, with a ball bearing, you have at the bottom of your carbs. You may want to check your float adjustments before you move forward. Once you have played with your SU's a little, you will begin to see how easy they really are! By the way, do you have a UNI-SYNC to balance the carbs air flow? If not, buy one. Pretty inexpensive at most auto parts stores. Good luck!

-

ArtCenter Classic

-

ArtCenter Classic

-

Speaker wiring

Tanny, If you are going to run new wires for the rear speakers, use large gauge multi-strand wires. Doing this will insure better high frequency responce. The small gauge stuff that is typically used in a long run to a speaker will degrade the higher frequency responce. ( The longer the run, the more the degradation). That one reason why MONSTER CABLE uses such a big cable. Just some food for thought!!!

-

Unused Rebuilt Head

TexasZ, Before you install the head, you may want to lay a straight edge across the head just to make sure it is flat and true. Check it from end to end as well as across. Also, if it looks like its been milled down (resurfaced) check that it has not been milled too far. I've read that too much milling can cause problems with the cam tower height. There's a post some where on this!!? I don't know the details on it however. Just something to consider.

-

Window weather stripping

Victor, I saw a post some time ago that said it is available from J.C. Whittney. I will look through my notes at home for the part number on the item. Will be able to post it some time next monday (07-28-03).

-

suggestions needed......

dero, Just a suggestion.....save up some $$$ and get yourself a 82 - 83 280ZX 5 speed and 3.90 gears. You will be so happy you did. I found mine at a pic-a-parts for less than $200.00 and that included an R200 diff with 3.90 ratio. Of course I had to remove the parts myself. If you install only the 5 speed with your original gears, your gearing will be less than ideal. Good luck on your adventure.

-

2" english Su's..anyone used them???

Datfreak, Type in REBELLO RACING....it will take you to their site!

-

'73 rear control arm

2ManyZ's is correct.....many have asked the same question. Review the posts, but in the mean time you may want to order up a set of new spindles, nuts, and locking pin assemblies. They are relatively inexpensive and will go back together pretty easy and it is likely that the old ones may get dorked up during removel. Nothing like having new parts on your baby!!! If you are installing urethane bushings in this location, it is helpful to grind a slight chamfer on the hub housing to facilitate sliding the rebushed control arm into place. It sure made it easier for me anyway! Good luck with your effort and let us know what happens.