Everything posted by 240260280z

-

Camshaft Oil Spray Bar Redesign and Rebuild

Thermal expansion of the single bar may tweak the cam towers.

-

Roof Liner, Header Liner and A Pillar Vinyl Installation

Here is the final pics ~8 months later. Sadly some of the bumps mildly reappeared but they are not very noticeable when in the car. I like how straight the a-piller trim turned out. Installing the mirror and sunvisor mounts was easy. You just have to use your fingers to feel for the hole locations, then use a philips screwdriver to make a hole in the material at the spot before fastening. But I used to take blood and developed sensitive finger tips for feeling for veins under flabby arms so maybe I had an unfair advantage at this chore.

-

THE RUST HUNTER ( must see thread that shows what lurks in your Z)

This cool cat down-unda literally tears a Z apart at the seams to do the best no-rust-resto I have seen. Lots of superb pics worth saving that show the inside of nearly every part of the body! Go through the 6 pages. http://www.viczcar.com/forum/index.php/topic,7360.0.html

-

[2012] What did you do to/with your S30 today?

- Gasket sealant?

I think using sealant or not using sealant is more of personal taste. Some areas really need it but others only need it for long term peace of mind. Dry gaskets look cleaner. It is like using antiseize. Factory never used it but I do.- Gasket sealant?

I always use the Permatex aviation gasket sealer (aka molasses) to be safe for most oil and water gaskets.- run as is or have removed

If the cam tower is cracked under the bolt, it looks like the one to the right is also cracked too. I can't discern so please explain problem in more detail so that we can advise.- Fuel bowl level and bending tab not working

Thanks guys. With the stock needles (unknown number) for the carbs and 17degree advance at idle (no vac advance). I get AF~ 16-17 at idle and ~ 13.5 around 3500. It revs nice but I am thinking I should be more ~14.7 at idle. I may have to modify the needles slightly. The engine is 2.4litre over-bored 0.75mm with Maxima N47 head and mild Delta re-ground cam ~270degrees and 0.46" lift. Any suggestions? I may try raising needles in dome and compare to dropping jet nozzles for fun. In theory it should have the same effect but who knows? I have LM-1 so I can gather empirical data whooo hoooo.- run as is or have removed

Is the bolt stripped in the hole? Please provide more details of the failure and we can provide better advice.- STE Syncrometer and higher RPM balancing Arghhhhh

I also noted that on these carbs, 23mm of fuel to fuel bowl top lip height is ~13 turns (1.3cm) down (max) of the jet.- N49 & N54 Needles?

I'll concur...~14 a/f at zero turns of jet depth. I think it may be due to the shorter needle.- Fuel bowl level and bending tab not working

Found the problem. Turned out that the new short N54 and M49 needles were the culprits. Grrrrrr. It was supposed to be a 240z kit they came from.- STE Syncrometer and higher RPM balancing Arghhhhh

Thanks again John. You are spot-on. I figured it out (silly me)... the main trick is that the meter is best viewed when rotated sideways 90 degrees . I was first trying it in vertical and 180 degree rotation but the parallax was preventing a useful measurement . I also figured out (now that I could see the scale in more detail side on) that around ~2,000rpm I could set fast idle screw so that the front carb measures exactly 25kg/hr I could then measure the rear carb and adjust the balance screw so that it matched exactly at 25kg/hr. It was very easy to balance at off-idle and at idle and more importantly, absolute and repeatable measurements. I would recommend the BK version to others to tune in the higher rpm range.- STE Syncrometer and higher RPM balancing Arghhhhh

I always used a friend's Unisyn flowgauge when balancing carbs. It worked fine at low RPMS and at high RPMS. IT DID THE JOB. I am now using an STE Synchometer with absolute measurement dial but it pegs at higher RPM's. I tried the two different rubber fitting that came with the STE tool and also tried to use the holes in these fittings as bleeders but no luck. How can this tool be used at 3000rpm?- Fuel bowl level and bending tab not working

Yeah, everything check OK. I'll have another look at the fuel rail for an obstruction on the return. I'll also change the fuel pump today.- CAn you clean an O2 sensor?

I read about using a propane torch...use Google to find out if it works. edit: http://www.bobistheoilguy.com/forums/ubbthreads.php?ubb=showflat&Number=1612066 "Hillbilly reasoning"- Duel fuel pumps

- Fuel bowl level and bending tab not working

No holes, and I tried 3 different floats/tops.- Fuel bowl level and bending tab not working

that is nearly the same... maybe we should take parts from each others carbs and the levels will be in the right spot. How I managed to run rich with no turns on the jet knobs still confuses me. I think my carbs are haunted. I have a second set of new needle valves and a used fuel pump that I disassembled today to ensure no surprises. I'll try theses and see if I can find the elusive parameter that is causing the problem.- Time Capsule 1976 Car

- Time Capsule 1976 Car

Arne.... a lone z is out there somewhere looking for you calling "Arne Arne where art thou Arneeeeeeeeeeeeeeeeeeeeeeeeeeeee!"- Duel fuel pumps

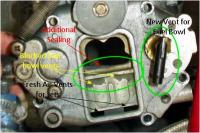

An old thread but it just happened to our club racer so I figured I would try to simplify the great info above. From what I understand: Basically in right high G corners, the fuel sloshes to the left side of the car. Inside the carb, the sloshed fuel works itself up through the fuel bowl vents and gets sucked into the top of the air jets (which are supposed to suck air, not fuel). The problem is that Mikuni has only one fresh air inlet into the carb to feed both the jets and to vent the fuel bowl. The mod basically makes the stock fresh air inlet only for the jets and a new system is used to vent the fuel.- Fuel bowl level and bending tab not working

It is nice to be in good company. Actually it is the first time I actually measured the fuel height as the 90° technique has worked fine. This time I used my calipers and scribed two accurate marks on the outside of the bowl at 23mm down from the lip and at 25mm down from the lip. I used a brass "T" and three sections of clear hose to connect the bowl outlet to the jet inlet and to run vertical for measuring. I'll swap fuel pumps today and see if that helps.- N49 & N54 Needles?

Thanks! That is appreciated and all on the net who search will find your data too!- Fuel bowl level and bending tab not working

I normally set the needle valve closure point on carbs by blowing in the inlet and adjusting the tab so that the valve is shut at 90 degree point of swing (top of float is parallel to top of fuel bowl). The carbs I have set like this have always worked fine. However, I ran into some problems today with a set I did this fuel level technique too so I decided to check in more detail as I could not get the A/F ratio to work no matter what I did with the jet height. I decided it was best to back track and recheck every thing. I first tried adjusting the fuel level at 23mm in the bowl and also the other technique of meniscus 10 turns of the jet down the well. The carbs initially were ~ 25mm and 23mm for the front/back bowls respectively (distance from bottom of gasket to top of fuel) with the same needle valves and tab bridge heights (not the 72 carbs). I readjusted the tabs and got the offending one to ~ 24mm and left it. After this I put new M49 needles in the pistons and set the correct needle depth using the "jet-push-piston-home" technique. I ran the motor and it was super rich. I tried bringing the jets up but it was still 12:1 with zero turns on the jets! I then tried new N54 needles and it was only mildly leaner (14:1) at 0 turns of jet depth. I then re-checked the fuel height and it was still 24mm. I then re-bent the tab many times (drain, bend, run starter for 15sec, wait for fuel to finish rising and I always got 24mm...I repeated ~ 5 times until the tab was nearly pushing the needle valve closed with only a few degrees of freedom. It was as if the new needle valve was not working. I then tried an older fuel bowl top with old float and old needle valve but the same problem...24mm of fuel level. I then thought that the fuel pump or return lines may be the problem. I was able to confirm the fuel rail return flow a few days ago, and today I blew on the return line to the tank and could pass air and hear it bubble so no problem there. I am thinking the lines are fine but the fuel pressure is too high. I do not have a fuel pressure gauge nor an adjustable FPR for carbs so I am thinking of rigging a hose to check the column of fuel height the pump can head and then converting to PSI.... any input? I am also lost as to why I still get 24mm of fuel height and not over flowing? It is like the needle valves are working independently of the tabs. I had a quick inspection of the jet holes and they look fine. I put a 2.40mm brass rod in each and visually confirmed similar side clearance to the wall and round shape. Also the floats are not cracked or sinking. ????? - Gasket sealant?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.