Everything posted by 240260280z

-

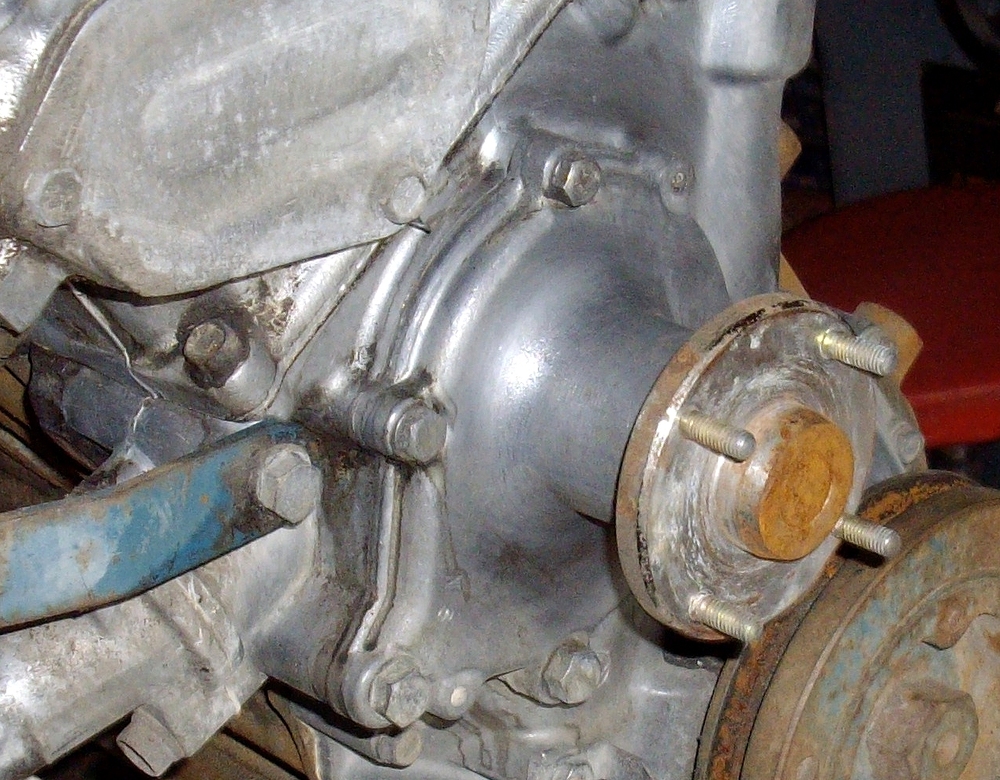

Brake Booster Disassembly

drilling a 2X4 to make a lever and a big vice to hold it helps. Caveman mode for that one.....

-

Setting Fuel Level Weber DCOE

The float will always close at the same level no matter how big the basin. It is vertical height only from the lid to the float. Fluid density is the only other factor. Think of pressing the lid into the surface of a fluid rather than filling the basin... it may seem more logical with the reference being the lid moving up and down over the surface. In the experiment we did, had we have used a bath tub, we would just have to pour more water in but the results would be the same. That 370z is messing you up.

-

Greetings from New England

Be sure to join Z Car Club of New England! Great club!

-

Setting Fuel Level Weber DCOE

You can use the gasket or compensate for it. Check the pipette tool from sk racing.

-

Need Parts for Early 240z

Interior Hatch Area Panel that Covers Tail Lights: No access holes for bulbs: Early Water Pump (Smooth) Rad Cap (with Japanese Text)

-

Variations on radiator caps

HLS30-00249 came to me with a faded Cadmium cap like the one above. It is probably not original but it is like other earlier caps but w/o the Japanese text.

-

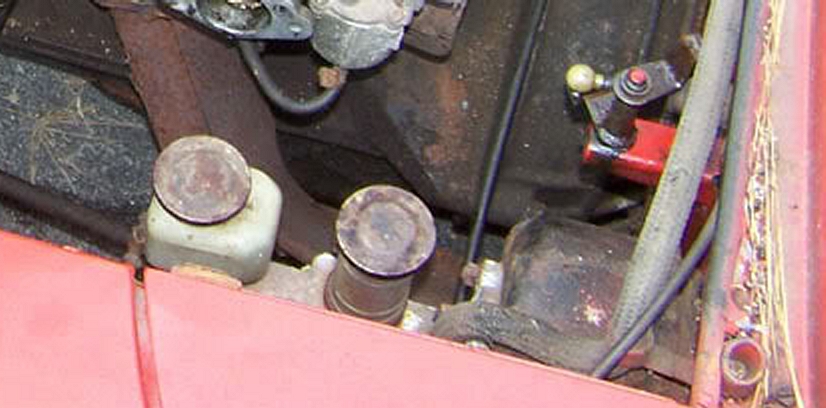

Early Brake Master Cylinder Covers

- Caswell Plating

Another home brew: http://www.mgexp.com/phorum/read.php?2,2013753 1 bottle White vinegar as the acid base for the plating solution 5T Epsom salts (table salt creates chlorine gas - "Epsom" is magnesium sulfide) to improve conductivity 10T White table sugar (as a "brightener" ) 1 drop dish soap (as a water "wetter" ) 3" wide coil of zinc (from the Home Depot roofing section - used to prevent moss on roofs) "Acid Safe" muriatic acid Acetone (small metal or glass container with a lid) Baking soda dissolved in a bucket of warm water (to neutralize the acid) Battery charger or 6V power supply - one dry cell battery works just fine. ***Mix the sugar, salt and vinegar. Line a small plastic tub or pail with the zinc and make a triangular fold in the flat stock so that one end sticks up and over the side as the negative electrode connection point. I put a small piece of copper tubing across the top and bent up some copper (14g romex) wire S-hooks to hang my parts. The battery charger Positive (+)terminal goes to the zinc, and the Negative (-) goes to the copper bar or the part to be plated. When you hang the parts off the copper into the solution, it completes the circuit. ***Wire wheel all loose rust and scale and crud off the parts, clean with hot soapy water to degrease if necessary. Put part on copper hook. Dip part in acid (don't breathe it) to de-rust, then in baking soda and water to neutralize, then dry with paper towel and dip in acetone to completely degrease (denatured alcohol works too). Then let the acetone evaporate and place the part into the vinegar and salt bath by hanging on the copper bar. ***Part will plate in about 3 minutes. If you leave it in too long, it gets lumpy. Take the part out, neutralize in baking soda/water. It will appear black. Wire wheel until shiny. Then dip in acetone again to clean and re-plate. Think coats work better than thick coats. After two or three coats you can wire wheel (a soft metal wheel or brass wheel is good) to a dull shine. As the day went on, the parts plated faster, I think because the vinegar was "polluted" with more zinc ions that it had been initially. If you leave the parts in too long, the copper hooks start to plate the parts with copper, so again, thin coats are best. For small parts (like screws) instead of the hooks you can wrap them with copper stranded wire to hang them. I am now making up a copper plating bath as well. For pitted parts, you can copper plate them to fill the pits, then plate with the zinc. The zinc is shiny-er over copper than pitted steel. I also want to experiment with the amount of sugar and salts. Too much salt isn't bad - it just precipitates out and sits on the bottom of the bath. I want to try it with no sugar (you can always add more) to see what the result is.- Hello from across the pond! Searching for a 240z

I wonder if the brakes were soft when they parked it on the lot.- Caswell Plating

If you just want silver coloured zinc (like door strikers) The plating solution recipe (which you can scale up or down as you like): 1 liter of vinegar (5%) 100 grams Epsom Salt 120 grams sugar 8 - 10 square inches of zinc pieces Add the Epsom Salt and sugar to room temperature vinegar and stir until dissolved. Add the zinc pieces and leave lightly covered for 24 hours. http://thefactoryfiveforum.com/attachment.php?attachmentid=29064&d=1400040203- Caswell Plating

old brightener trick was sugar! http://thefactoryfiveforum.com/showthread.php?14392-DIY-Zinc-Plating-for-Donor-Nuts-and-Bolts "5) Sugar from the grocery store (plain old table sugar). Sugar is the "Brightener" of the plating solution. It actually interferes with the formation of zinc crystals, causing many smaller crystals to form on the surface instead of fewer larger crystals, thereby improving a frosty looking surface to a smoother more reflective one.- Caswell Plating

I had the same problem however when I said I wanted 1% they said no problem I have 4 gallons of the stuff... minimum order. I think vinegar is more dangerous!- Caswell Plating

Sorry the internet died I dug up the old thread: http://www.britishcarforum.com/bcf/archive/index.php/t-8760.html Pictures are gone but the Nitric acid sure made the parts look mighty purdy. Here is the good stuff from the thread (in fact read the full thread!): John Loftus 11-23-2005, 11:58 AM I use the bucket that came with the kit and it works fine although the rectangular tank would probably be more efficient use of space. I use a small aquarium air pump (I bought the one from Caswell when ording additional supplies and it was only $15). Don't use an air stone on the line .. the large bubbles from the air line work better to stir up the mixture. The line wants to float so I wired a nut to the end to drop it down to the bottom of the tank. I have changed my methods just last week. I learned from Sean that chromate conversions add to the durability of the zinc finish so I purchased the clear (blue) chromate dip from Caswell. I also obtained some Nitric acid that has been diluted down to 1% solution. Now my process is: 1. Clean, prep parts by bead blast, tumbling or wirewheel. 2. remove all traces of old zinc with muriatic acid (diluted 4 parts of water, 1 part of muriatic). Leave parts in until bubbling stops. 3. rinse parts with water and then use fine brass wirewheel on grinder to shine parts, clean threads, etc. 4. degrease parts using diluted (about 20%) purple industrial cleaner (from Home depot) or Simple green with brush. Rinse with water 5. Wire parts and zinc plate. 6. Dip parts in distilled water bucket 7. Dip parts in Nitric acid for 1 to 5 seconds (this brightens the parts and removes the brown tint of zinc plate solution) 8. dip parts in distilled water bucket 9 dip parts in blue chromate bucket for 15 to 30 seconds. 10. unwire the parts and put them in shop oven 140 degrees F for 15 minutes or so to dry the parts. The parts now look store bought and the zinc is far more protected (some of my early experiments were losing their shine quickly because the zinc was exposed to the elements) http://www.loftusdesign.net/zinc11_23.jpg- Caswell Plating

I read that a dip in nitric acid helps to brighten in one of the links earlier in this post.- Datsun-240z Vs Fairlady-z432

Carl, a friend here has the same wagon! Tres cool!- Type "B" Transmission Production Dates

Hi Guys, Try this nice PDF reader from Canada: hmmm this seems screwy cant copy and paste into this box? Go to foxit.com- Type "B" Transmission Production Dates

http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-assembly Looks like 8/71 was when production changed. See pdf attached datsun-240-transmissions-and-options.pdf- Factory Series 1 ALT & SMOG Belts???

try these: http://www.zcarsource.com/smog-pump-belt-240z-260z_8_77827.html http://www.thezstore.com/page/TZS/PROD/15-6105 The type of pulley will affect size as well.- Caswell Plating

I'll be in the fray soon! Just got a 30V 5A Power supply and vibratory tumbled all of my extra hardware. Now to open the Caswell kit that I bought way back in 2012..... vintage plating.- Early Brake Master Cylinder Covers

Thanks! I noticed 2 different covers on #249 and one in the spares box. I have two correct ones. Now to get the black paint off them.- Early Brake Master Cylinder Covers

- Brand New Set of Complete Reproduction 240z Door Panels

They go for twice that in Japan on Yahoo Auctions https://translate.google.ca/translate?sl=auto&tl=en&js=y&prev=_t&hl=en&ie=UTF-8&u=http%3A%2F%2Fpage6.auctions.yahoo.co.jp%2Fjp%2Fauction%2Ff187800981&edit-text=&act=url- Brand New Set of Complete Reproduction 240z Door Panels

Mercy!- Anyone running MegaSquirt in their Z?

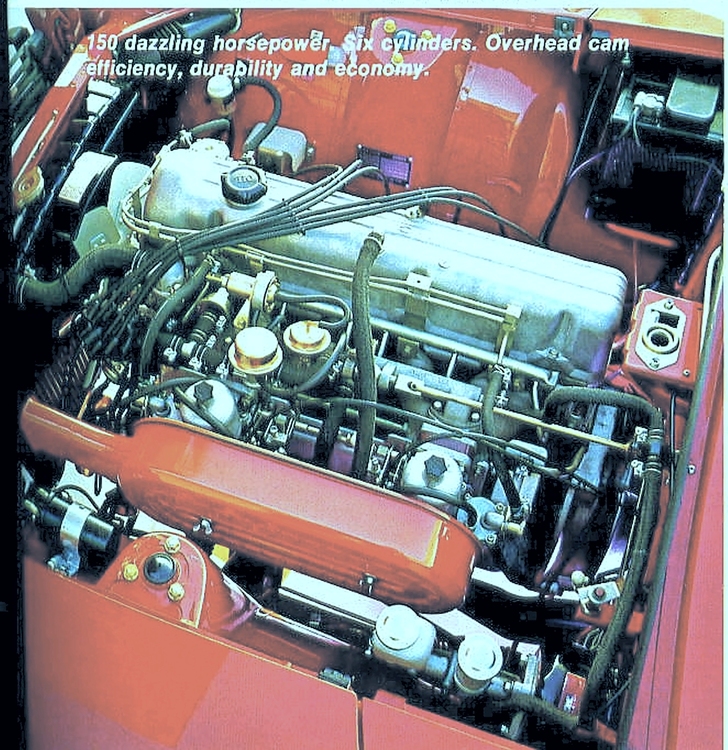

You will have close to NA 290HP & 250ft-lbs ...... you are in the class of the early BRE and Sharpe cars and modern Rebello's!- Exhaust Header and Year

Trying to figure out what exhaust headers went with the year for North American Z's Here is a stab: 240z E30 E36 N33 (U98 non-Emissions) 260z E36 280z N42 N47 280zx U87 P71 W48 Corrections, additions are welcome. - Caswell Plating

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.