Everything posted by 240260280z

-

Reproduction S30 parts NLA.......

Well there is a member on this site that makes the covers for the Gnose w/o the trim so it would be great to have the trim made for those. I can send you some MSA clears that I have for stock buckets.

-

Untamed Z's in the wild

- Reproduction S30 parts NLA.......

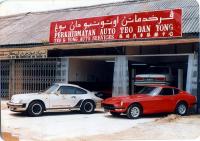

Bright metal surrounds for stock and gnose light covers.- ZCar owners in Malaysia

Happy new year ZAF! I know of two from way back. They now live in NJ and Alberta. They spoke of fun times with their Z's. Here is a photo I have of one: Notice the Z w/o parking lights, logos and passenger wiper- Harmonic Damper problem

- [2013] What did you do to/with your Z today?

Thanks for the Tradition Arne! HAPPY NEW YEAR.... maybe a Z in 2013 for you? Picked up a Weber 55DCO /SP Crazy big. 48mm chokes, 180F9180 mains, 60F8 Idles, 0Spill just before the New Years party... finally looked at it now... not a 50.- Rear Suspension Rebuild Thread

A scissor jack can spread the control arm to fit the bushings w/o trimming.- When is the best time of the week to end an Ebay Auction?

Since you're in Fla, this is not important but in the north, people get sports car fever ~ March-April and prices are usually higher. Nov. is best for buyers in show rooms and close to Christmas is when used car sellers will take most reasonable and some below reasonable offers.- Bought another Z yesterday :-)

Nice ZZZ!- Harmonic Damper problem

I bought two, one for me and one for a resto. The one for the resto is to go on in the spring after it is machined. I am not sure if it should now.- Can anyone identify this break upgrade it is on my 71 240Z

Hey Jean Philippe! Philip here in NS. Happy New Year!- Harmonic Damper problem

Must ultimately be crappy metal or rubber or hardware that made it from mainland China.- Harmonic Damper problem

I am a sucker and bought two of those. They do not fit. Seeing that they now self destruct on top of not fitting...what a joke that company is for making it, motorsport for selling it, and me for buying it.- Mustache Bar Bushings (rubber)

- Single DCOE50mm

Thanks guys, I gave the balancing some thought and a method for addressing. Here is the idea: Test bench flowing of air into the manifold at the carb mount and measuring the flow out at each runner could possibly simulate the manifold in use. Some extended dividers/vanes inside the manifold at a point between the 3 converging runners may enable some tuning of the flow between adjacent runners. However this would be for the 3 runners being side-by-side. With further thought: converging 3 runner tubes at the single carb throat must have symmetry rather than being side by side as in the stock manifold to balance better. An analogy would be like the collector where the exhaust runners converge on a single pipe. Next step is to ensure the 3 runners' impedance is similar. I did a bit of web searching and found others seem to point away from a significantly sized plenum.- Fusible link update

Hi Mike, I am not sure of the burn through rates of fusible links but the slo-blow fuses in the link above have a max/min time. They are convenient for circuits like wiper motors that have a big in-rush only on start-up.- Fusible link update

Hi Tomohawk, That is a great link! Thanks! Here is another similar but not well known solution that can help in some special applications: http://www.littelfuse.com/~/media/Files/Littelfuse/Technical%20Resources/Documents/Data%20Sheets/313_315.pdf- Single DCOE50mm

Air flow will be about the same through the carbs orifices so not much of a difference there for power. The Weber has 3 circuits where as the SU has one so air/fuel can be tweaked more conveniently on the webers for different conditions however I take the point that needles are infinitely tuneable. For the manifold, having 3 runners and optimizing the same distance and curve impediments into each carb throat will be the challenge... sort of like building an exhaust header. Maybe a plenum like on an EFI intake as an intermediate buffer would also work. Still building up ideas so thanks for the quick input- Single DCOE50mm

I am thinking of making an intake manifold for attaching a single 50mm DCOE weber. It would simply replace the two SU's. I am just at the concept stage and about to buy the 50DCOE....any suggestions/input on how to optimize the design or (been there done that) is most welcome. I do not think it will have any performance benefits but it should be more tuneable.- '78 Clutch Engagement Issues

Hi Jamie, Here is a quick overview of hydraulic systems: 1. A system is made of two plungers at each end and a line connecting them. Inside is a fluid that is contained by seals. It is a closed system. 2. A push on one plunger causes a corresponding movement of the same distance and force at the other end's plunger. (as long as both plungers have the same surface area (piston diameter), 3. By making the piston of the pushing plunger bigger, more fluid will move and the far end plunger will move forward more. (note 1) 4. By making the piston of the pushing plunger smaller, less fluid will move and the far end plunger will move forward less. (note 2) Note 1: For a car brake system, a bigger diameter pusher will cause the brake pedal to feel harder faster as more force (pressure in the system) is "caught" by the piston face as it is proportional to the surface area (i.e. psi and bigger has more i) Note 2: For a car brake system, a smaller diameter pusher will cause the brake pedal to move farther but not feel as hard to exert the same braking force on the wheels... again it is due to the psi geometry and the ratios of the surface pushing and the surface being pushed. The clever way pressure systems works to amplify applied pressure: If you have a pressurized chamber (like a diver's air tank) and two plungers attached (one which has a surface of one square inch and one that had a surface or two square inches), then if you fill the take with air to 1,000psi, it will take 1000 pounds of applied force on the small plunger to hold it in place. It will take 2000 pounds of applied force on the larger plunger to hold it in place as the surface area is 2 sq" and the pressure is 1000psi so the force is 2000 pounds. In your case, you must ensure that the master clutch plunger moves sufficiently far by the pedal so that the slave plunger moves sufficiently far enough to move the clutch yoke. Sometimes the problem is that the master piston is adjusted incorrectly and its plunger rod's resting state is actually well into its excursion. If this is the case, back the rod out towards the cab as far as it will go. It could also be that your replacement master is made to a high Mainland China quality and the rod is too short or does not have enough thread to allow for full adjustment. If so, you may have to scavenge the old one or get a longer one from another vehicle (fyi I had this problem with a RAV4 master and used a rod from a Z to make it work).- Car won't rev/idle pass 3k " Video"

If you have EFI, look up the TVS switch and the idle cut feature. This is the typical cause of a 3k rev limit.- Car won't rev/idle pass 3k " Video"

If you have EFI, look up the TVS switch and the idle cut feature. This is the typical cause of a 3k rev limit.- If you've ever owned a race set you'll like this

Especially at Christmas:- Epic battle of vintage z's at 2012 Mitty

It's interesting seeing the air pressure build up with speed in the white car on the straights. The corner of the hood and inspection lid really open up and flap.- Epic battle of vintage z's at 2012 Mitty

I feel sorry for the lone BMW ~ 7:50min in when a pack of Z's gang up on him . He got spooked and cut in off the racing line only to swipe a Z. - Reproduction S30 parts NLA.......

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.