Everything posted by 240260280z

-

freeing corroded tube in tube...ideas sought

Got one camber adjuster rotating after a few cycles of heat, water, slide hammer. Now working on the other adjuster. Not fun work. The adjuster only works easily with the wheel unloaded.

-

Engine woes-just had to walk away

I think you found the problem

-

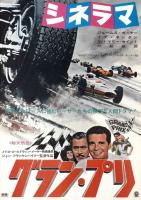

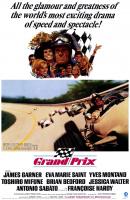

Garner's Grand Prix

- Garner's Grand Prix

- Moving to the Digital age

How's the forest fire situation where you are? We are thinking of you every time we hear the news for BC.- Triple Mikuni thread

Is it possible a different circuit is leaking such as a cold start/choke? I'm not sure about Mikuni's but it can happen to dcoe's. Also check jet diameters. A poorly drilled made in mainland china jet could be the culprit. ' You can move jet and e-tubes around to see if the problem moves to eliminate items.- Progress on rust repairs

Dr. 240z bought his series 1 (Jan 71) Z in spring 71 in BC as none were available here on the east coast of Canada.- Radiator cooling capacity is dropping

Is the pump working correctly. Sometimes the timing cover erodes behind the pump vanes.- Progress on rust repairs

Looks great. Scrutinize the cam for wear wrt noise.- B 17 bomber

Cool. I saw a B25 Mitchell in Seattle a few weeks ago. Summer is great for this stuff.- SU piston and dome have matching casting numbers

I missed that much tracking but I will look on the carb bodies for numbers. Funny thing is that the fuel bowl tops have a 1 and 2 so it may trace from there.- SU piston and dome have matching casting numbers

I just noticed this. The Domes have a 1 and 2 inside on the roof that match the piston's 1 and 2. Not sure if it happens for all years but it does on these 4 screws.- Lemon Carb Cleaning

OK I gave it another go: Enamel pot on the Barbie with lemon juice and some vinegar. Rolling boil for ~ 20min is the trick. It degreased the carbs and the carbon flakes off. Here are some pictures:- Pass side rear break sticking....

http://www.classiczcars.com/forums/misc-s30/43793-lubricating-refreshing-cables.html- My Datsun 280Z "Rustoration"

for sound deadening you can do the tap test to hear what vibrates. Another way would be to mount a speaker on a location then use a software tool to do a frequency sweep. You should hear the points were resonance occurs (excitation of the metal). The speaker's magnets and steel car shell make this easy to do but a super magnet may also help couple the speaker to the metal. If you use a magnetic parts bowl to couple the speaker, remove the rubber base as you do not want isolation of the speaker from the body.- 240Z Design Development Process - Exterior

Looks like more here: IMCDb.org: "Full Throttle, 2004-2005": cars, bikes, trucks and other vehicles- faster amphibious car

- freeing corroded tube in tube...ideas sought

Thanks guys. I like the drilling idea.... another tool for the upcoming battle. I'll keep you all posted. btw I just tried the Evaporust on a relic and it worked great. I am about to pick up a dishwasher and recirculate evaporust through it like a parts washer but it will be more of a wetter/heater for big objects that can't be soaked.- freeing corroded tube in tube...ideas sought

Thanks CO It is a 2004 RAV but Toyota enjoys torturing us all with this design and lack of factory antiseize. It is like a Toyota engineer saw the spindle pin problem from 1970 and said lets do this in 6 places on every model after at least 1996. (front and rear camber and rear toe and both my ravs are this design/lack there-of). So far, with patience, I have the centre locking bolt out as well as the eccentric nut/washer part. I have a slide hammer so I was considering running a shaft through the eccentric tube and pull-hammering with a nut and washer applying the force where the eccentric nut had been. I was also considering making a puller to draw the eccentric out but there is not much to use for a base for the puller plus it has to clear the eccentric. A come-along on a distant tree may be another possibility but it may just slowly bend the sheet metal mount for the control arm. Using a breaker bar on the eccentric bolt may be something else to try but with the frozen eccentric still in the captive sides, I don't think it is a good idea at this stage. I'm wondering if there is another trick or when to try the heat. For heat I am thinking that propane on the eccentric face/hole followed by a garden hose of water shooting through it may draw the heat out of it fast enough to contract and break the bond? I am guessing that a lot of water will pull more heat more rapidly than spraying canned freeze?- freeing corroded tube in tube...ideas sought

OK it is a toyota. The rear camber adjustments are eccentric's that go through the control arm bushings. These things are like the wonderful spindle pins in that two cylindrical surfaces corrode due to water. The difference is that the hollow eccentric tube fits in a slightly larger tube that is moulded to the bushing (see cut up lca end bushings and eccentric tube that I found on line). Any ideas on how to separate? I will build a puller and spray with penetrating oil but I am thinking that controlled heating then cooling of the eccentric may help break the bond between the surfaces?- 1970 240z in NY - AWESOME AND CHEAP $5K

I'll ask for pics.- 1970 240z in NY - AWESOME AND CHEAP $5K

A friend in Toronto got it Thanks for the heads up.- Triple Mikuni thread

Jim, That last sentence seems like you(Jim) are an organic O2 sensor How about this variation: Maybe a straw from the tail pipe to a nostril and a motorized fuel height screw controlled by the choke lever (for adding fuel when you need it w/o the jet swap).- new member

- Steam Powered Z???

I installed ~5 with no problems. - Garner's Grand Prix

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.