Everything posted by 240260280z

-

Anyone interested in selling cars in Europe?

My friend and I have been bringing cars into Eastern Canada for many years for our club members and for Datsun enthusiasts across Canada. We are located at an autoport on the western side of the Atlantic and shipping a car to an European port is ~ $1,500 USD We would like to start exporting Datsuns and other cars to European buyers and we would like to find car enthusiasts with entrepreneurial drives in western European countries. Restored classic automobiles are at depressed prices here in Eastern Canada due to the historically poorer economy. Fair profits and low prices to the buyers is the basic business model. Please contact if interested. Here is a car we shipped by rail to western Canada ~ 5 years ago:

-

Fuel pump

Just use the mechanical pump.

-

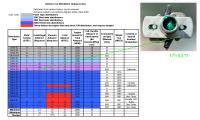

Tuning 40 DCOE Weber 151 on an L24

The plots are from a nice guy on the yahoo side draft forum. I have a theory about the rich spot at ~2,200 rpm too. It is because the top of the throttle plate pinches off with a thick choke next to the accel. nozzle promoting more flow. The accel pump will always open and push as the throttle is pressed and vacuum at this pinched spot will pull more fuel for a moment of transitition. I was banned from HybridZ so I will never join...even if I wasn't banned... some useful info there but the admin are "weenies" I am sniffing at the tail pipe like you. The copper pipe I made is 600mm long to get a better sniff at idle as it goes deep into the exhaust system.

-

Plastic Sheet Behind Door Panels

Yeah, it comes off easily. Honda has a nice latex like sealant on my S2000 that stays fairly tacky 9 years after the car is assembled. I am not sure what they used but it has the dry chalk-like properties of latex.

-

POR / Undercoating

This one is more interesting... keep Por out of the sun and it works nicely: http://www.drjing.com/Mini/BLOG/SideBySide.htm

-

POR / Undercoating

Not a very scientific test as the data became useless when they put the plate in a pool and on a roof but interesting: Rust Bullet Prepped seems to be the way to go. http://www.thesamba.com/vw/forum/viewtopic.php?t=131753

-

A very clean 260z for sale. What do you think?

Yeah beautiful resto. I am not keen on the orange bumpers and orange interior "additions" but all of this can be changed back easily. The plastic door handle inserts are not there and the chrome finishers on the door pulls are black so the resto guys missed a few minor items.

-

72 240z wont start

if your car just has a mechanical pump, it made need to be primed. You can try filling the float bowls for each carb to get it to run then it should draw enough fuel to the pump... or you can run from a gerry-can to the engine fuel filter... be sure to have the return line from the fuel rail go back to the gerry can. Check your hose/lines to tank by blowing into it at fuel filter inlet and at fuel rail outlet. You should hear bubbles in the tank.

-

Tuning 40 DCOE Weber 151 on an L24

Hi Lazeum, The point I was making is that a/f at idle and progression depend on where you initially set the throttle plate AND covering /revealing the first progression hole. I am not sure what is ideal. In my case, I can set 900rpm idle with little idle enrichment and run lean at cruise or set 900 rpm with lots of idle enrichment and run rich a cruise, all with the same 55F11 idle jet. There is important interplay between the two screws. As well, my transition to mains is not very different in both cases as the fuel level is high at 25mm down and the mains comes in quickly. I have more experiments to do but plotting a/f against initial throttle plate position is one that I look forward to measuring. Yes you are correct, the acceleration nozzle can be part of WOT tuning. Here is a plot of its effect. The second plot has the accel/ circuit completely blocked and out of service.

-

Tuning 40 DCOE Weber 151 on an L24

Yeah I got off it a while ago because interesting exploration was mostly by one or two chaps and often poo-pooed by another if their findings were not within his personal limits. Some great data in the archives there. I just jumped in today for a much delighted "told you so...and so did the data from last year". That forum has so much potential.

-

Clock not working on '77

yup. fixable but maybe look for a quartz version to swap in. Or you can send it here for repair: http://www.zclocks.com/identify-clock-types.html For the analogue clock, I read that cleaning the works and maybe changing a cap and/or transistor is all that is usually done. Search the archives here.

-

Tuning 40 DCOE Weber 151 on an L24

Something interesting from this site: http://www.webercarburatori.com/?p=handbook&s=2 The main features of accelerating pump operation are the amount of fuel injected at each stroke and the promptness and duration of each injection. When tuning up for proper adjustment settings, the pump jet and drain diameters are determined by trying to minimise, as far as practicable, the amount of fuel injected. Often, also the direction of the fuel spray proves to be a significant factor. Generally, when engine operates at high rpm rates the pump jet (diameter between 0.35 and 1 mm) is subject to a vacuum sufficient to produce an uninterrupted flow of fuel, that is, it performs as a high speed jet and its role falls under the adjustment setting data. I had brought this up to Keith Frank on his forum when I saw it in data and another forum member did a few additional runs to verify what I saw (a "leaky accelerator circuit"). I even suggested turning the jet nozzle around. Now it is documented in a Weber manual so I am happy:) My solution for a Weber mod was to put small springs rather than weights over the ball valves as vibration and mass cause the balls and weights to jiggle and bounce and not seal effectively. A spring would not do this and keep the ball down until fluid pressure was applied by the plunger. Eureka! A video to prove it! Not a DCOE but the same principal: Look at the leaky accel jet spraying at the Philips screw head. I saw this on a graph nearly a year ago... now I see the theoretical! That's a Higgs Boson to me.

-

Tuning 40 DCOE Weber 151 on an L24

Correction: In theory this should be completely closed so that all air is from the idle needle port however it can not be completely stopped due to wear AND if the choke circuit upstream is to be functional! Wrong as the choke is down stream

-

Tuning 40 DCOE Weber 151 on an L24

4 (continued). The progression holes upstream from the idle enrichment needle valve also allow air to mix with the enriched fuel from the idle jet. 5. Depending on the location of the top of the throttle plate relative to the first progression hole: i. If the plate is far from the first progression hole and inboard towards the block,the progression holes will only add air to the idle mix (assumption) ii. If the plate is very near the first progression hole, the first progression hole may draw fuel and air from the idle jet due to the venturi effect at the throttle plate. This may decrease the flow out of the idle port or it may have minimal effect on the idle port's flow (unknown). Of course there will be more air past the throttle plate that dilutes the fuel mix. iii. If the plate is under the first progression hole, the first progression hole may draw additional fuel and air from the idle jet due to the venturi effect at the throttle plate and from more exposure to manifold vacuum.(assumption) This may decrease the flow out of the idle port or it may have minimal effect on the idle port's flow (unknown). Of course there will be more air past the throttle plate that dilutes the fuel mix. iv. If the plate is past the first progression hole, the first progression hole may draw fuel and air from the idle jet due to the venturi effect at the throttle plate and from more exposure to manifold vacuum.(assumption) This should decrease the flow out of the idle port however the combined flow out of the idle port and the well exposed first progression hole may flow more fuel or less fuel. (unknown) Of course there will be more air past the throttle plate that dilutes the fuel mix. From the above, as the the throttle valve is opened more and the idle enrichment screw is correspondingly closed, the idle mix will become weaker AND the idle enrichment screw somewhat balances how much fuel is pulled from the idle port vs the progression holes (i.e. taken to the extreme, a huge 2mm idle jet fuel hole will cause fuel to pour into the progression holes but the idle enrichment screw can completely block any fuel from reaching the idle port....thus the balance effect) It is clear that as the throttle valve is opened, the idle port's flow will decrease thus the idle jet will certainly affect the progression enrichment thus there is an important transitional relationship between idle and progression that must be addressed by idle jet selection. As the throttle valve opens further, the main circuit will come in. From experiments, the fuel level in the bowl will affect when the main circuit comes in. When the fuel level is high, the main will come in earlier and reduce the amount of time during progression. My intuitive recommendation for tuning the idle and progression is: 1. Keep the throttle plate as closed as much as possible. 2. Assuming timing, linkage, fuel level, mains, air flow, valves, etc are all correct, turn out the idle enrichment screws until smooth 900 rpm idle is reached. Adjust throttle plates minimally to achieve 900 rpm. 3. Measure idle A/F 4. Drive and measure A/F at low rpms and plot the transition to mains. 5. If too rich or too lean at idle and progression the switch idle jets and repeat. 6. If rich at idle and lean at progression then open throttle plate more and turn idle enrichment screw in to have more fuel pulled from the progression holes. (The acceleration pump bleed back and related piston/throw can also be given attention) 7. If lean at idle and rich at progression then close throttle plate more and turn idle enrichment screw out to have more fuel pulled from the idle hole. (The acceleration pump bleed back and related piston/throw can also be given attention)

-

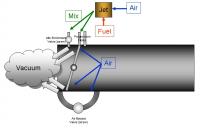

Tuning 40 DCOE Weber 151 on an L24

Stephen, I think you are going in the right direction. New chokes will change things in the upper end for sure... not sure about idle as the air flow is too low for the choke to affect anything...probably during progression that you will see a change. I read a huge post on HybridZ on DCOE configurations but most of it is useless as there is very little useful reference data coupled with a possible "hillbilly" element.I figured the "Use a configuration that someone else took a lot of time and energy and money to achieve" would be the way to go but when the fuel level or initial timing or idle throttle plate opening, or # of turns out on the enrichment screw for someone's "perfect setup for XXX engine" is not disclosed,who knows if they set it right or their set-up is fixing a problem they caused. For me, the only way forward is to do it scientifically and try to control/understand the variables.Here is a start for the idle circuit and the inter-relationships of the parts.Here is a crude drawing I made to represent the variables: I did notice that I could play the Idle Enrichment against the Throttle Valve stop screw to get a variety of A/F ratios so here is what I think is going on along with unknowns:Idle Circuit Interworking Analysis "Talk-Through": 1. Fuel level 25mm below shoulder of main jet. 2. Timing >=15 degrees at 900 RPM 3. Throttle Valve stop screw 1/4 turn in from the plate resting in the throat (this is to prevent wear on the plate and throat and only allows a wee bit of air into the motor). Assume all linkage and throttle plates are set correctly and all 6 work the same. In theory this should be completely closed so that all air is from the idle needle port however it can not be completely stopped due to throttle-plate-to-throat wear. 4. Idle enrichment screw. This allows air and fuel mix into the motor. High manifold vacuum "sucks" both air and fuel out of the small hole below the screw. The amount drawn is dependent on manifold vacuum and the number of turns on screw and the taper of the screw's needle. (pitch of the screw thread is the same for most if not all DCOE carbs). Gotta go to lunch. More later.

-

Plastic Sheet Behind Door Panels

I like the chaulk-ie latex sealers on the door panels. The seal and peel cleans up nice but you only have 1 pass at applying the poly film before it seems to cure. $1or $2 a tube is not so bad for experimenting though.

-

Plastic Sheet Behind Door Panels

You can get temporary silicone-like tube of window seal at Ace (DAP Seal n'Peel) . It is for cottages where people throw up a temporary poly sheet over the window as a winterizing insulation. You can also use double sided tape . http://www.dap.com/product_details.aspx?product_id=20

- is there a painless kit that fits the 73' ,thats relatively painless?

-

A word about progression holes on a 151 Weber

and post #14 here:http://www.alfabb.com/bb/forums/carburetors-fuel-injection/151191-dcoe-fast-idle-problems.html

-

A word about progression holes on a 151 Weber

Some very useful DCOE tuning data (and plots) on this page: http://www.japanesenostalgiccar.com/forum/viewtopic.php?f=1&t=1600&start=960

-

'72 Vacuum Advance Dashpot

- Good Luck to the Z Racers at the Solo Nationals!

That is amazing driving! I don't think I have the optical skills to see the cone from the forest of cones nor the track memory skills so it is all the more impressive/magical to see the apexing and path selection.- BRE 311 cam + C cam question

4 Cylinder versions: http://www.datsun510.com/bbmail/2007-1/1779.html http://www.the510realm.com/viewtopic.php?f=2&t=9551- A word about progression holes on a 151 Weber

Some useful info (source:http://www.poustusa.com/weber_carb_pages/weber_carb_page.htm): Idle Mixture and Fuel Mixture: There are alot of theories about setting idle mixture adjustment on a Weber carb to determine Rich or Lean jetting....A Weber will run correctly with the mixture screws from 1/2 turn to 3 turns out...The late style DCOE carbs with the extra Air Bleed Screws on the top take 2.5 to 3 turns to operate correctly...So you cannot say that because it is 1/2 turn out that you need smaller jets....You need to find what is right for that particular engine...An engine with a strong vacuum signal will draw more fuel in with less turns of the screw than an engine with a weak vacuum signal will...This is the kind of thing that throws the "certain number of turns" theory out the window.. The Mixture screw and idle circuit is CRITICAL to the overall drive ability of the car. It does not just control idle but the entire low speed running and part throttle transition. The mixture screw lets in an ALREADY MIXED volume of Fuel and Air to the engine. This is not an Air Screw. The more you open it the more mixed fuel and air enters the engine. Clockwise is Leaner and Counter-Clockwise is Richer. The mixture screw is very easy to set whether it be a downdraft, side draft or multiple side drafts. Start with the screw or screws out 1.5 turns....Start the car and let it warm up. Set the Idle SPEED to approx 900-1000 RPM.. Make sure multiple carbs are synchronized...Turn the mixture screws in until the idle starts to stumble and get rough...On a side draft with 2 screws do them each a little at a time....Then back them out until the best idle quality is achieved. This is a very simple operation...The car should idle well and small adjustments leaner (Turning them in) should make the idle drop off. Opening the screws more should make it a bit richer but it should still idle. Assuming you have no vacuum leaks this is a very simple process. If you cannot get a good adjustment on these screws and you have to open the idle speed screws quite a bit to get the engine to idle there is a good chance you have a Vacuum Leak and you need to fix it. DCOE Series On a DCOE or multiple DCOE's you should be between 3/4 turn and 1.5 turns out for all older model DCOE's (DCOE 2, 9, 18, etc.) and 2 1/4 to 3 turns out for late style DCOES (151 and 152 with air bleed screws under the white caps.) Idle Jets and tuning the idle circuit: Very Simply.. The bigger the number the richer the jet. A 50 Idle jet is a .5mm fuel hole. On the DCOE series carbs they have 2 numbers on them like 50F8. The 50 refers to the .5mm fuel hole and the F8 Refers to the Air Bleed hole in the side. In a DCOE you are actually tuning the Air and Fuel for the idle circuit with the idle jets. This is a little more tricky but not too bad...Basically you can tune just about any car in the world with an F8 or an F9 idle jet. The F8 is Leaner (Has a larger Air hole) than the F9...Soooooo. You can have a 50F8 and a 50F9 and both have the same amount of fuel but the 50F9 has a richer MIXTURE (Less Air to the same volume of fuel.) Generally speaking you should start with an F8 and play with the fuel size until you get close then experiment with an F9 to see if that works any better... Choke Tubes and the Main Circuit: Okay...So now your car should idle correctly, the carbs are synched, the timing is set, everything is good....Time to get the main circuit right. Drive the car. It should come off of idle good and transition to the main circuit smoothly...If it falls on its face and will not take any throttle or runs better if you back off the then you could have a few different problems depending the type of carb. Before you blame the carb make sure you have the Fuel delivery right and the Spark Timing. If you do not have enough advance you will have this problem and it will have nothing to do with the carb tuning. DCOE Here we go....This is the real tricky part. I feel that Sidedraft DCOE carbs are easy to tune but you have to have a real feel for Rich and Lean and understand how the carb works. To get a good understanding of this I cannot recommend too highly to get the Weber Factory Tuning manual and really understand what each component does. That said this is the real Cliff Notes version of tuning the power circuit of these carbs. Choke Tube or Main Venturi size is the basis for everything in tuning DCOE carbs. If you get the Venturis wrong you will never get it running right. Too big and you will always have a flat spot that you cannot tune...Too small and it will always run rich and not make any power. If you have poor throttle response at low RPM This is a guideline only to get you started or to make sure you are not totally out of range making it very difficult to tune. There are many of you running cars successfully with choke sizes outside this range. The difficulty in tuning these types of cars is that there are many combinations that work well depending on the engine and the state of tune. That is why everything is tunable. You can tailor the carbs to suit your needs, driving style, engine, location, weather and altitude conditions, etc..... Here is a very basic chart of what venturi sizes you need to popular vehicles and engine sizes for STREET USE...All out race engines are a totally different story. Use the engine size and HP rating to estimate what you need for your car or engine if it is not listed. This is a guideline only to get you started or to make sure you are not totally out of range making it very difficult to tune. There are many of you running cars successfully with choke sizes outside this range so don't e-mail me about it. The difficulty in tuning these types of cars is that there are many combinations that work well depending on the engine and the state of tune. That is why everything is tunable. You can tailor the carbs to suit your needs, driving style, engine, location, weather and altitude conditions, etc..... Engine / Car Approximate HP Carb or Carbs Starting Choke Tube Size Datsun Z 2.8 - 3.0 250-280 Triple 45 DCOE 36mm Datsun Z 2.4 - 2.8 200-250 Triple 40 DCOE 34mm Do not try to choke down a DCOE carb that is too large to try and cure a problem...you will just create more problems....A 45 DCOE should NEVER need less than a 34mm choke to run properly. If it does then the carbs are too large or you have another problem...A 40 DCOE can use as small as a 28mm choke tube but chances are the performance will not be good with anything smaller than a 30mm choke....I have found that a correctly sized 40 DCOE application should always stat with a 30mm choke and do up to a 34mm max....Bigger or smaller than that and you probably have either the wrong size carbs or another problem that is causing you to tune outside of this range...This same info applies to IDF carbs as well...- A word about progression holes on a 151 Weber

WRT 30mm chokes: EFI runners on L28 are 30mm in diameter but the ports on the EFI and carb heads are ~ 34mm. Weber books simply specify choke dia. against cylinder volume and rpm however, I think port diameter and valve diameter also enter into the formula. - Good Luck to the Z Racers at the Solo Nationals!

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.