Everything posted by 240260280z

-

My 78 z at the beach in hawaii

Say hi to Kammy!

-

Quarter Windows Installed

I found the quarters to be a 2 person job. 1 to push in and one to fix those wee screws. Some soapy water on the opening helps a lot. Sorry this info is late, but the next poor bloke doing the job may read this. Nice car!

-

I have broken 6 drill bits.. help!!

Yeah use cutting oil or similar for sure and take your time. Try to drill from vertical if possible and do not put any side forces on the bit when drilling.

-

Plating Nickle Acetate

http://www.americanelements.com/nioxp.html

-

Internet Etiquette

times r a chang'n

-

Decided to stop guessing and bought a colortune

Some quick carb theory: There are two forces holding your SU's pistons down at any time: 1. Gravity (constant) 2. Spring pressure F~kx + delta x (where delta x is the excursion) There is one force lifting your piston up: 1. Venturi Vacuum The carb is supposed to be constant velocity air flow through the bridge/piston venturi from idle to WOT but I don't think it is (I plan to measure and model winter/spring time) IF's - if the piston is too heavy or the spring is too strong then the piston will rise less for each cfm flowing - if the piston seal is poor then the vaccum lift will be weaker and the piston will rise less for each cfm flowing - if the piston is lower than spec at a specific cfm then the venturi effect will be greater and pull more on the piston to self correct but it will always be lower than spec AND the greater venturi effect will also pull more fuel through the orifice. So if you want to lean out at higher rpms, you have to alter the needle and at the same time balance how high the piston is at a particular rpm. The two parameters are intertwined. I think the first step to understanding these beasties is to find at what rpm the piston maxes out and hits the roof. Should it be at max RPM or before? I hope to explore. If the piston maxes prior to max rpm then the venturi will draw more fuel between these points AND it is a restriction to airflow & power. If the piston maxes at max rpm then the venturi should be CV across the rpm range. Needles will have to be cut for each variation. In your case, the richness above 4000 may be addressed by shooting an in-engine compartment video of your piston height vs rpm (use a remote USB camera).Check to see where the piston height is.

-

Internet Etiquette

You'll be over for dinner? http://youtu.be/m3N5l-URMJw

-

Any advice on lowering 72 Z?

- 1977 FSM not helping.

What month 77?(on driver door pillar plate) How many wires to oil pump sensor (next to oil filter). 1 or 2- spray bar gasket?

to The "how to rebuild..." book references enlarging the oil passage to the head. Maybe that is what Reb. does to increase flow to both oilers.- 1977 280z Fuel Issue

What month is you 77? I think they switched from afm to fuel pump switch in May of 77 . After that it would be the oil pressure switch controlling fuel pump- 1977 FSM not helping.

Do you have spark? If you have an early77 then the vane switch in the AFM should be checked as it enable/disables the fuel pump.- spray bar gasket?

I agree, blow out the oiler bar or spray-out with carb cleaner using a stray (I hit each hole to back flow then tip on end and spray from the inputs so that all 6 holes flow the same. Just use the cheap felpro gasket paper from any autoparts shop and cut new gaskets to fit the margins of the tube with appropriate holes for oil flow..- Internet Etiquette

Hey, it's "étiquette" not "etiquette".- need help removing the steering wheel!

Too late but how about: 1. Open hatch 2. Lower driver seat flat 3. Tie long rope to a tree 4. Tie end of rope to steering wheel........- 70' 240z Engine Harness Connection

- concave headlights

- 70' 240z Engine Harness Connection

Lots of info here: http://www.xenons30.com/files/1971%20FSM%20Supplement.pdf- Decided to stop guessing and bought a colortune

Can you turn the lights off and just put some aluminum foil over the device or a diffuser to send the light in many directions? http://www.youtube.com/watch?v=a9fpolCvM-8&feature=youtu.be- Weber or Mikuni carbs for 240z

- Decided to stop guessing and bought a colortune

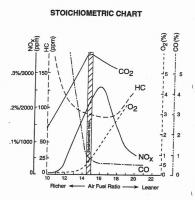

# of turns will vary with temperature. Colour tune can not tell you what is happening under load. Setting jet depth to spec then reading plugs is most likely similar or better in results. Measuring gases removes most guess work. An interesting phenomena shown on the graph below is that HC's increase when pig rich and also when very lean.- Finally clanked the clunk!!

- Anyone here live in Santa Clara area / work at Google?

Anyone here live in Santa Clara area / work at Google? Is so and you can answer some questions please pm me.- Finally clanked the clunk!!

The so-called Ron Tyler mount is over rated and far too complex. Easier Mounts: The Blue Racing Mount: Running stainless steel strap/banding under the differential neck (between the differential and the front mount) then wrapping it under the cross member and binding the strap there will do the trick and come in as the most lightweight and economical solution. Some correctly placed rubber and voila race ready strapping differential. Here are two other variants I like:- Garage Cabinets

- 1977 FSM not helping.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.