Everything posted by 240260280z

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

Fuel Bowl Needle Valve Found all the parts (Everything will workout if you let it) Note the black rubber nose on the needle. Installed The float. Note: the tab in the middle is adjustable by bending. To install the float, a free floating pin is used. Closeup of how the float presses against the needle valve Fuel filter and banjo joint Detail Locking fastener. Same

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

The Parts Install shock mount washer Install rubber shock mount Install mounting shaft Some images of the fuel bowl Hitachi Logo

-

SU Mod: Sealing worn throttle bushings

Excellent point! Presently the side force on the shaft is minimal as the O-ring is very low in height. As well, I am guessing that a leak would suck the washer in closer, especially at idle. I could put a thinner washer there to completely unload the butterfly valve but I did not have one here in NJ. Maybe I should just drill out another plastic screw cap, sand it to the correct height then glue it on... yes I think that would be even better! At $0.20 each it is not a risky venture. Thanks for your insight! Another set of eyes and brain is great!

-

SU Mod: Sealing worn throttle bushings

Nah, I defined thrifty canuck eh? Lets hope the engine heat does not loosen the glue or it will be RTV time.

-

what piston rings i need?

The microfiche shows a part number 12033-P7910 replaces 12033-P7900 replaces 12033-P8370 Reference: http://carfiche.com/fiche009/s130/2/c07.gif

-

Modern material for making new interior firewall insulator?

I am fortunate and have everything out of the car. I just need to make a new one. I tried to order one from VB/BD yesterday but no availability.

-

fasteners for trim panels

What is the actual hole diameter(in mm) for the pin-clips?

-

Tranny Oil

Synthetic is ok. Just make sure it is NOT GL-5 gear formula with sulfur.

-

Cracked Head? In Need of an Experts Opinion!

Thanks a million Phred! I appreciate your intervention

-

SU Mod: Sealing worn throttle bushings

A plastic cap (screw cover) from ACE hardware's parts bin and sealant/goo/glue seal the outside bushing nicely. Installed A thin washer and an o-ring seal the inside bushing with negligible effect on the throttle return.

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

The limit of 10 pictures per post bumped this one: Exploded drawing of throttle assembly Idle set screw and spring. Note the fine thread. Installed.

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

Throttle Assembly parts in their relative positions. Throttle shaft. The first part is installed. This is the idle lever. A set screw pushes it down to open the throttle and increase idle speed. Next is another plate. This is just the WOT stopping plate. A washer is installed. Grease it well on both sides. Next is another plate with a connecting rod to the choke assembly. You have to twist and bend a little to fit this one. The first step to fitting is to insert the rod into the choke assemble. The way this works is very simple: As the choke is applied, it pulls the rod. In turn, the rod turns the throttle assembly which opens the throttle a little and increases engine rpms when the choke is on. Another sleeve is installed. Note that it fits in the plate above. Use lots of grease on the ends and inside. This is the plate that is pushed by your foot via the throttle linkage. A lock washer holds it all together A final deep bolt with recess is installed.

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

Insert the nozzle and prepare the hardware. Install the sleeve. Insert the screw and lock washer. Insert the flat washer on the other side. Use lots of grease. Move the choke lever and rotate the nozzle to position the long plate so that the screw aligns with the threaded hole in the nozzle. Snug the screw in place. Test the choke functioning by lifting the lever. The nozzle should drop and no binding should occur. Release the choke lever and the nozzle should snap up into place without binding.

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

This is the most complex assembly. I started to photocopy a step-by-step but I messed up so I got tired and reassembled and took fewer ones. Here are the key parts loosely in their relative positions. The long plate on the left lowers and raises the jet nozzle. The plate on the right is connected to the choke cable. The assembly is also connects via a small rod to the throttle assemble (as the jet is lowered i.e. choke applied, the small rod opens the throttle a little to give a faster idle. Lots of grease helps this assembly work well. Here are the remaining parts with the items in the above photo assembled. A spring and washer are installed on the body. The rest of the assembly mounts on top and looks like this: The bolt that holds it together needs antiseize and grease. Here is another angle with interconnection details: And another:

-

Cracked Head? In Need of an Experts Opinion!

This is #6 in the E31 I am restoring. Looks like water but maybe detonation? Sure it can be ground and welded up then machined back to shape like a racing head plus new seats but I went for a Maxima N47 with custom cam from BMC in Arizona.... and probably saved $. Unfortunately, I am now reassembling and noted the corresponding piston top from #6 is peppered with small holes and it is 5grams less that the others. I may need that tended to with a welder and surface grind.

-

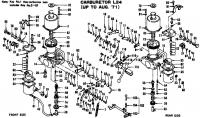

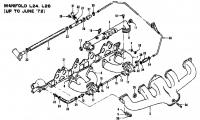

Early 240z SU Carb Parts List and Exploded Diagram

Note: I compressed all files into a .zip archive (winzip.com). This way you can get the big parts list in its full glory and clarity. I had to do this as, unfortunately, this website limits image size and compresses images so the parts list picture below is not very useful. 240Z SU Exploded View and Parts List.zip

-

Running rough then stalls

Oops! I even looked at that too. Duh I am sorry :stupid:

-

Cracked Head? In Need of an Experts Opinion!

Yikes.... it is those darn exhaust liners that are the cause. They expand and contract at a different rate from the aluminum that surrounds them. They probably conduct heat faster as they are thin and less of a heat sink than the surrounding aluminum. Time to get a new head. You can use that one for porting experiments. A Maxima N47 would work nicely but you have those pesky liners again. Mine cracked in exactly the same spot: btw this follows my question last week as to why Nissan placed the two exhaust runners for 3 and 4 side-by-side in the head? So much heat in one area is unwise.

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

Below are a drawing and photo showing how to set needle depth in the FSM. The only difference in this technique is that the needle shoulder is above the bridge by the depth of the stand-off. When the nozzle is lowered to operating location, this should not make a big difference however, with the NON-FSM method shown above in Part 7, the nozzle top is matched against the needle's shoulder, so any mechanical differences in the sleeve, washers, stand-offs,etc between carbs will be nulled. One turn of the Idle Adjust Nut on both carbs will yield the same nozzle/shoulder gap and effectively "annular fuel orifice size".

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

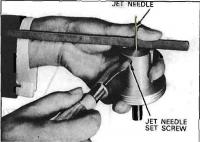

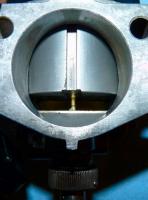

The needle can be placed at nearly any depth in the piston; however, there is only one correct depth. Lubricate the needle hole and loosely fit the needle in the hole. You may need to use the side screw to hold the needle if it is too loose. The needle should be nearly fully out of the hole (Don't worry, we will push it back in). For greatest accuracy, you can reassemble the suction chamber and secure all 4 (3) screws as mentioned above. Turn the Idle Adjust Nut all the way up and insert the nozzle. Drop or, in this photo, press the piston into the nozzle. The shoulder of the needle will seat tightly against the jet at the correct depth. Here you can see the shoulder is out of the hole at the correct depth. Another shot. Be careful because if the needle is loose, it can drop out or fall back in the hole. Correct tension on the needle is needed to do these steps. As mentioned above, the side screw may be required to loosely hold the needle in place. When satisfied with the needle's depth, slap some antiseize on the side screw and install. Lock it up. If you are wondering if you bent a needle, here is a quick way to check: Throw the piston and needle in the dome and spin. You can try to straighten or you can get a new one. You can also spin it in a drill press for inspection and straightening.

-

SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

-

Hitachi SU Carb Jet Alignment Tool DIY for Datsun Nissan 240z

- SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

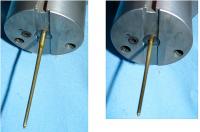

You can build your own alignment tools here: http://www.classiczcars.com/forums/showthread.php?43152-Hitachi-SU-Carb-Jet-Alignment-Tool-DIY-for-Datsun-Nissan-240z Mark I: Aligns the nozzle in the sleeve Mark II: Aligns the sleeve Fit alignment pin to piston. (use grease in the hole). Install piston and chamber. Here is where the tool aligns the Nozzle Sleeve. Note the sleeve is loose at this point and can move. Strange photo... note that the 4 (3) rusty screws that hold the chamber are all evenly tensioned to just less than snug (see the lock washers are not compressed). This is how you want the chamber attached for the next step. To align the chamber, spin it Counter Clock Wise (CCW) to full stop, then spin it CW. Note the limits and try to set the chamber in the middle of these. Continue to tighten evenly like car wheel lug nuts... opposites. You can now lift and drop the piston. It should rest flat on the bridge. Here is a photo with no flash showing the piston on the bridge. The only light is from the two hole cut in the piston's bottom (due to the dome removed) and a razor thin gap between the bridge and the piston bottom (due to the inserted stand-off mentioned above). Normally you can see through the grove in the piston bottom but the alignment tool is installed and blocks the light. Here is how to tighten the Nozzle Sleeve Set Screw. A thin walled 19mm socket with a T handle will work even better. Note: If you only have a stock needle to align with, install it as well as the nozzle then tighten the Nozzle Sleeve Set Screw slowly. When doing this, hold the carb vertically and move the piston up and down ensuring it hits the bridge and the needle does not bind against the nozzle. The Nozzle and the alignment tool are same outside diameter. Here is a shot showing the centered sleeve (left) and the centered sleeve with the nozzle in place. If you want to double check nozzle alignment you can use this second tool that aligns the nozzle and sleeve at the same time.- SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

- SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

Reference: Suction Piston Reference: Piston bottom. Note the centre groove and the two holes on each side of it as well as the needle hole in the centre. Note 2: The black insert next to the needle is an inserted stand-off that prevents the piston from sealing against the bridge. This and the centre groove allow air to flow across the bridge when the piston is down Reference: Piston front with guide groove Reference: Top of piston. Note the oil well and two holes on each side of it in the floor. Insert plastic/nylon washer over oil well and push to bottom Insert Spring. Ensure it surrounds the washer and is centered. Reference: Suction Chamber. Note the passage in the top front. This points away from the motor when installed. Reference: Inside the suction chamber Reference: Oil plunger assembly Oil plunger installed - SU Reassembly Step-by-Step [Part 1 Tear Down /Torn n Tattered /Worse for Wear n Tear]

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.